Professional Documents

Culture Documents

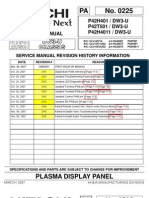

Important Information: Section 1A - General Information

Important Information: Section 1A - General Information

Uploaded by

Jorge SoberanoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Important Information: Section 1A - General Information

Important Information: Section 1A - General Information

Uploaded by

Jorge SoberanoCopyright:

Available Formats

General Information

Important Information

1

Section 1A - General Information A

Table of Contents

Introduction........................................................................ 1A-2 SeaCore Components and Castings.......................... 1A-9

Quicksilver Products.......................................................... 1A-2 Stainless Steel Fasteners........................................... 1A-9

Accessories................................................................ 1A-2 SeaCore System.........................................................1A-9

How to Use This Manual....................................................1A-2 Corrosion Information...................................................... 1A-10

MerCruiser Color Wiring Diagrams.................................... 1A-2 Corrosion Protection................................................. 1A-10

Abbreviations..................................................................... 1A-2 Anti‑Fouling Paint..................................................... 1A-10

Sterndrive Models Identification.........................................1A-4 Emissions Information For Engines With Emission Control

Engine Exhaust With and Without Emissions Control ..................................................................................... 1A-12

................................................................................ 1A-4 Emission Control Information Label..........................1A-12

Information Decal........................................................1A-5 Emission Certification Star Label..............................1A-13

Serial Number Decal Strips........................................ 1A-5 Hang Tag.................................................................. 1A-15

Engine Serial Number ................................................1A-6 Exhaust Gas Sampling............................................. 1A-16

Bravo Sterndrive Serial Number and Identification.....1A-6 Emissions Control System Overview............................... 1A-16

Bravo Transom Serial Number................................... 1A-7 Combustion...............................................................1A-16

Inboard Models Identification............................................. 1A-8 Emissions................................................................. 1A-17

Information Decal........................................................1A-8 Controlling Emissions With Catalysts....................... 1A-17

Serial Number Decal Strips........................................ 1A-8 Closed‑Loop Control.................................................1A-18

Engine Serial Number.................................................1A-9 Emissions Information For Engines Without Emission

Transmission Identification Plate................................ 1A-9 Control..........................................................................1A-19

SeaCore Models................................................................ 1A-9 Emission Control Information Label..........................1A-19

90-879172243 DECEMBER 2011 Page 1A-1

General Information

Introduction

This overhaul and repair manual is intended as a comprehensive service guide for the models listed earlier. It provides specific

information, including procedures for disassembly, inspection, assembly and adjustment to enable dealers and service

mechanics to repair these products.

Before attempting repairs we suggest that the procedure first be read in its entirety to gain knowledge of the methods and tools

used and of the cautions and warnings required for safety.

Quicksilver Products

Accessories

Quicksilver gauges, remote controls, steering systems, propellers, and other accessories are available for this product. Mercury

MerCruiser recommends the use of Quicksilver parts on all applications. Refer to Mercury Precision Parts Accessories

Guide for a complete listing.

This Guide is available from:

Attn: Parts Department

Mercury Marine

W6250 W. Pioneer Road

P.O. Box 1939

Fond du Lac, WI 54935-1939

Outside of U.S.A., order through Distribution Center or Distributor.

How to Use This Manual

This manual is divided into volumes and sections that represent the major components and systems.

Some sections are further divided into parts that more fully describe the component.

Refer to the Service Manual Outline following Models Covered in this manual for section titles.

MerCruiser Color Wiring Diagrams

Large scale, oversized color wiring diagrams are available in the MerCruiser Diagram Binder. The initial distribution of the

MerCruiser Diagram Binder was delivered to MerCruiser authorized repair facilities in June and July of 2007. As new diagrams

are developed they will be distributed along with a revised, comprehensive index for addition to an existing binder.

The MerCruiser Diagram Binder features:

• An index that identifies the diagrams by harness number, by engine group and drive, and by engine size and type

• The diagrams are printed on an extremely durable, coated synthetic paper and can be wiped clean of grease and oil after

use.

• The larger diagrams are easier to read. The diagrams will come in two sizes, depending on the complexity of the related

harness.

• Removable pages are easier to reference and allow the technician to take only the required diagram to a repair site instead

of a complete service manual.

• Dry erase markers can be used directly on the diagrams for tracing circuits or for training. They wipe clean after use.

• Harness number headings make the drawings easy to find. The accompanying MerCruiser Diagram Binder Index speeds

lookup when the harness number is not known.

For information about ordering additional copies of the MerCruiser Diagram Binder or binder updates contact:

• MerCruiser Authorized Dealers, Repair Centers, or OEMs can order service literature on MercNET.

• Consumers can order service literature through the Mercury Dock Store (www.mercurydockstore.com), contacting Mercury

MerCruiser publications at 920‑929‑5110 or by contacting their local MerCruiser Authorized Dealer or Repair Center.

Abbreviations

IMPORTANT: Throughout this manual abbreviations of terms will be used, following is a listing of the abbreviations and related

definitions.

BARO Barometric Pressure INJ Injection

Battery Positive Terminal, Battery

BAT kPa Kilopascal

or System Voltage

B+ Battery Positive KS Knock Sensor

CKT Circuit KV Kilovolts

Page 1A-2 90-879172243 DECEMBER 2011

General Information

CONN Connector MAP Manifold Absolute Pressure

CYL Cylinder MDTC Marine Diagnostic Trouble Code

DEG Degrees MIL Malfunction Indicator Lamp

DIAG Diagnostic mSec Millisecond

DIST Distributor N/C Normally Closed

DLC Data Link Connector N/O Normally Open

DTC Diagnostic Trouble Code OBD On Board Diagnostic

Programmable Read Only

DVOM Digital Volt Ohm Meter PROM

Memory

PCM Propulsion Control Module RAM Random Access Memory

ECT Engine Coolant Temperature REF. HI Reference High

Electronic Erasable

EPROM Programmable Read Only REF. LO Reference Low

Memory

EMI Electromagnetic Interference ROM Read Only Memory

ENG Engine SLV Slave

EST Electronic Spark Timing SW Switch

GND Ground TACH Tachometer

GPH Gallons Per Hour TERM Terminal

HEI High Energy Ignition TPS Throttle Position

IAC Idle Air Control V Volts

IAT Intake Air Temperature VAC Vacuum

IC Ignition Control WOT Wide Open Throttle

IGN Ignition in. Hg Inches of Mercury

MCM MerCruiser Marine

MIE Mercury Inboard Engine

MPI Multi‑Port Injection

90-879172243 DECEMBER 2011 Page 1A-3

General Information

Sterndrive Models Identification

Engine Exhaust With and Without Emissions Control

Engine With Emissions Control

c Typical 8.2 MAG sterndrive with

b emissions control

a a - Catalyst sensors

b - Exhaust collector

c - Exhaust elbow riser

d - Exhaust manifold

45681

Page 1A-4 90-879172243 DECEMBER 2011

General Information

Engine Without Emissions Control

b Typical 8.2 MAG sterndrive

without emissions control

a a - Exhaust manifold

b - Exhaust elbow

45495

Information Decal

The information decal is located on the top starboard side of the heat exchanger.

a b c d e a - Service point decal

b - Emissions control

information decal

c - Specification decal

d - Serial numbers decal

e - Heat exchanger

43187

Serial Number Decal Strips

There are 3 sets of engine, transom assembly, and sterndrive serial number decal strips provided with each power package.

Affix one of each to the following:

• Serial numbers decal

• Warranty registration Card

90-879172243 DECEMBER 2011 Page 1A-5

General Information

• Operation, Maintenance and Warranty Manual identification page

a a- Heat exchanger

b- Engine serial number

c- Transom serial number

d- Sterndrive serial number

b

c

d

43188

Engine Serial Number

The engine serial number stamp is located on the starboard‑side of the engine block next to the flywheel housing cover.

a b c a - Flywheel housing cover

b - Engine serial number stamp

c - Engine block

43554

Bravo Sterndrive Serial Number and Identification

The Bravo sterndrive serial number, gear ratio, model number, and bar code are embedded in the ground plate on the port side

of the sterndrive.

33533

Bravo sterndrive information on ground plate

Page 1A-6 90-879172243 DECEMBER 2011

General Information

The serial number is also stamped on the drive shaft housing behind the back cover. This is used as a permanent reference for

authorized MerCruiser Dealers.

44426

Bravo sterndrive serial number stamping

Bravo Transom Serial Number

The Bravo transom serial number is stamped in the U‑bolt plate of the Bravo transom assembly.

44433

Serial number location on U-bolt plate

The serial number is also stamped on the gimbal housing. This is used as a permanent reference for authorized MerCruiser

Dealers.

44425

Serial number location on gimbal housing

90-879172243 DECEMBER 2011 Page 1A-7

General Information

Inboard Models Identification

Information Decal

The information decal is located on the top starboard‑side of the heat exchanger.

a b c d e a - Service point decal

b - Emissions control

EMISSION CONTROL INFORMATION

information decal

ECIEPA

NOT FOR SALE IN CALIFORNIA

THIS MARINE ENGINE COMPLIES WITH U.S. EPA EXHAUST c - Specification decal

REGULATIONS FOR 2009

REFER TO THE OWNER'S MANUAL FOR MAINTENANCE d - Serial numbers decal

SPECIFICATIONS AND ADJUSTMENTS

SERIAL #: XXXXXXXX e - Belt routing

FAMILY: XXXXXXX.XXXX DOM: MMM YYYY

FEL: XX.X g/kWh DISP: X.XL 0575

43688

Serial Number Decal Strips

There are 3 sets of engine serial number decal strips provided with each power package. Affix one to the following:

• Engine serial number decal

• Warranty registration Card

• Operation, Maintenance and Warranty Manual identification page

EMISSION CONTROL INFORMATION

ECIEPA

NOT FOR SALE IN CALIFORNIA

THIS MARINE ENGINE COMPLIES WITH U.S. EPA EXHAUST

REGULATIONS FOR 2009

REFER TO THE OWNER'S MANUAL FOR MAINTENANCE

SPECIFICATIONS AND ADJUSTMENTS

SERIAL #: XXXXXXXX

FAMILY: XXXXXXX.XXXX DOM: MMM YYYY

FEL: XX.X g/kWh DISP: X.XL 0575

43689

Engine serial number decal on heat exchanger

Page 1A-8 90-879172243 DECEMBER 2011

General Information

Engine Serial Number

The engine serial number stamp is located on the starboard‑side of the engine block next to the flywheel housing cover.

a b c a - Flywheel housing cover

b - Engine serial number stamp

c - Engine block

43554

Transmission Identification Plate

On the ZF Marine 8 Degree Down‑Angle and V‑Drive Transmissions, the transmission identification plate indicates gear ratio,

serial number, and model.

43683

Typical ZF Marine down-angle transmission shown (V-drive similar)

SeaCore Models

SeaCore Components and Castings

Mercury MerCruiser SeaCore power packages are equipped with additional stainless steel components and particular

aluminum castings with special coatings. Do not replace SeaCore components with non‑SeaCore. Use only the specified

Mercury MerCruiser SeaCore components and castings on these power packages.

Stainless Steel Fasteners

SeaCore models are equipped with additional stainless steel fasteners to maximize corrosion resistance in salt water

environments.

Stainless steel fasteners are subject to galling when installed without lubrication. Galling can result in fastener destruction,

improper clamp loads, or both. Galled fasteners may appear to torque properly, but still have incorrect clamp loads.

Apply a lubricant, such as Special Lubricant 101 or an equivalent, on the threads of stainless steel fasteners during installation

to avoid galling. Lubricate at least the first 8 mm (1/4 in.) of the threads before installation.

SeaCore System

The SeaCore System is a complete engine sterndrive package. The SeaCore engine and sterndrive enhancements are:

• Hardcoat anodized external castings

• Additional stainless steel fasteners and hardware

90-879172243 DECEMBER 2011 Page 1A-9

General Information

• Closed cooling on the engine

• Freshwater flush system—flushes the entire system

The SeaCore System provides corrosion protection for the engine with these standard features:

• Closed‑cooling system with 5‑year, long‑life coolant

• Stainless steel steering shaft

• Stainless steel engine motor mounts and fasteners

• Dry joint exhaust

• MerCathode Corrosion Protection System

• SmartCraft Engine Guardian

• Compatible with 87 octane fuel

The following stainless steel fasteners and hardware are used on this engine and sterndrive package for increased corrosion

resistance:

• Gimbal housing studs

• Power steering hose—high pressure end

• Flywheel housing bolts

• Pulley attaching bolts and all engine component fasteners

• Engine mount stud and fastener

NOTE: Hardcoat anodizing is more abrasion resistant than case‑hardened steel, and if the drive is scratched, the anodizing

slows the destructive growth of corrosion through the drive surface.

The SeaCore System provides corrosion protection for the sterndrive with the following standard features:

• Industrial hardcoat anodized XK360 aluminum drive housings and transom components

• Protected interior passages

• Through‑the‑propeller exhaust

• Non‑conductive surface to reduce galvanic corrosion

• Stainless steel sterndrive and transom fasteners

• Power Trim XD

• New SeaCore transom identification plate

• Bravo III stainless steel bearing carrier

• The transom is equipped with stainless steel upper swivel shaft (and new shaft seal)

Corrosion Information

Corrosion Protection

Mercury MerCruiser power packages are equipped with anodes to help protect them from galvanic corrosion under moderate

conditions. However, for severe conditions or if using a stainless steel propeller, it is recommended that a Quicksilver

Anti‑Corrosion Anode Kit and/or a MerCathode System with 2 additional transom mounted anode assemblies be installed

(some models have a MerCathode System as standard equipment). A MerCathode Monitor also is available to allow the

operator to check the operation of the MerCathode System with the push of a button. (Refer to Mercury Precision Parts

Accessories Guide for part numbers.)

Boats that are connected to AC shore power require additional protection to prevent destructive low voltage galvanic currents

from passing through the shore power ground wire. A Quicksilver Galvanic Isolator can be installed to block the passage of

these currents while still providing a path to ground for dangerous fault (shock) currents. (Refer to Mercury Precision Parts

Accessories Guide for part number.)

IMPORTANT: If AC shore power is not isolated from boat ground, the MerCathode System and anodes may be unable to

handle the increased galvanic corrosion potential.

Anti‑Fouling Paint

IMPORTANT: Corrosion damage that results from the improper application of anti‑fouling paint will not be covered by the

limited warranty.

Painting Boat Hull or Boat Transom: Anti‑fouling paint may be applied to boat hull and boat transom but you must observe

the following precautions:

IMPORTANT: Do not paint anodes or pressure wash anodes or MerCathode System reference electrode and anode, as this

will render them ineffective as galvanic corrosion inhibitors.

Page 1A-10 90-879172243 DECEMBER 2011

General Information

IMPORTANT: If anti‑fouling protection is required for boat hull or boat transom, copper base paint, if not prohibited by law, can

be used. If using copper based anti‑fouling paint, observe the following:

• Avoid an electrical interconnection between the Mercury MerCruiser Product, Anodic Blocks, or MerCathode System and

the paint by allowing a minimum of 40 mm (1‑1/2 in.) UNPAINTED area on transom of the boat around these items.

a - Painted boat transom

b - Minimum 40 mm (1‑1/2 in.) unpainted area around

transom assembly

8107

NOTE: Sterndrive unit and transom assembly can be painted with a good quality marine paint or an anti‑fouling paint that

DOES NOT contain copper or any other material that could conduct electrical current. Do not paint drain holes, anodes,

MerCathode system or items specified by boat manufacturer.

NOTICE

Washing the MerCathode assembly can damage components and lead to rapid corrosion. Do not use any cleaning

equipment such as brushes or high‑pressure washers to clean the MerCathode assembly.

Do not wash the sterndrive unit with a power washer as this can damage the coating on the reference wire of the MerCathode

assembly, if equipped, and increase corrosion.

c a a - MerCathode reference electrode

b - Do not paint

c - Do not pressure wash

b

6211

90-879172243 DECEMBER 2011 Page 1A-11

General Information

Emissions Information For Engines With Emission Control

Emission Control Information Label

A tamper‑resistant emission control information (ECI) label is affixed to the engine in a visible location at the time of

manufacture by Mercury MerCruiser. Please note that the low emissions certification will not affect the fit, function, or

performance of the engine. Boatbuilders and dealers may not remove the label or the part it is affixed to before sale. If

modifications are necessary, contact Mercury MerCruiser about the availability of replacement decals before proceeding. In

addition to the required emissions statement, the label lists the engine serial number, family, applicable emission standard, date

of manufacture (month, year), and engine displacement.

ECIEPACA

EMISSION CONTROL INFORMATION a- Applicable standard

b- Engine serial number

THIS ENGINE CONFORMS TO 2009 CALIFORNIA AND U.S. EPA

EMISSION REGULATIONS FOR SPARK IGNITION MARINE ENGINES a c- Engine family name

REFER TO THE OWNER'S MANUAL FOR MAINTENANCE d- Hydrocarbons plus oxides of nitrogen family

SPECIFICATIONS AND ADJUSTMENTS emission limit

SERIAL #: XXXXXXXX b DOM: MMM YYYY e

e - Date of manufacture

FAMILY: XXXXXXXXXXXX c DISP: X.XL POWER : XXX kW f

f - Engine displacement, engine power

HC+NOx FEL : XX.X g/kWh

d CO FEL : XXX g/kWh g 0575

g - Carbon monoxide family emission limit

43500

IMPORTANT: A CE mark in the lower right corner of the Emission Control Information label indicates that an EU Declaration of

Conformance applies. Refer to the front page of this manual for further information.

IMPORTANT: Engines designated as exempt from either Federal EPA or California emission control regulations are not

covered by a separate emission control component warranty. The product's Mercury MerCruiser manufacturer's warranty is not

affected by the engine's designation under Federal EPA or California emission control regulations.

ECI Label Standard of Compliance

EMISSION CONTROL INFORMATION

ECIEPA

NOT FOR SALE IN CALIFORNIA

THIS MARINE ENGINE COMPLIES WITH U.S. EPA EXHAUST

REGULATIONS FOR 2009

Indicates a marine engine compliant with United States EPA

REFER TO THE OWNER'S MANUAL FOR MAINTENANCE

SPECIFICATIONS AND ADJUSTMENTS

exhaust emission regulations for 2009.

SERIAL #: XXXXXXXX DOM: MMM YYYY

This marine engine is not for sale in California.

FAMILY: XXXXXXXXXXXX DISP: X.XL POWER : XXX kW

HC+NOx FEL : XX.X g/kWh CO FEL : XXX g/kWh 0575

43518

ECICARB

EMISSION CONTROL INFORMATION

THIS ENGINE CONFORMS TO 2009 CALIFORNIA EMISSION

REGULATIONS FOR SPARK IGNITION MARINE ENGINES

REFER TO THE OWNER'S MANUAL FOR MAINTENANCE Indicates a marine engine compliant with California CARB

SPECIFICATIONS AND ADJUSTMENTS exhaust emission regulations for 2009

SERIAL #: XXXXXXXX DOM: MMM YYYY

FAMILY: XXXXXXXXXXX DISP: X.XL POWER : XXX kW

HC+NOx FEL : XX.X g/kWh CO FEL : XXX g/kWh 0575

43519

ECIEPACA

EMISSION CONTROL INFORMATION

THIS ENGINE CONFORMS TO 2009 CALIFORNIA AND U.S. EPA

EMISSION REGULATIONS FOR SPARK IGNITION MARINE ENGINES

REFER TO THE OWNER'S MANUAL FOR MAINTENANCE Indicates a marine engine compliant with California CARB and

SPECIFICATIONS AND ADJUSTMENTS U.S. EPA regulations for 2009

SERIAL #: XXXXXXXX DOM: MMM YYYY

FAMILY: XXXXXXXXXXXX DISP: X.XL POWER : XXX kW

HC+NOx FEL : XX.X g/kWh CO FEL : XXX g/kWh 0575

43520

Page 1A-12 90-879172243 DECEMBER 2011

General Information

ECI Label Standard of Compliance

ECIEXEMP

EMISSION CONTROL INFORMATION

NOT FOR SALE IN CALIFORNIA

THIS ENGINE IS EXEMPT UNDER 40 CFR 1068.255 FROM

EMISSION STANDARDS AND RELATED REQUIREMENTS

Indicates a marine engine exempt under 40 CFR 1068.255 from

REFER TO THE OWNER'S MANUAL FOR MAINTENANCE

United States EPA exhaust emission regulations for 2010.

SPECIFICATIONS AND ADJUSTMENTS

SERIAL #: XXXXXXXX

This marine engine is not for sale in California.

DOM: MMM YYYY

FAMILY: XXXXXXXXXXXX DISP: X.XL POWER : XXX kW

HC+NOx FEL : XX.X g/kWh CO FEL : XXX g/kWh 0575

43521

ECICARBX

EMISSION CONTROL INFORMATION

THIS ENGINE CONFORMS TO 2010 CALIFORNIA EMISSION

REGULATIONS FOR SPARK IGNITION MARINE ENGINES. THIS ENGINE

IS EXEMPT UNDER 40 CFR 1068.255 FROM EMISSION STANDARDS Indicates a marine engine compliant with 2010 California

AND RELATED REQUIREMENTS. REFER TO THE OWNERS MANUAL emission regulations and exempt under 40 CFR 1068.255 from

FOR MAINTENANCE SPECIFICATIONS AND ADJUSTMENTS.

SERIAL #: XXXXXXXX

United States EPA exhaust emission regulations

DOM: MMM YYYY

FAMILY: XXXXXXXXXXXX DISP: X.XL POWER : XXX kW

HC+NOx FEL : XX.X g/kWh CO FEL : XXX g/kWh 0575

43522

ECISERV

EMISSION CONTROL INFORMATION

THIS ENGINE DOES NOT COMPLY WITH U.S. EPA NONROAD EMISSION

REQUIREMENTS. SELLING OR INSTALLING THIS ENGINE FOR ANY

PURPOSE OTHER THAN TO REPLACE A NONROAD ENGINE BUILT

BEFORE JANUARY 1, 2010 MAY BE A VIOLATION OF FEDERAL LAW Indicates a service marine engine that can replace a marine

SUBJECT TO CIVIL PENALTY. engine built prior to January 1, 2010.

SERIAL #: XXXXXXXX DOM: MMM YYYY

FAMILY: XXXXXXXXXXXX DISP: X.XL POWER : XXX kW

HC+NOx FEL : XX.X g/kWh CO FEL : XXX g/kWh 0575

43499

Owner Responsibility

The operator must have routine engine maintenance performed to maintain emission levels within prescribed certification

standards.

The operator may not modify the engine in any manner that alters the horsepower or allows emissions levels to exceed factory

specifications.

Emission Certification Star Label

Your boat is labeled on the hull with one of the following star labels. The Symbol for Cleaner Marine Engines Means:

1. Cleaner Air and Water ‑ for a healthier lifestyle and environment.

2. Better Fuel Economy ‑ burns up to 30‑40 percent less gas and oil than conventional carbureted two‑stroke engines, saving

money and resources.

3. Longer Emission Warranty ‑ Protects consumer for worry free operation.

Beginning January 1, 2003, one Three‑Star or Four‑Star label will be included with each factory‑certified Mercury MerCruiser

engine.

All Mercury MerCruiser engines (500 hp and below) will have a Three‑Star Ultra Low Emission rating or Four‑Star Super Ultra

Low Emission rating. The Star label identifies that these engines meet the California Air Resources Board's Sterndrive and

Inboard marine engine 2007 and later exhaust emission standards. Engines meeting these standards have 65‑90% lower

emissions than One‑Star – Low Emissions engines.

90-879172243 DECEMBER 2011 Page 1A-13

General Information

The Star label will be affixed on the left side of the hull as shown.

a - Recommended location

b - Secondary location

XX 1234 XX

a b

32770

Page 1A-14 90-879172243 DECEMBER 2011

General Information

One Star ‑ Low emission

The one‑star label identifies personal watercraft, outboard, sterndrive and inboard

engines that meet the Air Resources Board's Personal Watercraft and Outboard

marine engine 2001 exhaust emission standards. Engines meeting these standards

have 75% lower emissions than conventional carbureted two‑stroke engines.

These engines are equivalent to the U.S. EPA's 2006 standards for marine

mc79569-1 engines.

Two Stars ‑ Very Low emission

The two‑star label identifies personal watercraft, outboard, sterndrive and inboard

engines that meet the Air Resources Board's Personal Watercraft and Outboard

marine engine 2004 exhaust emission standards. Engines meeting these standards

have 20% lower emissions than One Star ‑ Low‑Emission engines.

42145

Three Stars ‑ Ultra Low emission

The three‑star label identifies engines that meet the Air Resources Board's

Personal Watercraft and Outboard marine engine 2008 exhaust emission

standards or the Sterndrive and Inboard marine engine 2003 exhaust emission

standards. Engines meeting these standards have 65% lower emissions than One

Star ‑ Low Emission engines.

42146

Four Stars ‑ Super Ultra Low emission

The Four Star label identifies engines that meet the Air Resources Board's

Sterndrive and Inboard marine engine 2009 exhaust emission standards. Personal

Watercraft and Outboard marine engines may also comply with these standards.

Engines meeting these standards have 90% lower emissions than One Star ‑ Low

Emission engines.

42155

Hang Tag

The dealer must mark the appropriate box on one hang tag to match the Star label affixed to the boat. The dealer is responsible

for displaying the hang tag in a visible location on the boat on display in California. Failure to properly display the hang tag

could result in a citation and possible fine to the dealer from the California Air Resources Board.

90-879172243 DECEMBER 2011 Page 1A-15

General Information

If in California, the dealer must place the hang tag in a visible location in the boat prior to displaying the boat.

43291

Hang tag front side Hang tag back side

Exhaust Gas Sampling

Exhaust gas emission regulations require field access to uncontaminated and undiluted engine exhaust. Mercury MerCruiser

models covered by these regulations are equipped with (or have available) exhaust system components that allow access to

the exhaust gas stream suitable for analysis.

IMPORTANT: To comply with exhaust gas emission regulations, design considerations determined by the boat builder and

specific engine installations must allow for field access to the exhaust gas sampling ports.

The 8.2 engine models exhaust gas sampling access area is located on the exhaust elbow and is secured with a pipe plug.

43674

Pipe plug access for exhaust gas sampling

Emissions Control System Overview

Combustion

Combustion is a rapid chemical reaction, called oxidation, in which fuel chemically combines with oxygen to produce heat

energy. Among other elements, air contains oxygen and nitrogen, and gasoline contains hydrogen and carbon. These four

primary elements combine chemically during combustion to form new chemical compounds.

Page 1A-16 90-879172243 DECEMBER 2011

General Information

If combustion were complete, the oxidation of air and gasoline would result in water, carbon dioxide, and nitrogen, which are

not harmful to the environment. For combustion to be complete, it needs to occur at a specific air‑to‑fuel ratio called the

stoichiometric ratio (14.7:1 for gasoline). Although this ratio is ideal for reducing hydrocarbons (HC) and carbon monoxide (CO),

it is a lean mixture that can be difficult or slow to ignite, reducing engine power and efficiency.

Emissions

Since combustion is usually incomplete, not all of the exhaust gases burn, causing emissions. All engines sold in the state of

California must comply with the standards legislated by the California Air Resources Board (CARB). In accordance with these

standards, and in preparation of future standards, Mercury Marine is working to reduce the following: carbon monoxide (CO),

hydrocarbons (HC), and oxides of nitrogen (NOx).

Carbon Monoxide (CO)

Carbon monoxide (CO) is a poisonous gas created by incomplete combustion of gasoline. If combustion occurs in an

oxygen‑deficient environment, the limited amount of oxygen allows only one oxygen (O) atom to bond with a cabon (C) atom,

creating CO from partially burned fuel. Richer air‑to‑fuel ratios create more CO than lean ratios.

Hydrocarbons (HC)

Hydrocarbon (HC) emissions are caused by incomplete combustion of gasoline and other hydrocarbon‑based fuels. When

gasoline burns, oxidation occurs; however, some hydrocarbons do not oxidize. Lower engine temperatures make it harder for

the hydrocarbons to oxidize. Therefore, some hydrogen and carbon atoms remain bonded and pass through the exhaust

system as HC gases from unburned fuel.

Oxides of Nitrogen (NOx)

Oxides of nitrogen (NOx) is a generic term for a group of chemical compounds that contain nitrogen (N) and oxygen (O) in

varying amounts (x). NOx is created by overheated hydrogen and oxygen. At extremely high tempertures, N atoms can

combine with O atoms to create NOx. Unlike CO and HC, which form when combustion temperatures are too low, NOx forms

when combustion temperatures are too high. NOx itself is not harmful. However, when exposed to sunlight, NOx combines with

unburned hydrocarbons to create the visible air pollutant called smog.

Controlling Emissions With Catalysts

Catalyst Components

A catalyst, or catalytic converter, is a device installed into the engine's exhaust system that reduces the toxicity of emissions.

Mercury MerCruiser engines use three‑way catalysts with the following components:

• Substrate—The substrate is a metallic foil core that provides a large surface area for the washcoat.

• Washcoat—The washcoat is applied to the substrate to act as a carrier for the catalyst. This washcoat creates an irregular,

porous surface, providing more surface area for the precious metal of the catalyst.

• Catalyst—The catalyst is a combination of precious metals applied to the porous structure of the washcoat. The heated

exhaust gases react with the precious metals in the catalyst to reduce harmful emissions. This catalyst assembly is housed

in the mantle.

• Mantle—The mantle is the tube that contains the catalyst. The mantle is installed in the exhaust manifold housing.

• Oxygen sensors—Multiple oxygen sensors transmit emissions data to the propulsion control module (PCM) to control

emissions.

• Propulsion control module—Models with emissions control use a PCM09 controller to manage fuel delivery to the engine

and maintain CARB (California Air Resources Board) emissions standards.

Catalyst Operation

Mercury MerCruiser's engines with emissions control meet the CARB requirements for exhaust emissions levels that went into

effect January 2008 in the state of California. These engines feature three‑way catalysts, which use a combination of platinum,

palladium, and rhodium (and other precious metals) to convert harmful emissions to safe levels. A three‑way catalyst reduces

emissions in the following ways:

• It reduces nitrogen oxides to nitrogen and oxygen (2NOx → xO2 + N2).

• It oxidizes carbon monoxide into carbon dioxide (2CO + O2 → CO2).

90-879172243 DECEMBER 2011 Page 1A-17

General Information

• It oxidizes unburnt hydrocarbons to carbon dioxide and water (C2H4 + 3O2 → 2CO2 + 2H2O).

Typical exhaust manifold

shown

1 - Exhaust gases from the

combustion chamber

4 2 - Pre‑catalyst oxygen

sensor

3 - Catalysts

5 4 - Post‑catalyst oxygen

3 3 sensor

5 - Reduced emissions

1 1 1 1

34004

Closed‑Loop Control

The oxygen sensors send oxygen information to the PCM before and after the catalysts in the exhaust system. This

dual‑sensor system provides a closed‑loop monitoring system, ensuring required air‑to‑fuel ratios and emissions. This engine is

equipped with a catalytic converter on each exhaust manifold. Each catalytic converter houses three catalysts, a pre‑oxygen

sensor, and a post‑oxygen sensor.

34003

Closed-loop control

Reference Action

1 PCM calculates air‑fuel ratio.

Page 1A-18 90-879172243 DECEMBER 2011

General Information

Reference Action

2 Fuel system delivers the required air‑to‑fuel ratio to the combustion chamber.

3 Combustion occurs (power stroke).

4 Exhaust gases enter the exhaust manifold (exhaust stroke).

5 The first oxygen sensor sends a signal to the PCM, delivering pre‑catalyst oxygen information.

The exhaust gases pass through the catalyst. Reactions in the catalyst oxidize hydrocarbons (HC) and

6

carbon monoxide (CO) and reduce oxides of nitrogen (NOx).

7 The second oxygen sensor sends a signal to the PCM, delivering post‑catalyst oxygen information.

NOTE: Each oxygen sensor is protected by a 5 amp fuse.

NOTE: Mercury MerCruiser engines do not depend on closed‑loop control to calculate air‑to‑fuel ratios at all times. During

some operating situations, the PCM operates in open‑loop control, relying on its default programming to make fuel‑delivery

calculations.

Emissions Information For Engines Without Emission Control

Emission Control Information Label

A tamper‑resistant emission control information (ECI) label is affixed to the engine in a visible location at the time of

manufacture by Mercury MerCruiser. Please note that the low emissions certification will not affect the fit, function, or

performance of the engine. Boatbuilders and dealers may not remove the label or the part it is affixed to before sale. If

modifications are necessary, contact Mercury MerCruiser about the availability of replacement decals before proceeding. In

addition to the required emissions statement, the label lists the engine serial number, family, applicable emission standard, date

of manufacture (month, year), and engine displacement.

ECIEXEMP

EMISSION CONTROL INFORMATION

a- Applicable standard

NOT FOR SALE IN US

b- Engine serial number

THIS ENGINE IS SOLELY FOR EXPORT AND IS THEREFORE EXEMPT

UNDER 40 CFR 1068.230 FROM U.S. EMISSION STANDARDS AND a c- Engine family name

RELATED REQUIREMENTS. REFER TO THE OWNERS MANUAL

FOR MAINTENANCE SPECIFICATIONS AND ADJUSTMENTS.

d- Hydrocarbons plus oxides of nitrogen family

emission limit

SERIAL #: XXXXXXXX b DOM: MMM YYYY e e - Date of manufacture

FAMILY: XXXXXXXXXXXX c DISP: X.XL POWER : XXX kW f f - Engine displacement, engine power

HC+NOx FEL : XX.X g/kWh d CO FEL : XXX g/kWh g 0575

44881 g - Carbon monoxide family emission limit

IMPORTANT: A CE mark in the lower right corner of the Emission Control Information label indicates that an EU Declaration of

Conformance applies. Refer to the front page of this manual for further information.

IMPORTANT: Engines designated as exempt from either Federal EPA or California emission control regulations are not

covered by a separate emission control component warranty. The product's Mercury MerCruiser manufacturer's warranty is not

affected by the engine's designation under Federal EPA or California emission control regulations.

ECI Label Standard of Compliance

ECIEXEMP

EMISSION CONTROL INFORMATION

NOT FOR SALE IN US

THIS ENGINE IS SOLELY FOR EXPORT AND IS THEREFORE EXEMPT

UNDER 40 CFR 1068.230 FROM U.S. EMISSION STANDARDS AND Indicates a marine engine for export and is exempt under 40

RELATED REQUIREMENTS. REFER TO THE OWNERS MANUAL CFR 1068.255 from United States EPA exhaust emission

FOR MAINTENANCE SPECIFICATIONS AND ADJUSTMENTS.

regulations for 2010.

SERIAL #: XXXXXXXX DOM: MMM YYYY This marine engine is not for sale in U.S.

FAMILY: XXXXXXXXXXXX DISP: X.XL POWER : XXX kW

HC+NOx FEL : XX.X g/kWh CO FEL : XXX g/kWh 0575

44880

Owner Responsibility

The operator must have routine engine maintenance performed to maintain emission levels within prescribed certification

standards.

The operator may not modify the engine in any manner that alters the horsepower or allows emissions levels to exceed factory

specifications.

90-879172243 DECEMBER 2011 Page 1A-19

General Information

Notes:

Page 1A-20 90-879172243 DECEMBER 2011

You might also like

- MERCURY OUTBOARD MOTOR PCM DiagnosticsDocument20 pagesMERCURY OUTBOARD MOTOR PCM DiagnosticsKaivan Kalyaniwalla100% (2)

- MBE Electronic Controls TRBLSHTNG GuideDocument366 pagesMBE Electronic Controls TRBLSHTNG GuideRicardo Diaz81% (21)

- 1220 Manual enDocument50 pages1220 Manual enNitin ChavanNo ratings yet

- 1K 2K In-Chassis MaintenanceDocument76 pages1K 2K In-Chassis MaintenanceLiviu Neda100% (1)

- MEFI 4 and 4B DIAGNOSTIC MANUAL (L510005P) PDFDocument337 pagesMEFI 4 and 4B DIAGNOSTIC MANUAL (L510005P) PDFedgar luis100% (1)

- Abc of Power Modules: Functionality, Structure and Handling of a Power ModuleFrom EverandAbc of Power Modules: Functionality, Structure and Handling of a Power ModuleNo ratings yet

- Ad3zp0ac (COMBISEM1-ing)Document29 pagesAd3zp0ac (COMBISEM1-ing)Kaique MelloNo ratings yet

- Combi Sem 1 Ing (Ad3zp0aa)Document29 pagesCombi Sem 1 Ing (Ad3zp0aa)Russell WoodNo ratings yet

- K-Line Mini - Contactors, Overload Relays and Accessories: Class 8502Document48 pagesK-Line Mini - Contactors, Overload Relays and Accessories: Class 8502hassan karimiNo ratings yet

- Electrical Interface Specification EMS2.4 47714300Document104 pagesElectrical Interface Specification EMS2.4 47714300KASSIMNo ratings yet

- MAX17260Document33 pagesMAX17260123No ratings yet

- TMEngines.01en - General ECH FLT - EnginesDocument170 pagesTMEngines.01en - General ECH FLT - EnginesNgoc NguyenNo ratings yet

- Infct and Infct-Xxxb: Infinity C Programmable Digital Thermocouple MeterDocument56 pagesInfct and Infct-Xxxb: Infinity C Programmable Digital Thermocouple MeterenticoNo ratings yet

- Repair Instructions: EBA 20 Eba 20 CDocument31 pagesRepair Instructions: EBA 20 Eba 20 CDian Gusti RamadhonaNo ratings yet

- Manual XTRA6415AN V2.2.ENDocument36 pagesManual XTRA6415AN V2.2.ENAmer AlmansoryNo ratings yet

- Sanyo Cm21g81Document26 pagesSanyo Cm21g81KathafiNo ratings yet

- LM2907 and LM2917 Frequency To Voltage Converter: 1 Features 3 DescriptionDocument41 pagesLM2907 and LM2917 Frequency To Voltage Converter: 1 Features 3 DescriptionSoeAyeNo ratings yet

- LM2907 and LM2917 Frequency To Voltage Converter: 1 Features 3 DescriptionDocument38 pagesLM2907 and LM2917 Frequency To Voltage Converter: 1 Features 3 DescriptionJuan UcNo ratings yet

- LM2907 and LM2917 Frequency To Voltage Converter: 1 Features 3 DescriptionDocument42 pagesLM2907 and LM2917 Frequency To Voltage Converter: 1 Features 3 Descriptioncontrol tejidoNo ratings yet

- LM2907 and LM2917 Frequency To Voltage Converter: 1 Features 3 DescriptionDocument41 pagesLM2907 and LM2917 Frequency To Voltage Converter: 1 Features 3 Descriptionziko23No ratings yet

- P42H401Document124 pagesP42H401jangel332045No ratings yet

- Boost Controller: TDA4863 Power Factor Controller IC For High Power Factor and Low THDDocument27 pagesBoost Controller: TDA4863 Power Factor Controller IC For High Power Factor and Low THDSaifuddin SidikiNo ratings yet

- VLT Micro SeriesDocument88 pagesVLT Micro SeriesEdwinNo ratings yet

- SCRDocument36 pagesSCRJuan Antonio Rodriguez Meza100% (1)

- Interrupts 23Document248 pagesInterrupts 23cmchristoNo ratings yet

- KODAK MAXII 10KW Service Manual 20210730Document29 pagesKODAK MAXII 10KW Service Manual 20210730amirNo ratings yet

- YASKAWA AC Drive A1000: Technical ManualDocument590 pagesYASKAWA AC Drive A1000: Technical ManualJavier MartínezNo ratings yet

- Service Manual GB: Valid From Serial Number: 364690AADocument98 pagesService Manual GB: Valid From Serial Number: 364690AANgo Ngoc Tu100% (1)

- Sylvania 6842thgDocument123 pagesSylvania 6842thggmackp829No ratings yet

- 0 PH 49 DF 93 RQ 9 Wtfew 02 K 49 G 3 CQ 3 yDocument28 pages0 PH 49 DF 93 RQ 9 Wtfew 02 K 49 G 3 CQ 3 ycarlos andradeNo ratings yet

- Electric Interface Specification 47711360 - ENDocument78 pagesElectric Interface Specification 47711360 - ENKASSIMNo ratings yet

- PA Service ManualDocument140 pagesPA Service ManualaudiolabgaNo ratings yet

- ABB High Voltage Unigear GuideDocument163 pagesABB High Voltage Unigear GuideMohammad Saidul Islam ShantoNo ratings yet

- SIEP C71061627C 02 YAS+A1000+UsersManual PDFDocument544 pagesSIEP C71061627C 02 YAS+A1000+UsersManual PDFJorge MorenoNo ratings yet

- MGD-32 and AGD-048: Remote Multiplex Graphic Driver Annunciators and Adder BoardsDocument36 pagesMGD-32 and AGD-048: Remote Multiplex Graphic Driver Annunciators and Adder BoardsErick CastilloNo ratings yet

- 044-05288-B Remote Electrical Tilt (RET) 05.2008Document111 pages044-05288-B Remote Electrical Tilt (RET) 05.2008Тарас ДегилевNo ratings yet

- Alternator Voltage Regulator With Load Response Control: FeaturesDocument14 pagesAlternator Voltage Regulator With Load Response Control: FeaturesAvanindra SharmaNo ratings yet

- Yaskawa V1000 CIMR VC ManualDocument418 pagesYaskawa V1000 CIMR VC ManualjikishanjiservicesNo ratings yet

- Maq. Fromm P326 - ManualDocument56 pagesMaq. Fromm P326 - ManualAllison MouraNo ratings yet

- In Chasis Maintainance 1000 2000 PDFDocument78 pagesIn Chasis Maintainance 1000 2000 PDFMauricio Gomez Gomez100% (1)

- GE Troubleshooting Aid AC MachinesDocument249 pagesGE Troubleshooting Aid AC MachinessidewaysuteNo ratings yet

- Allen Bradley 1321 Reactors - Isolation Transformers PDFDocument26 pagesAllen Bradley 1321 Reactors - Isolation Transformers PDFCristian MardonesNo ratings yet

- Did1 Ecu - Reference Manual: Baldur Gíslason January 17, 2021Document95 pagesDid1 Ecu - Reference Manual: Baldur Gíslason January 17, 2021achuo charles100% (1)

- A78xx Fixed Positive Voltage Regulators: 1 Features 3 DescriptionDocument27 pagesA78xx Fixed Positive Voltage Regulators: 1 Features 3 DescriptionGeraldo Aparecido SantosNo ratings yet

- Ad3na0ab (COMBI NACCO-ing)Document30 pagesAd3na0ab (COMBI NACCO-ing)Kaique MelloNo ratings yet

- 42hds52 PDFDocument141 pages42hds52 PDFpapa123No ratings yet

- AC Drive A1000Document556 pagesAC Drive A1000Anup TrivediNo ratings yet

- Elect Diag DeviceDocument11 pagesElect Diag DevicehamadaabdelgawadNo ratings yet

- Philips 32PFL1507-F8 Chasis PL11.10Document65 pagesPhilips 32PFL1507-F8 Chasis PL11.10Gustavo ReynaNo ratings yet

- Fendt 500 Vario s4 SeriesDocument744 pagesFendt 500 Vario s4 Seriesaw1228818No ratings yet

- Liebert Gxt2U: User Manual - 120V, 500-3000VADocument44 pagesLiebert Gxt2U: User Manual - 120V, 500-3000VAppp2000No ratings yet

- Philips DLP - FieldServiceGuide - SCB Training ManualDocument138 pagesPhilips DLP - FieldServiceGuide - SCB Training ManualReginald SosaNo ratings yet

- 2UEB000132 - ACS - 2000 - 4 - KV - MV - Switchgear - Guide REV DDocument15 pages2UEB000132 - ACS - 2000 - 4 - KV - MV - Switchgear - Guide REV DSherifNo ratings yet

- Max40108 3128706Document14 pagesMax40108 3128706hassan yosefiNo ratings yet

- InteliCharger 240 24 Reference Guide - r4Document17 pagesInteliCharger 240 24 Reference Guide - r4GiangDoNo ratings yet

- Ga 16Document142 pagesGa 16Ericsson Via90% (10)

- Electronic Automotive Transmission Troubleshooter Nissan-Infinity VehiclesFrom EverandElectronic Automotive Transmission Troubleshooter Nissan-Infinity VehiclesNo ratings yet

- Automotive Electronic Diagnostics (Course 2)From EverandAutomotive Electronic Diagnostics (Course 2)Rating: 4 out of 5 stars4/5 (2)

- WS PRM500 Marine TransDocument54 pagesWS PRM500 Marine TransJorge SoberanoNo ratings yet

- Twindisc ProductsDocument59 pagesTwindisc ProductsJorge SoberanoNo ratings yet

- Removal and Installation: Section 2A - Sterndrive ModelsDocument54 pagesRemoval and Installation: Section 2A - Sterndrive ModelsJorge SoberanoNo ratings yet

- Section 6A - Closed Cooling SystemDocument48 pagesSection 6A - Closed Cooling SystemJorge SoberanoNo ratings yet

- 90-879172243 - 4b - Sistema ElectricoDocument8 pages90-879172243 - 4b - Sistema ElectricoJorge SoberanoNo ratings yet

- Removal and Installation: Section 2B - Inboard ModelsDocument40 pagesRemoval and Installation: Section 2B - Inboard ModelsJorge SoberanoNo ratings yet

- 90-879172243 - 4d - Sistema ElectricoDocument8 pages90-879172243 - 4d - Sistema ElectricoJorge SoberanoNo ratings yet

- 90-879172243 - 4a - Sistema ElectricoDocument6 pages90-879172243 - 4a - Sistema ElectricoJorge SoberanoNo ratings yet

- Important Information: Section 1D - TroubleshootingDocument22 pagesImportant Information: Section 1D - TroubleshootingJorge SoberanoNo ratings yet

- 2009 Sport Boat Sport Cruiser Prop ChartDocument5 pages2009 Sport Boat Sport Cruiser Prop ChartJorge SoberanoNo ratings yet

- Fuel Pressure Is Low CAT 320D2Document3 pagesFuel Pressure Is Low CAT 320D2falahNo ratings yet

- Sac PDFDocument5 pagesSac PDFabood mohammadNo ratings yet

- Honda WT20X Water Pump Shop Manual (Serial No GX140-1000001 To 9999999 & GC02-2000001 To 8669999, WAAJ-1000001 To 9999999)Document105 pagesHonda WT20X Water Pump Shop Manual (Serial No GX140-1000001 To 9999999 & GC02-2000001 To 8669999, WAAJ-1000001 To 9999999)Tomás CappaNo ratings yet

- Owners Manual: FW2080 Series Fifth WheelDocument16 pagesOwners Manual: FW2080 Series Fifth WheelSIVARAMANJAGANATHANNo ratings yet

- Control Torsional Vibrations: Highly Flexible CouplingsDocument12 pagesControl Torsional Vibrations: Highly Flexible Couplingscosty_transNo ratings yet

- Copia de MTA - Kits de Distribucion (MORENO)Document16 pagesCopia de MTA - Kits de Distribucion (MORENO)Moron MotorNo ratings yet

- Study of Sigma and Rocam Assembly Line And22Document32 pagesStudy of Sigma and Rocam Assembly Line And22Rohan GangwaniNo ratings yet

- Easa Emergency Airworthiness Directive: AD No.: 2011-0023-EDocument3 pagesEasa Emergency Airworthiness Directive: AD No.: 2011-0023-ESantiago ArroyoNo ratings yet

- Standard Value Table For Engine Related PartsDocument1 pageStandard Value Table For Engine Related PartsReza SiregarNo ratings yet

- Wheel Loader Aggregate Handler: Reliability Ease of OperationDocument8 pagesWheel Loader Aggregate Handler: Reliability Ease of Operationعباس محمدNo ratings yet

- Ex5500 6Document16 pagesEx5500 6RAJIV GandhiNo ratings yet

- SC Session 1 Intensive Batch Nov 2023Document32 pagesSC Session 1 Intensive Batch Nov 2023anujmaingi95No ratings yet

- Drillman GT20 Brochure Jul21Document4 pagesDrillman GT20 Brochure Jul21Tasha KuskNo ratings yet

- Adjustment Procedures For RSV Type Hybrid (Cam Lock) Governor Equipped Injection Pump For Komatsu: Part 2Document11 pagesAdjustment Procedures For RSV Type Hybrid (Cam Lock) Governor Equipped Injection Pump For Komatsu: Part 2duongbk24 luu quang duongNo ratings yet

- 352 TGBDocument84 pages352 TGBJno PartsNo ratings yet

- 580 Super N: Loader/Backhoe Emissions CertifiedDocument6 pages580 Super N: Loader/Backhoe Emissions CertifiedBlytzx GamesNo ratings yet

- Ford Powershift Transmission: Automotive Transmissions ManualDocument4 pagesFord Powershift Transmission: Automotive Transmissions ManualHese MasNo ratings yet

- Installation EMS 2 Dec-08Document70 pagesInstallation EMS 2 Dec-08DanielDosSantosLNo ratings yet

- FSR800 Spec Sheets A4Document2 pagesFSR800 Spec Sheets A4yitaNo ratings yet

- Chapter 1 Engine: SpecificationsDocument9 pagesChapter 1 Engine: Specificationsmdias_650100No ratings yet

- Ferrari - Cap2 Sicurezze F121618 EDocument21 pagesFerrari - Cap2 Sicurezze F121618 EYoseth Jose Vasquez ParraNo ratings yet

- 4045HFG92 ADocument2 pages4045HFG92 AArmando Jr AmoresNo ratings yet

- MAK Diamond 15W-40Document1 pageMAK Diamond 15W-40Indus StoreNo ratings yet

- Auction: Odessa TexasDocument8 pagesAuction: Odessa Texasayman akrabNo ratings yet

- Fuel Consumption by EngineDocument2 pagesFuel Consumption by EngineRie ReiNo ratings yet

- Mini Skid Steer: Optimal Power. Productivity. High StandardsDocument2 pagesMini Skid Steer: Optimal Power. Productivity. High StandardsMichael BrandonNo ratings yet

- Liebherr R9400Document22 pagesLiebherr R9400Rohman FashihinNo ratings yet

- GR-1000XL-4: Hydraulic Rough Terrain CraneDocument24 pagesGR-1000XL-4: Hydraulic Rough Terrain Cranesrikanthc85No ratings yet

- Gnome Engine: Mayank Baid Surotia Parth Karan Choubay Virender Singh Bhati Hemant Kumar YadavDocument23 pagesGnome Engine: Mayank Baid Surotia Parth Karan Choubay Virender Singh Bhati Hemant Kumar YadavMayank BaidNo ratings yet