Professional Documents

Culture Documents

FABIG TM79 DDTandDetonationPredictionswithCFD ORHansen

FABIG TM79 DDTandDetonationPredictionswithCFD ORHansen

Uploaded by

AbabOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FABIG TM79 DDTandDetonationPredictionswithCFD ORHansen

FABIG TM79 DDTandDetonationPredictionswithCFD ORHansen

Uploaded by

AbabCopyright:

Available Formats

DDT AND DETONATION

PREDICTIONS WITH CFD - TIME TO

BE CONSIDERED IN EXPLOSION

RISK ASSESSMENTS?

Olav Roald Hansen

Llyod’s Register Consulting

E: olav.hansen@lr.org

T: +47 91 17 17 87

Technical meeting proceedings - JUNE 2014 www.fabig.com 101

DDT and Detonation Predictions with CFD

- Time to be Considered in Explosion Risk Assessments?

FABIG technical meeting, Aberdeen & London June 25-26, 2014

Olav Roald Hansen Lloyd’s Register Consulting, Bergen, Norway

Working together

for a safer world

FLACS validation and new application areas - Focus for 20 years:

Good results for explosion and dispersion- hydrocarbons, hydrogen, LNG, dust, explosives etc.

Sometimes hard to understand reasons for deviation

FLACS validation against full scale tests1997-98, HSE Phase 3A test 4, 19 and 22

©Lloyd’s Register Consulting

Technical meeting proceedings - JUNE 2014 www.fabig.com 102

HSE Phase 3A Test 4 - blast pressures severely underpredicted

3.7 barg

17 barg

2.0 barg

TEST

Pressure at end of test rig Pressure 12m, 24m and 48m outside

FLACS

1.0 barg

0.6 barg

2.4 barg

©Lloyd’s Register Consulting

Deflagrations

Strong deflagrations require turbulence

(obstructions– e.g. pipes/equipment or trees)

1 to 10+ barg pressure & ~1000 m/s flame speed

Flames slow down outside congestion

DNV GL video from 1980s

Most (near all) explosion studies consider deflagrations to be worst-case

(sometimes only 5-10% of energy contributes)

Deflagration -

only congested

units contribute Unit 1 Unit 2

Blast energy

Unit 3 Unit 4

Safe design not stimulated

Gas cloud

=> Focus on sufficient distance to congestion

©Lloyd’s Register Consulting

Technical meeting proceedings - JUNE 2014 www.fabig.com 103

Deflagration

DNV GL video

©Lloyd’s Register Consulting

Detonation

Detonations propagate by ignition of unburnt gas ahead of flame due to shock waves

16-20 barg pressure & 1600-2000 m/s (detonation limits similar to flammability limits - LFL:UFL)

From OECD hydrogen safety report and other sources

~1 cm ~3 cm ~ 5-10 cm ~ 30 cm

©Lloyd’s Register Consulting

Technical meeting proceedings - JUNE 2014 www.fabig.com 104

Fast deflagrations may transit to detonations (DDT)

Detonations propagate by shockwave interaction

16-20 barg pressure & 1600-2000 m/s

Both within congestion and gas cloud outside

DDT is deflagration-to-detonation-transition DNV GL video from1980s

At

Flame speed > 600 m/s DDT BLASTENERGY Unit 1 Unit 2

Pressure > 2 barg Unit 5

and sufficient scale Unit 3 Unit 4

DDT has been observed in experiments Gas Cloud

ALL energy in flammable cloud may contribute to blast waves

©Lloyd’s Register Consulting

Detonation

DNV GL video

©Lloyd’s Register Consulting

Technical meeting proceedings - JUNE 2014 www.fabig.com 105

DDT observed in several recent major accidents

Buncefield 2005 (DDT)

Jaipur

Puerto Rico 2009 (likely DDT)

Jaipur 2009 (DDT)

Sunrise Toronto 2008 (concluded DDT)

Buncefield

There are likely more …

Sunrise

Puerto Rico???

©Lloyd’s Register Consulting

DDT also observed in several large scale experiments

45m BG test (cyclohexane)

BEX tests (ethylene/propane)

MERGE tests (propane, ethylene)

HSE Phase 3A full-scale rig (natural gas)

Buncefield explosions in trees (propane) 28m x 12m x 8m rig HSE Phase 3A

Various hydrogen tests (FLAME facility, KOPER tests, pipe-tests, BakerRisk, Fh-ICT)

BakerRisk congestion rig tests (ethylene)

Shell tests congestion block (e.g. ethane)

NIOSH 73m 1.05m diameter pipe tests (natural gas)

Car and drum placed inside detonation test

GL Spadeadam April 2013

©Lloyd’s Register Consulting

Technical meeting proceedings - JUNE 2014 www.fabig.com 106

DDT predictions using FLACS (Middha & Hansen) 2006=>

DDT predicted using normalised spatial pressure gradient DPDX (-)

[Simple explanation: Max pressure change (bar) per grid cell inside flame front]

Max DPDX < 0.5 DDT unlikely

0.5 < Max DPDX < 5 DDT possible criterion to be fulfilled,

5 < Max DPDX DDT likely DPDX-region > 7-10 across

Validated against numerous tests:

Hydrogen tests (FLAME, KOPER, BakerRisk, Fh-ICT, …) Buncefield tre simulering DPDX

Ethylene tests (MERGE & BakerRisk)

Propane tests (Buncefield trees)

Natural gas (fullscale rig, 73m pipe)

From Hansen & Johnson (2013)

2012: Method to simulate DDT and detonation with FLACS (Hansen & Johnson 2013)

©Lloyd’s Register Consulting

Simulated Buncefield Test 2 (DDT and detonation) in 2012

Proper analysis of trees

used to develop “dummy trees”

Handout from Mike Johnson’s presentation at FABIG March 2014

mm % vol/m m/m3 m2/m3 m/m3 adj m2/m3 adj Diameter model m/m3 m2/m3 Pr 3 x 3 x 4m

170 0,00 0,023 0,00 0,00 0,00 0,00

120 0,41 0,011 0,36 0,14 0,12 0,05 100 1 0,314 V 36

85 1,04 0,006 1,83 0,49 0,61 0,16

60 0,40 0,003 1,42 0,27 0,47 0,09 50 2 0,314 H 72

42 0,21 0,001 1,52 0,20 0,51 0,07

30 0,24 0,001 3,40 0,32 1,13 0,11 25 4 0,314 H+V 144

22 0,18 0,000 4,74 0,33 1,58 0,11

18 0,19 0,000 7,47 0,42 2,49 0,14 10 20 0,628 H+V 720

12 0,23 0,000 20,35 0,77 6,78 0,26

8 0,23 0,000 45,78 1,15 15,26 0,38 5 52 0,816 1872

3 0,23 0,000 325,55 3,07 108,52 1,02

7,15 2,382 Original estimate 2,386

3 x high 3 x high 2,65 Final estimate

©Lloyd’s Register Consulting Method used November 2012 to develop tree-model used by Hansen & Johnson (2013)

Technical meeting proceedings - JUNE 2014 www.fabig.com 107

Simulation of Buncefield Test 2 with trees

FLACS simulation predicted likely DDT, can we also predict consequences?

Tweaking parameters in FLACS => detonation can be simulated

Test 2 – standard FLACS simulation (video)

Test 2 – simulated with DDT and detonation settings (video)

Video frames

From Hansen & Johnson (2013) Mike Johnson FABIG presentation March 2014

©Lloyd’s Register Consulting

Good results predicting DDT and detonations

Test 2 detonation modelling: Realistic pressures and flame speeds

From Hansen & Johnson (2013) [updated to include experimental results]

©Lloyd’s Register Consulting

Technical meeting proceedings - JUNE 2014 www.fabig.com 108

Good results predicting DDT and detonations

Test 2 detonation modelling: Observed and simulated pressures

Sensor 1-3 Sensor 4-6 Sensor 7-9

©Lloyd’s Register Consulting

HSE Phase 3A Test 4 – ”perfect results” assuming DDT

From Hansen & Johnson (2013)

©Lloyd’s Register Consulting

Technical meeting proceedings - JUNE 2014 www.fabig.com 109

LRC has made automatic DDT & detonation prediction functionality

Scripts are developed which will

Evaluate potential for DDT in running simulation

Define exact time and location for DDT

If DDT, start detonation simulation in parallel

=> Efficient evaluation of DDT risk (including consequences)

©Lloyd’s Register Consulting

Automatic scripts for Safety Gap Issue + Blast Smearing also developed

FLACS will give too high pressures

after safety gap, work-around exists

Standard FLACS Improved

FLACS will smear and underpredict far-field

Improved

blast from strong explosions, work-around exist

Standard

FLACS

©Lloyd’s Register Consulting

Technical meeting proceedings - JUNE 2014 www.fabig.com 110

Summary Differences Deflagration & Detonation Flames

Parameter Deflagration: Detonation:

Flame propagation: by turbulence/congestion by shock-waves

Flame speeds: 1 m/s – 1000 m/s 1600-2000 m/s

Pressures 0.001 to ~10 barg 16-20 barg

Blast waves Often directional Strong in all directions

Strong explosion expected Inside congestion & near stoichiometry Anywhere flammable

Natural gas 8-11% Natural gas 5-15%

Deflagration

Visual look

Detonation

GL Buncefield tree test video captures (Source New Scientist Website)

©Lloyd’s Register Consulting

Implication of DDT: Onshore & offshore (FPSO/FLNG and platforms)

For onshore facilities it may be a “game changer” to consider DDT in design

Must optimize design for individual units to prevent DDT

Must ensure deflagrations

do not undergo DDT Unit 1 Unit 2

Blast energy

Unit 3 Unit 4

Gas cloud

For FPSO and FLNG risk for DDT should be considered (more slides follow)

Optimize design to minimize DDT potential

Avoid gas clouds detonating at critical locations (e.g. at hull deck)

Extreme loads may be seen locally, still it is feasible to design for far field loads onto LQ

Offshore platforms

Illustration

Already optimized using CFD (?) Not caused by DDT

Higher loads expected with DDT

However, already in “trouble” at DDT

Could make automatic deluge more attractive! DDT can represent a significant potential for complete loss

©Lloyd’s Register Consulting

Technical meeting proceedings - JUNE 2014 www.fabig.com 111

FPSO study: Geometry model and study approach

From GCPS 2014 paper by O. R. Hansen, R. Martini, Y. Ryu and J. Choi

Lloyd’s Register Consulting & Samsung Heavy Industries

Process areas below yellow decks

Study approach:

1 Ventilation & dispersion study

=> frequency for ignitied clouds estimated

2 Clouds are exploded (deflagration) evaluating DDT crieria

=> Likely DDT scenarios will be re-simulated assuming DDT

3 Risk reduction measures evaluated

=> Study repeated with 3 separation walls through process areas

©Lloyd’s Register Consulting

FPSO study: Dispersion Study (84 CFD calculations)

From GCPS 2014 paper by O. R. Hansen, R. Martini, Y. Ryu and J. Choi

Lloyd’s Register Consulting & Samsung Heavy Industries

Simplified Probabilistic Approach

• Three (3) release locations/directions (R1, R2 and R3 in Figure)

• Two (2) gas compositions: Propane and NG (85% methane, 10% C2 and 5% C3)

• Seven (7) release rates (3, 6, 12, 24, 48, 96 and 192 kg/s)

• One (1) wind direction (-10 degrees)

• Two (2) wind speeds 3 m/s and 9 m/s

• 60s to ESD + 60s to stop release

Wind direction and 3 release locations indicated

©Lloyd’s Register Consulting

Technical meeting proceedings - JUNE 2014 www.fabig.com 112

FPSO study: 84 CFD dispersion calculations

From GCPS 2014 paper by O. R. Hansen, R. Martini, Y. Ryu and J. Choi

Lloyd’s Register Consulting & Samsung Heavy Industries

Leak frequencies:

• Typical distribution

• Somewhat low (0.5/year)

Ignition model:

• Time dependent OGP (UKOOA)

• 55% of ignition frequency from 10s to 150s

• Not sensitive to gas cloud size, only initial release rate

Likely conservatism in leak location/direction + ignition model (compared to NORSOK OLF)

©Lloyd’s Register Consulting

FPSO study: Results from dispersion calculations

From GCPS 2014 paper by O. R. Hansen, R. Martini, Y. Ryu and J. Choi

Lloyd’s Register Consulting & Samsung Heavy Industries

Cloud development

• Natural gas rises, propane/condensate fall when losing momentum

• Comparable maximum cloud sizes, longer duration for propane

• Significant clouds at hull deck for large propane releases

Natural gas

96 kg/s

Propane 96 kg/s

©Lloyd’s Register Consulting

Technical meeting proceedings - JUNE 2014 www.fabig.com 113

FPSO study: Resultats from dispersion simulations

From GCPS 2014 paper by O. R. Hansen, R. Martini, Y. Ryu and J. Choi

Lloyd’s Register Consulting & Samsung Heavy Industries

Q9-cloud is used as hazard indicator

(Q9 is an ESC= equivalent stoichiometric cloud)

Observations:

• 2-3 times larger Q9 cloud during low winds

• Flammable cloud (LFL:UFL) ~ twice the size of Q9

• NG & propane have similar maximum cloud sizes

• 10-4/year ignited cloud comparable for NG & propane

NG release frequency 50% higher

Longer exposure for propane clouds

10-4/year clouds twice the size as normal for FPSOs

Main reasons:

Conservative choice of free horizontal jet into domain

Choice of transient ignition model (normally OLF used)

©Lloyd’s Register Consulting

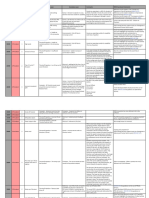

FPSO study: Explosion calculations

From GCPS 2014 paper by O. R. Hansen, R. Martini, Y. Ryu and J. Choi

Lloyd’s Register Consulting & Samsung Heavy Industries

~45 FLACS explosion calculations performed Cloud size Base case Base case

Q9 (m3) NG Propane

• 13-15 different cloud sizes, 1-3 ignition positions 400

• propane and natural gas 700

• conservative ignition location 1000

1400

• some simulations repeated as DDT 2000

Too few scenarios for quantitative DDT evaluation 3000

4500 Near DDT

6000

Observations: 8000 Near DDT

10000 DDT DDT

• DDT seems likely for all propane clouds Q9 > 10,000m3

12000 DDT

• DDT seems likely or near for some natural gas clouds 14000 DDT

17000 DDT

20000 N/A DDT

24000 N/A DDT

The figure shows identified DDT potential.

Too few simulations for quantitative evaluation

and to conclude there is no DDT in green cells.

©Lloyd’s Register Consulting

Technical meeting proceedings - JUNE 2014 www.fabig.com 114

FPSO study: Explosion study, worst-case example

From GCPS 2014 paper by O. R. Hansen, R. Martini, Y. Ryu and J. Choi

Lloyd’s Register Consulting & Samsung Heavy Industries

Ignited cloud at process deck Pressure at hull deck

Cloud at hull deck Maximum pressure at hull deck

DDT indication at process deck

Maximum pressure at process deck

©Lloyd’s Register Consulting

FPSO study: Explosion study, example worst-case

From GCPS 2014 paper by O. R. Hansen, R. Martini, Y. Ryu and J. Choi

Lloyd’s Register Consulting & Samsung Heavy Industries

Maximum pressure distribution

Deflagration only DDT and detonation

Hull deck LQ LQ

Process deck

LQ LQ

Detonation more energetic, sending energy in all directions

Predicted pressure at LQ comparable (or higher) for deflagration

©Lloyd’s Register Consulting

Technical meeting proceedings - JUNE 2014 www.fabig.com 115

FPSO study: Risk reduction with separation walls

From GCPS 2014 paper by O. R. Hansen, R. Martini, Y. Ryu and J. Choi

Lloyd’s Register Consulting & Samsung Heavy Industries

Aim to reduce cloud sizes and explosion pressures

OK for ventilation:

• 45% reduction in typical flow velocities

• 20% reduction in air changes / hour

Good for dispersion:

• Clouds > 10,000m3 strongly reduced

• Minor changes for smaller clouds

Worse with explosions

• Much higher loads for same cloud sizes

• Increased DDT potential

Base case Walls

Deflagration pressures significantly higher with separation walls

©Lloyd’s Register Consulting

FPSO study: Conclusion separation walls

From GCPS 2014 paper by O. R. Hansen, R. Martini, Y. Ryu and J. Choi

Lloyd’s Register Consulting & Samsung Heavy Industries

Separation walls

• Reduce cloud sizes

• Give stronger explosions

• DDT predicted for smaller clouds

• Helps ensuring safe distance to LQ

=> Not convincing for risk reduction

Identified DDT potential, too few simulations for quantitative

PS: evaluation, DDT in green cells can not be ruled out.

More extensive study to be performed before concluding

Soft barriers may be better alternative.

©Lloyd’s Register Consulting

Technical meeting proceedings - JUNE 2014 www.fabig.com 116

Supertankers disappeared in moments Berge Istra 228,000 tons

315m long 50m wide

“Unsinkable”, double hull designs Iron ore & oil combination carrier

Berge Vanga + 2 more sister ships

29 Dec 1975: Berge Istra disappears near the Philippines

20 days later 2 crew members found on a raft

Hearing strictly confidential (insurance/claims?)

29 Oct 1979: Sister Berge Vanga disappears in Atlantic

70 officers and crew missing from 2 ships

Company stops combination cargo business

Berge Istra sank due to strong explosions inside tanks

Was this due to

* Oil spills in double hull + welding, or

* Unreliable flue gas inerting of empty tanks?

Not important => big ships can sink in moments!

©Lloyd’s Register Consulting

Conclusion:

Must prevent this from happening on FPSOs/FLNGs

Strong explosions may lead to DDT

Simplified FPSO study: DDT to be feared every 10-4 – 10-5/year

Detonations will give massive damage locally

Even with frequency lower than10-4/year we should:

Ensure hull integrity to avoid sinking of ship

Ensure that LQ can survive far field blast loads

Measures:

Limit significant gas cloud build-up at hull deck

Deluge activation at gas detection may limit DDT risk

DDT scenarioes should be considered when evaluating design

Tanker Shoku Maru explodes and sinks

A potential DDT offshore would not be “a black swan” May 29, 2014

©Lloyd’s Register Consulting

Technical meeting proceedings - JUNE 2014 www.fabig.com 117

… Questions or comments?

Olav Roald Hansen

Senior Principal Consultant

Bergen Norway

T +47 91 17 17 87 E olav.hansen@lr.org

Lloyd’s Register Consulting

www.lr.org/consulting

Working together

for a safer world

Lloyd’s Register and variants of it are trading names of Lloyd’s Register Group Limited, its subsidiaries and affiliates.

Copyright © Lloyd’s Register Consulting. 2013. A member of the Lloyd’s Register group.

Technical meeting proceedings - JUNE 2014 www.fabig.com 118

Questions and answers

Q: For a FPSO, you advised to design so as to prevent DDT; do you have any

suggestions on how this can be done?

A: The only way I know to prevent DDT is to be very efficient at activating the deluge

system upon gas detection. Another solution is to prevent the gas from filling large

volumes at the hull deck. A DDT high up on the process deck would be significantly

less problematic than one occurring on the hull deck. You should therefore make

sure that gas is prevented from going down to the hull deck. If a gas cloud

detonates, it should be as far as possible from the hull deck as extreme loads are

inside the detonating cloud.

Q: Accidental DDTs are very rare and only seem to occur in large clouds in calm

condition. I have never come across DDTs on offshore structures; can you comment

on this?

A: Perhaps not, but does anyone want to be the first to experience a DDT offshore? After

the Buncefield accident which was the first of its kind, many similar events occurred.

We have seen experimentally that a stoichiometric natural gas can detonate in

modules of 28x12x8m; similar conditions can be achieved for a major gas release in

an offshore structure, so I think that a DDT offshore is a possibility.

Q: I understand that in many cases DDT occurs when the pressure rises ahead of the

flame, for instance when a reflected blast wave hits the flame front. As such, do you

think the DPDX parameter is reliable for predicting DDTs as it looks at the difference

between the pressure at the flame front and ahead of it?

A: We have simulated a lot of cases and the DPDX parameter seems quite reliable. What

you mentioned regarding ignition due to reflection seems to be more related to

laboratory experiments within a channel with pressure waves hitting a corner and

detonating there. In the case of large scale experiments, the occurrence of DDT is

mainly linked to what happens at the flame front.

Technical meeting proceedings - JUNE 2014 www.fabig.com 119

Questions and answers

Q: Are you saying that if the difference between the pressure at the flame front and

ahead of it is more than one bar (for instance), then it is very likely that a DDT

will occur?

A: Not exactly. The parameter that we have developed looks at the next grid cell and a

very high flame speed is required to obtain large pressure differences within one grid

cell. More than two bar in the flame front and no pressure ahead seems to have led

to DDT in some experiments, both from the Spadeadam test site and from Hydrogen

experiments from the literature.

Q: Are you simulating everything with the same solver, or do you use one for

deflagration and another one for detonation?

A: It is the same solver, but we do a dump the results, tweak the parameters and

restart the simulation.

Q: Have you looked at DDTs in hydrogen gas clouds?

A: Yes, a lot. We actually started by considering hydrogen and then considered

other fuels.

Q: What is the effect of reduced congestion on DDT?

A: Reducing congestion will prevent DDTs as it will take longer to reach a DDT in

reduced congestion.

Technical meeting proceedings - JUNE 2014 www.fabig.com 120

You might also like

- Chap 1-6 Mixed ReviewDocument16 pagesChap 1-6 Mixed ReviewanNo ratings yet

- BR Knauf Ceiling Solutions Mineral Solutions ND MEDocument94 pagesBR Knauf Ceiling Solutions Mineral Solutions ND MEsacdawoodNo ratings yet

- Flamability of High Flash Point Liquid Fuels: Peter J Kay, Andrew P. Crayford, Philip J. Bowen James LuxfordDocument8 pagesFlamability of High Flash Point Liquid Fuels: Peter J Kay, Andrew P. Crayford, Philip J. Bowen James LuxfordEfari BahcevanNo ratings yet

- Science Week Proposal 2 JuneDocument26 pagesScience Week Proposal 2 Junecsanjeevan100% (1)

- DDT - Experiments Revisited and New Insight: - Part II - Modelling Olav Roald Hansen UKELG Meeting Cardiff July 10, 2013Document34 pagesDDT - Experiments Revisited and New Insight: - Part II - Modelling Olav Roald Hansen UKELG Meeting Cardiff July 10, 2013igor VladimirovichNo ratings yet

- Gexcon DDT Scotts PresentationDocument33 pagesGexcon DDT Scotts PresentationMochamad SafarudinNo ratings yet

- Expansive Cements and Soundless Chemical DemolitioDocument8 pagesExpansive Cements and Soundless Chemical DemolitioaugustoNo ratings yet

- IECEx Motors Check List - ED03 - 13aDocument9 pagesIECEx Motors Check List - ED03 - 13atopendwarriorNo ratings yet

- TDS 5220 Proguard Euk GBDocument5 pagesTDS 5220 Proguard Euk GBSamuel AgusNo ratings yet

- TDS 574 Marathon Euk GBDocument5 pagesTDS 574 Marathon Euk GBsbry.anwrNo ratings yet

- Ç Ç Á Ç° Í FLACS 2010 ExtendedDocument47 pagesÇ Ç Á Ç° Í FLACS 2010 Extendedandi suntoroNo ratings yet

- Intro To DBCDocument34 pagesIntro To DBCSutiyo PrawiroNo ratings yet

- Stat-X Vs Other Gaseous SystemsDocument13 pagesStat-X Vs Other Gaseous SystemsKhaled OmarNo ratings yet

- TDS 1055 Safeguard Universal ES Euk GBDocument5 pagesTDS 1055 Safeguard Universal ES Euk GBBarathan RajandranNo ratings yet

- Wednesday Cumberland Jim We DwickDocument21 pagesWednesday Cumberland Jim We Dwick2000kar.25No ratings yet

- UF1173Document18 pagesUF1173yussif.zhangNo ratings yet

- Presentation Duxvalves B.VDocument25 pagesPresentation Duxvalves B.Vanwarhas05No ratings yet

- Declaration of Performance (Dop) - Byg0056-003: Thermal Insulation of BuildingDocument2 pagesDeclaration of Performance (Dop) - Byg0056-003: Thermal Insulation of BuildingjamesosulNo ratings yet

- ASTM E1226-19 Standard Test Method For Explosibility of Dust Clouds1Document15 pagesASTM E1226-19 Standard Test Method For Explosibility of Dust Clouds1benson.caisNo ratings yet

- TDS 35042 Marathon IQ2 Euk GBDocument5 pagesTDS 35042 Marathon IQ2 Euk GBserge.angarita.sNo ratings yet

- Division 2.2: Linde Gas LLC P.O. Box 94737 Cleveland, Ohio 44101Document4 pagesDivision 2.2: Linde Gas LLC P.O. Box 94737 Cleveland, Ohio 44101Ruang RenungNo ratings yet

- JotunDocument5 pagesJotunraza.slietNo ratings yet

- Marathon: Technical Data SheetDocument5 pagesMarathon: Technical Data SheetPablo Ahumada G.No ratings yet

- Macropoxy 920 Pre-Prime: Protective & Marine CoatingsDocument4 pagesMacropoxy 920 Pre-Prime: Protective & Marine CoatingstsuregiNo ratings yet

- TDS 684 Resist 86 Euk GBDocument5 pagesTDS 684 Resist 86 Euk GBNgô Trung NghĩaNo ratings yet

- 06 AntifoulingDocument89 pages06 Antifoulingputu100% (1)

- Carz Explosion Isolation FlapDocument2 pagesCarz Explosion Isolation Flappios.helectorNo ratings yet

- TDS Penguard Midcoat M20 (Midcoat)Document5 pagesTDS Penguard Midcoat M20 (Midcoat)rndsb.aopNo ratings yet

- TDS 2920 Penguard Express ZP Eng USDocument5 pagesTDS 2920 Penguard Express ZP Eng USnatig samedovNo ratings yet

- Muki Z 2001Document5 pagesMuki Z 2001CESAR CHAVEZNo ratings yet

- Marathon 1000GF Technical Data SheetDocument5 pagesMarathon 1000GF Technical Data SheetGurdeep Sungh AroraNo ratings yet

- Journal of Loss Prevention in The Process Industries: Graham Atkinson, Edmund Cowpe, Julie Halliday, David PainterDocument9 pagesJournal of Loss Prevention in The Process Industries: Graham Atkinson, Edmund Cowpe, Julie Halliday, David PainterJOHN SEIS100% (1)

- Safeguard Universal ES: Technical Data SheetDocument5 pagesSafeguard Universal ES: Technical Data SheetIsaacNarendraAkbarNo ratings yet

- 010ModelHL 22magnumDocument4 pages010ModelHL 22magnumJoão Carlos Wollentarski JúniorNo ratings yet

- Improved Insensitive Hytemp/DOA Bonded HMX and RDX Mixtures by Paste ProcessDocument21 pagesImproved Insensitive Hytemp/DOA Bonded HMX and RDX Mixtures by Paste ProcessIvan Katchanovski falsifierNo ratings yet

- Raychem e CatalogDocument99 pagesRaychem e Catalogarifayee-1No ratings yet

- Barrier ZEP HS 环氧富锌底漆 (6KW) (United States - English)Document5 pagesBarrier ZEP HS 环氧富锌底漆 (6KW) (United States - English)longNo ratings yet

- Risk Assessment of Aviation Fuel Shipment: M. O. Nafd, W. A. Ibrahim and Medhat A.E. MoustafaDocument6 pagesRisk Assessment of Aviation Fuel Shipment: M. O. Nafd, W. A. Ibrahim and Medhat A.E. MoustafaAlessandro LeonardiNo ratings yet

- TDS 625 Penguard Topcoat Euk GBDocument5 pagesTDS 625 Penguard Topcoat Euk GBBarathan RajandranNo ratings yet

- TDS MarathonDocument5 pagesTDS MarathonSyamsul MaripNo ratings yet

- TDS MarathonDocument5 pagesTDS MarathonSyamsul MaripNo ratings yet

- Penguard Express ZP: Technical Data SheetDocument5 pagesPenguard Express ZP: Technical Data Sheetinfospinster0% (1)

- Basic BlastingDocument79 pagesBasic BlastingSunilNo ratings yet

- Safety Data Sheet Carbon Dioxide, Solid (Dry Ice)Document2 pagesSafety Data Sheet Carbon Dioxide, Solid (Dry Ice)SridharNo ratings yet

- AFM 34 - Far Better Than Required by German TA Luft : Even After A 2,000-Hour Exposure To Air at 200 °CDocument2 pagesAFM 34 - Far Better Than Required by German TA Luft : Even After A 2,000-Hour Exposure To Air at 200 °Cmaheshthemtb_8197478No ratings yet

- Sdmyers Fluid Testing EbookDocument18 pagesSdmyers Fluid Testing EbookJesus TzianNo ratings yet

- Pengenalan Fire Suppression SystemDocument29 pagesPengenalan Fire Suppression Systemfriska melindaNo ratings yet

- Validation of PHAST Dispersion ModelDocument6 pagesValidation of PHAST Dispersion ModelAshwini NikamNo ratings yet

- Safety Distances For Hydrogen Refuelling StationDocument8 pagesSafety Distances For Hydrogen Refuelling Station이응우No ratings yet

- Carbon Dioxide Fire Fighting System DesignDocument28 pagesCarbon Dioxide Fire Fighting System Designfojice3817No ratings yet

- TDS - 2080 - Penguard Midcoat - Euk - GBDocument5 pagesTDS - 2080 - Penguard Midcoat - Euk - GBRifki ArifinNo ratings yet

- Novec Flux RemoverDocument2 pagesNovec Flux Removerquang trinhNo ratings yet

- Astar 02Document5 pagesAstar 02HAKANNo ratings yet

- In Line Flame Arrest ErsDocument48 pagesIn Line Flame Arrest Ershwang2No ratings yet

- Gas Monitoring and Testing in Underground Mines Using Wireless Technology IJERTV6IS010306 PDFDocument5 pagesGas Monitoring and Testing in Underground Mines Using Wireless Technology IJERTV6IS010306 PDFKushana SaikirannNo ratings yet

- Md. Fazal Hussain, L.Min.E, AMIE (Mining), M. Tech (ISM), FMMC Dy Manager, R&D DepartmentDocument54 pagesMd. Fazal Hussain, L.Min.E, AMIE (Mining), M. Tech (ISM), FMMC Dy Manager, R&D Departmenttridev kant tripathiNo ratings yet

- TDS 11480 Pilot ACR Euk GBDocument5 pagesTDS 11480 Pilot ACR Euk GBeeng gilangNo ratings yet

- Penguard Midcoat MIO: Technical Data SheetDocument4 pagesPenguard Midcoat MIO: Technical Data Sheetgst ajahNo ratings yet

- KTR ATEXDocument16 pagesKTR ATEXIvano VerbiNo ratings yet

- Alkyd Primer Technical Data SheetDocument5 pagesAlkyd Primer Technical Data SheetGurdeep Sungh AroraNo ratings yet

- Energies 14 00024Document19 pagesEnergies 14 00024Marcelo Javier FríasNo ratings yet

- Fairplay-14-Datenblatt-1 - HTDocument1 pageFairplay-14-Datenblatt-1 - HTAbabNo ratings yet

- IMCAM261 DP Station Keeping Events Summary 2022 nj3zf0Document17 pagesIMCAM261 DP Station Keeping Events Summary 2022 nj3zf0AbabNo ratings yet

- Standard Detail X-BT - FCMDocument1 pageStandard Detail X-BT - FCMAbabNo ratings yet

- Jacking SystemsDocument19 pagesJacking SystemsAbabNo ratings yet

- Part FVol 02Document160 pagesPart FVol 02AbabNo ratings yet

- Incertezza Con D 85mm (P86 - T-15 - DP125)Document2 pagesIncertezza Con D 85mm (P86 - T-15 - DP125)AbabNo ratings yet

- Rosemount PT 3051SDocument5 pagesRosemount PT 3051SAbabNo ratings yet

- FABIG TM79 DesignExplosionLoadSpecificationforLargeFloatingFacilities LParisDocument17 pagesFABIG TM79 DesignExplosionLoadSpecificationforLargeFloatingFacilities LParisAbabNo ratings yet

- FABIG TM79 ExplosionRiskAssessmentforanFPSOandDALSpecificationforNLFEA CAzzi RBrewertonDocument30 pagesFABIG TM79 ExplosionRiskAssessmentforanFPSOandDALSpecificationforNLFEA CAzzi RBrewertonAbabNo ratings yet

- Grating FixingsDocument17 pagesGrating FixingsAbabNo ratings yet

- R109 - p9-11 - Barge Optimisation Leads To Cuts in Fuel ConsumptionDocument2 pagesR109 - p9-11 - Barge Optimisation Leads To Cuts in Fuel ConsumptionAbabNo ratings yet

- FABIG TM79 FactorsInfluencingtheExplosionDALandQuantificationoftheirImportance GNalvarteDocument21 pagesFABIG TM79 FactorsInfluencingtheExplosionDALandQuantificationoftheirImportance GNalvarteAbabNo ratings yet

- Hum1 5 7Document2 pagesHum1 5 7jjjjjjjjjjjjjjjNo ratings yet

- Marcus James Santer - Qigong15 - 7 Common Mistakes Beginners Make in Chi Kung and How To Avoid Them (12 PGS)Document12 pagesMarcus James Santer - Qigong15 - 7 Common Mistakes Beginners Make in Chi Kung and How To Avoid Them (12 PGS)Khepri100% (2)

- Percentage Composition Lesson PlanDocument3 pagesPercentage Composition Lesson PlanMarie Vic100% (4)

- UC XLPE CatalogueDocument63 pagesUC XLPE CatalogueMay OngNo ratings yet

- Datasheet scl3300-d01Document41 pagesDatasheet scl3300-d01mhasansharifiNo ratings yet

- PAGSUSURIDocument2 pagesPAGSUSURIMaricel RaguindinNo ratings yet

- Neonatal ResuscitationDocument5 pagesNeonatal ResuscitationDoc Prince CaballeroNo ratings yet

- Greyhound Free Patt.Document14 pagesGreyhound Free Patt.claire_garland100% (2)

- Hydroscand Catalogue PDFDocument382 pagesHydroscand Catalogue PDFemaus100% (1)

- "7 Streams of Income For The Average Nigerian": by Oluwatoyin Omotoso ofDocument29 pages"7 Streams of Income For The Average Nigerian": by Oluwatoyin Omotoso ofOliver Dennis100% (1)

- Linear Equation - Two Points - Equation Level1 AllDocument10 pagesLinear Equation - Two Points - Equation Level1 AllKevin HolcombNo ratings yet

- YS VIII Steam ArtbookDocument19 pagesYS VIII Steam ArtbookTuukka MäkinenNo ratings yet

- Grade 9 Math Q1 M1Document12 pagesGrade 9 Math Q1 M1Renny Romero Luzada100% (2)

- An Outline of The Life and Works of Col Paul Revere (1901)Document164 pagesAn Outline of The Life and Works of Col Paul Revere (1901)liketoreadNo ratings yet

- Test 6Document33 pagesTest 6Балнур АмантайNo ratings yet

- March 2015Document84 pagesMarch 2015Jn BmNo ratings yet

- Gas Turbine Simulator - VisSimDocument2 pagesGas Turbine Simulator - VisSimAbdelkader TayebiNo ratings yet

- Guidelines Current List Updated March 2019Document9 pagesGuidelines Current List Updated March 2019MehrdadNo ratings yet

- Jaguar XK - TYPE 2003 Model Year Electrical GuideDocument69 pagesJaguar XK - TYPE 2003 Model Year Electrical GuideCesar ArteagaNo ratings yet

- Shining The Light I ... by Robert Shapiro Tom... (Z-Lib - orDocument1,016 pagesShining The Light I ... by Robert Shapiro Tom... (Z-Lib - orbatiyeNo ratings yet

- MC Ad Lab2023Document111 pagesMC Ad Lab202321131a0445No ratings yet

- Designator Description Part NumberDocument54 pagesDesignator Description Part NumbervietsangtaoNo ratings yet

- Light Dependant ResisterDocument10 pagesLight Dependant ResisterAyush PattnaikNo ratings yet

- Platimagen Customer DatabaseDocument4 pagesPlatimagen Customer DatabaseErik OrtizNo ratings yet

- Blouse Body Measurement ChartDocument2 pagesBlouse Body Measurement ChartScarletBeauty Enriquez-DiagbelNo ratings yet

- Operating Instructions Mechanical Temperature Switches ML1H, MT1H, L2H, T2H, L1X/L1X-EX, T1X/T1X-EX, T2X/T2X-EXDocument8 pagesOperating Instructions Mechanical Temperature Switches ML1H, MT1H, L2H, T2H, L1X/L1X-EX, T1X/T1X-EX, T2X/T2X-EXمحمد فرحاتNo ratings yet

- Aircraft Vehicle Systems Modelling and Simulation Under UncertaintyDocument64 pagesAircraft Vehicle Systems Modelling and Simulation Under Uncertaintyjakub_gramolNo ratings yet