Professional Documents

Culture Documents

Principles:: 9D Bim Software (Usbim)

Principles:: 9D Bim Software (Usbim)

Uploaded by

Nourhan IhabOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Principles:: 9D Bim Software (Usbim)

Principles:: 9D Bim Software (Usbim)

Uploaded by

Nourhan IhabCopyright:

Available Formats

9D BIM (Lean Construction)

9D BIM Software (usBIM):

This dimension aims to:

• optimize construction processes

• reduce waste through the use of BIM.

• Lean construction involves a shift in focus from maximizing productivity to minimizing waste.

• Recommended tool for design, execution, and maintenance.

• Offers real-time collaboration, project sharing, and online work across devices.

Principles:

1.Optimizing or Eliminating Non-Value-Added Activities:

1. Analyzing the entire production chain to identify and eliminate unnecessary or repetitive

processes.

2. Examples include optimizing transportation methods, such as using larger trucks to reduce

the number of trips.

2.Customer-Centric Approach:

1. Identifying customer needs through market research and satisfaction surveys.

2. Focusing on activities that add value to the customer to ensure smoother operations.

3.Standardizing Processes:

1. Adopting standardized construction processes to minimize site diversification.

2. Reducing variables to maintain predefined standards and improve the ability to manage

unforeseen events.

4.Optimizing Time:

1. Minimizing the time impact of activities like transport, waiting, processing, and inspection.

2. Enhancing work quality and meeting client delivery timelines.

5.Increasing Process Transparency:

1. Promoting greater participation of all stakeholders in the process.

2. Encouraging active and conscious intervention in the development of improvement

solutions.

Comparison with Traditional Construction:

•Lean Construction:

1. Categorizes activities into those that add value and those that do not.

2. Value is directly tied to customer satisfaction.

3. Focuses on waste management and activity planning from project

inception.

•Traditional Construction:

1. Divides activities into sub-processes without consideration for

customer satisfaction.

2. Lacks careful waste management and preliminary activity planning.

Advantages:

•Elimination of Waste: Reduces inefficiencies and unnecessary processes.

•Customer Satisfaction: Aligns activities with customer needs, enhancing

satisfaction.

•Standardization: Minimizes site diversification, making processes smoother and

safer.

•Time Optimization: Improves project timelines by optimizing various activities.

•Transparency: Facilitates greater stakeholder participation and informed

decision-making.

Disadvantages:

•Implementation Challenges: Transitioning from traditional methods to lean

construction may face resistance.

•Initial Planning Time: Requires comprehensive planning at the project's outset.

•Flexibility Concerns: Standardization may limit flexibility in unique project

conditions.

In summary, 9D BIM, or lean construction, offers numerous advantages such as waste reduction, customer satisfaction, and improved

timelines. However, challenges may arise during implementation, and there could be concerns regarding initial planning time and

flexibility. The use of dedicated software like usBIM facilitates efficient project management.

You might also like

- Project Management MCQsDocument49 pagesProject Management MCQsIncredible video's100% (9)

- PQ-Sample TwoDocument11 pagesPQ-Sample Twocpkakope100% (6)

- Answer Key For Electronic Principles by Albert Malvino PDFDocument84 pagesAnswer Key For Electronic Principles by Albert Malvino PDFMark Erwin CamaraoNo ratings yet

- Literature ReviewDocument9 pagesLiterature Reviewpradeep_venkata_1No ratings yet

- Construction Management SystemDocument68 pagesConstruction Management SystemRuth DinamlingNo ratings yet

- Lesson 3Document23 pagesLesson 3facnepomuceno.studentNo ratings yet

- Vu Re Lecture 41Document47 pagesVu Re Lecture 41AlirezaNo ratings yet

- PMC IpdDocument19 pagesPMC IpdAbhik BhattacharjeeNo ratings yet

- Experiment No 1Document9 pagesExperiment No 1harisraja47985No ratings yet

- Step Wise Project PlanningDocument56 pagesStep Wise Project Planninghaiqa suhailNo ratings yet

- Topic: Managing A Project From An Idea To ImplementationDocument10 pagesTopic: Managing A Project From An Idea To Implementationsaim raza arif100% (2)

- 10 Project ManagementDocument7 pages10 Project ManagementAjay BansroleNo ratings yet

- Project ManagementDocument15 pagesProject ManagementChandrika RajaramNo ratings yet

- Project Management: by Rory BurkeDocument14 pagesProject Management: by Rory BurkeThantZin111No ratings yet

- 08 Project Performance DomainsDocument9 pages08 Project Performance DomainsShivansh TulsyanNo ratings yet

- Process Groups and MethodologiesDocument46 pagesProcess Groups and MethodologiesAct VjNo ratings yet

- Turnkey and EPC Contracts: AdvantagesDocument3 pagesTurnkey and EPC Contracts: Advantagesmeghana rsNo ratings yet

- 2.0 Effective Const MGMT Part1Document43 pages2.0 Effective Const MGMT Part1alsahari100% (1)

- Process ManagementDocument41 pagesProcess ManagementHeirvy NicolasNo ratings yet

- Case Study - Maple Solutions Consulting CorporationDocument9 pagesCase Study - Maple Solutions Consulting CorporationJitenNo ratings yet

- Presentation 7Document9 pagesPresentation 7Amrit SapkotaNo ratings yet

- Construction Project ManagementDocument30 pagesConstruction Project ManagementLAL SANKAR100% (1)

- 0050.2014 BIM Trial - RecommenDocument25 pages0050.2014 BIM Trial - Recommenkleos1No ratings yet

- Principles of Construction Management Lesson 1Document67 pagesPrinciples of Construction Management Lesson 1Jesser SollerNo ratings yet

- SPM-B Question BankDocument25 pagesSPM-B Question BankThiyaga RajanNo ratings yet

- Cep473 Module 1-Introduction To Project ManagementDocument25 pagesCep473 Module 1-Introduction To Project ManagementseraevioslNo ratings yet

- Best Practices in ConstructionDocument16 pagesBest Practices in ConstructionXDXDXDNo ratings yet

- Lecture 15 20Document122 pagesLecture 15 20DANIYAL IRSHADNo ratings yet

- Construction and Engineering ManagementDocument8 pagesConstruction and Engineering ManagementChristian ConsignaNo ratings yet

- Product and Service DesignDocument18 pagesProduct and Service DesignMary Elaine DiasantaNo ratings yet

- Uaalo-SCOPE MANAGEMENTDocument3 pagesUaalo-SCOPE MANAGEMENTPhương MinhNo ratings yet

- Project Management BasicsDocument7 pagesProject Management BasicsBlue HeartNo ratings yet

- Chapter 7: Process StrategiesDocument14 pagesChapter 7: Process StrategiesElie DibNo ratings yet

- CONSTRUCTION ENGINEERING AND MANAGEMENT (Chapter 7) by DR B VIDIVELLIDocument70 pagesCONSTRUCTION ENGINEERING AND MANAGEMENT (Chapter 7) by DR B VIDIVELLIDouglas WafulaNo ratings yet

- MIS Unit 2Document7 pagesMIS Unit 2Devesh GandhiNo ratings yet

- Agile Project Management For Construction Projects: Capability Enhancement PMIBC-18-1-001Document15 pagesAgile Project Management For Construction Projects: Capability Enhancement PMIBC-18-1-001Fernando VenantiNo ratings yet

- Sahil PMDocument14 pagesSahil PMrohin gargNo ratings yet

- PM2 - Certified PM - 2023-10-16Document19 pagesPM2 - Certified PM - 2023-10-16Muhammad HarisNo ratings yet

- Lean ConstructionDocument47 pagesLean ConstructionphelixoNo ratings yet

- Lean Technology and Waste Minimization in Construction Industry Using SPSSDocument11 pagesLean Technology and Waste Minimization in Construction Industry Using SPSSInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Introduction Module 1Document34 pagesIntroduction Module 1NinithaNo ratings yet

- Assignment 1 CompleteDocument16 pagesAssignment 1 CompleteEvonYongNo ratings yet

- Chapter 5 - Project Scope ManagementDocument29 pagesChapter 5 - Project Scope ManagementdshoaibiNo ratings yet

- Spring Assingment Project Management MB0049: Nandeshwar Singh ROLL NO. 1408001255Document9 pagesSpring Assingment Project Management MB0049: Nandeshwar Singh ROLL NO. 1408001255Nageshwar singhNo ratings yet

- Module - 2 Process Management MappingDocument26 pagesModule - 2 Process Management Mappingrakshith0402No ratings yet

- Modern Management Strategies Will Only Be Implemented WhenDocument14 pagesModern Management Strategies Will Only Be Implemented Whenashleymakwarimba1No ratings yet

- Lean Production For Competitive Advantage A Comprehensive Guide To Lean Methodologies and Management Practices 1st Nicholas Solution ManualDocument38 pagesLean Production For Competitive Advantage A Comprehensive Guide To Lean Methodologies and Management Practices 1st Nicholas Solution Manualwilsonpadillae65p0100% (17)

- Sub: Master of Buisness Administrator-Mba Semester 2 Subject: - Project ManagementDocument7 pagesSub: Master of Buisness Administrator-Mba Semester 2 Subject: - Project ManagementPranavDarjiNo ratings yet

- Assignment On Project Management: MBA - II Section - ADocument20 pagesAssignment On Project Management: MBA - II Section - Adilip_maniyaNo ratings yet

- Pme Unit-3Document47 pagesPme Unit-3Akriti SonkerNo ratings yet

- Digital Quality Control of Construction WorkDocument8 pagesDigital Quality Control of Construction Work19-137 IVNo ratings yet

- PM Notes CombinedDocument898 pagesPM Notes CombinedMahir MalikNo ratings yet

- ISSN: 1314-3395 (On-Line Version) Url: HTTP://WWW - Ijpam.eu Special IssueDocument12 pagesISSN: 1314-3395 (On-Line Version) Url: HTTP://WWW - Ijpam.eu Special IssueMohammed NizamNo ratings yet

- Unit 4Document36 pagesUnit 4153-B RAKSHITHANo ratings yet

- Project Management: An OverviewDocument30 pagesProject Management: An OverviewPrashant GhimireNo ratings yet

- Project Management Civil EngineersDocument32 pagesProject Management Civil EngineersJenifer JosephNo ratings yet

- Critical Success Factors For Software Projects: Group 8Document15 pagesCritical Success Factors For Software Projects: Group 8Pranay PrannuNo ratings yet

- 2.1 Example - Scope, V1.0.1Document3 pages2.1 Example - Scope, V1.0.1Mitul VanasiwalaNo ratings yet

- Icr - Abb Project Management 1009Document4 pagesIcr - Abb Project Management 1009hareeshksomanNo ratings yet

- Digital Project Management: A Comprehensive Guide: cybersecurity and compute, #40From EverandDigital Project Management: A Comprehensive Guide: cybersecurity and compute, #40No ratings yet

- Human 32Document3 pagesHuman 32Nourhan IhabNo ratings yet

- Report AnalysisDocument10 pagesReport AnalysisNourhan IhabNo ratings yet

- Nene EeeDocument1 pageNene EeeNourhan IhabNo ratings yet

- Children Cultrural Center2Document10 pagesChildren Cultrural Center2Nourhan IhabNo ratings yet

- SKP2Document1 pageSKP2Nourhan IhabNo ratings yet

- Long Quiz About HeatDocument2 pagesLong Quiz About HeatLynne Tuiza EndonNo ratings yet

- Noun Clauses: Definition, Examples, & ExercisesDocument10 pagesNoun Clauses: Definition, Examples, & ExercisesGerson SetyoNo ratings yet

- Lesson PlanDocument3 pagesLesson Planapi-644493680No ratings yet

- Biology Investigatory Experiments and Project ReportsDocument5 pagesBiology Investigatory Experiments and Project ReportsJasim AbdullaNo ratings yet

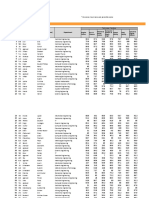

- Innoventure List of Short Listed CandidatesDocument69 pagesInnoventure List of Short Listed CandidatesgovindmalhotraNo ratings yet

- Listening Test 1 Cam 15Document4 pagesListening Test 1 Cam 15Cao Thi HienNo ratings yet

- Who Moved My Cheese Research PaperDocument5 pagesWho Moved My Cheese Research Paperfvhk298x100% (2)

- Laporan Kimia Organik - Asam FumaratDocument40 pagesLaporan Kimia Organik - Asam FumaratTuttaTutiWidyaNo ratings yet

- CSR May June 2013 DigitalDocument60 pagesCSR May June 2013 DigitalmwuestNo ratings yet

- Brown Bag Introduction SpeechDocument3 pagesBrown Bag Introduction Speechcathy johnsonNo ratings yet

- Exercise 2 Exam1practice SaDocument11 pagesExercise 2 Exam1practice SaRobert JoeNo ratings yet

- PMS07K 60Hz AC Wiring DiagramDocument5 pagesPMS07K 60Hz AC Wiring DiagramuserfileNo ratings yet

- Surfynol® 440 Surfactant: Description Shelf LifeDocument2 pagesSurfynol® 440 Surfactant: Description Shelf LifeWangYunNo ratings yet

- Site Organisation in Construction: Samson Adesope & YaredDocument18 pagesSite Organisation in Construction: Samson Adesope & YaredSHRADDHA GHUGENo ratings yet

- Activity 3: Code Connect! Question: How Does The Self-Learning Module Help You in Understanding Quantitative Research Descriptive Codes ThemesDocument1 pageActivity 3: Code Connect! Question: How Does The Self-Learning Module Help You in Understanding Quantitative Research Descriptive Codes ThemesKeven FloresNo ratings yet

- Eden - Atlantis ProjectDocument25 pagesEden - Atlantis ProjectLeomar MartínezNo ratings yet

- Renderoc LADocument2 pagesRenderoc LAMansoor AliNo ratings yet

- Physics-E Chapters 31 - 38Document8 pagesPhysics-E Chapters 31 - 38look porrNo ratings yet

- Introduction - Noel BoyleDocument15 pagesIntroduction - Noel BoyleblurbNo ratings yet

- Quiz Game ProjectDocument37 pagesQuiz Game ProjectShahvaar KmNo ratings yet

- The Earliest Concepts On Mathematics That That GainedDocument5 pagesThe Earliest Concepts On Mathematics That That GainedRodelNo ratings yet

- Arb 03 Pid ControlDocument14 pagesArb 03 Pid ControlSajitha NishaliNo ratings yet

- Business Spotlight Space Exploration Adv. SSDocument6 pagesBusiness Spotlight Space Exploration Adv. SSDaniel NazwiskoNo ratings yet

- Saeed Ahmad CVDocument1 pageSaeed Ahmad CVnoman razaNo ratings yet

- Education: Section 5Document8 pagesEducation: Section 5api-548946265No ratings yet

- Soda-Lime and Zoelite MethodDocument4 pagesSoda-Lime and Zoelite MethodcIBIM29No ratings yet

- Bakti MW Linkbudget 20230705Document2,033 pagesBakti MW Linkbudget 20230705muhammad alibNo ratings yet

- Ian Doyle Olson: Professional Experience SpecialtiesDocument1 pageIan Doyle Olson: Professional Experience SpecialtiesIan OlsonNo ratings yet