Professional Documents

Culture Documents

Electrical Safety Webinar PDF

Electrical Safety Webinar PDF

Uploaded by

Binod KafleCopyright:

Available Formats

You might also like

- bc1000xl p1 10 sn8802Document214 pagesbc1000xl p1 10 sn8802bleexblox100% (5)

- Yamaha XJ550 Seca XJ 550 Service Specifications ManualDocument11 pagesYamaha XJ550 Seca XJ 550 Service Specifications ManualNabucco Donosor0% (3)

- Elevator Troubleshooting & Repair: A Technician's Certification Study GuideFrom EverandElevator Troubleshooting & Repair: A Technician's Certification Study GuideRating: 4 out of 5 stars4/5 (9)

- QAQC Electrical Inspection: A Beginner's GuideFrom EverandQAQC Electrical Inspection: A Beginner's GuideRating: 4 out of 5 stars4/5 (1)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 4 out of 5 stars4/5 (2)

- Main Engine MAN B&W K 80 MC-CDocument868 pagesMain Engine MAN B&W K 80 MC-CAbsar Mamun94% (18)

- PLC Programming from Novice to Professional: Learn PLC Programming with Training VideosFrom EverandPLC Programming from Novice to Professional: Learn PLC Programming with Training VideosRating: 5 out of 5 stars5/5 (1)

- SP0509 Circuit Breaker Testing SWPDocument6 pagesSP0509 Circuit Breaker Testing SWPEnthusiastNo ratings yet

- Electrical Safety: Casimiro L. Flores JRDocument23 pagesElectrical Safety: Casimiro L. Flores JRJoseph CeaNo ratings yet

- Electrical Safety Management Procedure May 2013Document35 pagesElectrical Safety Management Procedure May 2013Roni Enjelani100% (2)

- Long-Term Experiences and Review With Offline and Online PD Measure-Ments On-Site On EHV XLPE Cable Systems 330 KV To 500 KVDocument6 pagesLong-Term Experiences and Review With Offline and Online PD Measure-Ments On-Site On EHV XLPE Cable Systems 330 KV To 500 KVSitiSaodahNo ratings yet

- SP0512 Ver 4Document4 pagesSP0512 Ver 4Rebeca VargasNo ratings yet

- Commissioning Ground Mounted Distribution SubstationsDocument6 pagesCommissioning Ground Mounted Distribution SubstationsSergio Henrique F. CArniettoNo ratings yet

- 00-SATP-busway, Rev01Document9 pages00-SATP-busway, Rev01islam mohamedNo ratings yet

- FeedbackDocument641 pagesFeedbackAnonymous bntbU1ibNo ratings yet

- EPS Startup Test Procedure - SECDocument45 pagesEPS Startup Test Procedure - SECEng Zaid NawaysehNo ratings yet

- E2 Relay CommissioningDocument14 pagesE2 Relay CommissioningShailesh ChettyNo ratings yet

- Circuit Breaker Testing SWP: 1 Purpose AND ScopeDocument6 pagesCircuit Breaker Testing SWP: 1 Purpose AND ScopeJarrett MathewsNo ratings yet

- Simplified Method For Using The NFPA 70E Tables?Document43 pagesSimplified Method For Using The NFPA 70E Tables?Mohsin JamshaidNo ratings yet

- Switchgear and Switchboard Inspection and Testing GuideDocument22 pagesSwitchgear and Switchboard Inspection and Testing GuideArif KhanNo ratings yet

- Voltage Transformer TestingDocument19 pagesVoltage Transformer TestingAfrin HossainNo ratings yet

- Schneider Startup Test ProcedureDocument45 pagesSchneider Startup Test ProcedureJonathan Feruelo100% (1)

- Some Lessons Learned From Commissioning Substation and Medium Voltage Switchgear EquipmentDocument17 pagesSome Lessons Learned From Commissioning Substation and Medium Voltage Switchgear EquipmentPrecious AdeboboyeNo ratings yet

- Installation, Operation, & Maintenance ManualDocument24 pagesInstallation, Operation, & Maintenance ManualPablo Jefferson MedinaNo ratings yet

- Schneider Recloser, Load Break Switch, Sectionaliser 2902134 PDFDocument10 pagesSchneider Recloser, Load Break Switch, Sectionaliser 2902134 PDFSanjay BhattNo ratings yet

- Safe Work Procedure R ElectricalDocument12 pagesSafe Work Procedure R ElectricalScribdTranslationsNo ratings yet

- Final - Version - Buscano, Jon Hermie A.Document34 pagesFinal - Version - Buscano, Jon Hermie A.api-20012905No ratings yet

- Preventive Maintenance and Reliability of LV Overcurrent Protective DevicesDocument7 pagesPreventive Maintenance and Reliability of LV Overcurrent Protective DevicesHamayoun MurtazaNo ratings yet

- Electro 1 E13 Construct The DC Series-Parallel CircuitDocument6 pagesElectro 1 E13 Construct The DC Series-Parallel CircuitDzenrhe ParanNo ratings yet

- Wave Let TutorialDocument26 pagesWave Let TutorialBhavik PrajapatiNo ratings yet

- NFPA 70 E Training Manual-Training PDFDocument77 pagesNFPA 70 E Training Manual-Training PDFUdoy PaulNo ratings yet

- Electro 1 E5 Construction of Resistive-Capacitive (RC) CircuitDocument6 pagesElectro 1 E5 Construction of Resistive-Capacitive (RC) CircuitDzenrhe ParanNo ratings yet

- Chapter 5 SAFETY PROCEDURES AND METHODSDocument28 pagesChapter 5 SAFETY PROCEDURES AND METHODSMelchor CarabayasNo ratings yet

- Ground, Fault, Circuit Interrupters (GFCI)Document46 pagesGround, Fault, Circuit Interrupters (GFCI)Abdul Hameed OmarNo ratings yet

- Electro 1 E2 Drawing and Construction of Electrical Circuit in SeriesDocument7 pagesElectro 1 E2 Drawing and Construction of Electrical Circuit in SeriesDzenrhe ParanNo ratings yet

- SSD 650 DriveDocument308 pagesSSD 650 DriveKamikase VilãoNo ratings yet

- Paleco Safety PlanDocument17 pagesPaleco Safety PlanBobomo PoNo ratings yet

- Pre Commissioning Procedures TR Rev01 Pgcil PDFDocument52 pagesPre Commissioning Procedures TR Rev01 Pgcil PDFChandraNo ratings yet

- SLPG - Emergency Light Fixture-1yDocument2 pagesSLPG - Emergency Light Fixture-1yAshraf MohammedNo ratings yet

- 650V 123 Installation Manual HA467649U002Document101 pages650V 123 Installation Manual HA467649U002vdalsheroqNo ratings yet

- 550KV GIS On-Site Commissioning Procedure (ELK-03) SF Gas Insulated SwitchgearDocument25 pages550KV GIS On-Site Commissioning Procedure (ELK-03) SF Gas Insulated SwitchgearDeiby Peña CaicedoNo ratings yet

- Drives Ap003 en PDocument20 pagesDrives Ap003 en PPablo LimachiNo ratings yet

- Functions and Features of Advanced Hipot Testers: June 18, 2018 by Lee TeschlerDocument4 pagesFunctions and Features of Advanced Hipot Testers: June 18, 2018 by Lee TeschlerVishal ShahNo ratings yet

- Electrical Safety Related Work Practices: Cherie K. Berry John R. Bogner, JRDocument13 pagesElectrical Safety Related Work Practices: Cherie K. Berry John R. Bogner, JRBalaji NaNo ratings yet

- EDOC - 10 Critical Tests For New Power Circuit BreakersDocument7 pagesEDOC - 10 Critical Tests For New Power Circuit BreakersEl Comedor BenedictNo ratings yet

- Electrical Maintenance Manual Chapter 1Document18 pagesElectrical Maintenance Manual Chapter 1ScribdTranslationsNo ratings yet

- SP0518Document15 pagesSP0518NgigiDanielNo ratings yet

- Final - Version - Buscano, Jon Hermie AlobDocument23 pagesFinal - Version - Buscano, Jon Hermie Alobapi-20012905No ratings yet

- Pre Job BriefingDocument5 pagesPre Job Briefingliveconnectionz2820% (1)

- Electro 1 E6 Construction of Inductive-Resistive-Capacitive (IRC)Document7 pagesElectro 1 E6 Construction of Inductive-Resistive-Capacitive (IRC)Dzenrhe ParanNo ratings yet

- WMS - MV PANEL Maintenance - BIN MAHMOUD PLAZADocument7 pagesWMS - MV PANEL Maintenance - BIN MAHMOUD PLAZAvipinkmlNo ratings yet

- GCS-VSD Course HSEDocument20 pagesGCS-VSD Course HSEMohamed MostafaNo ratings yet

- Test Equipment 101 - The Basics of Electrical TestingDocument31 pagesTest Equipment 101 - The Basics of Electrical TestingSas BetroNo ratings yet

- Methods for Increasing the Quality and Reliability of Power System Using FACTS DevicesFrom EverandMethods for Increasing the Quality and Reliability of Power System Using FACTS DevicesNo ratings yet

- Electrician's Troubleshooting and Testing Pocket Guide, Third EditionFrom EverandElectrician's Troubleshooting and Testing Pocket Guide, Third EditionRating: 5 out of 5 stars5/5 (1)

- How To Read Your International (IEC) Style Electrical SchematicsDocument19 pagesHow To Read Your International (IEC) Style Electrical SchematicsBinod KafleNo ratings yet

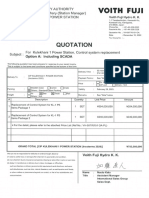

- Quotation VH-00776151 - KL-1 Control System Replace - Option A (Incl. SCADA) - 20221212Document4 pagesQuotation VH-00776151 - KL-1 Control System Replace - Option A (Incl. SCADA) - 20221212Binod KafleNo ratings yet

- Cast Coil Power TransformerDocument2 pagesCast Coil Power TransformerBinod KafleNo ratings yet

- CRC Power Contact CleanerDocument3 pagesCRC Power Contact CleanerBinod KafleNo ratings yet

- TR Filter TDS FlowerDocument7 pagesTR Filter TDS FlowerBinod KafleNo ratings yet

- General Scheme of Distribution & Transmission: Pavol BauerDocument6 pagesGeneral Scheme of Distribution & Transmission: Pavol BauerBinod KafleNo ratings yet

- Definition of A Microgrid: Laura Ramírez ElizondoDocument8 pagesDefinition of A Microgrid: Laura Ramírez ElizondoBinod KafleNo ratings yet

- Energy Storage Technologies Part 1: Pavol BauerDocument7 pagesEnergy Storage Technologies Part 1: Pavol BauerBinod KafleNo ratings yet

- Renewable and Non-Renewable Distributed Generation TechnologiesDocument10 pagesRenewable and Non-Renewable Distributed Generation TechnologiesBinod KafleNo ratings yet

- Active & Reactive Power in Microgrids: Mahdi IzadkhastDocument14 pagesActive & Reactive Power in Microgrids: Mahdi IzadkhastBinod KafleNo ratings yet

- Distribution Networks: Laura Ramírez ElizondoDocument8 pagesDistribution Networks: Laura Ramírez ElizondoBinod KafleNo ratings yet

- PV4x 2018 Week 1 1-5 Microgrid Representation and Misconceptions-SlidesDocument8 pagesPV4x 2018 Week 1 1-5 Microgrid Representation and Misconceptions-SlidesBinod KafleNo ratings yet

- Virtual Power Plant: Laura Ramírez ElizondoDocument5 pagesVirtual Power Plant: Laura Ramírez ElizondoBinod KafleNo ratings yet

- Definition of A Smart Grid: Laura Ramírez ElizondoDocument8 pagesDefinition of A Smart Grid: Laura Ramírez ElizondoBinod KafleNo ratings yet

- Sequences & Reference Transformations of Three Phase SystemsDocument9 pagesSequences & Reference Transformations of Three Phase SystemsBinod KafleNo ratings yet

- Operational Challenges of Power Systems: Laura Ramírez ElizondoDocument8 pagesOperational Challenges of Power Systems: Laura Ramírez ElizondoBinod KafleNo ratings yet

- (Assignment No: 4 & 5) Summation Date: 2074/11/25Document1 page(Assignment No: 4 & 5) Summation Date: 2074/11/25Binod KafleNo ratings yet

- Fixed Co2 Fire Fighting SystemDocument20 pagesFixed Co2 Fire Fighting SystemMagesh ShanmughamNo ratings yet

- SSR M200-LV M250-LV: Operation and Maintenance ManualDocument38 pagesSSR M200-LV M250-LV: Operation and Maintenance ManualPadmanaban Pasuvalingam100% (1)

- GPS WheelsDocument48 pagesGPS WheelsYang GomezNo ratings yet

- AOP BSS Ball ValveDocument2 pagesAOP BSS Ball ValvehamadaNo ratings yet

- Cooking: Service ManualDocument48 pagesCooking: Service ManualTudor FlorianNo ratings yet

- Protection and Control Ieds: Selection GuideDocument7 pagesProtection and Control Ieds: Selection Guide男は私 彼女のNo ratings yet

- Lecture 2 Version 1 EEE 471 Switchgear and Protection - NMKHANDocument12 pagesLecture 2 Version 1 EEE 471 Switchgear and Protection - NMKHANMortuzaNo ratings yet

- Audio-Visual System: SectionDocument156 pagesAudio-Visual System: Sectionanmec20No ratings yet

- Electrical Regulations and Standards - Electrical Installation GuideDocument4 pagesElectrical Regulations and Standards - Electrical Installation Guideanirban 007No ratings yet

- Design and Construction of An Electric Arc Welding Machine With Digital Display.Document11 pagesDesign and Construction of An Electric Arc Welding Machine With Digital Display.michael gorgeNo ratings yet

- User Manual Evolis 17.5kVDocument28 pagesUser Manual Evolis 17.5kVCamacho FreNo ratings yet

- Wiring The 9X-9591 Electrical Converter GP (PULSE WIDTH MODULATED) (1421, 1901, 7490)Document6 pagesWiring The 9X-9591 Electrical Converter GP (PULSE WIDTH MODULATED) (1421, 1901, 7490)Jose FavaNo ratings yet

- Obd1 Toyota Codigos de ECUDocument42 pagesObd1 Toyota Codigos de ECUDaniel GarciaNo ratings yet

- 8085 Instruction Set: Instruction Summary Data Transfer InstructionsDocument2 pages8085 Instruction Set: Instruction Summary Data Transfer Instructionsganesh92No ratings yet

- Sony DSC-V3 Level 2 Service Manual (P. N. - 987676232)Document59 pagesSony DSC-V3 Level 2 Service Manual (P. N. - 987676232)tm5u2r0% (1)

- Perkins Series 400 Injection AnglesDocument40 pagesPerkins Series 400 Injection Anglesbudimir231083% (6)

- Pau Fas FPS FSSDocument4 pagesPau Fas FPS FSSAntonio SerranoNo ratings yet

- Experiment 3 ACA PDFDocument11 pagesExperiment 3 ACA PDFaakash dabasNo ratings yet

- AFFIDAVIT of DAMAGE To VEHICLE - Self Accident - Affidavit of OwnerDocument2 pagesAFFIDAVIT of DAMAGE To VEHICLE - Self Accident - Affidavit of Ownerabietan1119No ratings yet

- LO #1-Plan and Prepare For Maintenance/ RepairDocument17 pagesLO #1-Plan and Prepare For Maintenance/ RepairDEMEKE BEYENENo ratings yet

- Ikey Plus Portable USB Recorder User's GuideDocument109 pagesIkey Plus Portable USB Recorder User's Guidecantius100% (1)

- Bolt 2015Document67 pagesBolt 2015DiegoFonsecaNo ratings yet

- Single Dog Kennel DIY Plans - Build Blueprint+ - 1641485253643Document10 pagesSingle Dog Kennel DIY Plans - Build Blueprint+ - 1641485253643AndrewNo ratings yet

- C091 (J) Aisg C091 (K) 1MDocument2 pagesC091 (J) Aisg C091 (K) 1MВадим ЧеховскийNo ratings yet

- Cooper Deadbreak Elbow 55010Document4 pagesCooper Deadbreak Elbow 55010denzil_1000No ratings yet

- PCHardwarHbk2ndEdSH PDFDocument132 pagesPCHardwarHbk2ndEdSH PDFAlexis78No ratings yet

- GIS Specification 170 - 245 KV ELK14 - Rev01 - To CustomerDocument41 pagesGIS Specification 170 - 245 KV ELK14 - Rev01 - To Customerwaqar100% (1)

Electrical Safety Webinar PDF

Electrical Safety Webinar PDF

Uploaded by

Binod KafleCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electrical Safety Webinar PDF

Electrical Safety Webinar PDF

Uploaded by

Binod KafleCopyright:

Available Formats

www.

tpctraining

Electrical Safety and Establishing an

Electrically Safe Work Condition

Bob Clukey – TPC Instructor

Virtual Instructor Led Training www.tpctraining

tpctraining.com

Chapter 1 Safety-Related Work Practices

Electrically Safe Work Condition.

A state in which an electrical conductor or circuit part has been disconnected from

energized parts, locked/tagged in accordance with established standards, tested to verify

the absence of voltage, and, if necessary, temporarily grounded for personnel protection.

This is the just the definition, we will introduce you to the steps that are needed to

complete this process and later in the presentation go into greater detail about this

process.

110.3 Electrically Safe Work Condition.

Energized electrical conductors and circuit parts operating at voltages equal to or greater

than 50 volts shall be put into an electrically safe work condition before an employee

performs work if any of the following conditions exist:

The employee is within the limited approach boundary.

The employee interacts with equipment where conductors or circuit parts are not exposed

but an increased likelihood of injury from an exposure to an arc flash hazard exists.

The Total Training Solution

Virtual Instructor Led Training www.tpctraining

tpctraining.com

Chapter 1 Safety-Related Work Practices

120.5 Introducing the Process for Establishing and Verifying an Electrically Safe Work

Condition. This will be reviewed later in the presentation for reinforcement!

Establishing and verifying an electrically safe work condition shall include all of the

following steps, which shall be performed in the order presented, if feasible:

Determine all possible sources of electrical supply to the specific equipment. Check

applicable up-to-date drawings, diagrams, and identification tags.

What is the voltage of the circuit below?

Are you qualified to work on this voltage?

The Total Training Solution

Virtual Instructor Led Training www.tpctraining

tpctraining.com

Chapter 1 Safety-Related Work Practices

120.5 Introducing the Process for Establishing and Verifying an Electrically Safe Work

Condition. This will be reviewed later in the presentation for reinforcement!

Establishing and verifying an electrically safe work condition shall include all of the

following steps, which shall be performed in the order presented, if feasible:

After properly interrupting the load current, open the disconnecting device(s) for each

source.

There are 2 steps here. First, interrupt the load current with a stop button or however the

machine is usually stopped. Then open the disconnecting device. Most disconnects are non-

load break devices, which means do not open them when there is current flowing.

The Total Training Solution

Virtual Instructor Led Training www.tpctraining

tpctraining.com

Chapter 1 Safety-Related Work Practices

120.5 Introducing the Process for Establishing and Verifying an Electrically Safe Work

Condition. This will be reviewed later in the presentation for reinforcement!

Establishing and verifying an electrically safe work condition shall include all of the

following steps, which shall be performed in the order presented, if feasible:

Apply lockout/tagout devices in accordance with a documented and established

procedure.

The Total Training Solution

Virtual Instructor Led Training www.tpctraining

tpctraining.com

Chapter 1 Safety-Related Work Practices

120.5 Introducing the Process for Establishing and Verifying an Electrically Safe Work

Condition. This will be reviewed later in the presentation for reinforcement!

Establishing and verifying an electrically safe work condition shall include all of the

following steps, which shall be performed in the order presented, if feasible:

Wherever possible, visually verify that all blades of the disconnecting devices are fully

open or that drawout-type circuit breakers are withdrawn to the test or fully disconnected

position.

The Total Training Solution

Virtual Instructor Led Training www.tpctraining

tpctraining.com

Chapter 1 Safety-Related Work Practices

120.5 Introducing the Process for Establishing and Verifying an Electrically Safe Work

Condition. This will be reviewed later in the presentation for reinforcement!

Establishing and verifying an electrically safe work condition shall include all of the

following steps, which shall be performed in the order presented, if feasible:

Block or relieve stored nonelectrical energy in devices to the extent that

the circuit parts cannot be unintentionally energized by such devices.

The Total Training Solution

Virtual Instructor Led Training www.tpctraining

tpctraining.com

Chapter 1 Safety-Related Work Practices

120.5 Introducing the Process for Establishing and Verifying an Electrically Safe Work

Condition. This will be reviewed later in the presentation for reinforcement!

Establishing and verifying an electrically safe work condition shall include all of the

following steps, which shall be performed in the order presented, if feasible:

Release stored electrical energy.

The Total Training Solution

Virtual Instructor Led Training www.tpctraining

tpctraining.com

Chapter 1 Safety-Related Work Practices

Use an adequately rated portable test instrument to test each phase conductor or circuit

part to test for the absence of voltage. Test each phase conductor or circuit part both

phase-to-phase and phase-to-ground. Before and after each test, determine that the test

instrument is operating satisfactorily through verification on any known voltage source.

Exception No. 1 to 7: An adequately rated permanently mounted absence of voltage

tester shall be permitted to be used to test for the absence of voltage of the conductors or

circuit parts at the work location, provided it meets the all following requirements: (1) It is

permanently mounted and installed in accordance with the manufacturer’s instructions

and tests the conductors and circuit parts at the point of work; (2) It is listed and labeled

for the purpose of testing for the absence of voltage; (3) It tests each phase conductor or

circuit part both phase-to-phase and phase-to-ground; (4) The test device is verified as

operating satisfactorily on any known voltage source before and after testing for the

absence of voltage.

Exception No. 2 to 7: On electrical systems over 1000 volts, noncontact capacitive test

instruments shall be permitted to be used to test each phase conductor.

The Total Training Solution

Virtual Instructor Led Training www.tpctraining

tpctraining.com

Chapter 1 Safety-Related Work Practices

Informational Note No. 1: See UL 61010-1, Safety Requirements for Electrical Equipment

for Measurement, Control, and Laboratory Use, Part 1: General Requirements, for rating,

overvoltage category, and design requirements for voltage measurement and test

instruments intended for use on electrical systems 1000 volts and below.

Informational No. 2: For additional information on rating and design requirements for

permanently mounted absence of voltage testers, refer to UL 1436, Outlet Circuit Testers

and Other Similar Indicating Devices.

Informational Note No. 3: For additional information on rating and design requirements

for voltage detectors, refer to IEC 61243-1, Live Working — Voltage Detectors — Part 1:

Capacitive type to be used for voltages exceeding 1kV a.c., or IEC 61243-2, Live Working

— Voltage Detectors — Part 2: Resistive type to be used for voltages of 1kV to 36 kV a.c.,

or IEC 61243-3, Live Working — Voltage Detectors — Part 3: Two-pole low voltage type.

The Total Training Solution

Virtual Instructor Led Training www.tpctraining

tpctraining.com

Chapter 1 Safety-Related Work Practices

Where the possibility of induced voltages or stored electrical energy exists, ground all circuit

conductors and circuit parts before touching them. Where it could be reasonably anticipated that

the conductors or circuit parts being de-energized could contact other exposed energized conductors

or circuit parts, apply temporary protective grounding equipment in accordance with the following:

Placement. Temporary protective grounding equipment shall be placed at such locations and

arranged in such a manner as to prevent each employee from being exposed to a shock hazard (i.e.,

hazardous differences in electrical potential). The location, sizing, and application of temporary

protective grounding equipment shall be identified as part of the employer’s job planning.

Capacity. Temporary protective grounding equipment shall be capable of conducting the maximum

fault current that could flow at the point of grounding for the time necessary to clear the fault.

Informational Note: ASTM F855, Standard Specification for Temporary Protective Grounds to be

Used on De-energized Electric Power Lines and Equipment, is an example of a standard that contains

information on capacity of temporary protective grounding equipment.

Impedance. Temporary protective grounding equipment and connections shall have an impedance

low enough to cause immediate operation of protective devices in case of unintentional energizing of

the electric conductors or circuit parts.

The Total Training Solution

Virtual Instructor Led Training www.tpctraining

tpctraining.com

Chapter 1 Safety-Related Work Practices

Where the possibility of induced voltages or stored electrical energy exists, ground all

circuit conductors and circuit parts before touching them. Where it could be reasonably

anticipated that the conductors or circuit parts being de-energized could contact other

exposed energized conductors or circuit parts, apply temporary protective grounding

equipment in accordance with the following:

Placement. Temporary protective grounding equipment shall be placed at such locations

and arranged in such a manner as to prevent each employee from being exposed to a

Informational Note: ASTM

shock hazard (i.e., hazardous differences in electrical potential). The location, sizing, and

F855, Standard Specification

application of temporary protective grounding equipment shall be identified as part of

for Temporary Protective

the employer’s job planning.

Grounds to be Used on De-

Capacity. Temporary protective grounding equipment shall be capable of conducting energized Electric Power Lines

the maximum fault current that could flow at the point of grounding for the time and Equipment, is an example

necessary to clear the fault. of a standard that contains

information on capacity of

Impedance. Temporary protective grounding equipment and connections shall have an temporary protective

impedance low enough to cause immediate operation of protective devices in case of grounding equipment.

unintentional energizing of the electric conductors or circuit parts.

The Total Training Solution

Virtual Instructor Led Training www.tpctraining

tpctraining.com

Demo on Live Dead Live

The Total Training Solution

www.tpctraining

Questions?

If you’d like to learn more about electrical Browse the course catalog:

safety at your facility, Live.tpctraining.com

TPC can help!

Email: sales@tpctraining.com

Phone: (847) 808-4000

Subscribe for the NEC Challenge Today:

JADELearning.com/nec-challenge

New Solar PV online course available!

JADELearning.com/solar-technician-training

You might also like

- bc1000xl p1 10 sn8802Document214 pagesbc1000xl p1 10 sn8802bleexblox100% (5)

- Yamaha XJ550 Seca XJ 550 Service Specifications ManualDocument11 pagesYamaha XJ550 Seca XJ 550 Service Specifications ManualNabucco Donosor0% (3)

- Elevator Troubleshooting & Repair: A Technician's Certification Study GuideFrom EverandElevator Troubleshooting & Repair: A Technician's Certification Study GuideRating: 4 out of 5 stars4/5 (9)

- QAQC Electrical Inspection: A Beginner's GuideFrom EverandQAQC Electrical Inspection: A Beginner's GuideRating: 4 out of 5 stars4/5 (1)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 4 out of 5 stars4/5 (2)

- Main Engine MAN B&W K 80 MC-CDocument868 pagesMain Engine MAN B&W K 80 MC-CAbsar Mamun94% (18)

- PLC Programming from Novice to Professional: Learn PLC Programming with Training VideosFrom EverandPLC Programming from Novice to Professional: Learn PLC Programming with Training VideosRating: 5 out of 5 stars5/5 (1)

- SP0509 Circuit Breaker Testing SWPDocument6 pagesSP0509 Circuit Breaker Testing SWPEnthusiastNo ratings yet

- Electrical Safety: Casimiro L. Flores JRDocument23 pagesElectrical Safety: Casimiro L. Flores JRJoseph CeaNo ratings yet

- Electrical Safety Management Procedure May 2013Document35 pagesElectrical Safety Management Procedure May 2013Roni Enjelani100% (2)

- Long-Term Experiences and Review With Offline and Online PD Measure-Ments On-Site On EHV XLPE Cable Systems 330 KV To 500 KVDocument6 pagesLong-Term Experiences and Review With Offline and Online PD Measure-Ments On-Site On EHV XLPE Cable Systems 330 KV To 500 KVSitiSaodahNo ratings yet

- SP0512 Ver 4Document4 pagesSP0512 Ver 4Rebeca VargasNo ratings yet

- Commissioning Ground Mounted Distribution SubstationsDocument6 pagesCommissioning Ground Mounted Distribution SubstationsSergio Henrique F. CArniettoNo ratings yet

- 00-SATP-busway, Rev01Document9 pages00-SATP-busway, Rev01islam mohamedNo ratings yet

- FeedbackDocument641 pagesFeedbackAnonymous bntbU1ibNo ratings yet

- EPS Startup Test Procedure - SECDocument45 pagesEPS Startup Test Procedure - SECEng Zaid NawaysehNo ratings yet

- E2 Relay CommissioningDocument14 pagesE2 Relay CommissioningShailesh ChettyNo ratings yet

- Circuit Breaker Testing SWP: 1 Purpose AND ScopeDocument6 pagesCircuit Breaker Testing SWP: 1 Purpose AND ScopeJarrett MathewsNo ratings yet

- Simplified Method For Using The NFPA 70E Tables?Document43 pagesSimplified Method For Using The NFPA 70E Tables?Mohsin JamshaidNo ratings yet

- Switchgear and Switchboard Inspection and Testing GuideDocument22 pagesSwitchgear and Switchboard Inspection and Testing GuideArif KhanNo ratings yet

- Voltage Transformer TestingDocument19 pagesVoltage Transformer TestingAfrin HossainNo ratings yet

- Schneider Startup Test ProcedureDocument45 pagesSchneider Startup Test ProcedureJonathan Feruelo100% (1)

- Some Lessons Learned From Commissioning Substation and Medium Voltage Switchgear EquipmentDocument17 pagesSome Lessons Learned From Commissioning Substation and Medium Voltage Switchgear EquipmentPrecious AdeboboyeNo ratings yet

- Installation, Operation, & Maintenance ManualDocument24 pagesInstallation, Operation, & Maintenance ManualPablo Jefferson MedinaNo ratings yet

- Schneider Recloser, Load Break Switch, Sectionaliser 2902134 PDFDocument10 pagesSchneider Recloser, Load Break Switch, Sectionaliser 2902134 PDFSanjay BhattNo ratings yet

- Safe Work Procedure R ElectricalDocument12 pagesSafe Work Procedure R ElectricalScribdTranslationsNo ratings yet

- Final - Version - Buscano, Jon Hermie A.Document34 pagesFinal - Version - Buscano, Jon Hermie A.api-20012905No ratings yet

- Preventive Maintenance and Reliability of LV Overcurrent Protective DevicesDocument7 pagesPreventive Maintenance and Reliability of LV Overcurrent Protective DevicesHamayoun MurtazaNo ratings yet

- Electro 1 E13 Construct The DC Series-Parallel CircuitDocument6 pagesElectro 1 E13 Construct The DC Series-Parallel CircuitDzenrhe ParanNo ratings yet

- Wave Let TutorialDocument26 pagesWave Let TutorialBhavik PrajapatiNo ratings yet

- NFPA 70 E Training Manual-Training PDFDocument77 pagesNFPA 70 E Training Manual-Training PDFUdoy PaulNo ratings yet

- Electro 1 E5 Construction of Resistive-Capacitive (RC) CircuitDocument6 pagesElectro 1 E5 Construction of Resistive-Capacitive (RC) CircuitDzenrhe ParanNo ratings yet

- Chapter 5 SAFETY PROCEDURES AND METHODSDocument28 pagesChapter 5 SAFETY PROCEDURES AND METHODSMelchor CarabayasNo ratings yet

- Ground, Fault, Circuit Interrupters (GFCI)Document46 pagesGround, Fault, Circuit Interrupters (GFCI)Abdul Hameed OmarNo ratings yet

- Electro 1 E2 Drawing and Construction of Electrical Circuit in SeriesDocument7 pagesElectro 1 E2 Drawing and Construction of Electrical Circuit in SeriesDzenrhe ParanNo ratings yet

- SSD 650 DriveDocument308 pagesSSD 650 DriveKamikase VilãoNo ratings yet

- Paleco Safety PlanDocument17 pagesPaleco Safety PlanBobomo PoNo ratings yet

- Pre Commissioning Procedures TR Rev01 Pgcil PDFDocument52 pagesPre Commissioning Procedures TR Rev01 Pgcil PDFChandraNo ratings yet

- SLPG - Emergency Light Fixture-1yDocument2 pagesSLPG - Emergency Light Fixture-1yAshraf MohammedNo ratings yet

- 650V 123 Installation Manual HA467649U002Document101 pages650V 123 Installation Manual HA467649U002vdalsheroqNo ratings yet

- 550KV GIS On-Site Commissioning Procedure (ELK-03) SF Gas Insulated SwitchgearDocument25 pages550KV GIS On-Site Commissioning Procedure (ELK-03) SF Gas Insulated SwitchgearDeiby Peña CaicedoNo ratings yet

- Drives Ap003 en PDocument20 pagesDrives Ap003 en PPablo LimachiNo ratings yet

- Functions and Features of Advanced Hipot Testers: June 18, 2018 by Lee TeschlerDocument4 pagesFunctions and Features of Advanced Hipot Testers: June 18, 2018 by Lee TeschlerVishal ShahNo ratings yet

- Electrical Safety Related Work Practices: Cherie K. Berry John R. Bogner, JRDocument13 pagesElectrical Safety Related Work Practices: Cherie K. Berry John R. Bogner, JRBalaji NaNo ratings yet

- EDOC - 10 Critical Tests For New Power Circuit BreakersDocument7 pagesEDOC - 10 Critical Tests For New Power Circuit BreakersEl Comedor BenedictNo ratings yet

- Electrical Maintenance Manual Chapter 1Document18 pagesElectrical Maintenance Manual Chapter 1ScribdTranslationsNo ratings yet

- SP0518Document15 pagesSP0518NgigiDanielNo ratings yet

- Final - Version - Buscano, Jon Hermie AlobDocument23 pagesFinal - Version - Buscano, Jon Hermie Alobapi-20012905No ratings yet

- Pre Job BriefingDocument5 pagesPre Job Briefingliveconnectionz2820% (1)

- Electro 1 E6 Construction of Inductive-Resistive-Capacitive (IRC)Document7 pagesElectro 1 E6 Construction of Inductive-Resistive-Capacitive (IRC)Dzenrhe ParanNo ratings yet

- WMS - MV PANEL Maintenance - BIN MAHMOUD PLAZADocument7 pagesWMS - MV PANEL Maintenance - BIN MAHMOUD PLAZAvipinkmlNo ratings yet

- GCS-VSD Course HSEDocument20 pagesGCS-VSD Course HSEMohamed MostafaNo ratings yet

- Test Equipment 101 - The Basics of Electrical TestingDocument31 pagesTest Equipment 101 - The Basics of Electrical TestingSas BetroNo ratings yet

- Methods for Increasing the Quality and Reliability of Power System Using FACTS DevicesFrom EverandMethods for Increasing the Quality and Reliability of Power System Using FACTS DevicesNo ratings yet

- Electrician's Troubleshooting and Testing Pocket Guide, Third EditionFrom EverandElectrician's Troubleshooting and Testing Pocket Guide, Third EditionRating: 5 out of 5 stars5/5 (1)

- How To Read Your International (IEC) Style Electrical SchematicsDocument19 pagesHow To Read Your International (IEC) Style Electrical SchematicsBinod KafleNo ratings yet

- Quotation VH-00776151 - KL-1 Control System Replace - Option A (Incl. SCADA) - 20221212Document4 pagesQuotation VH-00776151 - KL-1 Control System Replace - Option A (Incl. SCADA) - 20221212Binod KafleNo ratings yet

- Cast Coil Power TransformerDocument2 pagesCast Coil Power TransformerBinod KafleNo ratings yet

- CRC Power Contact CleanerDocument3 pagesCRC Power Contact CleanerBinod KafleNo ratings yet

- TR Filter TDS FlowerDocument7 pagesTR Filter TDS FlowerBinod KafleNo ratings yet

- General Scheme of Distribution & Transmission: Pavol BauerDocument6 pagesGeneral Scheme of Distribution & Transmission: Pavol BauerBinod KafleNo ratings yet

- Definition of A Microgrid: Laura Ramírez ElizondoDocument8 pagesDefinition of A Microgrid: Laura Ramírez ElizondoBinod KafleNo ratings yet

- Energy Storage Technologies Part 1: Pavol BauerDocument7 pagesEnergy Storage Technologies Part 1: Pavol BauerBinod KafleNo ratings yet

- Renewable and Non-Renewable Distributed Generation TechnologiesDocument10 pagesRenewable and Non-Renewable Distributed Generation TechnologiesBinod KafleNo ratings yet

- Active & Reactive Power in Microgrids: Mahdi IzadkhastDocument14 pagesActive & Reactive Power in Microgrids: Mahdi IzadkhastBinod KafleNo ratings yet

- Distribution Networks: Laura Ramírez ElizondoDocument8 pagesDistribution Networks: Laura Ramírez ElizondoBinod KafleNo ratings yet

- PV4x 2018 Week 1 1-5 Microgrid Representation and Misconceptions-SlidesDocument8 pagesPV4x 2018 Week 1 1-5 Microgrid Representation and Misconceptions-SlidesBinod KafleNo ratings yet

- Virtual Power Plant: Laura Ramírez ElizondoDocument5 pagesVirtual Power Plant: Laura Ramírez ElizondoBinod KafleNo ratings yet

- Definition of A Smart Grid: Laura Ramírez ElizondoDocument8 pagesDefinition of A Smart Grid: Laura Ramírez ElizondoBinod KafleNo ratings yet

- Sequences & Reference Transformations of Three Phase SystemsDocument9 pagesSequences & Reference Transformations of Three Phase SystemsBinod KafleNo ratings yet

- Operational Challenges of Power Systems: Laura Ramírez ElizondoDocument8 pagesOperational Challenges of Power Systems: Laura Ramírez ElizondoBinod KafleNo ratings yet

- (Assignment No: 4 & 5) Summation Date: 2074/11/25Document1 page(Assignment No: 4 & 5) Summation Date: 2074/11/25Binod KafleNo ratings yet

- Fixed Co2 Fire Fighting SystemDocument20 pagesFixed Co2 Fire Fighting SystemMagesh ShanmughamNo ratings yet

- SSR M200-LV M250-LV: Operation and Maintenance ManualDocument38 pagesSSR M200-LV M250-LV: Operation and Maintenance ManualPadmanaban Pasuvalingam100% (1)

- GPS WheelsDocument48 pagesGPS WheelsYang GomezNo ratings yet

- AOP BSS Ball ValveDocument2 pagesAOP BSS Ball ValvehamadaNo ratings yet

- Cooking: Service ManualDocument48 pagesCooking: Service ManualTudor FlorianNo ratings yet

- Protection and Control Ieds: Selection GuideDocument7 pagesProtection and Control Ieds: Selection Guide男は私 彼女のNo ratings yet

- Lecture 2 Version 1 EEE 471 Switchgear and Protection - NMKHANDocument12 pagesLecture 2 Version 1 EEE 471 Switchgear and Protection - NMKHANMortuzaNo ratings yet

- Audio-Visual System: SectionDocument156 pagesAudio-Visual System: Sectionanmec20No ratings yet

- Electrical Regulations and Standards - Electrical Installation GuideDocument4 pagesElectrical Regulations and Standards - Electrical Installation Guideanirban 007No ratings yet

- Design and Construction of An Electric Arc Welding Machine With Digital Display.Document11 pagesDesign and Construction of An Electric Arc Welding Machine With Digital Display.michael gorgeNo ratings yet

- User Manual Evolis 17.5kVDocument28 pagesUser Manual Evolis 17.5kVCamacho FreNo ratings yet

- Wiring The 9X-9591 Electrical Converter GP (PULSE WIDTH MODULATED) (1421, 1901, 7490)Document6 pagesWiring The 9X-9591 Electrical Converter GP (PULSE WIDTH MODULATED) (1421, 1901, 7490)Jose FavaNo ratings yet

- Obd1 Toyota Codigos de ECUDocument42 pagesObd1 Toyota Codigos de ECUDaniel GarciaNo ratings yet

- 8085 Instruction Set: Instruction Summary Data Transfer InstructionsDocument2 pages8085 Instruction Set: Instruction Summary Data Transfer Instructionsganesh92No ratings yet

- Sony DSC-V3 Level 2 Service Manual (P. N. - 987676232)Document59 pagesSony DSC-V3 Level 2 Service Manual (P. N. - 987676232)tm5u2r0% (1)

- Perkins Series 400 Injection AnglesDocument40 pagesPerkins Series 400 Injection Anglesbudimir231083% (6)

- Pau Fas FPS FSSDocument4 pagesPau Fas FPS FSSAntonio SerranoNo ratings yet

- Experiment 3 ACA PDFDocument11 pagesExperiment 3 ACA PDFaakash dabasNo ratings yet

- AFFIDAVIT of DAMAGE To VEHICLE - Self Accident - Affidavit of OwnerDocument2 pagesAFFIDAVIT of DAMAGE To VEHICLE - Self Accident - Affidavit of Ownerabietan1119No ratings yet

- LO #1-Plan and Prepare For Maintenance/ RepairDocument17 pagesLO #1-Plan and Prepare For Maintenance/ RepairDEMEKE BEYENENo ratings yet

- Ikey Plus Portable USB Recorder User's GuideDocument109 pagesIkey Plus Portable USB Recorder User's Guidecantius100% (1)

- Bolt 2015Document67 pagesBolt 2015DiegoFonsecaNo ratings yet

- Single Dog Kennel DIY Plans - Build Blueprint+ - 1641485253643Document10 pagesSingle Dog Kennel DIY Plans - Build Blueprint+ - 1641485253643AndrewNo ratings yet

- C091 (J) Aisg C091 (K) 1MDocument2 pagesC091 (J) Aisg C091 (K) 1MВадим ЧеховскийNo ratings yet

- Cooper Deadbreak Elbow 55010Document4 pagesCooper Deadbreak Elbow 55010denzil_1000No ratings yet

- PCHardwarHbk2ndEdSH PDFDocument132 pagesPCHardwarHbk2ndEdSH PDFAlexis78No ratings yet

- GIS Specification 170 - 245 KV ELK14 - Rev01 - To CustomerDocument41 pagesGIS Specification 170 - 245 KV ELK14 - Rev01 - To Customerwaqar100% (1)