Professional Documents

Culture Documents

Deluge Valve Installation Manual

Deluge Valve Installation Manual

Uploaded by

rahull.miishraCopyright:

Available Formats

You might also like

- 303.5E2 CR EXCAVADORA Diagrama Electrico PDFDocument2 pages303.5E2 CR EXCAVADORA Diagrama Electrico PDFRICHARD100% (2)

- D210-375 MedAir PDFDocument4 pagesD210-375 MedAir PDFjulianmataNo ratings yet

- Oreda Volume 1 PDFDocument794 pagesOreda Volume 1 PDFdigeca100% (2)

- Alarm Valve DetailsDocument5 pagesAlarm Valve DetailsRoshan JaiswalNo ratings yet

- Series DDocument3 pagesSeries DHugo Martinez LopezNo ratings yet

- Well Testing Brochure PWP Series Pressureguard Wellhead Protection Us Bettis en 85924Document10 pagesWell Testing Brochure PWP Series Pressureguard Wellhead Protection Us Bettis en 85924Yasser AbdulkareemNo ratings yet

- Pneumatically Operated With Manual Reset Deluge Valve For Freshwater and Seawater ServiceDocument2 pagesPneumatically Operated With Manual Reset Deluge Valve For Freshwater and Seawater ServicedmitosNo ratings yet

- Catalog Functional Safety Solutions Asco en 5084612Document16 pagesCatalog Functional Safety Solutions Asco en 5084612alejomariana03No ratings yet

- BERMAD Fire Protection: TORRENT 400Y - Product CatalogDocument32 pagesBERMAD Fire Protection: TORRENT 400Y - Product CatalogAlberth Rojas CastellanosNo ratings yet

- Electric Actuated Butterfly Valves: FeaturesDocument7 pagesElectric Actuated Butterfly Valves: FeaturesRicardo NapitupuluNo ratings yet

- 729 Double Interlock Preaction DDXDocument22 pages729 Double Interlock Preaction DDXfarshan296015No ratings yet

- Rs 4700Document12 pagesRs 4700Juan JuanNo ratings yet

- Nautilus XMLA160D2S11Document2 pagesNautilus XMLA160D2S11Nazar AbbasNo ratings yet

- F19460 RB 4700 GB 07-007 LowDocument8 pagesF19460 RB 4700 GB 07-007 LowJuan JuanNo ratings yet

- Bermad: Fire ProtectionDocument4 pagesBermad: Fire ProtectionalbertoNo ratings yet

- List Outstanding Material Production Line 7 Texturing: Section MachineDocument6 pagesList Outstanding Material Production Line 7 Texturing: Section MachineMaxNo ratings yet

- XMLA160D2S11: Product Data SheetDocument3 pagesXMLA160D2S11: Product Data SheetJuan MoralesNo ratings yet

- F30178 RB4700 08 2005 LowDocument8 pagesF30178 RB4700 08 2005 LowJuan JuanNo ratings yet

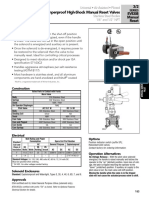

- Tamperproof High-Shock Manual Reset Valves: FeaturesDocument2 pagesTamperproof High-Shock Manual Reset Valves: FeaturesDio MaseraNo ratings yet

- Mooney 1" Flowgrid Regulator: With Shutoff ValveDocument2 pagesMooney 1" Flowgrid Regulator: With Shutoff ValveLuis Alberto Portugal MariacalNo ratings yet

- Samsung RL 25 DATDocument28 pagesSamsung RL 25 DATAleksei EvchuNo ratings yet

- Data Sheet Triac Es, As, Ns Series Butterfly ValvesDocument28 pagesData Sheet Triac Es, As, Ns Series Butterfly Valves4Chat GptNo ratings yet

- Manual Balancing 130seriesDocument16 pagesManual Balancing 130seriesa_salehiNo ratings yet

- Model Solenoid Operated Ventable Relief Assembly: CAPACITY: 30 GPMDocument7 pagesModel Solenoid Operated Ventable Relief Assembly: CAPACITY: 30 GPManandsubbiahNo ratings yet

- Flow Meter PDFDocument20 pagesFlow Meter PDFJoe Mari CapaNo ratings yet

- PuROMax Commercial RO Instructions 2015Document49 pagesPuROMax Commercial RO Instructions 2015Jcc ChoNo ratings yet

- HD ND ZUE - enDocument28 pagesHD ND ZUE - enwylie01No ratings yet

- Gate Valve Die-Forged: Pressure Seal BonnetDocument8 pagesGate Valve Die-Forged: Pressure Seal Bonnetedark2009No ratings yet

- Tech Sheet Series CDocument2 pagesTech Sheet Series CLalu Adam Akmal IsnenNo ratings yet

- Indian Oil Corporation Limited, BG (CRYOGENICS) विशेष वििरण/Standard Specification इंवियन ऑयल कॉर्पोरेशन वलविटेि, व्यिसाय सिूह (क्रायोजेवनक)Document3 pagesIndian Oil Corporation Limited, BG (CRYOGENICS) विशेष वििरण/Standard Specification इंवियन ऑयल कॉर्पोरेशन वलविटेि, व्यिसाय सिूह (क्रायोजेवनक)kkaranagNo ratings yet

- Manual Wilden XP.025-metalDocument23 pagesManual Wilden XP.025-metalMarco SilvaNo ratings yet

- E30C - Globe Valves NewDocument20 pagesE30C - Globe Valves NewTaha FaNo ratings yet

- DB 410 GBDocument15 pagesDB 410 GBzoupezeenNo ratings yet

- Industrial Butterfly Valve ChecklistDocument1 pageIndustrial Butterfly Valve ChecklistnavidNo ratings yet

- ICO4S 1-4in 5-2way PBMRDocument4 pagesICO4S 1-4in 5-2way PBMRmaqbool1No ratings yet

- Service - Manual - For - Model - MPR-514-PA - MPR-514R-PA - Pharmaceutical - Refrigerators - 1440163966Document87 pagesService - Manual - For - Model - MPR-514-PA - MPR-514R-PA - Pharmaceutical - Refrigerators - 1440163966ahmed OsamaNo ratings yet

- Sanitary Diaphragm Valve: Type 612Document6 pagesSanitary Diaphragm Valve: Type 612Hilux PabloNo ratings yet

- Mooney Flowgrid Valve: Technical Specifications 12/2018Document2 pagesMooney Flowgrid Valve: Technical Specifications 12/2018Luis Yovany Aldana PonceNo ratings yet

- Series: Oil Sampling ValveDocument2 pagesSeries: Oil Sampling Valvemarran almarranyNo ratings yet

- Pneumatic ActuatorDocument9 pagesPneumatic ActuatorRamesh BabuNo ratings yet

- (Www.manuallib.com) LEISTRITZ&Mdash;L3MF 060 120 IFOKSO G 技术手册Document3 pages(Www.manuallib.com) LEISTRITZ&Mdash;L3MF 060 120 IFOKSO G 技术手册Agnel StanleyNo ratings yet

- Caleffi: Valvole Di BilanciamentoDocument16 pagesCaleffi: Valvole Di BilanciamentoThomas GregantiNo ratings yet

- 107 Differential Pressure Switch Cat459Document4 pages107 Differential Pressure Switch Cat459senthilrsenthilNo ratings yet

- Norm Ex ValvesDocument6 pagesNorm Ex Valvesapi-3712612No ratings yet

- 04BR05Document6 pages04BR05martiguada1No ratings yet

- Pentair Pilot Enclosures For Non-Hazardous LocationDocument6 pagesPentair Pilot Enclosures For Non-Hazardous LocationEdson MirandaNo ratings yet

- Data Sheet XV-3190Document1 pageData Sheet XV-3190alonsito6031No ratings yet

- Dorot 68-De - El - MRDocument6 pagesDorot 68-De - El - MRJosé Daniel ArenasNo ratings yet

- Data Sheet Daniel Model 788 Digital Control Valve en 43714Document16 pagesData Sheet Daniel Model 788 Digital Control Valve en 43714dreyko77No ratings yet

- Pressure Relief Valve 3/4" - 1"Document5 pagesPressure Relief Valve 3/4" - 1"Gisella Mariel RubilarNo ratings yet

- Compressor WP81L - WP101L - Data - Leaflet - 2015Document2 pagesCompressor WP81L - WP101L - Data - Leaflet - 2015RizzoRo1No ratings yet

- Series Features: Two-Stage Preset ValveDocument2 pagesSeries Features: Two-Stage Preset Valvefernando.juarezpetroserviciosNo ratings yet

- 19 400E 3D RL FinalDocument4 pages19 400E 3D RL FinalJose Omar ZaragozaNo ratings yet

- Innovair PEK 60Hz R410a Commercial Package Brochure EnglishDocument12 pagesInnovair PEK 60Hz R410a Commercial Package Brochure Englishcris melos100% (1)

- Globe Valve1 DatasheetDocument1 pageGlobe Valve1 DatasheetobumuyaemesiNo ratings yet

- Chilled Water Cooling Plant Quarterly Insepction ReportDocument1 pageChilled Water Cooling Plant Quarterly Insepction ReportFaisal MuneerNo ratings yet

- Solenoid Valve - Pneumatic: Direct Acting, Pressure RelievedDocument4 pagesSolenoid Valve - Pneumatic: Direct Acting, Pressure RelievedFrancisco Mones RuizNo ratings yet

- Preset Valve Ocv Model Sheet 115 - 25 Aviation 2020Document2 pagesPreset Valve Ocv Model Sheet 115 - 25 Aviation 2020varadarajck893No ratings yet

- 000-I-Ts-102 - DS - 2 PitDocument42 pages000-I-Ts-102 - DS - 2 PitCristian RománNo ratings yet

- CVS 1000L Electro-Pneumatic Linear Positioner: Product ManualDocument12 pagesCVS 1000L Electro-Pneumatic Linear Positioner: Product Manualmhidayat108No ratings yet

- Pressure Drop Equivalent Length of Pipes and Fittings - Engineers EdgeDocument2 pagesPressure Drop Equivalent Length of Pipes and Fittings - Engineers EdgeallovidNo ratings yet

- SU 816 - Parts - 2007Document58 pagesSU 816 - Parts - 2007Centrifugal SeparatorNo ratings yet

- Important Sample Viva QuestionsDocument3 pagesImportant Sample Viva QuestionsSanjay ShekarNo ratings yet

- PS0121-DWG-B-003 Sheet 3 Jalur Pemipaan Dari WDO Fase 1 & 2 Menuju Drain Tank CCDS - Isometric Sect. 2 R.4Document1 pagePS0121-DWG-B-003 Sheet 3 Jalur Pemipaan Dari WDO Fase 1 & 2 Menuju Drain Tank CCDS - Isometric Sect. 2 R.4yusak adi setiawanNo ratings yet

- Pumps and Pumping SystemsDocument40 pagesPumps and Pumping SystemsBhuneshwar ChelakNo ratings yet

- Diagrama Hidraulico A40E (De La 12558 A La 69999)Document2 pagesDiagrama Hidraulico A40E (De La 12558 A La 69999)CEVegaO50% (2)

- SKL Topic8 Hydraulics Handout ReducedDocument71 pagesSKL Topic8 Hydraulics Handout ReducedDiego Marchant100% (1)

- 3/2 AH-WRT™ - Horizontal Pump: InstallationDocument3 pages3/2 AH-WRT™ - Horizontal Pump: InstallationGuiver Santisteban IbañezNo ratings yet

- Parallel Pump Curves TA2538 X 4, 1760 RPM : L/Sec 200 300 400 500 600 700 800 900 1000 1100 1200Document1 pageParallel Pump Curves TA2538 X 4, 1760 RPM : L/Sec 200 300 400 500 600 700 800 900 1000 1100 1200Rubi AbionNo ratings yet

- Hydraulic Schemat (2Document2 pagesHydraulic Schemat (2Yacob PangihutanNo ratings yet

- Checklist DailyDocument1 pageChecklist DailySubistia IrwanNo ratings yet

- Plumbing FinalDocument30 pagesPlumbing Finalashe zinabNo ratings yet

- 966GII - Accumulator Charging Valve (Brake) - Test and Adjust PDFDocument4 pages966GII - Accumulator Charging Valve (Brake) - Test and Adjust PDFOfftap's100% (2)

- Dosing Pump DocumentsDocument7 pagesDosing Pump Documentsbmanojkumar16No ratings yet

- c03 962g College SchematicDocument32 pagesc03 962g College SchematicHENRY100% (1)

- Mechatronics: Fluid System ModelDocument34 pagesMechatronics: Fluid System ModelKARTHIK S SNo ratings yet

- Week 9 - Valves and Pipe Flow - Practice ProblemsDocument18 pagesWeek 9 - Valves and Pipe Flow - Practice ProblemsSandino Michael Angelo AguilarNo ratings yet

- BG Q2 MajorHazardsAwareness TeamSheet 6Document4 pagesBG Q2 MajorHazardsAwareness TeamSheet 6Said SalemNo ratings yet

- 468.01 821837931001 821837939999 Hydraulic Oil Tank BF 800 BPDocument5 pages468.01 821837931001 821837939999 Hydraulic Oil Tank BF 800 BPeshopmanual EnamNo ratings yet

- Backflow Vendor List PDFDocument11 pagesBackflow Vendor List PDFJAGUAR GAMINGNo ratings yet

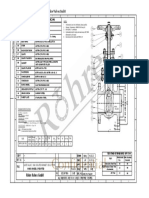

- Rohre - Valves GADocument1 pageRohre - Valves GAkapsarcNo ratings yet

- 320 D Esquema HidrahulicoDocument2 pages320 D Esquema Hidrahulicosebastian velasquez100% (1)

- Centrifugal Pump Douoble Life Model 118 - PartsDocument2 pagesCentrifugal Pump Douoble Life Model 118 - PartsrezandriansyahNo ratings yet

- Conveyance of Water 1Document79 pagesConveyance of Water 1NarasimharaoNo ratings yet

- RH-170 FS Legend H-Schematic 3668520Document15 pagesRH-170 FS Legend H-Schematic 3668520KJDNKJZEFNo ratings yet

- Research On Influence Factors of Landing Gear Retractile HydraulicDocument5 pagesResearch On Influence Factors of Landing Gear Retractile HydraulicPrateek GadagiNo ratings yet

- Rexroth Hydraulics Compontents PDFDocument11 pagesRexroth Hydraulics Compontents PDFMohamed Semeda100% (2)

- 1.0 EBSRAY EMVI CatalogDocument16 pages1.0 EBSRAY EMVI Catalogckyee88-1No ratings yet

- Hydraulic Principles Unit2l1Document26 pagesHydraulic Principles Unit2l1KJDNKJZEFNo ratings yet

Deluge Valve Installation Manual

Deluge Valve Installation Manual

Uploaded by

rahull.miishraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Deluge Valve Installation Manual

Deluge Valve Installation Manual

Uploaded by

rahull.miishraCopyright:

Available Formats

Instructions for Installation,

Operation, Test and Maintenance

1 of 7

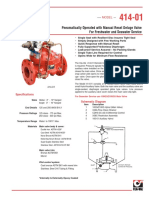

Preaction & Deluge Valve - PPD Series

• No False Alarm

• Outstanding Durability

• Anticorrosive Trim

• Reliable Operation

PPD 100(150)

General Description Technical Data

Safex Fire Services Ltd & Deluge Valve with

external resetting function is a differential latch MODEL : PPD 100(150)

type valve which designed for fire protection Maximum Working Pressure : 175 psi (12 bar)

system. Flange Connection : ANSI B16.1 FF Class 150

The external resetting feature of the PPD valve Factory Hydrostatic Test Pressure :

provides easy resetting of a preaction system 25 bar (350 psi)

without opening the valve cover for manual

Approximate Net Weight :

repositioning of the clapper and latch

mechanism. 100A – 59 kg (Included trim)

Actuation of electric system automatically 150A – 79 kg (Included trim)

releases the PPD valve by allowing water to

flow into the sprinkler piping system and to be Material

discharged from any sprinklers that is open. Body/Cover/Clapper.. . . . . Gray Cast Iron

Seat ring . . . . . . . . . .. . . . . . . . . . Bronze

Listings and Approvals Diaphragm. . . . . . . . . . . . . . . . . . . . EPDM

Clapper seat . . . . . . . . . . . . . . . . . . VITON

Features :-

- Simple configuration for easy maintenance.

- Field replaceable diaphragm and clapper seat.

Safex Fire Services Ltd.

2 of 7

Design Criteria

FIGURE 1. BASIC DIMENSIONS

A B C D E

PPD 100 243 260 367 270 150

PPD 150 259 285 372 290 150

Parts List

NO. ITEM MATERIAL NO. ITEM MATERIAL

1 Body/Cover Cast Iron 6 Solenoid Valve -

2 OS&Y Valve - 7 Drip Check Valve -

3 Air Control Valve - 8 PS Test Valve -

PS Signal

4 Pressure Switch - 9 -

Control Valve

5 Water Supply Valve - 10 Manual Valve -

Safex Fire Services Ltd.

3 of 7

DATA SHEET FOR – DELUGE VALVE

PROPERTY DATA

Manufacturer Safex Fire Services Ltd.

Number & Size As per approved drawing ( dia 150 mm

& 100mm)

Type ANSI 150lb FF type

Flow & pressure rating 175 PSI

Test pressure 350 PSI

MATERIAL

MOC Body IS 210 Gr. 260

Valve internals Cast bronze - IS 318 LTB -II

Seat Seal Neoprene rubber

Diaphragm Neoprene rubber

Differential pressure required for operation kg/cm2 Differential ratio - 50%

Water motor gong provided yes

TYpe Hydraulic ratio - 50%

Material of construction Housing Aluminium alloy - IS 617

Housing / cover / rotor Aluminium to IS 737

Gong Aluminium to IS 737

Manual actuation lever provided YES

Remote actuation with solenoid valve provided yes

Resetting type Manual resetting type

Deluge valve approved by TAC Yes, Also UL listed

Safex Fire Services Ltd.

4 of 7

Operation

Single Interlock Preaction System

When operation of the electrical detection

Single Interlock Preaction System is generally

device, heat sensitive detector and smoke

used to protect area where there is a danger of

detector, electrical manual control station

water damage that might result from

signals the valve releasing panel to operate the

malfunction of automatic sprinkler or piping.

solenoid valve. In turns, the operated solenoid

Typically, such areas include computer rooms,

valve opens to release water from the

storage areas for valuable artifacts, libraries

diaphragm chamber faster than when it

and archives.

replenished through the provided 3/8

restriction.

Single Interlock Preaction System is also

effectively used to protect properties where the

Deluge Valve Equipped with Trim

pre-alarm might activate(fire) prior to sprinkler

When the deluge valve operates, it continually

discharge that condition may allow time for fire

vents the diaphragm chamber to prevent the

extinguishment by alternate suppression.

deluge valve from the resetting condition.

Deluge valve can only be reset after the system

is taken out of service and trim piping is

depressurized and drained.

Operational Mechanism of PPD Preaction & Deluge Valve

In service In activate

Safex Fire Services Ltd.

5 of 7

In Service Condition

Electric Actuation Trim

System pressure is supplied to the diaphragm

To actuate the preaction & deluge valve

chamber through the restricted priming line

electrically, the solenoid valve is provided to

equipped with y-strainer. System water supply

drain the water from the diaphragm chamber

pressure which trapped in the diaphragm

of the valve body. The pressure switch is

chamber holds the clapper on seat due to its

provided to activate an electric alarm, to shut

area differential design.

down the desired equipment or to give alarm

signal to the panel.

In Activate Condition

When the release system operates, pressure is

released from the diaphragm chamber with the

speed that is faster than when it is supplied

through the setting pipeline. Water supply

pressure forces the clapper off seat allowing

water to flow through the outlet and into the

system and alarm devices.

14 LATCH

13 KNOB HANDLE

12 DIAPHRAGM

11 PUSH ROD

10 CHAMBER COVER

9 PUSH ROD DISC

8 CHAMBER

7 PUSH ROD DISC SEAT

6 SETTING BOLT

5 CLAPPER

4 CLAPPER SEAT

3 CLAPPER SEAT COVER

2 SEAT RING

1 BODY

NO. ITEM

Safex Fire Services Ltd.

6 of 7

Electric Actuation Trim

Installation Setting Procedure

Step 1.

Close the OS&Y valve. Open the main drain

Before Installation valve and close it when the flow of water

has ceased.

Prepare sealing materials suitable for the Step 2.

PPD Preaction & Deluge Valve to be Inspect and release if required or the

installed. detection system is subjected to “Actuate

Condition”.

When the installation is completed Step 3.

thoroughly, clean along inner side of the Push the “Reset Knob” inward to allow the

pipes. If possible, flush the pipe with water clapper to reseat. Check the clapper to seat

until it is completely rinsed out. on the seat ring closely.

Step 4.

Preaction & Deluge Valve Installation Open the “Water Supply Valve” and allow

time for full pressure to build up in the

Once again, clean inner side of the valve diaphragm chamber.

body. Check the disk, disk seat and seat ring Step 5.

hole before the installation. Push the “Drip Check Valve” inward to

check any leaks.

Install the Preaction & Deluge valve, Step 6.

pressure gauge and pressure switch. Slowly open the OS&Y valve, and close the

main drain valve.

Step 7.

Observe the main drain valve for any leaks.

If there is leak, determine and correct the

cause of the leakage problem. If there is no

leak, the PPD Valve is ready to be placed in

service condition.

Safex Fire Services Ltd.

7 of 7

Resetting Procedure Maintenance

Step 1. To test operation of the PPD Preaction &

Close the OS&Y valve. Open the main drain Deluge Valve, open the inspector’s test

valve and close it when the flow of water has connection which should activate

ceased. mechanical and electric alarm. This test

connection is usually located at the end or

Step 2. the top line of the system.

Close the “Water Supply Valve” if the valve is

opened.

Alarm valve and associated equipment has

Step 3. to have proper inspection and test

Push the “Reset Knob” fully several times periodically. The NFPA 25 directs minimum

inward to allow the clapper to reseat. Check inspection, test and maintenance

the clapper to seat on the seat ring closely. requirement. PPD Preaction & Deluge Valve

shall be tested, operated, cleaned, inspected

Step 4. ,and parts need to be replaced as required

Close the “Manual Valve” and “Solenoid at least annually.

Valve” if the valves are open.

Step 5.

Push the “Drip Check Valve” inward to check

any leaks.

Step 6.

Open the “Water Supply Valve” if the valve is

closed.

Step 7.

Slowly open the OS&Y valve and close the

main drain valve.

Step 8.

Observe the main drain valve for any leaks. If

there is leak, determine and correct the cause

of the leakage problem. If there is no leak,

the PPD Valve is ready to be placed in service

condition.

Safex Fire Services Ltd.

You might also like

- 303.5E2 CR EXCAVADORA Diagrama Electrico PDFDocument2 pages303.5E2 CR EXCAVADORA Diagrama Electrico PDFRICHARD100% (2)

- D210-375 MedAir PDFDocument4 pagesD210-375 MedAir PDFjulianmataNo ratings yet

- Oreda Volume 1 PDFDocument794 pagesOreda Volume 1 PDFdigeca100% (2)

- Alarm Valve DetailsDocument5 pagesAlarm Valve DetailsRoshan JaiswalNo ratings yet

- Series DDocument3 pagesSeries DHugo Martinez LopezNo ratings yet

- Well Testing Brochure PWP Series Pressureguard Wellhead Protection Us Bettis en 85924Document10 pagesWell Testing Brochure PWP Series Pressureguard Wellhead Protection Us Bettis en 85924Yasser AbdulkareemNo ratings yet

- Pneumatically Operated With Manual Reset Deluge Valve For Freshwater and Seawater ServiceDocument2 pagesPneumatically Operated With Manual Reset Deluge Valve For Freshwater and Seawater ServicedmitosNo ratings yet

- Catalog Functional Safety Solutions Asco en 5084612Document16 pagesCatalog Functional Safety Solutions Asco en 5084612alejomariana03No ratings yet

- BERMAD Fire Protection: TORRENT 400Y - Product CatalogDocument32 pagesBERMAD Fire Protection: TORRENT 400Y - Product CatalogAlberth Rojas CastellanosNo ratings yet

- Electric Actuated Butterfly Valves: FeaturesDocument7 pagesElectric Actuated Butterfly Valves: FeaturesRicardo NapitupuluNo ratings yet

- 729 Double Interlock Preaction DDXDocument22 pages729 Double Interlock Preaction DDXfarshan296015No ratings yet

- Rs 4700Document12 pagesRs 4700Juan JuanNo ratings yet

- Nautilus XMLA160D2S11Document2 pagesNautilus XMLA160D2S11Nazar AbbasNo ratings yet

- F19460 RB 4700 GB 07-007 LowDocument8 pagesF19460 RB 4700 GB 07-007 LowJuan JuanNo ratings yet

- Bermad: Fire ProtectionDocument4 pagesBermad: Fire ProtectionalbertoNo ratings yet

- List Outstanding Material Production Line 7 Texturing: Section MachineDocument6 pagesList Outstanding Material Production Line 7 Texturing: Section MachineMaxNo ratings yet

- XMLA160D2S11: Product Data SheetDocument3 pagesXMLA160D2S11: Product Data SheetJuan MoralesNo ratings yet

- F30178 RB4700 08 2005 LowDocument8 pagesF30178 RB4700 08 2005 LowJuan JuanNo ratings yet

- Tamperproof High-Shock Manual Reset Valves: FeaturesDocument2 pagesTamperproof High-Shock Manual Reset Valves: FeaturesDio MaseraNo ratings yet

- Mooney 1" Flowgrid Regulator: With Shutoff ValveDocument2 pagesMooney 1" Flowgrid Regulator: With Shutoff ValveLuis Alberto Portugal MariacalNo ratings yet

- Samsung RL 25 DATDocument28 pagesSamsung RL 25 DATAleksei EvchuNo ratings yet

- Data Sheet Triac Es, As, Ns Series Butterfly ValvesDocument28 pagesData Sheet Triac Es, As, Ns Series Butterfly Valves4Chat GptNo ratings yet

- Manual Balancing 130seriesDocument16 pagesManual Balancing 130seriesa_salehiNo ratings yet

- Model Solenoid Operated Ventable Relief Assembly: CAPACITY: 30 GPMDocument7 pagesModel Solenoid Operated Ventable Relief Assembly: CAPACITY: 30 GPManandsubbiahNo ratings yet

- Flow Meter PDFDocument20 pagesFlow Meter PDFJoe Mari CapaNo ratings yet

- PuROMax Commercial RO Instructions 2015Document49 pagesPuROMax Commercial RO Instructions 2015Jcc ChoNo ratings yet

- HD ND ZUE - enDocument28 pagesHD ND ZUE - enwylie01No ratings yet

- Gate Valve Die-Forged: Pressure Seal BonnetDocument8 pagesGate Valve Die-Forged: Pressure Seal Bonnetedark2009No ratings yet

- Tech Sheet Series CDocument2 pagesTech Sheet Series CLalu Adam Akmal IsnenNo ratings yet

- Indian Oil Corporation Limited, BG (CRYOGENICS) विशेष वििरण/Standard Specification इंवियन ऑयल कॉर्पोरेशन वलविटेि, व्यिसाय सिूह (क्रायोजेवनक)Document3 pagesIndian Oil Corporation Limited, BG (CRYOGENICS) विशेष वििरण/Standard Specification इंवियन ऑयल कॉर्पोरेशन वलविटेि, व्यिसाय सिूह (क्रायोजेवनक)kkaranagNo ratings yet

- Manual Wilden XP.025-metalDocument23 pagesManual Wilden XP.025-metalMarco SilvaNo ratings yet

- E30C - Globe Valves NewDocument20 pagesE30C - Globe Valves NewTaha FaNo ratings yet

- DB 410 GBDocument15 pagesDB 410 GBzoupezeenNo ratings yet

- Industrial Butterfly Valve ChecklistDocument1 pageIndustrial Butterfly Valve ChecklistnavidNo ratings yet

- ICO4S 1-4in 5-2way PBMRDocument4 pagesICO4S 1-4in 5-2way PBMRmaqbool1No ratings yet

- Service - Manual - For - Model - MPR-514-PA - MPR-514R-PA - Pharmaceutical - Refrigerators - 1440163966Document87 pagesService - Manual - For - Model - MPR-514-PA - MPR-514R-PA - Pharmaceutical - Refrigerators - 1440163966ahmed OsamaNo ratings yet

- Sanitary Diaphragm Valve: Type 612Document6 pagesSanitary Diaphragm Valve: Type 612Hilux PabloNo ratings yet

- Mooney Flowgrid Valve: Technical Specifications 12/2018Document2 pagesMooney Flowgrid Valve: Technical Specifications 12/2018Luis Yovany Aldana PonceNo ratings yet

- Series: Oil Sampling ValveDocument2 pagesSeries: Oil Sampling Valvemarran almarranyNo ratings yet

- Pneumatic ActuatorDocument9 pagesPneumatic ActuatorRamesh BabuNo ratings yet

- (Www.manuallib.com) LEISTRITZ&Mdash;L3MF 060 120 IFOKSO G 技术手册Document3 pages(Www.manuallib.com) LEISTRITZ&Mdash;L3MF 060 120 IFOKSO G 技术手册Agnel StanleyNo ratings yet

- Caleffi: Valvole Di BilanciamentoDocument16 pagesCaleffi: Valvole Di BilanciamentoThomas GregantiNo ratings yet

- 107 Differential Pressure Switch Cat459Document4 pages107 Differential Pressure Switch Cat459senthilrsenthilNo ratings yet

- Norm Ex ValvesDocument6 pagesNorm Ex Valvesapi-3712612No ratings yet

- 04BR05Document6 pages04BR05martiguada1No ratings yet

- Pentair Pilot Enclosures For Non-Hazardous LocationDocument6 pagesPentair Pilot Enclosures For Non-Hazardous LocationEdson MirandaNo ratings yet

- Data Sheet XV-3190Document1 pageData Sheet XV-3190alonsito6031No ratings yet

- Dorot 68-De - El - MRDocument6 pagesDorot 68-De - El - MRJosé Daniel ArenasNo ratings yet

- Data Sheet Daniel Model 788 Digital Control Valve en 43714Document16 pagesData Sheet Daniel Model 788 Digital Control Valve en 43714dreyko77No ratings yet

- Pressure Relief Valve 3/4" - 1"Document5 pagesPressure Relief Valve 3/4" - 1"Gisella Mariel RubilarNo ratings yet

- Compressor WP81L - WP101L - Data - Leaflet - 2015Document2 pagesCompressor WP81L - WP101L - Data - Leaflet - 2015RizzoRo1No ratings yet

- Series Features: Two-Stage Preset ValveDocument2 pagesSeries Features: Two-Stage Preset Valvefernando.juarezpetroserviciosNo ratings yet

- 19 400E 3D RL FinalDocument4 pages19 400E 3D RL FinalJose Omar ZaragozaNo ratings yet

- Innovair PEK 60Hz R410a Commercial Package Brochure EnglishDocument12 pagesInnovair PEK 60Hz R410a Commercial Package Brochure Englishcris melos100% (1)

- Globe Valve1 DatasheetDocument1 pageGlobe Valve1 DatasheetobumuyaemesiNo ratings yet

- Chilled Water Cooling Plant Quarterly Insepction ReportDocument1 pageChilled Water Cooling Plant Quarterly Insepction ReportFaisal MuneerNo ratings yet

- Solenoid Valve - Pneumatic: Direct Acting, Pressure RelievedDocument4 pagesSolenoid Valve - Pneumatic: Direct Acting, Pressure RelievedFrancisco Mones RuizNo ratings yet

- Preset Valve Ocv Model Sheet 115 - 25 Aviation 2020Document2 pagesPreset Valve Ocv Model Sheet 115 - 25 Aviation 2020varadarajck893No ratings yet

- 000-I-Ts-102 - DS - 2 PitDocument42 pages000-I-Ts-102 - DS - 2 PitCristian RománNo ratings yet

- CVS 1000L Electro-Pneumatic Linear Positioner: Product ManualDocument12 pagesCVS 1000L Electro-Pneumatic Linear Positioner: Product Manualmhidayat108No ratings yet

- Pressure Drop Equivalent Length of Pipes and Fittings - Engineers EdgeDocument2 pagesPressure Drop Equivalent Length of Pipes and Fittings - Engineers EdgeallovidNo ratings yet

- SU 816 - Parts - 2007Document58 pagesSU 816 - Parts - 2007Centrifugal SeparatorNo ratings yet

- Important Sample Viva QuestionsDocument3 pagesImportant Sample Viva QuestionsSanjay ShekarNo ratings yet

- PS0121-DWG-B-003 Sheet 3 Jalur Pemipaan Dari WDO Fase 1 & 2 Menuju Drain Tank CCDS - Isometric Sect. 2 R.4Document1 pagePS0121-DWG-B-003 Sheet 3 Jalur Pemipaan Dari WDO Fase 1 & 2 Menuju Drain Tank CCDS - Isometric Sect. 2 R.4yusak adi setiawanNo ratings yet

- Pumps and Pumping SystemsDocument40 pagesPumps and Pumping SystemsBhuneshwar ChelakNo ratings yet

- Diagrama Hidraulico A40E (De La 12558 A La 69999)Document2 pagesDiagrama Hidraulico A40E (De La 12558 A La 69999)CEVegaO50% (2)

- SKL Topic8 Hydraulics Handout ReducedDocument71 pagesSKL Topic8 Hydraulics Handout ReducedDiego Marchant100% (1)

- 3/2 AH-WRT™ - Horizontal Pump: InstallationDocument3 pages3/2 AH-WRT™ - Horizontal Pump: InstallationGuiver Santisteban IbañezNo ratings yet

- Parallel Pump Curves TA2538 X 4, 1760 RPM : L/Sec 200 300 400 500 600 700 800 900 1000 1100 1200Document1 pageParallel Pump Curves TA2538 X 4, 1760 RPM : L/Sec 200 300 400 500 600 700 800 900 1000 1100 1200Rubi AbionNo ratings yet

- Hydraulic Schemat (2Document2 pagesHydraulic Schemat (2Yacob PangihutanNo ratings yet

- Checklist DailyDocument1 pageChecklist DailySubistia IrwanNo ratings yet

- Plumbing FinalDocument30 pagesPlumbing Finalashe zinabNo ratings yet

- 966GII - Accumulator Charging Valve (Brake) - Test and Adjust PDFDocument4 pages966GII - Accumulator Charging Valve (Brake) - Test and Adjust PDFOfftap's100% (2)

- Dosing Pump DocumentsDocument7 pagesDosing Pump Documentsbmanojkumar16No ratings yet

- c03 962g College SchematicDocument32 pagesc03 962g College SchematicHENRY100% (1)

- Mechatronics: Fluid System ModelDocument34 pagesMechatronics: Fluid System ModelKARTHIK S SNo ratings yet

- Week 9 - Valves and Pipe Flow - Practice ProblemsDocument18 pagesWeek 9 - Valves and Pipe Flow - Practice ProblemsSandino Michael Angelo AguilarNo ratings yet

- BG Q2 MajorHazardsAwareness TeamSheet 6Document4 pagesBG Q2 MajorHazardsAwareness TeamSheet 6Said SalemNo ratings yet

- 468.01 821837931001 821837939999 Hydraulic Oil Tank BF 800 BPDocument5 pages468.01 821837931001 821837939999 Hydraulic Oil Tank BF 800 BPeshopmanual EnamNo ratings yet

- Backflow Vendor List PDFDocument11 pagesBackflow Vendor List PDFJAGUAR GAMINGNo ratings yet

- Rohre - Valves GADocument1 pageRohre - Valves GAkapsarcNo ratings yet

- 320 D Esquema HidrahulicoDocument2 pages320 D Esquema Hidrahulicosebastian velasquez100% (1)

- Centrifugal Pump Douoble Life Model 118 - PartsDocument2 pagesCentrifugal Pump Douoble Life Model 118 - PartsrezandriansyahNo ratings yet

- Conveyance of Water 1Document79 pagesConveyance of Water 1NarasimharaoNo ratings yet

- RH-170 FS Legend H-Schematic 3668520Document15 pagesRH-170 FS Legend H-Schematic 3668520KJDNKJZEFNo ratings yet

- Research On Influence Factors of Landing Gear Retractile HydraulicDocument5 pagesResearch On Influence Factors of Landing Gear Retractile HydraulicPrateek GadagiNo ratings yet

- Rexroth Hydraulics Compontents PDFDocument11 pagesRexroth Hydraulics Compontents PDFMohamed Semeda100% (2)

- 1.0 EBSRAY EMVI CatalogDocument16 pages1.0 EBSRAY EMVI Catalogckyee88-1No ratings yet

- Hydraulic Principles Unit2l1Document26 pagesHydraulic Principles Unit2l1KJDNKJZEFNo ratings yet