Professional Documents

Culture Documents

Naphtha To Storage Line Leak

Naphtha To Storage Line Leak

Uploaded by

00083583rfCopyright:

Available Formats

You might also like

- PDF Manual Taller Nissan Qr25 em DDDocument51 pagesPDF Manual Taller Nissan Qr25 em DDRDC producciones100% (1)

- Coiled Tubing - Emergency ProceduresDocument50 pagesCoiled Tubing - Emergency ProceduresSarasevina Anggraeni100% (2)

- 6.NCSPB 25150 ChargingDocument3 pages6.NCSPB 25150 Chargingravi kalariaNo ratings yet

- Skill Developement On Vgo HDT TripDocument2 pagesSkill Developement On Vgo HDT Trip00083583rfNo ratings yet

- Skill Developement On Total Steam FailureDocument2 pagesSkill Developement On Total Steam Failure00083583rfNo ratings yet

- Skill Development On Power FailureDocument2 pagesSkill Development On Power Failure00083583rfNo ratings yet

- Skill Development On P25ABC LOSES DIS FLOW.Document5 pagesSkill Development On P25ABC LOSES DIS FLOW.00083583rfNo ratings yet

- Procedure For Condenser Vacuum PullingDocument4 pagesProcedure For Condenser Vacuum PullingPulkit Agarwal100% (1)

- SOP For Deaerator Safety Valve FloatingDocument3 pagesSOP For Deaerator Safety Valve FloatingSAKTHIVEL MNo ratings yet

- 2B40208-2 Capacity TestDocument8 pages2B40208-2 Capacity Testameya gawadeNo ratings yet

- 5.12 Bop Es 15MDocument30 pages5.12 Bop Es 15MJavier Rivas50% (2)

- Chintana Naree BriefDocument11 pagesChintana Naree BriefWinston Rodrigues100% (1)

- Skill Developement On K3AB Start UpDocument2 pagesSkill Developement On K3AB Start Up00083583rfNo ratings yet

- 17 CHEMICAL fEED sYSTEMDocument13 pages17 CHEMICAL fEED sYSTEMnodalpcrktpsNo ratings yet

- Stg-1 TDBFP Isolation NormalisationDocument4 pagesStg-1 TDBFP Isolation Normalisationnetygen1No ratings yet

- PANTO Not Raising in Three Phase LocoDocument2 pagesPANTO Not Raising in Three Phase LocoProbhat Mondal100% (1)

- 1B 40208-2 ChargingDocument5 pages1B 40208-2 Chargingravi kalariaNo ratings yet

- Cracked Gas CompressorDocument7 pagesCracked Gas CompressorfvaefaNo ratings yet

- 52 32 Convertible Namur Solenoid Valve Model 51424 51424Lw 51424is PDFDocument7 pages52 32 Convertible Namur Solenoid Valve Model 51424 51424Lw 51424is PDFysr3eeNo ratings yet

- IB-14 - SCON - TBG Punch - Scope of Work Rev 00Document11 pagesIB-14 - SCON - TBG Punch - Scope of Work Rev 00Samson ObinnaNo ratings yet

- Tech Manual: 5.12", 10,000 Psi Working Pressure, Eh Series Single, Dual, Triple & Quad Combi BopDocument34 pagesTech Manual: 5.12", 10,000 Psi Working Pressure, Eh Series Single, Dual, Triple & Quad Combi BopPastor VelasquezNo ratings yet

- Tech Manual: Tech-5.12 10K Es54 Dual QcmaDocument24 pagesTech Manual: Tech-5.12 10K Es54 Dual QcmaRiski KurniawanNo ratings yet

- CEP Isolation & Normalisation ProcedureDocument2 pagesCEP Isolation & Normalisation ProcedureVishal GuptaNo ratings yet

- FakinasolDocument17 pagesFakinasolmasgontarNo ratings yet

- n19 Grey WaterDocument2 pagesn19 Grey WaterJames CKNo ratings yet

- Basic Production Training: Based On Api - 14 CDocument137 pagesBasic Production Training: Based On Api - 14 CAbdul MuqtadirNo ratings yet

- WEFIC WELLHEAD Rig Book KOM-103013-03 REV 0Document258 pagesWEFIC WELLHEAD Rig Book KOM-103013-03 REV 0tongsabaiNo ratings yet

- Opgs 0 BLR Opn 19-26-00 Sop For DM Initial Fill PumpDocument5 pagesOpgs 0 BLR Opn 19-26-00 Sop For DM Initial Fill PumpAnbu MathiNo ratings yet

- Coiled Tubing OperationDocument3 pagesCoiled Tubing Operationgben11No ratings yet

- Skill Developement FormatDocument2 pagesSkill Developement Format00083583rfNo ratings yet

- 4.1 Installation Valve ProcedureDocument6 pages4.1 Installation Valve ProcedureArieNo ratings yet

- Advanced Wireline Operations CourseDocument75 pagesAdvanced Wireline Operations CourseIbad sNo ratings yet

- M60es44 P449y Man 001Document23 pagesM60es44 P449y Man 001Riski Kurniawan100% (1)

- Opgs 0 BLR Opn 19-23-00 Sop For Hfo UnloadingDocument6 pagesOpgs 0 BLR Opn 19-23-00 Sop For Hfo UnloadingAnbu MathiNo ratings yet

- Package SsDocument2 pagesPackage SsNagaraj VjNo ratings yet

- Term of Reference Assessment Study of Unbalance Liquid Level of Central Separator of Ulubelu Unit 3&4Document7 pagesTerm of Reference Assessment Study of Unbalance Liquid Level of Central Separator of Ulubelu Unit 3&4tiantaufik100% (1)

- M60es54 S549y Man 001Document14 pagesM60es54 S549y Man 001Riski Kurniawan100% (1)

- Skill Developement On Mathura Ref Incident On 27.05.2023 e ShiftDocument7 pagesSkill Developement On Mathura Ref Incident On 27.05.2023 e Shift00083583rfNo ratings yet

- Tech Manual: 5.12", 10,000 Psi Working Pressure, Eh Series Single, Dual, Triple & Quad Combi BopDocument34 pagesTech Manual: 5.12", 10,000 Psi Working Pressure, Eh Series Single, Dual, Triple & Quad Combi BopRiski KurniawanNo ratings yet

- Skill Developement - CW FAILDocument3 pagesSkill Developement - CW FAIL00083583rfNo ratings yet

- PRO-03-31 FOR LINE BLOCKAGE NewDocument7 pagesPRO-03-31 FOR LINE BLOCKAGE NewNikhil DangariyaNo ratings yet

- D T Ra, Attt-440 006 (Htet) : PojepasthDocument5 pagesD T Ra, Attt-440 006 (Htet) : PojepasthMick DelantorNo ratings yet

- Erection Procedure For Control Battery - LatestDocument12 pagesErection Procedure For Control Battery - LatestAnmohieyNo ratings yet

- D04Document7 pagesD04Ahmed SoomroNo ratings yet

- Parveen: Technical ManualDocument16 pagesParveen: Technical ManualDEATH ASSASSIN GAMERNo ratings yet

- Work Instruction #S1 - Offline Slickline Packer Pressure Test - BRG-A5 - DRAFTDocument10 pagesWork Instruction #S1 - Offline Slickline Packer Pressure Test - BRG-A5 - DRAFTAnto NirmalNo ratings yet

- Wellhead Operations & Maintenance Course SummaryDocument65 pagesWellhead Operations & Maintenance Course SummaryMustafa NaithelNo ratings yet

- KF Ball Iom Series WBDocument10 pagesKF Ball Iom Series WBXing ChenNo ratings yet

- Ethylene Refrigeration CompressorDocument17 pagesEthylene Refrigeration CompressorfvaefaNo ratings yet

- D601005184 Man 001Document17 pagesD601005184 Man 001Riski Kurniawan100% (1)

- 4 in WL Bop & RiserDocument19 pages4 in WL Bop & RisersambhajiNo ratings yet

- ADS 11H Completion Program REV-0Document32 pagesADS 11H Completion Program REV-0Emmanuel IfedioraNo ratings yet

- 3.06 ES 10K DUAL BOP ManDocument15 pages3.06 ES 10K DUAL BOP ManRafael BolivarNo ratings yet

- Skill Developement On Rain Time ActionDocument4 pagesSkill Developement On Rain Time Action00083583rfNo ratings yet

- M60eh54 Z549xy Man 001Document22 pagesM60eh54 Z549xy Man 001Riski KurniawanNo ratings yet

- Uncontrolled Flow of Air From WellDocument4 pagesUncontrolled Flow of Air From WellMahesh GediyaNo ratings yet

- Process Calculation Sheet Tag No.: 1. PurposeDocument10 pagesProcess Calculation Sheet Tag No.: 1. PurposeAJAY1381No ratings yet

- Plugback For Sidetrack Procedure Proposed PDFDocument4 pagesPlugback For Sidetrack Procedure Proposed PDFPatrícia MouraNo ratings yet

- Skill Developement On p07 FailureDocument3 pagesSkill Developement On p07 Failure00083583rfNo ratings yet

- M/S. Auro Food Private Limited: Test Report For Out Door TransformerDocument5 pagesM/S. Auro Food Private Limited: Test Report For Out Door TransformerEngr Fahimuddin QureshiNo ratings yet

- VGOHVGO ROuting To Crude Tank - Nov2022Document6 pagesVGOHVGO ROuting To Crude Tank - Nov202200083583rfNo ratings yet

- 2 Avu&Srlpg - Sop - f101 - 201 Failure of 1 Passflow CVDocument3 pages2 Avu&Srlpg - Sop - f101 - 201 Failure of 1 Passflow CV00083583rfNo ratings yet

- Equipment Change Over Schedule AVU-2022-23Document3 pagesEquipment Change Over Schedule AVU-2022-2300083583rfNo ratings yet

- P&ID UpdationDocument3 pagesP&ID Updation00083583rfNo ratings yet

- Skill Cdu Pass Flo LossDocument2 pagesSkill Cdu Pass Flo Loss00083583rfNo ratings yet

- E360 QuestionsDocument3 pagesE360 Questions00083583rfNo ratings yet

- p7 Failure 29.01.2023Document2 pagesp7 Failure 29.01.202300083583rfNo ratings yet

- Skill DevDocument3 pagesSkill Dev00083583rfNo ratings yet

- 1 Avu&Srlpg - Sop - f002 Failure of 1 Passflow CVDocument3 pages1 Avu&Srlpg - Sop - f002 Failure of 1 Passflow CV00083583rfNo ratings yet

- 1 of ANYPASS - MergedDocument2 pages1 of ANYPASS - Merged00083583rfNo ratings yet

- Skill Development p7Document1 pageSkill Development p700083583rfNo ratings yet

- 3 Avu&Srlpg Sop P-003abc FailureDocument5 pages3 Avu&Srlpg Sop P-003abc Failure00083583rfNo ratings yet

- Skill Developement On p07 FailureDocument3 pagesSkill Developement On p07 Failure00083583rfNo ratings yet

- PM DecDocument1 pagePM Dec00083583rfNo ratings yet

- Mock Drill Report IA FAILUREDocument4 pagesMock Drill Report IA FAILURE00083583rfNo ratings yet

- Mockdrill Power Failure 11.05.2023 NightDocument5 pagesMockdrill Power Failure 11.05.2023 Night00083583rfNo ratings yet

- AVU Operating Manual Rev. 07Document965 pagesAVU Operating Manual Rev. 0700083583rfNo ratings yet

- Skill D FurnaceDocument1 pageSkill D Furnace00083583rfNo ratings yet

- Avu&Srlpg - SRN Leak Over CreekDocument9 pagesAvu&Srlpg - SRN Leak Over Creek00083583rfNo ratings yet

- Skill Developement On Cdu Anypass Flow LossDocument3 pagesSkill Developement On Cdu Anypass Flow Loss00083583rfNo ratings yet

- Skill Developement On K3AB Start UpDocument2 pagesSkill Developement On K3AB Start Up00083583rfNo ratings yet

- High TAN Study SummuaryDocument3 pagesHigh TAN Study Summuary00083583rfNo ratings yet

- Cdu Furnace Mock Drill DraftDocument8 pagesCdu Furnace Mock Drill Draft00083583rfNo ratings yet

- Steam Load Shedding SequenceDocument3 pagesSteam Load Shedding Sequence00083583rfNo ratings yet

- Mock Drill 24th July On Furnace Trip Due To Hi Arch PRDocument5 pagesMock Drill 24th July On Furnace Trip Due To Hi Arch PR00083583rfNo ratings yet

- Skill Developement On Total Steam FailureDocument2 pagesSkill Developement On Total Steam Failure00083583rfNo ratings yet

- Skill Developement FormatDocument2 pagesSkill Developement Format00083583rfNo ratings yet

- Avu&Srlpg SopsDocument732 pagesAvu&Srlpg Sops00083583rfNo ratings yet

- Steam FailureDocument2 pagesSteam Failure00083583rfNo ratings yet

- Electric BellDocument8 pagesElectric Bellnassoro waziriNo ratings yet

- Chapter 6 The Source of Hydraulic Powe-PumpsDocument17 pagesChapter 6 The Source of Hydraulic Powe-PumpscurrjekNo ratings yet

- The Reason For Overturned StructuresDocument2 pagesThe Reason For Overturned StructuresAbdelhamid MaymonNo ratings yet

- Timing Chain Components & Instalation Toyota Hilux 22R-E: Preparation of RemovalDocument7 pagesTiming Chain Components & Instalation Toyota Hilux 22R-E: Preparation of RemovalPablo FernandezNo ratings yet

- Chapter 1 Part 1Document8 pagesChapter 1 Part 1Renderizzah FloraldeNo ratings yet

- Inadequacy of Classical MechanicsDocument20 pagesInadequacy of Classical MechanicsKush SharmaNo ratings yet

- SafdDocument1 pageSafdtakeshi midoriNo ratings yet

- SP3 SOFT NO R Commercial UnitsDocument9 pagesSP3 SOFT NO R Commercial UnitsCristian ManzoNo ratings yet

- Project List Export 10-10-2023Document12 pagesProject List Export 10-10-2023Muhammad AzharuddinNo ratings yet

- Base Si UnitsDocument10 pagesBase Si UnitsJehana NaolNo ratings yet

- CDP 50Document55 pagesCDP 50denis burloiuNo ratings yet

- Ml21256a297 Nei 10CFR53Document59 pagesMl21256a297 Nei 10CFR53오덕환Oh DuckhwanNo ratings yet

- FM 660 Air Flow Experimental Bench - EdLabQuip - 2015Document53 pagesFM 660 Air Flow Experimental Bench - EdLabQuip - 2015yonasNo ratings yet

- Experiment 3Document7 pagesExperiment 3NUR SYAFIQAH BINTI MOHD SHAHIR STUDENTNo ratings yet

- Ehsx 04 P 30 ADocument56 pagesEhsx 04 P 30 AzdravkobreNo ratings yet

- Ge Proprietary InformationDocument13 pagesGe Proprietary Informationdavi de laraNo ratings yet

- Esa - Ue20ee101 - I Sem - April - 2021Document3 pagesEsa - Ue20ee101 - I Sem - April - 2021Shashank BakshiNo ratings yet

- Electronic Timer - Series Micon 225: Multi Function Timer Multi Function Timer With 1 Instant & 1 Delayed C/ODocument2 pagesElectronic Timer - Series Micon 225: Multi Function Timer Multi Function Timer With 1 Instant & 1 Delayed C/ORohit chavanNo ratings yet

- Unisonic Technologies Co., LTD: 2A, 600V N-Channel Power MosfetDocument6 pagesUnisonic Technologies Co., LTD: 2A, 600V N-Channel Power MosfetAlex tiendaNo ratings yet

- Jurnal PertamaDocument4 pagesJurnal PertamaJay KusumaNo ratings yet

- 74-3118 - XLS1000 Smoke Management Application ManualDocument170 pages74-3118 - XLS1000 Smoke Management Application ManualIssac WongNo ratings yet

- Fyreye MKII Conventional DetectorsDocument1 pageFyreye MKII Conventional Detectorscatalog testNo ratings yet

- Smart Ups On Line Srt10kxliDocument4 pagesSmart Ups On Line Srt10kxliBincy GejanNo ratings yet

- Rak Petroleum: MaterialsDocument24 pagesRak Petroleum: MaterialsMrEgyknightNo ratings yet

- 200 To 275 kVA Enclosure LEHF 1108-08 (01-07)Document2 pages200 To 275 kVA Enclosure LEHF 1108-08 (01-07)ramsey222No ratings yet

- Formulation of Design Strategies For Climate-Responsive Elements in Commercial Buildings To Lessen The Mechanical Resources: Case of PuneDocument13 pagesFormulation of Design Strategies For Climate-Responsive Elements in Commercial Buildings To Lessen The Mechanical Resources: Case of PuneRadheya ChopdeNo ratings yet

- Nuclear Physics and RadioactivityDocument58 pagesNuclear Physics and RadioactivityAvirup RayNo ratings yet

- Power Generation SystemDocument72 pagesPower Generation SystemAbshir Mohamed HajjiNo ratings yet

- E-Marking Notes On Physics HSSC I May 2017Document34 pagesE-Marking Notes On Physics HSSC I May 2017rabiaNo ratings yet

Naphtha To Storage Line Leak

Naphtha To Storage Line Leak

Uploaded by

00083583rfOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Naphtha To Storage Line Leak

Naphtha To Storage Line Leak

Uploaded by

00083583rfCopyright:

Available Formats

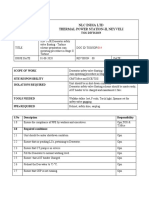

AVU & SR-LPG Treatment Unit

Paradip Refinery

DATED:09.07.2023

Topic Covered: SOP For: Leak of SR Naphtha from AVU to Offsite Piping/MS Blending Header at

Simplex Bridge (300-P-1123-A1AP-NI)

Faculty: MD ARIF

Training Session Attended By:

Sl. Sl.

Name Signature/Date Name Signature/Date

No. No.

1 AJEET 8

2 GAUTAM 9

3 CHANDAN 10

4 PRASHANT 11

5 DHARMENDRA 12

6 GYAN 13

7 14

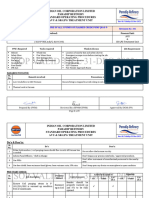

Discussion Points: Following points to be ensured

Ensure SRN to storage I/V are isolated at B/L.

Inform Panel Officers / Shift in Charge/ BOOT-3 Panel.

Ensure line is de-pressurized by proper connection to CBD system.

Inform NHT-CCR panel regarding isolation of cold feed towards NHT tanks.

Do not allow pressurization of process piping.

Don’t keep open any drains to atmosphere in open condition

Don’t allow movement of unauthorized personnel in the nearby area

Don’t allow any damaged hose/rubber hose connection for de-pressurization

Steps to be followed in case mentioned scenario appears:

1. Upon intimation from BOOT-3/CISF/OFFSITE regarding straight run Naphtha leak at Santa Creek

bridge immediately close 010-FV-2004

2. Increase hot feed towards NHT as per demand to control level in C-04. Open FV-2003 (SRN to GT

tanks) to maintain level in C-04, Pressurization of naphtha line towards GT tanks due to closure of

tank inlet valves Intimate GT panel to open receiving tank inlet valve. Open CV only after

confirmation from GT panel

3. Isolate both isolation valves at battery limit towards storage tanks. Gland leak while opening isolation

valve, Tighten gland of isolation valve before operating the valve.

4. Ensure isolation valves are closed at MS blending header and offsite storage tank inlet valves, Back

flow of SRN from tank/blending header.

5. Line up SRN towards light slop tank. SRN can be routed towards light slop tanks as per requirement by

AVU & SRLPG Treatment Unit - Skill DevelopmentPage 1 of 2

opening FV-2004. GT feeding can be stopped as per requirement of GT panel. Gland leak while

opening isolation valve, Tighten gland of isolation valve before operating the valve.

6. Connect metallic hose at LPD of SRN towards NHT/offsite tanks for depressurization of header, Non-

use of brass tools/Improper tightening NOT ALLOWED. Use brass tools while LPD de-

blinding/hose connection. Ensure hoses are properly secured.

7. Connect metallic hose at CBD drain piping of flare KOD pump P-301A/B, Non- use of brass

tools/Improper tightening NOT ALLOWED. Use brass tools while LPD de-blinding/hose

connection. Ensure hoses are properly secured.

AVU & SRLPG Treatment Unit - Skill DevelopmentPage 2 of 2

AVU & SRLPG Treatment Unit - Skill DevelopmentPage 3 of 2

You might also like

- PDF Manual Taller Nissan Qr25 em DDDocument51 pagesPDF Manual Taller Nissan Qr25 em DDRDC producciones100% (1)

- Coiled Tubing - Emergency ProceduresDocument50 pagesCoiled Tubing - Emergency ProceduresSarasevina Anggraeni100% (2)

- 6.NCSPB 25150 ChargingDocument3 pages6.NCSPB 25150 Chargingravi kalariaNo ratings yet

- Skill Developement On Vgo HDT TripDocument2 pagesSkill Developement On Vgo HDT Trip00083583rfNo ratings yet

- Skill Developement On Total Steam FailureDocument2 pagesSkill Developement On Total Steam Failure00083583rfNo ratings yet

- Skill Development On Power FailureDocument2 pagesSkill Development On Power Failure00083583rfNo ratings yet

- Skill Development On P25ABC LOSES DIS FLOW.Document5 pagesSkill Development On P25ABC LOSES DIS FLOW.00083583rfNo ratings yet

- Procedure For Condenser Vacuum PullingDocument4 pagesProcedure For Condenser Vacuum PullingPulkit Agarwal100% (1)

- SOP For Deaerator Safety Valve FloatingDocument3 pagesSOP For Deaerator Safety Valve FloatingSAKTHIVEL MNo ratings yet

- 2B40208-2 Capacity TestDocument8 pages2B40208-2 Capacity Testameya gawadeNo ratings yet

- 5.12 Bop Es 15MDocument30 pages5.12 Bop Es 15MJavier Rivas50% (2)

- Chintana Naree BriefDocument11 pagesChintana Naree BriefWinston Rodrigues100% (1)

- Skill Developement On K3AB Start UpDocument2 pagesSkill Developement On K3AB Start Up00083583rfNo ratings yet

- 17 CHEMICAL fEED sYSTEMDocument13 pages17 CHEMICAL fEED sYSTEMnodalpcrktpsNo ratings yet

- Stg-1 TDBFP Isolation NormalisationDocument4 pagesStg-1 TDBFP Isolation Normalisationnetygen1No ratings yet

- PANTO Not Raising in Three Phase LocoDocument2 pagesPANTO Not Raising in Three Phase LocoProbhat Mondal100% (1)

- 1B 40208-2 ChargingDocument5 pages1B 40208-2 Chargingravi kalariaNo ratings yet

- Cracked Gas CompressorDocument7 pagesCracked Gas CompressorfvaefaNo ratings yet

- 52 32 Convertible Namur Solenoid Valve Model 51424 51424Lw 51424is PDFDocument7 pages52 32 Convertible Namur Solenoid Valve Model 51424 51424Lw 51424is PDFysr3eeNo ratings yet

- IB-14 - SCON - TBG Punch - Scope of Work Rev 00Document11 pagesIB-14 - SCON - TBG Punch - Scope of Work Rev 00Samson ObinnaNo ratings yet

- Tech Manual: 5.12", 10,000 Psi Working Pressure, Eh Series Single, Dual, Triple & Quad Combi BopDocument34 pagesTech Manual: 5.12", 10,000 Psi Working Pressure, Eh Series Single, Dual, Triple & Quad Combi BopPastor VelasquezNo ratings yet

- Tech Manual: Tech-5.12 10K Es54 Dual QcmaDocument24 pagesTech Manual: Tech-5.12 10K Es54 Dual QcmaRiski KurniawanNo ratings yet

- CEP Isolation & Normalisation ProcedureDocument2 pagesCEP Isolation & Normalisation ProcedureVishal GuptaNo ratings yet

- FakinasolDocument17 pagesFakinasolmasgontarNo ratings yet

- n19 Grey WaterDocument2 pagesn19 Grey WaterJames CKNo ratings yet

- Basic Production Training: Based On Api - 14 CDocument137 pagesBasic Production Training: Based On Api - 14 CAbdul MuqtadirNo ratings yet

- WEFIC WELLHEAD Rig Book KOM-103013-03 REV 0Document258 pagesWEFIC WELLHEAD Rig Book KOM-103013-03 REV 0tongsabaiNo ratings yet

- Opgs 0 BLR Opn 19-26-00 Sop For DM Initial Fill PumpDocument5 pagesOpgs 0 BLR Opn 19-26-00 Sop For DM Initial Fill PumpAnbu MathiNo ratings yet

- Coiled Tubing OperationDocument3 pagesCoiled Tubing Operationgben11No ratings yet

- Skill Developement FormatDocument2 pagesSkill Developement Format00083583rfNo ratings yet

- 4.1 Installation Valve ProcedureDocument6 pages4.1 Installation Valve ProcedureArieNo ratings yet

- Advanced Wireline Operations CourseDocument75 pagesAdvanced Wireline Operations CourseIbad sNo ratings yet

- M60es44 P449y Man 001Document23 pagesM60es44 P449y Man 001Riski Kurniawan100% (1)

- Opgs 0 BLR Opn 19-23-00 Sop For Hfo UnloadingDocument6 pagesOpgs 0 BLR Opn 19-23-00 Sop For Hfo UnloadingAnbu MathiNo ratings yet

- Package SsDocument2 pagesPackage SsNagaraj VjNo ratings yet

- Term of Reference Assessment Study of Unbalance Liquid Level of Central Separator of Ulubelu Unit 3&4Document7 pagesTerm of Reference Assessment Study of Unbalance Liquid Level of Central Separator of Ulubelu Unit 3&4tiantaufik100% (1)

- M60es54 S549y Man 001Document14 pagesM60es54 S549y Man 001Riski Kurniawan100% (1)

- Skill Developement On Mathura Ref Incident On 27.05.2023 e ShiftDocument7 pagesSkill Developement On Mathura Ref Incident On 27.05.2023 e Shift00083583rfNo ratings yet

- Tech Manual: 5.12", 10,000 Psi Working Pressure, Eh Series Single, Dual, Triple & Quad Combi BopDocument34 pagesTech Manual: 5.12", 10,000 Psi Working Pressure, Eh Series Single, Dual, Triple & Quad Combi BopRiski KurniawanNo ratings yet

- Skill Developement - CW FAILDocument3 pagesSkill Developement - CW FAIL00083583rfNo ratings yet

- PRO-03-31 FOR LINE BLOCKAGE NewDocument7 pagesPRO-03-31 FOR LINE BLOCKAGE NewNikhil DangariyaNo ratings yet

- D T Ra, Attt-440 006 (Htet) : PojepasthDocument5 pagesD T Ra, Attt-440 006 (Htet) : PojepasthMick DelantorNo ratings yet

- Erection Procedure For Control Battery - LatestDocument12 pagesErection Procedure For Control Battery - LatestAnmohieyNo ratings yet

- D04Document7 pagesD04Ahmed SoomroNo ratings yet

- Parveen: Technical ManualDocument16 pagesParveen: Technical ManualDEATH ASSASSIN GAMERNo ratings yet

- Work Instruction #S1 - Offline Slickline Packer Pressure Test - BRG-A5 - DRAFTDocument10 pagesWork Instruction #S1 - Offline Slickline Packer Pressure Test - BRG-A5 - DRAFTAnto NirmalNo ratings yet

- Wellhead Operations & Maintenance Course SummaryDocument65 pagesWellhead Operations & Maintenance Course SummaryMustafa NaithelNo ratings yet

- KF Ball Iom Series WBDocument10 pagesKF Ball Iom Series WBXing ChenNo ratings yet

- Ethylene Refrigeration CompressorDocument17 pagesEthylene Refrigeration CompressorfvaefaNo ratings yet

- D601005184 Man 001Document17 pagesD601005184 Man 001Riski Kurniawan100% (1)

- 4 in WL Bop & RiserDocument19 pages4 in WL Bop & RisersambhajiNo ratings yet

- ADS 11H Completion Program REV-0Document32 pagesADS 11H Completion Program REV-0Emmanuel IfedioraNo ratings yet

- 3.06 ES 10K DUAL BOP ManDocument15 pages3.06 ES 10K DUAL BOP ManRafael BolivarNo ratings yet

- Skill Developement On Rain Time ActionDocument4 pagesSkill Developement On Rain Time Action00083583rfNo ratings yet

- M60eh54 Z549xy Man 001Document22 pagesM60eh54 Z549xy Man 001Riski KurniawanNo ratings yet

- Uncontrolled Flow of Air From WellDocument4 pagesUncontrolled Flow of Air From WellMahesh GediyaNo ratings yet

- Process Calculation Sheet Tag No.: 1. PurposeDocument10 pagesProcess Calculation Sheet Tag No.: 1. PurposeAJAY1381No ratings yet

- Plugback For Sidetrack Procedure Proposed PDFDocument4 pagesPlugback For Sidetrack Procedure Proposed PDFPatrícia MouraNo ratings yet

- Skill Developement On p07 FailureDocument3 pagesSkill Developement On p07 Failure00083583rfNo ratings yet

- M/S. Auro Food Private Limited: Test Report For Out Door TransformerDocument5 pagesM/S. Auro Food Private Limited: Test Report For Out Door TransformerEngr Fahimuddin QureshiNo ratings yet

- VGOHVGO ROuting To Crude Tank - Nov2022Document6 pagesVGOHVGO ROuting To Crude Tank - Nov202200083583rfNo ratings yet

- 2 Avu&Srlpg - Sop - f101 - 201 Failure of 1 Passflow CVDocument3 pages2 Avu&Srlpg - Sop - f101 - 201 Failure of 1 Passflow CV00083583rfNo ratings yet

- Equipment Change Over Schedule AVU-2022-23Document3 pagesEquipment Change Over Schedule AVU-2022-2300083583rfNo ratings yet

- P&ID UpdationDocument3 pagesP&ID Updation00083583rfNo ratings yet

- Skill Cdu Pass Flo LossDocument2 pagesSkill Cdu Pass Flo Loss00083583rfNo ratings yet

- E360 QuestionsDocument3 pagesE360 Questions00083583rfNo ratings yet

- p7 Failure 29.01.2023Document2 pagesp7 Failure 29.01.202300083583rfNo ratings yet

- Skill DevDocument3 pagesSkill Dev00083583rfNo ratings yet

- 1 Avu&Srlpg - Sop - f002 Failure of 1 Passflow CVDocument3 pages1 Avu&Srlpg - Sop - f002 Failure of 1 Passflow CV00083583rfNo ratings yet

- 1 of ANYPASS - MergedDocument2 pages1 of ANYPASS - Merged00083583rfNo ratings yet

- Skill Development p7Document1 pageSkill Development p700083583rfNo ratings yet

- 3 Avu&Srlpg Sop P-003abc FailureDocument5 pages3 Avu&Srlpg Sop P-003abc Failure00083583rfNo ratings yet

- Skill Developement On p07 FailureDocument3 pagesSkill Developement On p07 Failure00083583rfNo ratings yet

- PM DecDocument1 pagePM Dec00083583rfNo ratings yet

- Mock Drill Report IA FAILUREDocument4 pagesMock Drill Report IA FAILURE00083583rfNo ratings yet

- Mockdrill Power Failure 11.05.2023 NightDocument5 pagesMockdrill Power Failure 11.05.2023 Night00083583rfNo ratings yet

- AVU Operating Manual Rev. 07Document965 pagesAVU Operating Manual Rev. 0700083583rfNo ratings yet

- Skill D FurnaceDocument1 pageSkill D Furnace00083583rfNo ratings yet

- Avu&Srlpg - SRN Leak Over CreekDocument9 pagesAvu&Srlpg - SRN Leak Over Creek00083583rfNo ratings yet

- Skill Developement On Cdu Anypass Flow LossDocument3 pagesSkill Developement On Cdu Anypass Flow Loss00083583rfNo ratings yet

- Skill Developement On K3AB Start UpDocument2 pagesSkill Developement On K3AB Start Up00083583rfNo ratings yet

- High TAN Study SummuaryDocument3 pagesHigh TAN Study Summuary00083583rfNo ratings yet

- Cdu Furnace Mock Drill DraftDocument8 pagesCdu Furnace Mock Drill Draft00083583rfNo ratings yet

- Steam Load Shedding SequenceDocument3 pagesSteam Load Shedding Sequence00083583rfNo ratings yet

- Mock Drill 24th July On Furnace Trip Due To Hi Arch PRDocument5 pagesMock Drill 24th July On Furnace Trip Due To Hi Arch PR00083583rfNo ratings yet

- Skill Developement On Total Steam FailureDocument2 pagesSkill Developement On Total Steam Failure00083583rfNo ratings yet

- Skill Developement FormatDocument2 pagesSkill Developement Format00083583rfNo ratings yet

- Avu&Srlpg SopsDocument732 pagesAvu&Srlpg Sops00083583rfNo ratings yet

- Steam FailureDocument2 pagesSteam Failure00083583rfNo ratings yet

- Electric BellDocument8 pagesElectric Bellnassoro waziriNo ratings yet

- Chapter 6 The Source of Hydraulic Powe-PumpsDocument17 pagesChapter 6 The Source of Hydraulic Powe-PumpscurrjekNo ratings yet

- The Reason For Overturned StructuresDocument2 pagesThe Reason For Overturned StructuresAbdelhamid MaymonNo ratings yet

- Timing Chain Components & Instalation Toyota Hilux 22R-E: Preparation of RemovalDocument7 pagesTiming Chain Components & Instalation Toyota Hilux 22R-E: Preparation of RemovalPablo FernandezNo ratings yet

- Chapter 1 Part 1Document8 pagesChapter 1 Part 1Renderizzah FloraldeNo ratings yet

- Inadequacy of Classical MechanicsDocument20 pagesInadequacy of Classical MechanicsKush SharmaNo ratings yet

- SafdDocument1 pageSafdtakeshi midoriNo ratings yet

- SP3 SOFT NO R Commercial UnitsDocument9 pagesSP3 SOFT NO R Commercial UnitsCristian ManzoNo ratings yet

- Project List Export 10-10-2023Document12 pagesProject List Export 10-10-2023Muhammad AzharuddinNo ratings yet

- Base Si UnitsDocument10 pagesBase Si UnitsJehana NaolNo ratings yet

- CDP 50Document55 pagesCDP 50denis burloiuNo ratings yet

- Ml21256a297 Nei 10CFR53Document59 pagesMl21256a297 Nei 10CFR53오덕환Oh DuckhwanNo ratings yet

- FM 660 Air Flow Experimental Bench - EdLabQuip - 2015Document53 pagesFM 660 Air Flow Experimental Bench - EdLabQuip - 2015yonasNo ratings yet

- Experiment 3Document7 pagesExperiment 3NUR SYAFIQAH BINTI MOHD SHAHIR STUDENTNo ratings yet

- Ehsx 04 P 30 ADocument56 pagesEhsx 04 P 30 AzdravkobreNo ratings yet

- Ge Proprietary InformationDocument13 pagesGe Proprietary Informationdavi de laraNo ratings yet

- Esa - Ue20ee101 - I Sem - April - 2021Document3 pagesEsa - Ue20ee101 - I Sem - April - 2021Shashank BakshiNo ratings yet

- Electronic Timer - Series Micon 225: Multi Function Timer Multi Function Timer With 1 Instant & 1 Delayed C/ODocument2 pagesElectronic Timer - Series Micon 225: Multi Function Timer Multi Function Timer With 1 Instant & 1 Delayed C/ORohit chavanNo ratings yet

- Unisonic Technologies Co., LTD: 2A, 600V N-Channel Power MosfetDocument6 pagesUnisonic Technologies Co., LTD: 2A, 600V N-Channel Power MosfetAlex tiendaNo ratings yet

- Jurnal PertamaDocument4 pagesJurnal PertamaJay KusumaNo ratings yet

- 74-3118 - XLS1000 Smoke Management Application ManualDocument170 pages74-3118 - XLS1000 Smoke Management Application ManualIssac WongNo ratings yet

- Fyreye MKII Conventional DetectorsDocument1 pageFyreye MKII Conventional Detectorscatalog testNo ratings yet

- Smart Ups On Line Srt10kxliDocument4 pagesSmart Ups On Line Srt10kxliBincy GejanNo ratings yet

- Rak Petroleum: MaterialsDocument24 pagesRak Petroleum: MaterialsMrEgyknightNo ratings yet

- 200 To 275 kVA Enclosure LEHF 1108-08 (01-07)Document2 pages200 To 275 kVA Enclosure LEHF 1108-08 (01-07)ramsey222No ratings yet

- Formulation of Design Strategies For Climate-Responsive Elements in Commercial Buildings To Lessen The Mechanical Resources: Case of PuneDocument13 pagesFormulation of Design Strategies For Climate-Responsive Elements in Commercial Buildings To Lessen The Mechanical Resources: Case of PuneRadheya ChopdeNo ratings yet

- Nuclear Physics and RadioactivityDocument58 pagesNuclear Physics and RadioactivityAvirup RayNo ratings yet

- Power Generation SystemDocument72 pagesPower Generation SystemAbshir Mohamed HajjiNo ratings yet

- E-Marking Notes On Physics HSSC I May 2017Document34 pagesE-Marking Notes On Physics HSSC I May 2017rabiaNo ratings yet