Professional Documents

Culture Documents

4 Avu&Srlpg Sop P-007abc Failure

4 Avu&Srlpg Sop P-007abc Failure

Uploaded by

00083583rfOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4 Avu&Srlpg Sop P-007abc Failure

4 Avu&Srlpg Sop P-007abc Failure

Uploaded by

00083583rfCopyright:

Available Formats

INDIAN OIL CORPORATION LIMITED

PARADIP REFINERY

STANDARD OPERATING PROCEDURES

AVU & SR-LPG TREATMENT UNIT Rev-06 Validity:31-Dec-2022

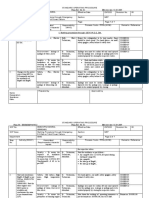

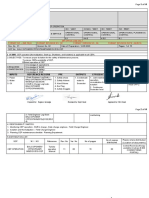

AVU. SOP/ SOP For: FAILURE OF ALL 3 RCO PUMP (010-P-007 A/B/C) Revision No : 06

Department: Equipment involved: Process Unit:

AVU

010-F-101,010-F-201,010-F-002

Production &

010-P-007 A/B/C, 010-C-001, 010-C-007

SR-LPG Treatment Unit

PPE’s Required Tools required Think & discuss JSA Requirement

Helmet Wheel Key Location of nearby Eye and safety shower.

Safety Shoe Fire Water Hose Emergency escape route before starting the job.

Hand Gloves Fire Extinguisher Nearby MCP

Ear plug Portable Gas Detector Nearby Fire monitor Not Required

Gas Detector Ignitor Wind direction

Face Shield CCTV Camera

IFR Suit Fire Tender Approach Route

HAZARDS INVOLVED:

SL.

Hazards involved Precautions to be taken

No.

1 Low RCO flow in VDU Furnace Ensure firing is stopped to avoid coking in coil.

2 Thermal sock in furnace

Prepared By (PNM) Reviewed By (SPNM/CPNM) Approved By DGM (PN)

Page 1 of 5

INDIAN OIL CORPORATION LIMITED

PARADIP REFINERY

STANDARD OPERATING PROCEDURES

AVU & SR-LPG TREATMENT UNIT Rev-06 Validity:31-Dec-2022

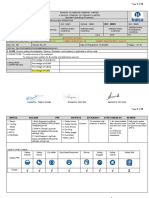

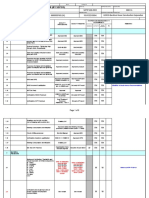

Do’s & Don’ts:

SL

Do’s Don’ts

No.

Either hydrocarbon / coil purging steam should flow in coils till furnace box

1 Do not allow the furnace run dry

is cooled.

2 Inform Panel Officers / Shift in Charge Don’t bypass any process interlocks / approved procedure.

Don’t allow movement of unauthorized personnel in the nearby

3 Use PPEs

area

4 Use face shield, heat resistance hand gloves, heat resistant suits, IFR suits. Don’t keep open any drains to atmosphere in open condition

PRE START CHECK:

Action to be taken by Signature

SL Potential

Job description Control measure EA/ EA/

No. Hazard SIC Panel SIC Panel

JEA JEA

Header should be

Ensure Coil purging steam in F-

Hammeri properly warmed up

1 101/201/002 is warmed up condition √ √

ng in Coil and IVs to be fully

free of condensate.

opened.

2

Prepared By (PNM) Reviewed By (SPNM/CPNM) Approved By DGM (PN)

Page 2 of 5

INDIAN OIL CORPORATION LIMITED

PARADIP REFINERY

STANDARD OPERATING PROCEDURES

AVU & SR-LPG TREATMENT UNIT Rev-06 Validity:31-Dec-2022

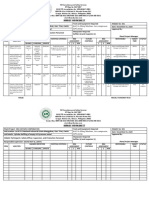

DETAILED STEPS:

Action taken by Signature

Sl. Potential

Job description Control Measure EA/ EA/

No. Hazard SIC Panel SIC Panel

JEA JEA

High COT Monitor COT and

Loss of flow from all 3 pump of RCO

1 Low Flow in reduce Firing as per √ √

pump (010-P-007 ABC) is observed. Furnace requirement.

Check XZVs in field

for physically verify √ √ √

valve closure.

Fully Close Vent

On flow reducing below trip value Gas XZV, FG and

2 ensure furnace F-002 is tripped on Coil Coke Up FO control valves. √

Low Low Pass Flow Interlock. Route Vent gas to

Atm.

Physically isolate all

FO, Vent Gas and √ √

FG burners.

Stop VR export and Start VDU

circulation from P-25 ABC to E- Ensure flow in all

3 Coil Coke Up √ √ √

127/227 A-E to F-002 to C-007 for passes.

furnace cooling.

Maximize velocity steam in Ensure flow in all

4 Coil Coke Up √ √ √

convection section of the furnace. passes.

Prepared By (PNM) Reviewed By (SPNM/CPNM) Approved By DGM (PN)

Page 3 of 5

INDIAN OIL CORPORATION LIMITED

PARADIP REFINERY

STANDARD OPERATING PROCEDURES

AVU & SR-LPG TREATMENT UNIT Rev-06 Validity:31-Dec-2022

Action taken by Signature

Sl. Potential

Job description Control Measure EA/ EA/

No. Hazard SIC Panel SIC Panel

JEA JEA

Break Vacuum and drop VGO/HVGO Ensure flow in all

to VDU column bottom to dilute the passes.

5 column bottom material. On Bottom Coil Coke Up Ensure running of √ √

ID / FD fans for

temp < 200 Deg C take FLO for

cooling of box.

dilution.

Ensure coil purging

If VDU circulation could not be steam is dry.

established in VDU furnace, Monitor VDU

6 Hammering √ √ √

introduce coil purging steam in all pressure, break

passes. vacuum with

Nitrogen

Loss of flow from P-25 A/B/C to DCU Reduce firing in F-

High Delta T 101/201 based on

7 will reduce Furnace Preheat √

in Furnace flow.

Temperature in F-101/201.

Advises BOOT-3 to

reduce crude flow.

Loss of flow in RCO Pump will Monitor C-001

8 Inform RSM, UIC, √ √

increase Crude Column level. level

Downstream units

about pump failure.

Reduce stripping steam flow to C-001 Monitor AGO color.

9 Monitor C-001

and on trip level, ensure stripping Route products to √ √ √

level

steam XZV is closed. off spec.

Prepared By (PNM) Reviewed By (SPNM/CPNM) Approved By DGM (PN)

Page 4 of 5

INDIAN OIL CORPORATION LIMITED

PARADIP REFINERY

STANDARD OPERATING PROCEDURES

AVU & SR-LPG TREATMENT UNIT Rev-06 Validity:31-Dec-2022

Action taken by Signature

Sl. Potential

Job description Control Measure EA/ EA/

No. Hazard SIC Panel SIC Panel

JEA JEA

Reduce Flow from P-003 A/B/C to C- Monitor C- Start for CDU

10 001. 001/V-003 shutdown. √

level

11 Gradually reduce

Reduce firing in F-101/201 √ √

firing in F-101/201

Check XZVs in field

for physically verify √ √

valve closure.

On continuous loss of flow in RCO Fully Close Vent

pump, stop CDU furnace (F-101/201) Gas XZV, FG and

12 and cool. If no HC flow is available in FO control valves. √ √ √

Hot furnace, start coil purging steam in Route Vent gas to

all passes. Atm.

Physically isolate all

FO, Vent Gas and √ √

FG burners.

13 Start activities for CDU and VDU

√ √ √

shutdown as per procedure.

Prepared By (PNM) Reviewed By (SPNM/CPNM) Approved By DGM (PN)

Page 5 of 5

You might also like

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- 1 Avu&Srlpg - Sop - f002 Failure of 1 Passflow CVDocument3 pages1 Avu&Srlpg - Sop - f002 Failure of 1 Passflow CV00083583rfNo ratings yet

- 3 Avu&Srlpg Sop P-003abc FailureDocument5 pages3 Avu&Srlpg Sop P-003abc Failure00083583rfNo ratings yet

- Avu&Srlpg SopsDocument732 pagesAvu&Srlpg Sops00083583rfNo ratings yet

- Starting Procedure Through Emergency DG Set On Total Power FailureDocument7 pagesStarting Procedure Through Emergency DG Set On Total Power FailureRajeev KumarNo ratings yet

- 09.work Instruction For Operation of Additive Ball MillDocument9 pages09.work Instruction For Operation of Additive Ball MillRahul Verma0% (1)

- 22 SOP of Vaccum PullingDocument18 pages22 SOP of Vaccum PullingSiddhant Satpathy100% (1)

- 100 KLPD of 2G Ethanol From Biomass at Iocl PanipatDocument7 pages100 KLPD of 2G Ethanol From Biomass at Iocl PanipatSuraj ShettyNo ratings yet

- Cable JointDocument1 pageCable Jointshonz georgeNo ratings yet

- Emergency Air FailureDocument17 pagesEmergency Air Failureabhrrajjit SANo ratings yet

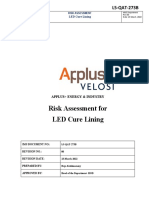

- RA - LED Cure Lining-L5-QAT-273BDocument25 pagesRA - LED Cure Lining-L5-QAT-273BrajaNo ratings yet

- Ds071n Im e GeorgiaDocument12 pagesDs071n Im e GeorgiaGiorgi KurtsikidzeNo ratings yet

- Light VehicleDocument1 pageLight VehicleEko SpdNo ratings yet

- Boiler O&M ManualDocument1,669 pagesBoiler O&M ManualLeonardo CoronadoNo ratings yet

- Confined Space Permit FormDocument3 pagesConfined Space Permit FormEbenezer OpuniNo ratings yet

- Mechanical Seal ReplacementDocument4 pagesMechanical Seal ReplacementhussienkadhoemNo ratings yet

- Process Upset Reporting: Description of EventDocument6 pagesProcess Upset Reporting: Description of EventAhmedNo ratings yet

- pt0-0197 GX-2000取説Ⅰ ja enDocument15 pagespt0-0197 GX-2000取説Ⅰ ja enAvinashNo ratings yet

- Hiradc Worksheet: KAYA Filling Machine, Air Compressor, LPG PumpDocument2 pagesHiradc Worksheet: KAYA Filling Machine, Air Compressor, LPG PumpDaved Roy LenticNo ratings yet

- Maintenance (21.09.2022)Document2 pagesMaintenance (21.09.2022)Imelisya JaulinNo ratings yet

- QAP With Covering Letter - 29112022Document4 pagesQAP With Covering Letter - 29112022PRASHANTNo ratings yet

- Shutdown Valve: B224 323 HPCL Rajasthan Refinery Limited Rajasthan Refinery Project OffsitesDocument1 pageShutdown Valve: B224 323 HPCL Rajasthan Refinery Limited Rajasthan Refinery Project OffsitesMirhasan GaziNo ratings yet

- 021 Finalsmp - PheDocument6 pages021 Finalsmp - PhePankaj PandeyNo ratings yet

- Indian Oil Corporation Limited, BG (CRYOGENICS) विशेष वििरण/Standard Specification इंवियन ऑयल कॉर्पोरेशन वलविटेि, व्यिसाय सिूह (क्रायोजेवनक)Document3 pagesIndian Oil Corporation Limited, BG (CRYOGENICS) विशेष वििरण/Standard Specification इंवियन ऑयल कॉर्पोरेशन वलविटेि, व्यिसाय सिूह (क्रायोजेवनक)kkaranagNo ratings yet

- Soot Blower OperationDocument9 pagesSoot Blower OperationShobhit SrivastavaNo ratings yet

- Registry of Sleeve PlacementDocument10 pagesRegistry of Sleeve PlacementJorge Isaac Lara RamosNo ratings yet

- Ds071s Im e GeorgiaDocument12 pagesDs071s Im e GeorgiaGiorgi KurtsikidzeNo ratings yet

- Testing Report For Pressure Relief Valves: Petrofac International (UAE) LLCDocument1 pageTesting Report For Pressure Relief Valves: Petrofac International (UAE) LLCmurthy challapalliNo ratings yet

- DET ReviewDocument2 pagesDET ReviewBasanta RoyNo ratings yet

- QAPDocument6 pagesQAPRahul ChandanNo ratings yet

- JHA For Pipe Scrap Loading and UnloadingDocument5 pagesJHA For Pipe Scrap Loading and Unloadingkunnar corrosionNo ratings yet

- Sample Transformer Life Assessment SheetDocument10 pagesSample Transformer Life Assessment SheetMuhammed Zubair NNo ratings yet

- Deluge Valve Installation ManualDocument7 pagesDeluge Valve Installation Manualrahull.miishraNo ratings yet

- SOP - Startup Shutdown and Operation of Coal MillDocument2 pagesSOP - Startup Shutdown and Operation of Coal MillJCSNo ratings yet

- r2b p2 203 03 H HD 51062 - Rev.b - Data Sheet SRV PSV 61152 A B 1st Stage DischargeDocument17 pagesr2b p2 203 03 H HD 51062 - Rev.b - Data Sheet SRV PSV 61152 A B 1st Stage Dischargedavid perezNo ratings yet

- CPS6 Chokes Sizing CalculationsDocument5 pagesCPS6 Chokes Sizing CalculationskarthikNo ratings yet

- DB 410 GBDocument15 pagesDB 410 GBzoupezeenNo ratings yet

- P030-E-1055A Job Map 2025 TADocument2 pagesP030-E-1055A Job Map 2025 TAabhijeetrnairNo ratings yet

- 34 CT FAN OperationDocument16 pages34 CT FAN OperationSiddhant SatpathyNo ratings yet

- Process Upset ReportingDocument4 pagesProcess Upset ReportingAhmedNo ratings yet

- Piping Stress AnalysisDocument159 pagesPiping Stress AnalysisSalah Eddine Ziani100% (1)

- PM F 13 OvefDocument1 pagePM F 13 Ovefjp mishraNo ratings yet

- Steam Turbine StartupDocument17 pagesSteam Turbine StartupRahul ChoubeyNo ratings yet

- Work Instructions: Standard Work Instruction - QSK60 Gas A Service Planned - ReactiveDocument13 pagesWork Instructions: Standard Work Instruction - QSK60 Gas A Service Planned - ReactiveTareq MollaNo ratings yet

- Testing Report For Pressure Relief Valves: Petrofac International (UAE) LLCDocument1 pageTesting Report For Pressure Relief Valves: Petrofac International (UAE) LLCmurthy challapalliNo ratings yet

- Cm-Mech - (49 To 50) - Send To MGPS at (13-08-2020)Document3 pagesCm-Mech - (49 To 50) - Send To MGPS at (13-08-2020)ali morisyNo ratings yet

- 10 Cep SopDocument14 pages10 Cep SopSiddhant SatpathyNo ratings yet

- Work - Instruction Transformer 33-11KV TRANSFORMERDocument5 pagesWork - Instruction Transformer 33-11KV TRANSFORMERTAHIR HUSAINNo ratings yet

- WHS Kambuna Mothballing - Rev1Document25 pagesWHS Kambuna Mothballing - Rev1Desy Haslyanti100% (1)

- S-900-1242-022 - 6a - 003 - A2 (Confined Space Entry Permit)Document2 pagesS-900-1242-022 - 6a - 003 - A2 (Confined Space Entry Permit)umar saidNo ratings yet

- 750 - 191 Fuel Air Ratio CSDocument84 pages750 - 191 Fuel Air Ratio CSAlexis CruzNo ratings yet

- Sow-Process EngineeringDocument38 pagesSow-Process EngineeringPaary AtNo ratings yet

- Checklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenace Department Gas DryerDocument1 pageChecklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenace Department Gas Dryerjp mishraNo ratings yet

- Attachmnet-7 Vendor-Coversheet QAPDocument2 pagesAttachmnet-7 Vendor-Coversheet QAPPRASHANTNo ratings yet

- Instru ChecksDocument4 pagesInstru ChecksTchikuteny CLovid OvidioNo ratings yet

- Procedure For Manual Ultrasonic Testing PDFDocument17 pagesProcedure For Manual Ultrasonic Testing PDFbaskaran ayyapparaj100% (2)

- SATIP-ME-2002 HRSG Installation Rev 5Document6 pagesSATIP-ME-2002 HRSG Installation Rev 5zhang100% (1)

- Bharat Aluminium Company LTDDocument9 pagesBharat Aluminium Company LTDAnil RaiNo ratings yet

- Automotive Actuators and EVAP System TestingFrom EverandAutomotive Actuators and EVAP System TestingRating: 4.5 out of 5 stars4.5/5 (4)

- Skill Cdu Pass Flo LossDocument2 pagesSkill Cdu Pass Flo Loss00083583rfNo ratings yet

- VGOHVGO ROuting To Crude Tank - Nov2022Document6 pagesVGOHVGO ROuting To Crude Tank - Nov202200083583rfNo ratings yet

- Equipment Change Over Schedule AVU-2022-23Document3 pagesEquipment Change Over Schedule AVU-2022-2300083583rfNo ratings yet

- Skill DevDocument3 pagesSkill Dev00083583rfNo ratings yet

- p7 Failure 29.01.2023Document2 pagesp7 Failure 29.01.202300083583rfNo ratings yet

- P&ID UpdationDocument3 pagesP&ID Updation00083583rfNo ratings yet

- 1 of ANYPASS - MergedDocument2 pages1 of ANYPASS - Merged00083583rfNo ratings yet

- E360 QuestionsDocument3 pagesE360 Questions00083583rfNo ratings yet

- 2 Avu&Srlpg - Sop - f101 - 201 Failure of 1 Passflow CVDocument3 pages2 Avu&Srlpg - Sop - f101 - 201 Failure of 1 Passflow CV00083583rfNo ratings yet

- 3 Avu&Srlpg Sop P-003abc FailureDocument5 pages3 Avu&Srlpg Sop P-003abc Failure00083583rfNo ratings yet

- AVU Operating Manual Rev. 07Document965 pagesAVU Operating Manual Rev. 0700083583rfNo ratings yet

- 1 Avu&Srlpg - Sop - f002 Failure of 1 Passflow CVDocument3 pages1 Avu&Srlpg - Sop - f002 Failure of 1 Passflow CV00083583rfNo ratings yet

- Skill Development p7Document1 pageSkill Development p700083583rfNo ratings yet

- PM DecDocument1 pagePM Dec00083583rfNo ratings yet

- Mockdrill Power Failure 11.05.2023 NightDocument5 pagesMockdrill Power Failure 11.05.2023 Night00083583rfNo ratings yet

- Mock Drill Report IA FAILUREDocument4 pagesMock Drill Report IA FAILURE00083583rfNo ratings yet

- Skill Developement On Cdu Anypass Flow LossDocument3 pagesSkill Developement On Cdu Anypass Flow Loss00083583rfNo ratings yet

- Skill D FurnaceDocument1 pageSkill D Furnace00083583rfNo ratings yet

- High TAN Study SummuaryDocument3 pagesHigh TAN Study Summuary00083583rfNo ratings yet

- Skill Developement On K3AB Start UpDocument2 pagesSkill Developement On K3AB Start Up00083583rfNo ratings yet

- Skill Developement FormatDocument2 pagesSkill Developement Format00083583rfNo ratings yet

- Skill Developement On p07 FailureDocument3 pagesSkill Developement On p07 Failure00083583rfNo ratings yet

- Avu&Srlpg - SRN Leak Over CreekDocument9 pagesAvu&Srlpg - SRN Leak Over Creek00083583rfNo ratings yet

- Skill Developement On Total Steam FailureDocument2 pagesSkill Developement On Total Steam Failure00083583rfNo ratings yet

- Avu&Srlpg SopsDocument732 pagesAvu&Srlpg Sops00083583rfNo ratings yet

- Mock Drill 24th July On Furnace Trip Due To Hi Arch PRDocument5 pagesMock Drill 24th July On Furnace Trip Due To Hi Arch PR00083583rfNo ratings yet

- Cdu Furnace Mock Drill DraftDocument8 pagesCdu Furnace Mock Drill Draft00083583rfNo ratings yet

- Steam Load Shedding SequenceDocument3 pagesSteam Load Shedding Sequence00083583rfNo ratings yet

- Steam FailureDocument2 pagesSteam Failure00083583rfNo ratings yet

- CPRI Feb Submitted-1Document5 pagesCPRI Feb Submitted-1YOHANES HANDREANNo ratings yet

- d16.906.90.0.Pr - Control Panel For d16 Crdi GensetDocument29 pagesd16.906.90.0.Pr - Control Panel For d16 Crdi GensetGiangDoNo ratings yet

- Neosensor (Two-Wire 4-20ma Output Sensor)Document16 pagesNeosensor (Two-Wire 4-20ma Output Sensor)Nguyễn Anh TuấnNo ratings yet

- Mini - General Purpose Regulators - R07, R46Document2 pagesMini - General Purpose Regulators - R07, R46Miguel Camacho BalabarcaNo ratings yet

- Routine Tests and Type Tests of Transformers - Electrical4uDocument18 pagesRoutine Tests and Type Tests of Transformers - Electrical4u2251 EE MANMAT BIRADARNo ratings yet

- 3-Terminal Positive Voltage Regulator: Semtech Electronics LTDDocument2 pages3-Terminal Positive Voltage Regulator: Semtech Electronics LTDDOMINGOSERPA4148No ratings yet

- FC Walk Behind v2 OP ENDocument54 pagesFC Walk Behind v2 OP ENbubjoeNo ratings yet

- SMAW PrinciplesDocument89 pagesSMAW Principlesdonnyars1979No ratings yet

- AP13 SLMSizingAndConfig V1 2 enDocument16 pagesAP13 SLMSizingAndConfig V1 2 enNgocNo ratings yet

- Engine Construction and Principles of Operation CH 4Document31 pagesEngine Construction and Principles of Operation CH 4Ashish SharmaNo ratings yet

- Motor Protection Fundamentals 4Document27 pagesMotor Protection Fundamentals 4nmulyonoNo ratings yet

- Quantum Mechanics-II Problem Set-02 Approximation MethodsDocument2 pagesQuantum Mechanics-II Problem Set-02 Approximation Methodsjon alexNo ratings yet

- TS20C (02250184-783) User ManualDocument124 pagesTS20C (02250184-783) User ManualMarcos CabreraNo ratings yet

- Selecting Your EquipmentDocument12 pagesSelecting Your EquipmentJaouad IDBOUBKERNo ratings yet

- Bumper CarsSEDocument5 pagesBumper CarsSETiara Peery [STUDENT]No ratings yet

- GYTR Power TunerDocument1 pageGYTR Power TunerPaul MartinNo ratings yet

- Ha 25 73 enDocument50 pagesHa 25 73 enTuan LeNo ratings yet

- Instruction Manual: Evaporative Air CoolerDocument10 pagesInstruction Manual: Evaporative Air Coolerjan carlo kayananNo ratings yet

- Fundamentals of Power Electronics Week 10 Assignment SolutionsDocument4 pagesFundamentals of Power Electronics Week 10 Assignment SolutionsDeep Gandhi100% (1)

- Mahindra 415 Di XP PlusDocument12 pagesMahindra 415 Di XP Plushugo fernandezNo ratings yet

- LT-series LT - Series: Rammers RammersDocument1 pageLT-series LT - Series: Rammers RammersarturoNo ratings yet

- Precalciner Kilns Systems & OperationDocument58 pagesPrecalciner Kilns Systems & OperationYhaneNo ratings yet

- Ypf DayDocument15 pagesYpf DayLPONo ratings yet

- EET-128 Assignment - 10177468Document4 pagesEET-128 Assignment - 10177468kugarajravi2002No ratings yet

- Electrical Safety Inspection Report TemplateDocument9 pagesElectrical Safety Inspection Report TemplateSOPHYNo ratings yet

- Parker - Compact EHA 3-09Document4 pagesParker - Compact EHA 3-09Mehmet Sencer KarakuşNo ratings yet

- Masters in Renewable Energy - Intake 2024Document43 pagesMasters in Renewable Energy - Intake 2024talrejaNo ratings yet

- Megaroyal - 20200713 v0Document38 pagesMegaroyal - 20200713 v0Balinderjit SinghNo ratings yet

- Ensto Novexia - Surge Arresters - Brochure 2017 nx2008256 A - LRDocument20 pagesEnsto Novexia - Surge Arresters - Brochure 2017 nx2008256 A - LRErick Santiago CardosoNo ratings yet

- References No 4Document355 pagesReferences No 4Tu Dang TrongNo ratings yet