Professional Documents

Culture Documents

Service Information: October/04 II 25 01/04

Service Information: October/04 II 25 01/04

Uploaded by

Marcelo GiussaniCopyright:

Available Formats

You might also like

- Stihl FS 130 Manual PDFDocument12 pagesStihl FS 130 Manual PDFGrundfos1989100% (2)

- 2 - Canrig Top Drive Rig Crew TrainingDocument104 pages2 - Canrig Top Drive Rig Crew TrainingDiego Fabian Ruiz Vacaflor89% (9)

- Manual Power Train Caterpillar 777d Off Highway Truck ComponentsDocument46 pagesManual Power Train Caterpillar 777d Off Highway Truck ComponentsDarmawan Putranto88% (25)

- AP Lockheed Remote Servo ManualDocument8 pagesAP Lockheed Remote Servo ManualjblodwellNo ratings yet

- Shogun R FD125XSD PDFDocument73 pagesShogun R FD125XSD PDFMichael Angelo Jandoc100% (1)

- Saab Official Service Manual: 900 16 Valve: 1985-1993 - ExcerptDocument2 pagesSaab Official Service Manual: 900 16 Valve: 1985-1993 - ExcerptBentley PublishersNo ratings yet

- Plunger Pump ManualDocument23 pagesPlunger Pump Manualgovindharajalu75% (4)

- Minor Project Report On Power Transmission in AutomobilesDocument77 pagesMinor Project Report On Power Transmission in AutomobilesMohitt Thakur81% (16)

- Case Studies On Industrial Accidents - 2Document84 pagesCase Studies On Industrial Accidents - 2Parth N Bhatt100% (2)

- PT Tech HPTO Clutch Control System - J1939 Diagnostic Trouble CodesDocument2 pagesPT Tech HPTO Clutch Control System - J1939 Diagnostic Trouble CodesgugiNo ratings yet

- Suzuki Shugun PDFDocument69 pagesSuzuki Shugun PDFPrashanthKumar33% (3)

- I and O-1012 - 1014 - 1015 - and 1017 Pumps 1-1Document9 pagesI and O-1012 - 1014 - 1015 - and 1017 Pumps 1-1Mo'men AdelNo ratings yet

- Cylinder Leakage Tester 2 - Gauge Vse2020.V3: 1. SafetyDocument2 pagesCylinder Leakage Tester 2 - Gauge Vse2020.V3: 1. Safetyhotmaail4No ratings yet

- Fitting Steering Pump SpidDocument15 pagesFitting Steering Pump SpidJuan GarcNo ratings yet

- Clu 1201Document1 pageClu 1201Aleix RamirezNo ratings yet

- MODEL V305000000 PMV 5:1 Oil Pump Series "A": Form 404421 MAR - 2012 SectionDocument12 pagesMODEL V305000000 PMV 5:1 Oil Pump Series "A": Form 404421 MAR - 2012 SectionFaidh Maulana Aksyar FaidhNo ratings yet

- Belt Filter PressDocument5 pagesBelt Filter PressMaku RajkumarNo ratings yet

- Valvula Doble Cheque DC-4 Bendix Manual de ServicioDocument4 pagesValvula Doble Cheque DC-4 Bendix Manual de Serviciojgomez30No ratings yet

- Maintenance and Repair InstructionsDocument12 pagesMaintenance and Repair InstructionsDhananjay NilkuteNo ratings yet

- Pump-Elite - Operating InstructionsDocument12 pagesPump-Elite - Operating Instructionsbookslover1No ratings yet

- PG1203Document17 pagesPG1203heriberto8280No ratings yet

- Cd250 Operation ManualDocument29 pagesCd250 Operation ManualThethanh PhamnguyenNo ratings yet

- Handbook Sealweld Valvulas de ProcesoDocument92 pagesHandbook Sealweld Valvulas de Procesofelipe castellanosNo ratings yet

- Forklift MaintenanceDocument11 pagesForklift MaintenanceTrường NguyenNo ratings yet

- Centrifugal Pump Checklist 2023Document7 pagesCentrifugal Pump Checklist 2023Caesar MutizeNo ratings yet

- L V406000000 GogigggDocument12 pagesL V406000000 Gogigggilyaswinduaji014No ratings yet

- MRP-004 - Brake Bleed - S08-001 v6.1Document4 pagesMRP-004 - Brake Bleed - S08-001 v6.1Matt CrossanNo ratings yet

- Holmatro PPU15Document16 pagesHolmatro PPU15riz333No ratings yet

- Centrifugal Pump MaintenanceDocument7 pagesCentrifugal Pump MaintenanceamasrurNo ratings yet

- VSE2020.V2: Cylinder Leakage TesterDocument2 pagesVSE2020.V2: Cylinder Leakage Testerwalson glen CrastaNo ratings yet

- IFRC - Customer Technical Training (RP - CPP2)Document24 pagesIFRC - Customer Technical Training (RP - CPP2)firdausshukri14No ratings yet

- Motion Pro Leak Test 2TDocument1 pageMotion Pro Leak Test 2TLeandro CaraccioliNo ratings yet

- tb9 2300 426 20Document20 pagestb9 2300 426 20Rolando DaclanNo ratings yet

- ENP-652 Cylinder Boss Wear and RepairDocument7 pagesENP-652 Cylinder Boss Wear and RepaireparodiesNo ratings yet

- WALLACH LL100 TWO TRIGGER CRYOSURGICAL UNIT For N2O Instructions For UseDocument8 pagesWALLACH LL100 TWO TRIGGER CRYOSURGICAL UNIT For N2O Instructions For UsePierre Richard MompremierNo ratings yet

- Maintenance ManualDocument32 pagesMaintenance Manualpratik2429No ratings yet

- Bleeding Hydraulics With No Bleeders 1Document1 pageBleeding Hydraulics With No Bleeders 1balmohankNo ratings yet

- A Procedure For Lube Oil FlushingDocument9 pagesA Procedure For Lube Oil FlushingBrosGeeNo ratings yet

- Amsoil Automatic Transmission Flush ProcedureDocument2 pagesAmsoil Automatic Transmission Flush ProcedureThomas JohnsonNo ratings yet

- EHS Moment - Compressed Gases - Inspection of Gas Cylinder - 12 Oct 23Document2 pagesEHS Moment - Compressed Gases - Inspection of Gas Cylinder - 12 Oct 23sanalkumar24No ratings yet

- Maintenance: Outboard CareDocument18 pagesMaintenance: Outboard Careshygal1981100% (1)

- Start Up Form MPDocument5 pagesStart Up Form MPBUDAPESNo ratings yet

- PT 102662 Iom UsDocument5 pagesPT 102662 Iom UsMo ZeroNo ratings yet

- Portatil AmerexDocument8 pagesPortatil AmerexGrillin GmNo ratings yet

- Mercury Maintenance ManualDocument27 pagesMercury Maintenance ManualJens Adam Hedegaard HansenNo ratings yet

- Mirage g4 Gls at ModelDocument3 pagesMirage g4 Gls at ModelSol S.No ratings yet

- Inspection and Overhaul For Reciprocating CompressorDocument79 pagesInspection and Overhaul For Reciprocating CompressorSalik Ali SyedNo ratings yet

- Kbu KBZ1Document4 pagesKbu KBZ1Andrew VNo ratings yet

- Manual For Hand Portable Halon 1211 ExtinguishersDocument8 pagesManual For Hand Portable Halon 1211 ExtinguishersMatthew ShalkNo ratings yet

- Unit Ii Inspection of Piston EngineDocument45 pagesUnit Ii Inspection of Piston Engineraj6062No ratings yet

- LPG MultivalvesDocument55 pagesLPG MultivalvesAPINo ratings yet

- dp7490 Pump ManualDocument16 pagesdp7490 Pump Manualvipequi50No ratings yet

- IB272Document2 pagesIB272Rodney AlvaradoNo ratings yet

- 3088 Instruction Manual (D) - 230911 - 142910Document20 pages3088 Instruction Manual (D) - 230911 - 142910gguadian21No ratings yet

- YWE P250 ManualDocument21 pagesYWE P250 ManualNuriffah Izzah100% (1)

- Instruct For OperationDocument1 pageInstruct For OperationAriel Martinez NNo ratings yet

- Liquid Ring Pump ManualDocument25 pagesLiquid Ring Pump ManualCornelius Toni KuswandiNo ratings yet

- ENP-562 CNG Field Service Bulletin Foam Cap Dome Installation RepairDocument9 pagesENP-562 CNG Field Service Bulletin Foam Cap Dome Installation RepaireparodiesNo ratings yet

- TB018 Cylinder Compression Test v2021Document2 pagesTB018 Cylinder Compression Test v2021Cristhian HuilcapazNo ratings yet

- Air Hydraulic Pump OTC EnglishDocument8 pagesAir Hydraulic Pump OTC EnglishEdSoloNo ratings yet

- Portable Cargo Pump TK80 Simillar To Marflex Portable PPDocument18 pagesPortable Cargo Pump TK80 Simillar To Marflex Portable PPSubramoniam MarineNo ratings yet

- Brake Bleeding: Service and Repair Brake System BleedingDocument3 pagesBrake Bleeding: Service and Repair Brake System BleedingSauli KlaavuNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- IS064IDocument2 pagesIS064IMarcelo GiussaniNo ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- Service Information: August/99 II 00 06/99Document2 pagesService Information: August/99 II 00 06/99Marcelo GiussaniNo ratings yet

- Service Information: December/99 II 58 10/99Document2 pagesService Information: December/99 II 58 10/99Marcelo GiussaniNo ratings yet

- Service Information: January/00 II 00 01/00Document10 pagesService Information: January/00 II 00 01/00Marcelo GiussaniNo ratings yet

- Service Information: Execution With CapDocument4 pagesService Information: Execution With CapMarcelo GiussaniNo ratings yet

- Service Information: November/99 I 35 01/99Document2 pagesService Information: November/99 I 35 01/99Marcelo GiussaniNo ratings yet

- Service Information: November/98 I 54 13/98Document14 pagesService Information: November/98 I 54 13/98Marcelo GiussaniNo ratings yet

- Service Information: December/99 II 58 09/99Document2 pagesService Information: December/99 II 58 09/99Marcelo GiussaniNo ratings yet

- Service Information: November/98 I 54 09/98Document14 pagesService Information: November/98 I 54 09/98Marcelo GiussaniNo ratings yet

- Service Information: September/98 II 26 07/98Document4 pagesService Information: September/98 II 26 07/98Marcelo GiussaniNo ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- Service Information: June/98 II 26 05/98Document2 pagesService Information: June/98 II 26 05/98Marcelo GiussaniNo ratings yet

- Service InformationDocument4 pagesService InformationMarcelo GiussaniNo ratings yet

- Service Information: May/97 II 32 01/97Document2 pagesService Information: May/97 II 32 01/97Marcelo GiussaniNo ratings yet

- Service Information: September/98 II 58 04/98Document10 pagesService Information: September/98 II 58 04/98Marcelo GiussaniNo ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- Service Information: May/98 II 58 03/98Document2 pagesService Information: May/98 II 58 03/98Marcelo GiussaniNo ratings yet

- Service Information: ST ND RD ST STDocument2 pagesService Information: ST ND RD ST STMarcelo GiussaniNo ratings yet

- Service Information: August/96 II 54 - Nº: 0695 54 04/96Document2 pagesService Information: August/96 II 54 - Nº: 0695 54 04/96Marcelo GiussaniNo ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- Service Information: July/97 I 54 09/97Document2 pagesService Information: July/97 I 54 09/97Marcelo GiussaniNo ratings yet

- Service Information: July/97 II 54 - Nº: 02/97 54 10/97Document2 pagesService Information: July/97 II 54 - Nº: 02/97 54 10/97Marcelo GiussaniNo ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- Service Information: July/97 I 25 01/97Document2 pagesService Information: July/97 I 25 01/97Marcelo GiussaniNo ratings yet

- Service Information: May/97 I 41 01/97Document2 pagesService Information: May/97 I 41 01/97Marcelo GiussaniNo ratings yet

- Service Information: May/97 II 01 01/97Document2 pagesService Information: May/97 II 01 01/97Marcelo GiussaniNo ratings yet

- Service Information: April/97 II 47 01/97Document2 pagesService Information: April/97 II 47 01/97Marcelo GiussaniNo ratings yet

- Smith-Jaeger - Chronometric OverhaulDocument4 pagesSmith-Jaeger - Chronometric OverhaulDamian RoweNo ratings yet

- Buku Manual Mesin Kisar UniversalDocument26 pagesBuku Manual Mesin Kisar Universalhill_me87No ratings yet

- Competencies: Automobile Transmission & Mechanism Course Code: 3330202Document7 pagesCompetencies: Automobile Transmission & Mechanism Course Code: 3330202DEADPOOL 2No ratings yet

- GV650 Parts Efi EditionDocument57 pagesGV650 Parts Efi EditionDavidson Esteves NunesNo ratings yet

- 2012 Uslmra RulesDocument34 pages2012 Uslmra RulesEvelyn ButcherNo ratings yet

- RE4F04ADocument374 pagesRE4F04AShowdown H. Blood100% (2)

- Tata Spacio Soft TopDocument72 pagesTata Spacio Soft TopxtempNo ratings yet

- Ford PartsDocument4 pagesFord PartsChandra Babu NaiduNo ratings yet

- ItemsDocument204 pagesItemsfattaninaveed786100% (1)

- Case IH CS 130 eDocument1 pageCase IH CS 130 eArmin van BurenNo ratings yet

- MDSPproblemsetDocument8 pagesMDSPproblemsetJustine SomentacNo ratings yet

- South Bend LatheDocument84 pagesSouth Bend LatheHoltelino TlocaletlasNo ratings yet

- Project End Semester Report - 6 Months Industrial Training - Mahindra and Mahindra - Swaraj Tractor DivisionDocument73 pagesProject End Semester Report - 6 Months Industrial Training - Mahindra and Mahindra - Swaraj Tractor DivisionHarpreet Randhawa67% (30)

- 6R80L 6R100 Zip inDocument12 pages6R80L 6R100 Zip inYisus 616No ratings yet

- 2012 Spring Master John DeereDocument120 pages2012 Spring Master John DeereEdgar Rojas Espejo33% (3)

- Kioti Daedong LK45 Tractor Service ManualDocument19 pagesKioti Daedong LK45 Tractor Service ManualLisakolyNo ratings yet

- Construction and Working of Single Plate ClutchDocument5 pagesConstruction and Working of Single Plate ClutchAmaran100% (1)

- Cat - Dcs.sis - Controller A6J JALFADocument25 pagesCat - Dcs.sis - Controller A6J JALFAMohammed EbrahimNo ratings yet

- Brochure A35F A40FDocument24 pagesBrochure A35F A40FRezhaNo ratings yet

- Online Technical Bulletin: Automatic Transmission Service GroupDocument4 pagesOnline Technical Bulletin: Automatic Transmission Service Groupvit83881825No ratings yet

- G T Start Up ProcedureDocument11 pagesG T Start Up ProcedureJJ100% (3)

- (GAS TURBINE MS 5001 PA) Volume IDocument159 pages(GAS TURBINE MS 5001 PA) Volume Ihayder ahmed100% (2)

- GearboxDocument7 pagesGearboxkismuganNo ratings yet

- Transmision A5hf Hyundai PDFDocument152 pagesTransmision A5hf Hyundai PDFIongornistuNo ratings yet

Service Information: October/04 II 25 01/04

Service Information: October/04 II 25 01/04

Uploaded by

Marcelo GiussaniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Service Information: October/04 II 25 01/04

Service Information: October/04 II 25 01/04

Uploaded by

Marcelo GiussaniCopyright:

Available Formats

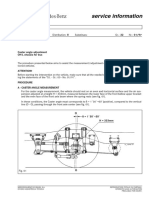

service information

Date: October/04 Distribution: II Substitues: Gr.: 25 Nr.: 01/04

if

Failure diagnosis in clutch drive master cylinders

Commercial vehicles

This circular letter has the scope to emphasize the importance of the correct bleeding of the hydraulic system in

order to obtain correct diagnoses, avoiding unnecessary replacement of clutch system components. Example:

master cylinders.

IMPORTANT: Before starting any job in the vehicle, be sure all required safety measures are followed as stated in

the “S.I. - Service and Safety - Gr.: 00 - Number: 01/91”.

PROCEDURES

The bleeding of the clutch hydraulic system consists in purging the air contained inside the clutch drive system

(cylinder and piping) replacing the air with brake fluid.

Procedures with the bleeding apparatus.

Follow the manufacturer’s instructions.

1 - Remove the fluid reservoir cap and attach the connecting piece of the

bleeding apparatus (1).

Example

DAIMLERCHRYSLER DO BRASIL LTDA. IN WHOLE OR PARTIAL REPRODUCTION

PROHIBITED WITHOUT PREVIOUS

WRITTEN AGREEMENT

S.I. 25 - 01/04

Page 02

2 - Adjust bleeding apparatus pressure to 1 bar.

3 - Lift off the protective cover and attach a transparent hose to the bleed-

ing bolt (arrow) to the slave cylinder.

• Remark: The brake fluid is not to be reused. Catch the fluid in a

suitable container and dispose it in an environmental way accord-

ing to the rules in force.

4 - Operate the bleeding apparatus until the brake fluid reaches the mini- Aparelho de sangria

mum level in the reservoir.

5 - Loosen the bleeding bolt and keep it loose until the brake fluid coming

off the transparent hose no longer contains air bubbles.

6 - Shut the bleeding bolt and depress the clutch pedal 3 to 5 times, keep-

ing it depressed in the last operation.

7 - Loosen the bleeding valve once again and check if there are any air in

the system. Example

8 - If air is detected coming off the hose after a few seconds, repeat procedures 5, 6 and 7.

9 - After confirming that there is no air in the system, tighten the bleeding bolt and detach the transparent hose,

relieve the pressure in the machine and detach the hose at the expansion reservoir.

Remarks:

• Check the brake fluid level in reservoir. Replenish if necessary.

• Use specified brake fluid.

Procedures without the bleeding apparatus.

1 - Check if the brake fluid in reservoir is at maximum level. Replenish if necessary.

Remarks:

• During the bleeding procedure the brake fluid level should not be allowed to get below the minimum level.

• Use specified brake fluid.

2 - The compressed air tanks in vehicle must be charged.

3 - Lift off the protective cover and attach a transparent hose to the bleed-

ing bolt (arrow) to the slave cylinder.

• Remark: The brake fluid is not to be reused. Catch the fluid in a

suitable container and dispose it in an environmental way accord-

ing to the rules in force.

4 - Depress the clutch pedal from 7 to 10 times holding it depressed in the

last operation.

Exemplo

5 - Loosen and tighten the bleeding bolt quickly checking at the transparent

S.I. 25 - 01/04

Page 02

hose if there is air in the system.

6 - If air bubbles are detected, repeat procedures 4 and 5 until its elimination.

Post bleeding procedures in case the results in the clutch system are not satisfactory.

1 - Check the positioning and conditions of the hydraulic master cylinder:

• The piston, when at rest, must be positioned at the snap-ring close to the face of the cylinder, and it should

not contain debris nor grease.

1 - Cylinder; 5 - Retaining ring;

2 - Snap-ring; 6 - Bellows;

3 - Spring; 7 - Rod;

4 - Piston with packings; A - Correct piston facing

NOTE: The cylinder piston in rest position must not be positioned along its stroke, as it is pushed by spring force

to its rest position.

• For the eventual cleaning of the master cylinder we recommend the use of ethyl alcohol, do not use gasoline,

solvents or paint thinner.

NOTE: Do not use the alcohol for more than 30 minutes to avoid drying out the packings.

• If there are traces of oxidation in the cylinder, use a fine sponge. Should the oxidation persist, replace the cyl-

inder.

2 - After carrying out the above steps, the clutch system should operate correctly. Should the fault persist, check

the connections, lines, slave cylinder and consequently the clutch disc and the clutch press plate. To obtain more

information refer to instructions in the SELiT (Electronic System of Technical Literature).

MERCEDES-BENZ

After-Sales

You might also like

- Stihl FS 130 Manual PDFDocument12 pagesStihl FS 130 Manual PDFGrundfos1989100% (2)

- 2 - Canrig Top Drive Rig Crew TrainingDocument104 pages2 - Canrig Top Drive Rig Crew TrainingDiego Fabian Ruiz Vacaflor89% (9)

- Manual Power Train Caterpillar 777d Off Highway Truck ComponentsDocument46 pagesManual Power Train Caterpillar 777d Off Highway Truck ComponentsDarmawan Putranto88% (25)

- AP Lockheed Remote Servo ManualDocument8 pagesAP Lockheed Remote Servo ManualjblodwellNo ratings yet

- Shogun R FD125XSD PDFDocument73 pagesShogun R FD125XSD PDFMichael Angelo Jandoc100% (1)

- Saab Official Service Manual: 900 16 Valve: 1985-1993 - ExcerptDocument2 pagesSaab Official Service Manual: 900 16 Valve: 1985-1993 - ExcerptBentley PublishersNo ratings yet

- Plunger Pump ManualDocument23 pagesPlunger Pump Manualgovindharajalu75% (4)

- Minor Project Report On Power Transmission in AutomobilesDocument77 pagesMinor Project Report On Power Transmission in AutomobilesMohitt Thakur81% (16)

- Case Studies On Industrial Accidents - 2Document84 pagesCase Studies On Industrial Accidents - 2Parth N Bhatt100% (2)

- PT Tech HPTO Clutch Control System - J1939 Diagnostic Trouble CodesDocument2 pagesPT Tech HPTO Clutch Control System - J1939 Diagnostic Trouble CodesgugiNo ratings yet

- Suzuki Shugun PDFDocument69 pagesSuzuki Shugun PDFPrashanthKumar33% (3)

- I and O-1012 - 1014 - 1015 - and 1017 Pumps 1-1Document9 pagesI and O-1012 - 1014 - 1015 - and 1017 Pumps 1-1Mo'men AdelNo ratings yet

- Cylinder Leakage Tester 2 - Gauge Vse2020.V3: 1. SafetyDocument2 pagesCylinder Leakage Tester 2 - Gauge Vse2020.V3: 1. Safetyhotmaail4No ratings yet

- Fitting Steering Pump SpidDocument15 pagesFitting Steering Pump SpidJuan GarcNo ratings yet

- Clu 1201Document1 pageClu 1201Aleix RamirezNo ratings yet

- MODEL V305000000 PMV 5:1 Oil Pump Series "A": Form 404421 MAR - 2012 SectionDocument12 pagesMODEL V305000000 PMV 5:1 Oil Pump Series "A": Form 404421 MAR - 2012 SectionFaidh Maulana Aksyar FaidhNo ratings yet

- Belt Filter PressDocument5 pagesBelt Filter PressMaku RajkumarNo ratings yet

- Valvula Doble Cheque DC-4 Bendix Manual de ServicioDocument4 pagesValvula Doble Cheque DC-4 Bendix Manual de Serviciojgomez30No ratings yet

- Maintenance and Repair InstructionsDocument12 pagesMaintenance and Repair InstructionsDhananjay NilkuteNo ratings yet

- Pump-Elite - Operating InstructionsDocument12 pagesPump-Elite - Operating Instructionsbookslover1No ratings yet

- PG1203Document17 pagesPG1203heriberto8280No ratings yet

- Cd250 Operation ManualDocument29 pagesCd250 Operation ManualThethanh PhamnguyenNo ratings yet

- Handbook Sealweld Valvulas de ProcesoDocument92 pagesHandbook Sealweld Valvulas de Procesofelipe castellanosNo ratings yet

- Forklift MaintenanceDocument11 pagesForklift MaintenanceTrường NguyenNo ratings yet

- Centrifugal Pump Checklist 2023Document7 pagesCentrifugal Pump Checklist 2023Caesar MutizeNo ratings yet

- L V406000000 GogigggDocument12 pagesL V406000000 Gogigggilyaswinduaji014No ratings yet

- MRP-004 - Brake Bleed - S08-001 v6.1Document4 pagesMRP-004 - Brake Bleed - S08-001 v6.1Matt CrossanNo ratings yet

- Holmatro PPU15Document16 pagesHolmatro PPU15riz333No ratings yet

- Centrifugal Pump MaintenanceDocument7 pagesCentrifugal Pump MaintenanceamasrurNo ratings yet

- VSE2020.V2: Cylinder Leakage TesterDocument2 pagesVSE2020.V2: Cylinder Leakage Testerwalson glen CrastaNo ratings yet

- IFRC - Customer Technical Training (RP - CPP2)Document24 pagesIFRC - Customer Technical Training (RP - CPP2)firdausshukri14No ratings yet

- Motion Pro Leak Test 2TDocument1 pageMotion Pro Leak Test 2TLeandro CaraccioliNo ratings yet

- tb9 2300 426 20Document20 pagestb9 2300 426 20Rolando DaclanNo ratings yet

- ENP-652 Cylinder Boss Wear and RepairDocument7 pagesENP-652 Cylinder Boss Wear and RepaireparodiesNo ratings yet

- WALLACH LL100 TWO TRIGGER CRYOSURGICAL UNIT For N2O Instructions For UseDocument8 pagesWALLACH LL100 TWO TRIGGER CRYOSURGICAL UNIT For N2O Instructions For UsePierre Richard MompremierNo ratings yet

- Maintenance ManualDocument32 pagesMaintenance Manualpratik2429No ratings yet

- Bleeding Hydraulics With No Bleeders 1Document1 pageBleeding Hydraulics With No Bleeders 1balmohankNo ratings yet

- A Procedure For Lube Oil FlushingDocument9 pagesA Procedure For Lube Oil FlushingBrosGeeNo ratings yet

- Amsoil Automatic Transmission Flush ProcedureDocument2 pagesAmsoil Automatic Transmission Flush ProcedureThomas JohnsonNo ratings yet

- EHS Moment - Compressed Gases - Inspection of Gas Cylinder - 12 Oct 23Document2 pagesEHS Moment - Compressed Gases - Inspection of Gas Cylinder - 12 Oct 23sanalkumar24No ratings yet

- Maintenance: Outboard CareDocument18 pagesMaintenance: Outboard Careshygal1981100% (1)

- Start Up Form MPDocument5 pagesStart Up Form MPBUDAPESNo ratings yet

- PT 102662 Iom UsDocument5 pagesPT 102662 Iom UsMo ZeroNo ratings yet

- Portatil AmerexDocument8 pagesPortatil AmerexGrillin GmNo ratings yet

- Mercury Maintenance ManualDocument27 pagesMercury Maintenance ManualJens Adam Hedegaard HansenNo ratings yet

- Mirage g4 Gls at ModelDocument3 pagesMirage g4 Gls at ModelSol S.No ratings yet

- Inspection and Overhaul For Reciprocating CompressorDocument79 pagesInspection and Overhaul For Reciprocating CompressorSalik Ali SyedNo ratings yet

- Kbu KBZ1Document4 pagesKbu KBZ1Andrew VNo ratings yet

- Manual For Hand Portable Halon 1211 ExtinguishersDocument8 pagesManual For Hand Portable Halon 1211 ExtinguishersMatthew ShalkNo ratings yet

- Unit Ii Inspection of Piston EngineDocument45 pagesUnit Ii Inspection of Piston Engineraj6062No ratings yet

- LPG MultivalvesDocument55 pagesLPG MultivalvesAPINo ratings yet

- dp7490 Pump ManualDocument16 pagesdp7490 Pump Manualvipequi50No ratings yet

- IB272Document2 pagesIB272Rodney AlvaradoNo ratings yet

- 3088 Instruction Manual (D) - 230911 - 142910Document20 pages3088 Instruction Manual (D) - 230911 - 142910gguadian21No ratings yet

- YWE P250 ManualDocument21 pagesYWE P250 ManualNuriffah Izzah100% (1)

- Instruct For OperationDocument1 pageInstruct For OperationAriel Martinez NNo ratings yet

- Liquid Ring Pump ManualDocument25 pagesLiquid Ring Pump ManualCornelius Toni KuswandiNo ratings yet

- ENP-562 CNG Field Service Bulletin Foam Cap Dome Installation RepairDocument9 pagesENP-562 CNG Field Service Bulletin Foam Cap Dome Installation RepaireparodiesNo ratings yet

- TB018 Cylinder Compression Test v2021Document2 pagesTB018 Cylinder Compression Test v2021Cristhian HuilcapazNo ratings yet

- Air Hydraulic Pump OTC EnglishDocument8 pagesAir Hydraulic Pump OTC EnglishEdSoloNo ratings yet

- Portable Cargo Pump TK80 Simillar To Marflex Portable PPDocument18 pagesPortable Cargo Pump TK80 Simillar To Marflex Portable PPSubramoniam MarineNo ratings yet

- Brake Bleeding: Service and Repair Brake System BleedingDocument3 pagesBrake Bleeding: Service and Repair Brake System BleedingSauli KlaavuNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- IS064IDocument2 pagesIS064IMarcelo GiussaniNo ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- Service Information: August/99 II 00 06/99Document2 pagesService Information: August/99 II 00 06/99Marcelo GiussaniNo ratings yet

- Service Information: December/99 II 58 10/99Document2 pagesService Information: December/99 II 58 10/99Marcelo GiussaniNo ratings yet

- Service Information: January/00 II 00 01/00Document10 pagesService Information: January/00 II 00 01/00Marcelo GiussaniNo ratings yet

- Service Information: Execution With CapDocument4 pagesService Information: Execution With CapMarcelo GiussaniNo ratings yet

- Service Information: November/99 I 35 01/99Document2 pagesService Information: November/99 I 35 01/99Marcelo GiussaniNo ratings yet

- Service Information: November/98 I 54 13/98Document14 pagesService Information: November/98 I 54 13/98Marcelo GiussaniNo ratings yet

- Service Information: December/99 II 58 09/99Document2 pagesService Information: December/99 II 58 09/99Marcelo GiussaniNo ratings yet

- Service Information: November/98 I 54 09/98Document14 pagesService Information: November/98 I 54 09/98Marcelo GiussaniNo ratings yet

- Service Information: September/98 II 26 07/98Document4 pagesService Information: September/98 II 26 07/98Marcelo GiussaniNo ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- Service Information: June/98 II 26 05/98Document2 pagesService Information: June/98 II 26 05/98Marcelo GiussaniNo ratings yet

- Service InformationDocument4 pagesService InformationMarcelo GiussaniNo ratings yet

- Service Information: May/97 II 32 01/97Document2 pagesService Information: May/97 II 32 01/97Marcelo GiussaniNo ratings yet

- Service Information: September/98 II 58 04/98Document10 pagesService Information: September/98 II 58 04/98Marcelo GiussaniNo ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- Service Information: May/98 II 58 03/98Document2 pagesService Information: May/98 II 58 03/98Marcelo GiussaniNo ratings yet

- Service Information: ST ND RD ST STDocument2 pagesService Information: ST ND RD ST STMarcelo GiussaniNo ratings yet

- Service Information: August/96 II 54 - Nº: 0695 54 04/96Document2 pagesService Information: August/96 II 54 - Nº: 0695 54 04/96Marcelo GiussaniNo ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- Service Information: July/97 I 54 09/97Document2 pagesService Information: July/97 I 54 09/97Marcelo GiussaniNo ratings yet

- Service Information: July/97 II 54 - Nº: 02/97 54 10/97Document2 pagesService Information: July/97 II 54 - Nº: 02/97 54 10/97Marcelo GiussaniNo ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- Service Information: July/97 I 25 01/97Document2 pagesService Information: July/97 I 25 01/97Marcelo GiussaniNo ratings yet

- Service Information: May/97 I 41 01/97Document2 pagesService Information: May/97 I 41 01/97Marcelo GiussaniNo ratings yet

- Service Information: May/97 II 01 01/97Document2 pagesService Information: May/97 II 01 01/97Marcelo GiussaniNo ratings yet

- Service Information: April/97 II 47 01/97Document2 pagesService Information: April/97 II 47 01/97Marcelo GiussaniNo ratings yet

- Smith-Jaeger - Chronometric OverhaulDocument4 pagesSmith-Jaeger - Chronometric OverhaulDamian RoweNo ratings yet

- Buku Manual Mesin Kisar UniversalDocument26 pagesBuku Manual Mesin Kisar Universalhill_me87No ratings yet

- Competencies: Automobile Transmission & Mechanism Course Code: 3330202Document7 pagesCompetencies: Automobile Transmission & Mechanism Course Code: 3330202DEADPOOL 2No ratings yet

- GV650 Parts Efi EditionDocument57 pagesGV650 Parts Efi EditionDavidson Esteves NunesNo ratings yet

- 2012 Uslmra RulesDocument34 pages2012 Uslmra RulesEvelyn ButcherNo ratings yet

- RE4F04ADocument374 pagesRE4F04AShowdown H. Blood100% (2)

- Tata Spacio Soft TopDocument72 pagesTata Spacio Soft TopxtempNo ratings yet

- Ford PartsDocument4 pagesFord PartsChandra Babu NaiduNo ratings yet

- ItemsDocument204 pagesItemsfattaninaveed786100% (1)

- Case IH CS 130 eDocument1 pageCase IH CS 130 eArmin van BurenNo ratings yet

- MDSPproblemsetDocument8 pagesMDSPproblemsetJustine SomentacNo ratings yet

- South Bend LatheDocument84 pagesSouth Bend LatheHoltelino TlocaletlasNo ratings yet

- Project End Semester Report - 6 Months Industrial Training - Mahindra and Mahindra - Swaraj Tractor DivisionDocument73 pagesProject End Semester Report - 6 Months Industrial Training - Mahindra and Mahindra - Swaraj Tractor DivisionHarpreet Randhawa67% (30)

- 6R80L 6R100 Zip inDocument12 pages6R80L 6R100 Zip inYisus 616No ratings yet

- 2012 Spring Master John DeereDocument120 pages2012 Spring Master John DeereEdgar Rojas Espejo33% (3)

- Kioti Daedong LK45 Tractor Service ManualDocument19 pagesKioti Daedong LK45 Tractor Service ManualLisakolyNo ratings yet

- Construction and Working of Single Plate ClutchDocument5 pagesConstruction and Working of Single Plate ClutchAmaran100% (1)

- Cat - Dcs.sis - Controller A6J JALFADocument25 pagesCat - Dcs.sis - Controller A6J JALFAMohammed EbrahimNo ratings yet

- Brochure A35F A40FDocument24 pagesBrochure A35F A40FRezhaNo ratings yet

- Online Technical Bulletin: Automatic Transmission Service GroupDocument4 pagesOnline Technical Bulletin: Automatic Transmission Service Groupvit83881825No ratings yet

- G T Start Up ProcedureDocument11 pagesG T Start Up ProcedureJJ100% (3)

- (GAS TURBINE MS 5001 PA) Volume IDocument159 pages(GAS TURBINE MS 5001 PA) Volume Ihayder ahmed100% (2)

- GearboxDocument7 pagesGearboxkismuganNo ratings yet

- Transmision A5hf Hyundai PDFDocument152 pagesTransmision A5hf Hyundai PDFIongornistuNo ratings yet