Professional Documents

Culture Documents

Flux 4380.MSDS.2018

Flux 4380.MSDS.2018

Uploaded by

paulus hermanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flux 4380.MSDS.2018

Flux 4380.MSDS.2018

Uploaded by

paulus hermanCopyright:

Available Formats

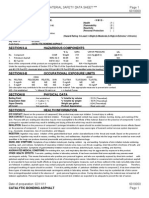

MATERIAL SAFETY DATA SHEET

1. IDENTIFICATION OF THE SUBSTANCE AND COMPANY

DESCRIPTION : Salt Flux

PRODUCT NAME : Flux 4380

MANUFACTURER : PT. REFRATECH MANDALAPERKASA

ADDRESS : Jln. Mayor Oking, Kampung Kamurang No 7 A,Rt002/006

Puspanegara Citeureup, Bogor – Indonesia. 16810

TELP : (62)21 87941455

FAX : (62) 21 8752624

CONTACT PERSON : AJI (TECHNICAL PRODUCT)

2. INFORMATION ON INGREDIENTS

TR Y

CHEMICAL NAME CAS NO NIOSH OSHA PEL ACGIH TLV WEIGHT%

Sodium Chloride 77647-14-5 n/I1 15*,5** 10 > 50

N IT

L

Sodium Fluorosilicate 16893-85-9 none 2.5 (F-) 2.5 (F-) > 20

Sodium Carbonate 5968-11-6 n/I1 15*,5** 10 < 10

O

AL

*,** Values expressed in mg/m3 * Total dust, ** Respirable dust

1 Classed as particulates, not otherwise classified

3. HAZARD IDENTIFICATION

IRRITANT

Causes eye, skin and inhalation irritation. Toxic – harmful by inhalation

Use proper engineering controls, work practices, and personal protective equipment to

U

prevent exposure to wet or dry product.

EMERGENCY OVERVIEW

Slag is a solid, grey/black or brown/ tan, odorless powder. It is not combustible or

explosive. A single, short-term exposure to the dry powder presents little or no hazard.

Q

POTENTIAL HEALTH EFFECTS

- Eye contact

Airborne dust may cause immediate or delayed irritation or inflammation. Eye contact

with large amounts of dry powder or with wet slag can cause moderate eye irritation.

Eye exposures require immediate first aid to prevent significant damage to the eye.

O

- Skin contact

Slag may cause dry skin, discomfort, irritation, and dermatitis

Dermatitis :

Slag is capable of causing dermatitis by irritation and allergy. Skin affected by dermatitis

may include symptoms such as, redness, itching, rash, scaling, and cracking. Irritant

C

dermatitis is caused by the physical properties of slag including moisture and abrasion.

Allergic contact dermatitis is caused by sensitization to hexavalent chromium (chromate)

present in slag. The reaction can range from a mild rash to severe skin ulcers. Persons

already sensitized may react to the first contact with slag. Others may develop allergic

dermatitis after years of repeated contact with slag.

- Inhalation (acute)

Breathing dust may cause nose, throat or lung irritation, including choking, depending

onthe degree of exposure.

- Inhalation (chronic)

Risk of injury depends on duration and level of exposure

Silicosis :

This product contains crystalline silica. Prolonged or repeated inhalation of respirable

crystalline silica from this product can cause silicosis, a seriously disabling and fatal lung

disease.

MSDS OF FLUX 4380 Page 1

Carcinogenicity :

Slag is not listed as a carcinogen by IARC or NTP, however slag caontains trace amounts of

crystalline silica and hexavalent chromium which are classified by IARC and NTP as known

human carcinogens.

Autoimmune disease :

Some studies show that exposure to respirable crystalline silica (without silicosis) or that the

disease silicosis may be associated with the increased incidence of several autoimmune

disorders such as scleroderma (thickening of the skin), systemic lupus erythematosus,

rheumatoid arthritis and diseases affecting the kidneys

Tuberculosis :

Silicosis increases the risk of tuberculosis

Renal diseases :

Some studies show an increased incidence of chronic kidney disease and end-stage renal

disease in workers exposed to respirable crystalline silica

- Ingestion

Do not ingest slag. Ingestion of small quantities of slag is not known to be harmful, large

quantities can cause distress to the digestive tract

- Medical conditions aggravated by exposure

Individuals with lung disease (e.g. bronchitis, emphysema, COPD, pulmonary disease) or

sensitivity to hexavalent chromium can be aggravated by exposure.

TR Y

4. FIRST AID MEASURES

N IT

EYE CONTACT

- Rinse eyes thoroughly with water for at least 15 minutes, including under lids, to remove

L

all particles. Seek medical attention for abbrasions.

SKIN CONTACT

- Wash with cool water and a pH neutral soap or a mild skin detergent. Seek medical

O

attention for rash, irritation, dermatitis, and prolonged unprotected exposures to wet slag,

AL

cement, cement mixtures or liquids from wet cement

INHALATION

• Move person to fresh air. Seek medical attention for discomfort or if coughing or other

symptoms do not subside

INGESTION

- Do not induce vomiting. If conscious, have person drink plenty of water. Seek medical

attention or contact poison control center immediately

U

NOTE TO PHYSICIAN - The three types of silicosis include :

* Simple chronic silicosis – which results from long-term exposure (more than 20 years) to

low amounts of respirable crystalline silica. Nodules of chronic inflammation and

scarring provoked by the respirable crystalline silica from in the lungs and chest lymph

Q

nodes. This disease may feature breathlessness and may resemble chronic obstructive

pulmonary disease (COPD)

* Accelerated silicosis – occurs after exposure to larger amounts of respirable crystalline

silica over a shorter period of time ( 5-15 years). Inflammation, scarring, and symptoms

progress faster in accelerated silicosis than in simple silicosis.

O

* Acute silicosis – results from short-term exposure to very large amounts of respirable

crystalline silica. The lungs become very inflamed and may fill with fluid, causing severe

shortness of breath and low blood oxygen levels.

Progressive massive fibrosis may occur in simple or accelerated silicosis, but is more

C

common in the accelerated form. Progressive massive fibrosis results from severe scarring

and leads to the destruction of normal lung structures.

5. FIREFIGHTING MEASURES

Flammability : Non Flammbale

Flashpoint and method : Non- combustible

General hazard : Avoid breathing dust

Extinguishing media : Use extinguishing media appropriate for surrounding fire

Firefighting equipment : Slag poses no fire-related hazard. A SCBA is recommended to limit

exposures to combustion products when fighting any fire

Combustion products : None

MSDS OF FLUX 4380 Page 2

6. ACCIDENTAL RELEASE MEASURES

GENERAL

- Place spilled material into a container. Avoid actions that cause the slag to become

airborne. Avoid inhalation of slag and contact with skin. Wear appropriate protective

equipment as described in section 9. scrape wet slag and place in container. Allow material

to dry or solidify before disposal. Do not wash slag down sewage and drainage systems or

into bodies of water (e.g. streams).

WASTE DISPOSAL METHOD

- Disposal of slag according to Federal, State, Provincial and Local regulations

7. HANDLING AND STORAGE

GENERAL

- Handle with care and use appropriate control measures. Keep bulk slag and cement dry

until used. When slag is kept wet for long periods of time, the leachate may be discolored

and have a sulfurous odor. When this liquid is exposed to oxygen elemental sulfur may

precipitate out leaving a solution of calcium thiosulfate.

Engulfment hazard. To prevent burial or suffocation, do not enter a confined space, such

as a silo, bin, bulk truck, or other storage container or vessel that stores or contains slag

or cement. Slag and cement can buildup or adhere to the walls of a confined space. The

TR Y

slag or cement can release, collapse or fall unexpectedly

Properly ground all pneumatic conveyance systems. The potential exist for static build-up

and static discharge when moving powders through a plastic, non-conductive, or non-

N IT

grounded pneumatic conveyance system. The static discharge may result in damage to

equipment and injury to workers.

L

USAGE

- Cutting, crushing or grinding hardened cement, concrete or other crystalline silica-

bearing materials will release respirable crystalline silica. Use all appropriate

O

measures of dust control or supperssions, and Personal Protective Equipment (PPE) .

AL

HOUSEKEEPING

- Avoid actions that cause the slag to become airborne during clean-up such as dry sweeping

or using compressed air. Use HEPA vacuum or thoroughly wet with water to clean-up dust.

STORAGE TEMPERATURE

- Unlimited

STORAGE PRESSURE

- Unlimited

U

CLOTHING

- Promptly remove and launder clothing that is dusty or wet with slag or cement. Thoroughly

wash skin after exposure to dust or wet slag or cement

Q

8. EXPOSURE CONTROLS AND PERSONAL PROTECTION

ENGINEERING CONTROLS

- Use local exhaust or general dilution ventilation or other suppression methods to maintain

O

dust levels below exposure limits

PERSONAL PROTECTIVE EQUIPMENT (PPE)

- Respiratory

Under ordinary conditions no respiratory protection is required. Wear a NIOSH

- Protection

C

Approved respirator that is properly fitted and is in good condition when exposed to dust

above exposure limits

- Eye protection

Wear ANSI approved glasses or safety goggles when handling dust or wet slag to prevent

contact with eyes. Wearing contact lenses when using slag, under dusty conditions, is

not recommended

- Skin protection

Wear gloves, boot covers and protective clothing impervious to water to prevent skin

contact. Do not rely on barrier creams, in place of impervious gloves. Remove clothing and

protective equipment that becomes saturated with wet slag or cement and

immediately wash exposed areas.

MSDS OF FLUX 4380 Page 3

9. PHYSICAL AND CHEMICAL PROPERTIES

Freezing point : N/A Vapor pressure : N/A

Melting point : approx 1256 - 15620 F Vapor density : N/A

Boiling point : N/A Specific gravity (g/cc) : max 2.7

Sublimes : N/A % Volatiles : none

Evaporation : N/A

Appearance and odor : white crystalline and no odor

10. STABILITY AND REACTIVITY DATA

STABILITY

- Stable. Keep dry until use. Slag may react with water resulting in a slight release of heat,

depending on the amount of lime (calcium dioxide) present. Avoid contact with incompatible

materials.

INCOMPATIBILITY

- Slag is incompatible with acids, ammonium salts and aluminium metal. Slag and cement

TR Y

dissolves in hydrofluoric acid, producing corrosive silicon tetrafluoride gas. Slag and

cmenet reacts with water to form silicates and calcium hydroxide. Silicates react with

powerful oxidizers such as fluorine, boron trifluoride, chlorine trifluoride, manganese

trifluoride, and oxygen difluoride.

N IT

HAZARDOUS POLYMERIZATION

L

- None

HAZARDOUS DECOMPOSITION

- Hydrogen sulfide gas may be released from moist or wet slag with it is heated

O

AL

11. TOXICOLOGICAL INFORMATION

Routes of Entry : Inhalation. Ingestion.

Toxicity to Animals : Acute oral toxicity (LD50): 70 mg/kg [Mouse].

Chronic Effects on Humans : CARCINOGENIC EFFECTS: A4 (Not classifiable for human or

animal.) by ACGIH, 3 (Not classifiable for human.) by IARC.

Other Toxic Effects on Humans : Hazardous in case of skin contact (irritant), of ingestion,

of inhalation.

U

Special Remarks on Toxicity to Animals : Not available.

Special Remarks on Chronic Effects on Humans : May cause cancer based on animal test

data. No human data found.

Special Remarks on other Toxic Effects on Humans :

Q

Acute Potential Health Effects: Skin: Causes mild to moderate skin irritation. Symptoms may

include redness, burning sensation (feeling), and sometimes ulcers. Eyes: Causes moderate

to severe irritation. Inhalation: It can irritate the nose,throat, lungs causing coughing,

wheezing and/or shortness of breath Ingestion: Harmful if swallowed. It is toxic by oral

exposure route. Symptoms of acute ingestion include a salty or soapy taste in the mouth,

O

excessive salivation, nausea, abdominal cramps, vomiting, diarrhea, thirst. It may also affect

behavior/central nervous system (central nervous system depression, muscle weakness,

tremors or spasms, ataxia, convulsions) and may also cause disturbed color vision, kidney

damage, liver damage, bleeding from the stomach, shortness of breath, loss of conciousness

or death.

C

Chronic Potential

Health Effects: Skin: Repeated or prolonged skin contact may produce pustular rash.

Inhalation or Ingestion: Prolonged or repeated exposure may cause excess respiratory,

cardiac, and gastrointestinal disturbances, and chronic bronchitis. It may also cause liver

and kidney damage, fluorosis and osteosclerosis. Fluorosis can cause mottling of teeth

12. ECOLOGICAL INFORMATION

Ecotoxicity : Not available.

BOD5 and COD :Not available

Special Remarks : When working with fluoride containing salts it is advisable : to wear eye

protection, a NIOSH approved respirator, and gloves to limit exposure. Contact with the

actual material should be minimized. Always wash thoroughly prior to eating or smoking.

MSDS OF FLUX 4380 Page 4

13. DISPOSAL CONSIDERATIONS

Dispose of waste and containers in compliance with applicable Federal, State, Provincial and

Local regulations

14. TRANSPORT INFORMATION

The data provided in this section is for information only and may not be specific to your

package size or mode of transport. You will need to apply the appropriate regulations to

properly classify your shipment for transportation. International transport regulations is not

regulated.

15. OTHER REGULATORY INFORMATION

Not regulated as dangerous products.

This material is not regulated by the DOT for land transportation.

Other Special Considerations : Not available

He a lt h 2

Fire 0

TR Y

Re a c t iv it y 0

P e rs o n a l A

P ro t e c tion

16.

N IT

OTHER INFORMATION

L

DATE PREPARED : 2011

DATE REVISED2nd : NOVEMBER 2017

O

DEFINITIONS :

AL

CAS : Chemical Abstracts Service Registry Number

NIOSH : National Institute for Occupational Safety and Health

OSHA : Occupational Safety and Health Administration

PEL : Permissible Exposure Limit

TLV :Threshold Limit Values ( ACGIH, American Conference of Governmental Industrial

Hygienists )

U

Q

O

C

MSDS OF FLUX 4380 Page 5

You might also like

- Limestone MSDSDocument6 pagesLimestone MSDSSamuel GaétanNo ratings yet

- Duke Energy Flyash MSDSDocument4 pagesDuke Energy Flyash MSDSSteven HowellNo ratings yet

- MSDS - Bostik 2402Document6 pagesMSDS - Bostik 2402Brian WelshNo ratings yet

- MSDS TccaDocument6 pagesMSDS Tccamita wahyuniNo ratings yet

- Material Safety Data Sheet: MSDS: Lafarge Fly Ash & Bottom AshDocument6 pagesMaterial Safety Data Sheet: MSDS: Lafarge Fly Ash & Bottom AshVăn phòng Phân xưởng Vận hành 1No ratings yet

- MSDS North America English - Natural GypsumDocument6 pagesMSDS North America English - Natural GypsumFauzi SunthreeNo ratings yet

- SDS - PLCDocument14 pagesSDS - PLCdeekshithNo ratings yet

- Cement Opc MSDSDocument6 pagesCement Opc MSDSmjaseemksNo ratings yet

- MSDS - Tuff-Krete HD - Part DDocument6 pagesMSDS - Tuff-Krete HD - Part DAl GuinitaranNo ratings yet

- Concrete MSDS 4 PDFDocument8 pagesConcrete MSDS 4 PDFmanil_5No ratings yet

- Msds p500 NagpurDocument7 pagesMsds p500 NagpurAnkur BarsainyaNo ratings yet

- Material Safety Data Sheet Ambuja Hirise CementDocument7 pagesMaterial Safety Data Sheet Ambuja Hirise CementMukesh KatarnavareNo ratings yet

- MSDS DiamondDocument4 pagesMSDS DiamondVishwakarma VishwakarmaNo ratings yet

- Concrete Mix: Safety Data SheetDocument5 pagesConcrete Mix: Safety Data SheetLily ShubinaNo ratings yet

- Material Safety Data Sheet MSDS NR:: Calcium Oxide CO001Document5 pagesMaterial Safety Data Sheet MSDS NR:: Calcium Oxide CO001mohdsuhail2k3055No ratings yet

- Material Safety Data SheetDocument4 pagesMaterial Safety Data SheetManivannan ChinnathambiNo ratings yet

- Holcimnz Sds EcoplanetDocument6 pagesHolcimnz Sds Ecoplanetmartinezryan725No ratings yet

- Safety Data Sheet Portland Cement Kiln Dust: Section 1: IdentificationDocument19 pagesSafety Data Sheet Portland Cement Kiln Dust: Section 1: Identificationomar rahmounNo ratings yet

- Material Safety Data Sheet (MSDS) : AggregatesDocument6 pagesMaterial Safety Data Sheet (MSDS) : AggregatesGemmar AmpoNo ratings yet

- 1101 Audrey Blackman Portelan Pasta 1250kgDocument3 pages1101 Audrey Blackman Portelan Pasta 1250kgmiha bNo ratings yet

- Geoscience Testing Laboratory: Material Safety Data SheetDocument4 pagesGeoscience Testing Laboratory: Material Safety Data SheetAnonymous G6ceYCzwtNo ratings yet

- Safety Data Sheet: Section 1. IdentificationDocument13 pagesSafety Data Sheet: Section 1. IdentificationharNo ratings yet

- P B Msds HydroxideDocument5 pagesP B Msds HydroxideJulioNo ratings yet

- Safety Data Sheet Loctite Super Glue Liquid: 1 Identification of The Substance/Preparation and Company/UndertakingDocument4 pagesSafety Data Sheet Loctite Super Glue Liquid: 1 Identification of The Substance/Preparation and Company/UndertakingqualityfreekNo ratings yet

- General Purpose Cement and Portland Cement - Safety Data SheetDocument5 pagesGeneral Purpose Cement and Portland Cement - Safety Data SheetLily ShubinaNo ratings yet

- Rapid Set Repair MaterialDocument7 pagesRapid Set Repair Materialsam damsNo ratings yet

- Natural Gypsum MSDS 2017Document6 pagesNatural Gypsum MSDS 2017Beautty Rahma ThikaNo ratings yet

- MSDS Cement ITPDocument6 pagesMSDS Cement ITPbobby birowoNo ratings yet

- Chlorine MSDSDocument4 pagesChlorine MSDSjoesuhreNo ratings yet

- Flyash Msds KenzoDocument5 pagesFlyash Msds KenzoErianto XuNo ratings yet

- MSDS DECON Beton InstanDocument5 pagesMSDS DECON Beton InstanMuhammad Ridwan100% (1)

- Material Safety Data Sheet Blended Cement FinalDocument14 pagesMaterial Safety Data Sheet Blended Cement FinalAndrea Dela CruzNo ratings yet

- Msds-Oreas (Nram)Document7 pagesMsds-Oreas (Nram)Heber Diaz ChavezNo ratings yet

- Material Safety Data Sheet Ethyl AlcoholDocument5 pagesMaterial Safety Data Sheet Ethyl Alcoholfred_marrufoNo ratings yet

- MSDS Petropath LimeDocument8 pagesMSDS Petropath LimeAlok SinghNo ratings yet

- Section I: Material Safety Data Sheet Date of Preparation: 02/11/11 6010000Document2 pagesSection I: Material Safety Data Sheet Date of Preparation: 02/11/11 6010000sebaversaNo ratings yet

- Sds Portland CementDocument11 pagesSds Portland Cementkwame fosterNo ratings yet

- 7 ?@'abcd - A+e FD', GHDDocument4 pages7 ?@'abcd - A+e FD', GHDPankaj UpadhyayNo ratings yet

- Material Safety Data Sheet: Section 1 - Chemical Product and Company IdentificationDocument7 pagesMaterial Safety Data Sheet: Section 1 - Chemical Product and Company IdentificationTeresa SilvaNo ratings yet

- MSDS Potassium DichromateDocument6 pagesMSDS Potassium DichromateIgede Sadiamba PNo ratings yet

- Fly Ash - Bottom Ash: Safety Data SheetDocument5 pagesFly Ash - Bottom Ash: Safety Data SheetMatt LNo ratings yet

- 1 Msds Naoh TeknisDocument5 pages1 Msds Naoh TeknisPita Sasa ShopNo ratings yet

- Dolomite 60 Dried SDS 6-28-20Document10 pagesDolomite 60 Dried SDS 6-28-20keshav44No ratings yet

- MSDS 80%Document6 pagesMSDS 80%Sales IndoreNo ratings yet

- Safety Data Sheet: Portland Cement ClinkerDocument11 pagesSafety Data Sheet: Portland Cement ClinkerJuan HenaoNo ratings yet

- SludgeDocument6 pagesSludgefahmiNo ratings yet

- Concrete MSDS 1 PDFDocument5 pagesConcrete MSDS 1 PDFmanil_5100% (1)

- Crystalline Silica SDSDocument9 pagesCrystalline Silica SDSJustin ChongNo ratings yet

- Australian Builders Ground SlagDocument5 pagesAustralian Builders Ground SlagDirga Delonix RegiaNo ratings yet

- CEMENTtDocument6 pagesCEMENTtmartinezryan725No ratings yet

- Potassium HydroxideDocument10 pagesPotassium HydroxideSyahrul MtiNo ratings yet

- Holcimnz Sds Envirocore100Document5 pagesHolcimnz Sds Envirocore100martinezryan725No ratings yet

- Odessa Portland Cement CoDocument7 pagesOdessa Portland Cement Cosaa6383No ratings yet

- Silica Sand MSDSDocument4 pagesSilica Sand MSDSAchmad Syariful HidayatNo ratings yet

- Silica Sand MSDS PDFDocument4 pagesSilica Sand MSDS PDFFadelNo ratings yet

- CASDS29 Rapid Set ConcreteDocument7 pagesCASDS29 Rapid Set ConcretedaveNo ratings yet

- Msds Eurokyd Bs36 Tx60Document4 pagesMsds Eurokyd Bs36 Tx60roybombomNo ratings yet

- Material Safety Data SheetsDocument6 pagesMaterial Safety Data Sheetsanhvnl6409No ratings yet

- PSA 580 Focus NotesDocument1 pagePSA 580 Focus Noteskristel-marie-pitogo-4419No ratings yet

- Nareg - Make It OutDocument2 pagesNareg - Make It OutLevani JavakhadzeNo ratings yet

- Print - Udyam Registration CertificateDocument2 pagesPrint - Udyam Registration CertificateanandranisatiNo ratings yet

- Kinh tế quốc tếDocument11 pagesKinh tế quốc tếLy Nguyễn Thị HươngNo ratings yet

- A. Identify The Weaknesses in Supremo's Internal Control Concerning The Purchases and Payments FunctionsDocument1 pageA. Identify The Weaknesses in Supremo's Internal Control Concerning The Purchases and Payments FunctionsTrâm LêNo ratings yet

- GAY DEL: TICKET - ConfirmedDocument3 pagesGAY DEL: TICKET - ConfirmedRajat RanjanNo ratings yet

- Advantages of UNM2000Document49 pagesAdvantages of UNM2000João LimaNo ratings yet

- DN500 Mounting Flange Installation ManualDocument12 pagesDN500 Mounting Flange Installation ManualSreekanthNo ratings yet

- SP Whitepaper Managing Your Contingent WorkforceDocument24 pagesSP Whitepaper Managing Your Contingent WorkforceVijayNo ratings yet

- SM Presentation On Garment IndustryDocument14 pagesSM Presentation On Garment IndustrytariqueshadabNo ratings yet

- Form 27Document1 pageForm 27JORDANNo ratings yet

- Grocery GuruDocument51 pagesGrocery GuruAbhishek Gautam0% (1)

- Global Village-OBassignmentDocument10 pagesGlobal Village-OBassignmentMOJAHID HASAN Fall 19No ratings yet

- USSEC 2021 Global Soy Foods Market OverviewDocument73 pagesUSSEC 2021 Global Soy Foods Market OverviewgiangNo ratings yet

- InternshipDocument65 pagesInternshipMohammed AhmedNo ratings yet

- Storm Review - Boost Your Commissions To The Max by Exploiting A $39.9B Dollar LoopholeDocument8 pagesStorm Review - Boost Your Commissions To The Max by Exploiting A $39.9B Dollar LoopholeHue TestPrepNo ratings yet

- Gonzales Cannon Oct 18 IssueDocument42 pagesGonzales Cannon Oct 18 IssueGonzales CannonNo ratings yet

- Steel Slab Rolling TechnologyDocument124 pagesSteel Slab Rolling TechnologylouisgatewayNo ratings yet

- RAB Jetty Dan Stock PileDocument1 pageRAB Jetty Dan Stock PilebimobimoprabowoNo ratings yet

- ADM NO: 1029667 Name: Omariba Sandra Moraa Unit Code: CMM 423 Unit Name: Public Relations Lecturer: Mr. MoyoDocument8 pagesADM NO: 1029667 Name: Omariba Sandra Moraa Unit Code: CMM 423 Unit Name: Public Relations Lecturer: Mr. MoyoKelvin MuemaNo ratings yet

- Prices Revenue Manageme NT: Setting and ImplementingDocument36 pagesPrices Revenue Manageme NT: Setting and ImplementingAl ImranNo ratings yet

- Enterprise Goverment - AssignmentDocument2 pagesEnterprise Goverment - AssignmentLokeraj RupnarainNo ratings yet

- Midterms Exam Tech BsitDocument8 pagesMidterms Exam Tech BsitAC GanadoNo ratings yet

- File DelDocument280 pagesFile DelCreoNo ratings yet

- Routes To Market ProcessDocument15 pagesRoutes To Market ProcessPetrNo ratings yet

- Aia Smart Growth BrochureDocument8 pagesAia Smart Growth BrochurebutterNo ratings yet

- HmsDocument13 pagesHmsveerNo ratings yet

- OSH in Vocational CollegesDocument10 pagesOSH in Vocational Collegescivichitam18No ratings yet

- Business Plan GuideDocument18 pagesBusiness Plan GuideAsrat AlemuNo ratings yet

- Nike's Digital Transformation Into Metaverse (22247094)Document23 pagesNike's Digital Transformation Into Metaverse (22247094)Academic HubNo ratings yet