Professional Documents

Culture Documents

Elc Catalog

Elc Catalog

Uploaded by

Rajesh SirsathCopyright:

Available Formats

You might also like

- CentrifugadorasDocument43 pagesCentrifugadorasTOBA100% (1)

- 4 NBT 4Document9 pages4 NBT 4api-29514981950% (2)

- Suggested Answer For Physics Paper 1 & 2: SPM SoalanDocument8 pagesSuggested Answer For Physics Paper 1 & 2: SPM Soalanjessysorry50% (2)

- Contamination Control: Produced by Steve Skinner, Eaton Hydraulics, Havant, UK October 2002Document313 pagesContamination Control: Produced by Steve Skinner, Eaton Hydraulics, Havant, UK October 2002mgarciaMPSANo ratings yet

- Renolin Ac Compressor Oils: Product InformationDocument2 pagesRenolin Ac Compressor Oils: Product InformationSoporte Técnico RyRNo ratings yet

- Eaton Hydraulics 2000 Steve Skinner, Eaton Hydraulics, Havant, UKDocument63 pagesEaton Hydraulics 2000 Steve Skinner, Eaton Hydraulics, Havant, UKbatuhan kılıçNo ratings yet

- A. Price-List Filter KatalogDocument88 pagesA. Price-List Filter KatalogHiperkes JogjaNo ratings yet

- Infinity Turbine Oil 32 46 BR180104-2Document4 pagesInfinity Turbine Oil 32 46 BR180104-2Ahmad ButtNo ratings yet

- Vane Pump FailureDocument62 pagesVane Pump Failurebatuhan kılıçNo ratings yet

- Avalon Range (Hydraulic Oil) - CorrectedDocument1 pageAvalon Range (Hydraulic Oil) - Correctedmannajoe7No ratings yet

- 004 Mba 15 Uk 1 PDFDocument2 pages004 Mba 15 Uk 1 PDFNermeen ElmelegaeNo ratings yet

- Carter EpDocument1 pageCarter EpNguyễn Quang HưngNo ratings yet

- GL XX Mobil Vacuoline 500 SeriesDocument3 pagesGL XX Mobil Vacuoline 500 SeriesFajar EkoNo ratings yet

- Contamination Control FinalDocument80 pagesContamination Control FinalFacundo SchabNo ratings yet

- CatalogDocument4 pagesCatalograjamutyala4uNo ratings yet

- GL XX Mobil Velocite Oil No SeriesDocument2 pagesGL XX Mobil Velocite Oil No SeriesShailesh BarbateNo ratings yet

- MAN Diesel & Turbo Teglholmsgade 41 2450 Copenhagen SV, Denmark Phone +45 33 85 11 00 Fax +45 33 85 10 30Document27 pagesMAN Diesel & Turbo Teglholmsgade 41 2450 Copenhagen SV, Denmark Phone +45 33 85 11 00 Fax +45 33 85 10 30Catalin SevastianNo ratings yet

- PDS Nytro Bear ASTM EN PDFDocument2 pagesPDS Nytro Bear ASTM EN PDFP_sanchezNo ratings yet

- 22 - Water-Borne Road Marking Resin - Eagacryl 6050 - 2019 EditionDocument4 pages22 - Water-Borne Road Marking Resin - Eagacryl 6050 - 2019 Editionleonardo16No ratings yet

- Microdyn BWRO-1Document2 pagesMicrodyn BWRO-1Rogerio SilvaNo ratings yet

- Nynas OilDocument2 pagesNynas OilusefiNo ratings yet

- L-CKD Heavy Duty Industrial Gear OilDocument3 pagesL-CKD Heavy Duty Industrial Gear OilDavidNo ratings yet

- Nuto H Series Nuto H Series Nuto H Series Nuto H SeriesDocument2 pagesNuto H Series Nuto H Series Nuto H Series Nuto H SeriestitanwlxNo ratings yet

- Lubricant Filtration Solutions Brochure - ENDocument8 pagesLubricant Filtration Solutions Brochure - ENJohn CuestaNo ratings yet

- Diesel Machine-Abby-VBOLTDocument30 pagesDiesel Machine-Abby-VBOLTМягмаржав БалчинNo ratings yet

- CArter EP PDFDocument1 pageCArter EP PDFdnoaisapsNo ratings yet

- GL XX Mobil Velocite Oil No SeriesDocument2 pagesGL XX Mobil Velocite Oil No SeriescruelweyNo ratings yet

- Issue Oil Testing GuidelinesDocument6 pagesIssue Oil Testing GuidelinesNaveen Kumar ChauhanNo ratings yet

- Carboguard 891: Selection & Specification DataDocument4 pagesCarboguard 891: Selection & Specification DataPrakashNo ratings yet

- ELC Datasheet 180814Document2 pagesELC Datasheet 180814Salim Edition100% (1)

- Rma 223Document2 pagesRma 223Sergio ChicNo ratings yet

- Nytro 10XN: Designed For Heavy Duty Product DescriptionDocument2 pagesNytro 10XN: Designed For Heavy Duty Product DescriptionusefiNo ratings yet

- Total Equivis XLT 22Document1 pageTotal Equivis XLT 22RZW RNo ratings yet

- 323+ Data SheetDocument5 pages323+ Data SheetSergioNo ratings yet

- Guide To Contamination StandardsDocument8 pagesGuide To Contamination StandardsCarlos MejíaNo ratings yet

- Agip Acer 15Document2 pagesAgip Acer 15nghiaNo ratings yet

- Mobil Vacuoline 500: Circulating OilsDocument2 pagesMobil Vacuoline 500: Circulating OilstribolasNo ratings yet

- Scan06 11 2022 150334 - OcredDocument14 pagesScan06 11 2022 150334 - OcredMarko PalekaNo ratings yet

- Liquid Epoxy Coating (3M)Document5 pagesLiquid Epoxy Coating (3M)Thamaraikani ManiNo ratings yet

- Specs For Transformer Oil (Normal Grade)Document9 pagesSpecs For Transformer Oil (Normal Grade)Georgina SuleNo ratings yet

- Brochure - Genuine Oil SPECIFICATIONS OILDocument14 pagesBrochure - Genuine Oil SPECIFICATIONS OILBouslimi SouhaibNo ratings yet

- Osc Leaflet en 2935082546Document2 pagesOsc Leaflet en 2935082546ramonNo ratings yet

- UV Catalogue 201510Document14 pagesUV Catalogue 201510ashfaq afzalNo ratings yet

- Scs Medical Coatings Scs Medical Coatings: Protection For Life's Most Critical DevicesDocument6 pagesScs Medical Coatings Scs Medical Coatings: Protection For Life's Most Critical DevicesNikolas Harada100% (1)

- TDS Total Azolla-Zs-32 157 202111 en IdnDocument1 pageTDS Total Azolla-Zs-32 157 202111 en IdnAnya J PamungkasNo ratings yet

- Desalting Part 2 May 2009Document51 pagesDesalting Part 2 May 2009ermusatNo ratings yet

- Teresstic Series Teresstic Series Teresstic Series Teresstic SeriesDocument3 pagesTeresstic Series Teresstic Series Teresstic Series Teresstic SeriesVictor ZhicayNo ratings yet

- NC-559-ASM, No-Clean Solder Paste: Product Data SheetDocument2 pagesNC-559-ASM, No-Clean Solder Paste: Product Data SheetAkhmad MukhsinNo ratings yet

- Spectra 977 Process: Technical Data SheetDocument2 pagesSpectra 977 Process: Technical Data SheetLuuThiThuyDuongNo ratings yet

- Drosera MsDocument1 pageDrosera MsCinta IndonesiaNo ratings yet

- TDS DARVAN 811 C and R WebDocument2 pagesTDS DARVAN 811 C and R WebAhmed ElgendyNo ratings yet

- Cummins Training (24mar2009) - ShortDocument34 pagesCummins Training (24mar2009) - ShortВиталийАлексеевNo ratings yet

- ZYD-50 MóvilDocument10 pagesZYD-50 MóvilDaniel SubelzaNo ratings yet

- Ultraclean Microbial Dna Isolation Kit: Instruction ManualDocument17 pagesUltraclean Microbial Dna Isolation Kit: Instruction ManualBodhi DharmaNo ratings yet

- Teresstic Series: Product DescriptionDocument3 pagesTeresstic Series: Product DescriptionsumitNo ratings yet

- Filtration HandbookDocument28 pagesFiltration HandbookMussardNo ratings yet

- 01 HPCL - INDUSTRIAL - BOOKLET - JAN 2017 - Part I - HYDRAULIC AND CIRCULATING OILSDocument12 pages01 HPCL - INDUSTRIAL - BOOKLET - JAN 2017 - Part I - HYDRAULIC AND CIRCULATING OILSMk EnterprisesNo ratings yet

- SharpFlow (Main Power)Document2 pagesSharpFlow (Main Power)Dwitha MeydinaNo ratings yet

- Introduction to Microsystem Technology: A Guide for StudentsFrom EverandIntroduction to Microsystem Technology: A Guide for StudentsRating: 5 out of 5 stars5/5 (1)

- Keywords: Stall, Parallel Operation of Axial Flow Fans, Anti-Stall DeviceDocument6 pagesKeywords: Stall, Parallel Operation of Axial Flow Fans, Anti-Stall DeviceRajesh SirsathNo ratings yet

- Vision Mission Values BHELDocument2 pagesVision Mission Values BHELRajesh SirsathNo ratings yet

- OPTIONS - January 2022Document1 pageOPTIONS - January 2022Rajesh SirsathNo ratings yet

- Scrip Code - 500180 Symbol - HDFCBANK: June 20, 2020 BSE Limited The National Stock Exchange of India LimitedDocument1 pageScrip Code - 500180 Symbol - HDFCBANK: June 20, 2020 BSE Limited The National Stock Exchange of India LimitedRajesh SirsathNo ratings yet

- Options - December 2021Document1 pageOptions - December 2021Rajesh SirsathNo ratings yet

- Power Sector Eastern Region, Dj-9/1, Salt Lake City, Kolkata - 700 091 (033) 23211960 23211798/ 1691Document3 pagesPower Sector Eastern Region, Dj-9/1, Salt Lake City, Kolkata - 700 091 (033) 23211960 23211798/ 1691Rajesh SirsathNo ratings yet

- RKLISX!202 1-22/84: CIN No. L26941Up1983pLCO27278Document10 pagesRKLISX!202 1-22/84: CIN No. L26941Up1983pLCO27278Rajesh SirsathNo ratings yet

- CIN: U40109MH2005SGC153645: (A Govt. of Maharashtra Undertaking)Document1 pageCIN: U40109MH2005SGC153645: (A Govt. of Maharashtra Undertaking)Rajesh SirsathNo ratings yet

- 103 CLT (For Conductive Media) : Features: SpecificationsDocument4 pages103 CLT (For Conductive Media) : Features: SpecificationsRajesh SirsathNo ratings yet

- NovLight SeemaDocument1 pageNovLight SeemaRajesh SirsathNo ratings yet

- Contracts 2Document3 pagesContracts 2Rajesh SirsathNo ratings yet

- Disocont Tersus (DT-9) Legacy: Stock Feeder Controller UpgradeDocument2 pagesDisocont Tersus (DT-9) Legacy: Stock Feeder Controller UpgradeRajesh SirsathNo ratings yet

- Larsen & Toubro: STOCK CODE: 500510 Stock Code: LTDocument4 pagesLarsen & Toubro: STOCK CODE: 500510 Stock Code: LTRajesh SirsathNo ratings yet

- Revisedchecklist 13032015Document29 pagesRevisedchecklist 13032015Rajesh SirsathNo ratings yet

- Ip Transducers Series 500FCDocument2 pagesIp Transducers Series 500FCRajesh SirsathNo ratings yet

- Tesi HE Pneumatic Retraction Unit - Power TechnologyDocument1 pageTesi HE Pneumatic Retraction Unit - Power TechnologyRajesh SirsathNo ratings yet

- Salary Scale 1 53 PDFDocument1 pageSalary Scale 1 53 PDFRajesh SirsathNo ratings yet

- Tps Parli: Pay Fixation Arrears: Apr-2018 To Sep-2018Document1 pageTps Parli: Pay Fixation Arrears: Apr-2018 To Sep-2018Rajesh SirsathNo ratings yet

- Report On Pressure Control OperationDocument3 pagesReport On Pressure Control OperationRajesh SirsathNo ratings yet

- Fire Fighting SystemDocument9 pagesFire Fighting SystemRajesh SirsathNo ratings yet

- Oil Fired Igniters, Pilots and Oil Guns For Power Plants and Utility BoilersDocument8 pagesOil Fired Igniters, Pilots and Oil Guns For Power Plants and Utility BoilersRajesh SirsathNo ratings yet

- Kawas (Liq) TPC U-7 (RLNG) Kawas (RLNG) Gandhar (RLNG) : State Mod Stack of Variable Charges (VC) For Oct-2020 (R1)Document1 pageKawas (Liq) TPC U-7 (RLNG) Kawas (RLNG) Gandhar (RLNG) : State Mod Stack of Variable Charges (VC) For Oct-2020 (R1)Rajesh SirsathNo ratings yet

- Electronic Remote Water Level Indicator Type EWLI-3B: EL65 EL60Document34 pagesElectronic Remote Water Level Indicator Type EWLI-3B: EL65 EL60Rajesh SirsathNo ratings yet

- Paystub 000000Document1 pagePaystub 000000Rajesh SirsathNo ratings yet

- Air Lock RelayDocument1 pageAir Lock RelayRajesh SirsathNo ratings yet

- Oil Fired Igniters, Pilots and Oil Guns For Power Plants and Utility BoilersDocument8 pagesOil Fired Igniters, Pilots and Oil Guns For Power Plants and Utility BoilersRajesh SirsathNo ratings yet

- D18 - 70 Minutes of Meeting 09 06 2017Document17 pagesD18 - 70 Minutes of Meeting 09 06 2017Rajesh SirsathNo ratings yet

- OAB TechnicalDocument2 pagesOAB Technicalvanitha_kundaramNo ratings yet

- Lecture 4 PDFDocument18 pagesLecture 4 PDFdeepakNo ratings yet

- High-Resolution Spectroscopic Analysis of Four Unevolved Barium StarsDocument29 pagesHigh-Resolution Spectroscopic Analysis of Four Unevolved Barium Starsl2j89zxwNo ratings yet

- Arabic To Bangla Machine Translation Using Encoder Decoder ApproachDocument4 pagesArabic To Bangla Machine Translation Using Encoder Decoder ApproachMoidul Hasan KhanNo ratings yet

- GenMath11 Q1 Mod26 Domain and Range of Logarithmic Functions 08082020Document19 pagesGenMath11 Q1 Mod26 Domain and Range of Logarithmic Functions 08082020Charity Myrh Pasquin ArzagaNo ratings yet

- Smoke Control Design - En12101-5Document16 pagesSmoke Control Design - En12101-5psmanasse100% (2)

- Management of Supraerupted TeethDocument4 pagesManagement of Supraerupted TeethankitbudhirajaNo ratings yet

- L4 RocksDocument33 pagesL4 RocksFARHA NAAZNo ratings yet

- Casting & ForgingDocument42 pagesCasting & ForgingMrinal100% (1)

- Aeroprakt A32-080-POHDocument60 pagesAeroprakt A32-080-POHRafael ShNo ratings yet

- Effect of Oxygen On Surface Tension of Liquid Ag-Sn AlloysDocument5 pagesEffect of Oxygen On Surface Tension of Liquid Ag-Sn AlloysBurak ÖZBAKIRNo ratings yet

- Dissertation Using T-TestDocument4 pagesDissertation Using T-TestCanSomeoneWriteMyPaperRiverside100% (1)

- Prestressed Concrete Structures Unit-3Document15 pagesPrestressed Concrete Structures Unit-3chinnaNo ratings yet

- Music Theory - Note ReadingDocument33 pagesMusic Theory - Note ReadingChristopher KondwelaniNo ratings yet

- HA With Active Data Guard 18cDocument26 pagesHA With Active Data Guard 18camartinbNo ratings yet

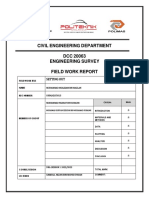

- Report Survey Setting Out Civil EngineeringDocument11 pagesReport Survey Setting Out Civil EngineeringMuhammad MuazzamNo ratings yet

- 1ov PDFDocument69 pages1ov PDFkatfy1No ratings yet

- Revised Gce As A Level Scheme of Work PhysicsDocument59 pagesRevised Gce As A Level Scheme of Work PhysicsNathaniell Dongo KasekeNo ratings yet

- Economic Crises and The European Revolutions of 1848Document34 pagesEconomic Crises and The European Revolutions of 1848Suraya SNo ratings yet

- Reflection On Student WorkDocument3 pagesReflection On Student Workapi-251651634No ratings yet

- Kinetic Theory of GassesDocument8 pagesKinetic Theory of GassesAziz Khan SultanNo ratings yet

- 1stQ-G7 - Test - Questions With TOSDocument8 pages1stQ-G7 - Test - Questions With TOSMichNo ratings yet

- Lipids and Proteins Are Associated in Biological Membranes: What Is A LipidDocument20 pagesLipids and Proteins Are Associated in Biological Membranes: What Is A Lipidcarlette11No ratings yet

- Evolution FinalDocument30 pagesEvolution FinalHari HaranNo ratings yet

- KKK 33Document7 pagesKKK 33the crowNo ratings yet

- RM Tools and Techniques PDFDocument118 pagesRM Tools and Techniques PDFAnonymous Hj7vA6No ratings yet

- Group 13 ElementsDocument32 pagesGroup 13 Elementstapas kunduNo ratings yet

- 800 X ADocument16 pages800 X Abigsteve9088No ratings yet

Elc Catalog

Elc Catalog

Uploaded by

Rajesh SirsathOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Elc Catalog

Elc Catalog

Uploaded by

Rajesh SirsathCopyright:

Available Formats

PRINCIPLES OPERATION OF ELECTROSTATIC LIQUID CLEANING (ELC) MACHINE

The ELC system uses the principles of electrostatics to collect fuild contaminants. ELC unique design with gradient force permits

it to take advantage of the natural charge that each contaminant contains. Contamination that have a positive charge are drawn

towards a negative electrode plate within the system while those with an inherent negative charge are drawn towards a positive

plate. Neutral contaminants are drawn and deposited by gradient force to the edge of the collectors where the intensity of the

deformed electric field is strongest.

As the fluid flows freely through the system. ELC removes contaminants, submicronic particles as 0.01 micron, dust, dirt and

products of oxidation such as tars and varnishes. ELC also removes particles such as paper, wood, plastic and rubber.

Contaminants are trapped on Cellulose Collectors for easy disposal. ELC will not affect soluble additives.

The Dust collector paper(s) is hosted in the oil cleaning chamber. Each Dust Collector is made of disposable cellulose fiber

and in form of pleated to hold the greatest quantity of contaminants. Dust collector can hold as much as 4.5 kgs. Before change

is required and will furnish 2000 hours of use depending upon the actual contaminants of oil.

PHOTOGRAPHS OF MEMBRANE PATCHES FOR CONTAMINATION CONTROL

An example of very high An example of An example of An example of An example of

contamination level which contamination contamination contamination contaminati on

can critically damage level which requires level to which the level which requires level which the

hydraulic equipment immediate cleaning oil can be cleaned to cleaning oil can be cleaned to

(10 mg I 100 ml) (4 mg I 100 ml) (1 mg I 100 ml) (2 mg I 100 ml) (0.5 mg / 100 ml)

Above NAS 12 Above NAS 12 NAS 7-8-9 NAS 10-11-12 NAS-6

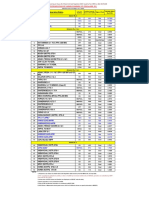

NAS 1638 CONTAMINANTS SPECIFICATIONS in 100 ml OIL

Grade 00 0 1 2 3 4 5 6 7 8 9 10 11 12

5-15µm 125 250 500 1,000 2,000 4,000 8,000 16,000 32,000 64,000 128,000 256,000 512,000 1,024,000

Number& 15-25µm 22 44 89 178 356 712 1,425 2,850 5,700 11,400 22,800 45,600 91,200 182,400

Sizes Of 25-50µm 4 8 16 32 63 126 253 506 1,012 2,025 4,050 8,100 16,200 32,400

50-lOOµm 1 2 3 6 11 22 45 90 180 360 720 1,440 2,880 5,760

Contaminants

Upper lOOµm 0 0 1 1 2 4 8 16 32 64 128 256 512 1,024

L Not existing _J For Missile L For NC M/C _J L_ New Oil._J

RELATED PRODUCTS & CONSUMABLES

DUST COLLECTOR PAPERS CONTAMINATION CHEKING KIT (CCK) 0.8 MICRON X 25 MM. DIA. MEMBRANES. BAG FILTER HOUSING t

DEHYDRATION CELL ( C.S. or S.S.)

Size: Dia. 4" x 10" L I Dia. 4" x 17" L

Dust collector paper zig-zag pleated, cured This kit enables the determination if the oil This Membrane can be used in

and cut to size condition, to facilitate convenient cleanliness level before and after its filtration. contamination checking kit (CCK).

for various model of ELCs of any make. Compare dirt and cleanliness with colour Millipore I Nupore

photo samples. ICM I PARTICLES COUNTER

A TRident ENgineering

B-61 & B-62, Maruti Industrial Estate, Plot No. 59/1, GIDC, Estate,

" PH-I "E" Road, vatva, AHMEDABAD - 382 445. INDIA

Phone: +91-79-40372241

� E-mail : oil@tridentengg.net, tridentengg@gmail.com

Mobile I Cell : '-' + 91 · 92272 40200 Measures and display NAS 1638

& ISO 4406: 1999

You might also like

- CentrifugadorasDocument43 pagesCentrifugadorasTOBA100% (1)

- 4 NBT 4Document9 pages4 NBT 4api-29514981950% (2)

- Suggested Answer For Physics Paper 1 & 2: SPM SoalanDocument8 pagesSuggested Answer For Physics Paper 1 & 2: SPM Soalanjessysorry50% (2)

- Contamination Control: Produced by Steve Skinner, Eaton Hydraulics, Havant, UK October 2002Document313 pagesContamination Control: Produced by Steve Skinner, Eaton Hydraulics, Havant, UK October 2002mgarciaMPSANo ratings yet

- Renolin Ac Compressor Oils: Product InformationDocument2 pagesRenolin Ac Compressor Oils: Product InformationSoporte Técnico RyRNo ratings yet

- Eaton Hydraulics 2000 Steve Skinner, Eaton Hydraulics, Havant, UKDocument63 pagesEaton Hydraulics 2000 Steve Skinner, Eaton Hydraulics, Havant, UKbatuhan kılıçNo ratings yet

- A. Price-List Filter KatalogDocument88 pagesA. Price-List Filter KatalogHiperkes JogjaNo ratings yet

- Infinity Turbine Oil 32 46 BR180104-2Document4 pagesInfinity Turbine Oil 32 46 BR180104-2Ahmad ButtNo ratings yet

- Vane Pump FailureDocument62 pagesVane Pump Failurebatuhan kılıçNo ratings yet

- Avalon Range (Hydraulic Oil) - CorrectedDocument1 pageAvalon Range (Hydraulic Oil) - Correctedmannajoe7No ratings yet

- 004 Mba 15 Uk 1 PDFDocument2 pages004 Mba 15 Uk 1 PDFNermeen ElmelegaeNo ratings yet

- Carter EpDocument1 pageCarter EpNguyễn Quang HưngNo ratings yet

- GL XX Mobil Vacuoline 500 SeriesDocument3 pagesGL XX Mobil Vacuoline 500 SeriesFajar EkoNo ratings yet

- Contamination Control FinalDocument80 pagesContamination Control FinalFacundo SchabNo ratings yet

- CatalogDocument4 pagesCatalograjamutyala4uNo ratings yet

- GL XX Mobil Velocite Oil No SeriesDocument2 pagesGL XX Mobil Velocite Oil No SeriesShailesh BarbateNo ratings yet

- MAN Diesel & Turbo Teglholmsgade 41 2450 Copenhagen SV, Denmark Phone +45 33 85 11 00 Fax +45 33 85 10 30Document27 pagesMAN Diesel & Turbo Teglholmsgade 41 2450 Copenhagen SV, Denmark Phone +45 33 85 11 00 Fax +45 33 85 10 30Catalin SevastianNo ratings yet

- PDS Nytro Bear ASTM EN PDFDocument2 pagesPDS Nytro Bear ASTM EN PDFP_sanchezNo ratings yet

- 22 - Water-Borne Road Marking Resin - Eagacryl 6050 - 2019 EditionDocument4 pages22 - Water-Borne Road Marking Resin - Eagacryl 6050 - 2019 Editionleonardo16No ratings yet

- Microdyn BWRO-1Document2 pagesMicrodyn BWRO-1Rogerio SilvaNo ratings yet

- Nynas OilDocument2 pagesNynas OilusefiNo ratings yet

- L-CKD Heavy Duty Industrial Gear OilDocument3 pagesL-CKD Heavy Duty Industrial Gear OilDavidNo ratings yet

- Nuto H Series Nuto H Series Nuto H Series Nuto H SeriesDocument2 pagesNuto H Series Nuto H Series Nuto H Series Nuto H SeriestitanwlxNo ratings yet

- Lubricant Filtration Solutions Brochure - ENDocument8 pagesLubricant Filtration Solutions Brochure - ENJohn CuestaNo ratings yet

- Diesel Machine-Abby-VBOLTDocument30 pagesDiesel Machine-Abby-VBOLTМягмаржав БалчинNo ratings yet

- CArter EP PDFDocument1 pageCArter EP PDFdnoaisapsNo ratings yet

- GL XX Mobil Velocite Oil No SeriesDocument2 pagesGL XX Mobil Velocite Oil No SeriescruelweyNo ratings yet

- Issue Oil Testing GuidelinesDocument6 pagesIssue Oil Testing GuidelinesNaveen Kumar ChauhanNo ratings yet

- Carboguard 891: Selection & Specification DataDocument4 pagesCarboguard 891: Selection & Specification DataPrakashNo ratings yet

- ELC Datasheet 180814Document2 pagesELC Datasheet 180814Salim Edition100% (1)

- Rma 223Document2 pagesRma 223Sergio ChicNo ratings yet

- Nytro 10XN: Designed For Heavy Duty Product DescriptionDocument2 pagesNytro 10XN: Designed For Heavy Duty Product DescriptionusefiNo ratings yet

- Total Equivis XLT 22Document1 pageTotal Equivis XLT 22RZW RNo ratings yet

- 323+ Data SheetDocument5 pages323+ Data SheetSergioNo ratings yet

- Guide To Contamination StandardsDocument8 pagesGuide To Contamination StandardsCarlos MejíaNo ratings yet

- Agip Acer 15Document2 pagesAgip Acer 15nghiaNo ratings yet

- Mobil Vacuoline 500: Circulating OilsDocument2 pagesMobil Vacuoline 500: Circulating OilstribolasNo ratings yet

- Scan06 11 2022 150334 - OcredDocument14 pagesScan06 11 2022 150334 - OcredMarko PalekaNo ratings yet

- Liquid Epoxy Coating (3M)Document5 pagesLiquid Epoxy Coating (3M)Thamaraikani ManiNo ratings yet

- Specs For Transformer Oil (Normal Grade)Document9 pagesSpecs For Transformer Oil (Normal Grade)Georgina SuleNo ratings yet

- Brochure - Genuine Oil SPECIFICATIONS OILDocument14 pagesBrochure - Genuine Oil SPECIFICATIONS OILBouslimi SouhaibNo ratings yet

- Osc Leaflet en 2935082546Document2 pagesOsc Leaflet en 2935082546ramonNo ratings yet

- UV Catalogue 201510Document14 pagesUV Catalogue 201510ashfaq afzalNo ratings yet

- Scs Medical Coatings Scs Medical Coatings: Protection For Life's Most Critical DevicesDocument6 pagesScs Medical Coatings Scs Medical Coatings: Protection For Life's Most Critical DevicesNikolas Harada100% (1)

- TDS Total Azolla-Zs-32 157 202111 en IdnDocument1 pageTDS Total Azolla-Zs-32 157 202111 en IdnAnya J PamungkasNo ratings yet

- Desalting Part 2 May 2009Document51 pagesDesalting Part 2 May 2009ermusatNo ratings yet

- Teresstic Series Teresstic Series Teresstic Series Teresstic SeriesDocument3 pagesTeresstic Series Teresstic Series Teresstic Series Teresstic SeriesVictor ZhicayNo ratings yet

- NC-559-ASM, No-Clean Solder Paste: Product Data SheetDocument2 pagesNC-559-ASM, No-Clean Solder Paste: Product Data SheetAkhmad MukhsinNo ratings yet

- Spectra 977 Process: Technical Data SheetDocument2 pagesSpectra 977 Process: Technical Data SheetLuuThiThuyDuongNo ratings yet

- Drosera MsDocument1 pageDrosera MsCinta IndonesiaNo ratings yet

- TDS DARVAN 811 C and R WebDocument2 pagesTDS DARVAN 811 C and R WebAhmed ElgendyNo ratings yet

- Cummins Training (24mar2009) - ShortDocument34 pagesCummins Training (24mar2009) - ShortВиталийАлексеевNo ratings yet

- ZYD-50 MóvilDocument10 pagesZYD-50 MóvilDaniel SubelzaNo ratings yet

- Ultraclean Microbial Dna Isolation Kit: Instruction ManualDocument17 pagesUltraclean Microbial Dna Isolation Kit: Instruction ManualBodhi DharmaNo ratings yet

- Teresstic Series: Product DescriptionDocument3 pagesTeresstic Series: Product DescriptionsumitNo ratings yet

- Filtration HandbookDocument28 pagesFiltration HandbookMussardNo ratings yet

- 01 HPCL - INDUSTRIAL - BOOKLET - JAN 2017 - Part I - HYDRAULIC AND CIRCULATING OILSDocument12 pages01 HPCL - INDUSTRIAL - BOOKLET - JAN 2017 - Part I - HYDRAULIC AND CIRCULATING OILSMk EnterprisesNo ratings yet

- SharpFlow (Main Power)Document2 pagesSharpFlow (Main Power)Dwitha MeydinaNo ratings yet

- Introduction to Microsystem Technology: A Guide for StudentsFrom EverandIntroduction to Microsystem Technology: A Guide for StudentsRating: 5 out of 5 stars5/5 (1)

- Keywords: Stall, Parallel Operation of Axial Flow Fans, Anti-Stall DeviceDocument6 pagesKeywords: Stall, Parallel Operation of Axial Flow Fans, Anti-Stall DeviceRajesh SirsathNo ratings yet

- Vision Mission Values BHELDocument2 pagesVision Mission Values BHELRajesh SirsathNo ratings yet

- OPTIONS - January 2022Document1 pageOPTIONS - January 2022Rajesh SirsathNo ratings yet

- Scrip Code - 500180 Symbol - HDFCBANK: June 20, 2020 BSE Limited The National Stock Exchange of India LimitedDocument1 pageScrip Code - 500180 Symbol - HDFCBANK: June 20, 2020 BSE Limited The National Stock Exchange of India LimitedRajesh SirsathNo ratings yet

- Options - December 2021Document1 pageOptions - December 2021Rajesh SirsathNo ratings yet

- Power Sector Eastern Region, Dj-9/1, Salt Lake City, Kolkata - 700 091 (033) 23211960 23211798/ 1691Document3 pagesPower Sector Eastern Region, Dj-9/1, Salt Lake City, Kolkata - 700 091 (033) 23211960 23211798/ 1691Rajesh SirsathNo ratings yet

- RKLISX!202 1-22/84: CIN No. L26941Up1983pLCO27278Document10 pagesRKLISX!202 1-22/84: CIN No. L26941Up1983pLCO27278Rajesh SirsathNo ratings yet

- CIN: U40109MH2005SGC153645: (A Govt. of Maharashtra Undertaking)Document1 pageCIN: U40109MH2005SGC153645: (A Govt. of Maharashtra Undertaking)Rajesh SirsathNo ratings yet

- 103 CLT (For Conductive Media) : Features: SpecificationsDocument4 pages103 CLT (For Conductive Media) : Features: SpecificationsRajesh SirsathNo ratings yet

- NovLight SeemaDocument1 pageNovLight SeemaRajesh SirsathNo ratings yet

- Contracts 2Document3 pagesContracts 2Rajesh SirsathNo ratings yet

- Disocont Tersus (DT-9) Legacy: Stock Feeder Controller UpgradeDocument2 pagesDisocont Tersus (DT-9) Legacy: Stock Feeder Controller UpgradeRajesh SirsathNo ratings yet

- Larsen & Toubro: STOCK CODE: 500510 Stock Code: LTDocument4 pagesLarsen & Toubro: STOCK CODE: 500510 Stock Code: LTRajesh SirsathNo ratings yet

- Revisedchecklist 13032015Document29 pagesRevisedchecklist 13032015Rajesh SirsathNo ratings yet

- Ip Transducers Series 500FCDocument2 pagesIp Transducers Series 500FCRajesh SirsathNo ratings yet

- Tesi HE Pneumatic Retraction Unit - Power TechnologyDocument1 pageTesi HE Pneumatic Retraction Unit - Power TechnologyRajesh SirsathNo ratings yet

- Salary Scale 1 53 PDFDocument1 pageSalary Scale 1 53 PDFRajesh SirsathNo ratings yet

- Tps Parli: Pay Fixation Arrears: Apr-2018 To Sep-2018Document1 pageTps Parli: Pay Fixation Arrears: Apr-2018 To Sep-2018Rajesh SirsathNo ratings yet

- Report On Pressure Control OperationDocument3 pagesReport On Pressure Control OperationRajesh SirsathNo ratings yet

- Fire Fighting SystemDocument9 pagesFire Fighting SystemRajesh SirsathNo ratings yet

- Oil Fired Igniters, Pilots and Oil Guns For Power Plants and Utility BoilersDocument8 pagesOil Fired Igniters, Pilots and Oil Guns For Power Plants and Utility BoilersRajesh SirsathNo ratings yet

- Kawas (Liq) TPC U-7 (RLNG) Kawas (RLNG) Gandhar (RLNG) : State Mod Stack of Variable Charges (VC) For Oct-2020 (R1)Document1 pageKawas (Liq) TPC U-7 (RLNG) Kawas (RLNG) Gandhar (RLNG) : State Mod Stack of Variable Charges (VC) For Oct-2020 (R1)Rajesh SirsathNo ratings yet

- Electronic Remote Water Level Indicator Type EWLI-3B: EL65 EL60Document34 pagesElectronic Remote Water Level Indicator Type EWLI-3B: EL65 EL60Rajesh SirsathNo ratings yet

- Paystub 000000Document1 pagePaystub 000000Rajesh SirsathNo ratings yet

- Air Lock RelayDocument1 pageAir Lock RelayRajesh SirsathNo ratings yet

- Oil Fired Igniters, Pilots and Oil Guns For Power Plants and Utility BoilersDocument8 pagesOil Fired Igniters, Pilots and Oil Guns For Power Plants and Utility BoilersRajesh SirsathNo ratings yet

- D18 - 70 Minutes of Meeting 09 06 2017Document17 pagesD18 - 70 Minutes of Meeting 09 06 2017Rajesh SirsathNo ratings yet

- OAB TechnicalDocument2 pagesOAB Technicalvanitha_kundaramNo ratings yet

- Lecture 4 PDFDocument18 pagesLecture 4 PDFdeepakNo ratings yet

- High-Resolution Spectroscopic Analysis of Four Unevolved Barium StarsDocument29 pagesHigh-Resolution Spectroscopic Analysis of Four Unevolved Barium Starsl2j89zxwNo ratings yet

- Arabic To Bangla Machine Translation Using Encoder Decoder ApproachDocument4 pagesArabic To Bangla Machine Translation Using Encoder Decoder ApproachMoidul Hasan KhanNo ratings yet

- GenMath11 Q1 Mod26 Domain and Range of Logarithmic Functions 08082020Document19 pagesGenMath11 Q1 Mod26 Domain and Range of Logarithmic Functions 08082020Charity Myrh Pasquin ArzagaNo ratings yet

- Smoke Control Design - En12101-5Document16 pagesSmoke Control Design - En12101-5psmanasse100% (2)

- Management of Supraerupted TeethDocument4 pagesManagement of Supraerupted TeethankitbudhirajaNo ratings yet

- L4 RocksDocument33 pagesL4 RocksFARHA NAAZNo ratings yet

- Casting & ForgingDocument42 pagesCasting & ForgingMrinal100% (1)

- Aeroprakt A32-080-POHDocument60 pagesAeroprakt A32-080-POHRafael ShNo ratings yet

- Effect of Oxygen On Surface Tension of Liquid Ag-Sn AlloysDocument5 pagesEffect of Oxygen On Surface Tension of Liquid Ag-Sn AlloysBurak ÖZBAKIRNo ratings yet

- Dissertation Using T-TestDocument4 pagesDissertation Using T-TestCanSomeoneWriteMyPaperRiverside100% (1)

- Prestressed Concrete Structures Unit-3Document15 pagesPrestressed Concrete Structures Unit-3chinnaNo ratings yet

- Music Theory - Note ReadingDocument33 pagesMusic Theory - Note ReadingChristopher KondwelaniNo ratings yet

- HA With Active Data Guard 18cDocument26 pagesHA With Active Data Guard 18camartinbNo ratings yet

- Report Survey Setting Out Civil EngineeringDocument11 pagesReport Survey Setting Out Civil EngineeringMuhammad MuazzamNo ratings yet

- 1ov PDFDocument69 pages1ov PDFkatfy1No ratings yet

- Revised Gce As A Level Scheme of Work PhysicsDocument59 pagesRevised Gce As A Level Scheme of Work PhysicsNathaniell Dongo KasekeNo ratings yet

- Economic Crises and The European Revolutions of 1848Document34 pagesEconomic Crises and The European Revolutions of 1848Suraya SNo ratings yet

- Reflection On Student WorkDocument3 pagesReflection On Student Workapi-251651634No ratings yet

- Kinetic Theory of GassesDocument8 pagesKinetic Theory of GassesAziz Khan SultanNo ratings yet

- 1stQ-G7 - Test - Questions With TOSDocument8 pages1stQ-G7 - Test - Questions With TOSMichNo ratings yet

- Lipids and Proteins Are Associated in Biological Membranes: What Is A LipidDocument20 pagesLipids and Proteins Are Associated in Biological Membranes: What Is A Lipidcarlette11No ratings yet

- Evolution FinalDocument30 pagesEvolution FinalHari HaranNo ratings yet

- KKK 33Document7 pagesKKK 33the crowNo ratings yet

- RM Tools and Techniques PDFDocument118 pagesRM Tools and Techniques PDFAnonymous Hj7vA6No ratings yet

- Group 13 ElementsDocument32 pagesGroup 13 Elementstapas kunduNo ratings yet

- 800 X ADocument16 pages800 X Abigsteve9088No ratings yet