Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

22 viewsCabinete 2

Cabinete 2

Uploaded by

andres silvestre1) The article describes a small gas-powered model airplane called the G.E. "Cabinette" that is easy to build and fly despite its small size.

2) The model can climb quickly and soar high, with one flight carrying the plane out of sight until it was found a week later by a passerby with only minor damage.

3) The plans show how to construct the simple but realistic-looking model using basic materials like balsa wood and paper covering. With a gas engine it can perform well in various weather.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Hangar Rat PDFDocument5 pagesHangar Rat PDFDarlysson50% (6)

- F-14 Park Jet Construction Guide 2Document23 pagesF-14 Park Jet Construction Guide 2John MondoNo ratings yet

- Marine Capacity Table Hitachi GearboxDocument51 pagesMarine Capacity Table Hitachi Gearboxarieznaval67% (3)

- Taylorcraft L-2 GrasshopperDocument10 pagesTaylorcraft L-2 GrasshopperAviation/Space History Library100% (1)

- Culver Cadet MonoplaneDocument5 pagesCulver Cadet MonoplaneAviation/Space History LibraryNo ratings yet

- The Pacemaker - A Free-Flight Model Airplane (Fuel Engine) (Convert To R/C?)Document11 pagesThe Pacemaker - A Free-Flight Model Airplane (Fuel Engine) (Convert To R/C?)Bob KowalskiNo ratings yet

- The Skyfarer: by Jim NoonanDocument3 pagesThe Skyfarer: by Jim NoonanathrellusNo ratings yet

- Vultee A-31 VengeanceDocument4 pagesVultee A-31 VengeanceAviation/Space History LibraryNo ratings yet

- Baby DurationDocument5 pagesBaby DurationWilmer Chinomes PinzónNo ratings yet

- Interstate Cadet MonoplaneDocument7 pagesInterstate Cadet MonoplaneAviation/Space History LibraryNo ratings yet

- North American BC-1 TrainerDocument7 pagesNorth American BC-1 TrainerAviation/Space History LibraryNo ratings yet

- AirHopper - A Free-Flight Model Airplane (Glider)Document7 pagesAirHopper - A Free-Flight Model Airplane (Glider)Bob KowalskiNo ratings yet

- Tyro 1 - A Free-Flight Model Airplane (Glider)Document4 pagesTyro 1 - A Free-Flight Model Airplane (Glider)Bob KowalskiNo ratings yet

- Taylorcraft O-57 GrasshopperDocument8 pagesTaylorcraft O-57 GrasshopperAviation/Space History Library100% (1)

- The Rocketeer - A Free-Flight Model Airplane (Rocket Engine)Document4 pagesThe Rocketeer - A Free-Flight Model Airplane (Rocket Engine)Bob KowalskiNo ratings yet

- Cessna 195Document2 pagesCessna 195MehdiNo ratings yet

- Dethermalizer - A Free-Flight Model AirplaneDocument4 pagesDethermalizer - A Free-Flight Model AirplaneBob KowalskiNo ratings yet

- Curtiss O-52 - A Free-Flight Model AirplaneDocument5 pagesCurtiss O-52 - A Free-Flight Model AirplaneBob KowalskiNo ratings yet

- Fundamentals of Model Airplane Part 5 PDFDocument6 pagesFundamentals of Model Airplane Part 5 PDFMarian PaunaNo ratings yet

- ERCO 415-A ErcoupeDocument8 pagesERCO 415-A ErcoupeAviation/Space History LibraryNo ratings yet

- Rearwin SportsterDocument7 pagesRearwin SportsterAviation/Space History LibraryNo ratings yet

- High Efficiency Soarer - A Free-Flight Model Airplane (Glider)Document4 pagesHigh Efficiency Soarer - A Free-Flight Model Airplane (Glider)Bob KowalskiNo ratings yet

- The Jersey Albatross - A Free-Flight Model Airplane (Glider)Document4 pagesThe Jersey Albatross - A Free-Flight Model Airplane (Glider)Bob Kowalski100% (1)

- Cessna 140Document18 pagesCessna 140getuliobraiaNo ratings yet

- Republic RC-3 SeabeeDocument4 pagesRepublic RC-3 SeabeeAviation/Space History Library100% (2)

- Building The Fairchild Ranger: by Paul W. LindbergDocument4 pagesBuilding The Fairchild Ranger: by Paul W. LindbergBrunno VasquesNo ratings yet

- Sopwith Camel - A Free-Flight Model AirplaneDocument6 pagesSopwith Camel - A Free-Flight Model AirplaneBob KowalskiNo ratings yet

- The Wisp: by Dan HealdDocument4 pagesThe Wisp: by Dan Healdmuca11No ratings yet

- Bede BD5Document4 pagesBede BD5Alfredo Arnéz Paz SoldánNo ratings yet

- Piper J-3 CubDocument9 pagesPiper J-3 CubAviation/Space History LibraryNo ratings yet

- Rearwin SpeedsterDocument5 pagesRearwin SpeedsterAviation/Space History LibraryNo ratings yet

- Planta de AeronaveDocument18 pagesPlanta de AeronaveKellLuz100% (1)

- Gee Bee Super SportsterDocument8 pagesGee Bee Super SportsterAviation/Space History LibraryNo ratings yet

- Bebe Jodel Oz760 TranscriptDocument3 pagesBebe Jodel Oz760 TranscriptAlessandro Dal BoscoNo ratings yet

- Douglas DB-7 BomberDocument8 pagesDouglas DB-7 BomberAviation/Space History Library50% (2)

- Vought SBU-1 FF 1936 Oz6837Document3 pagesVought SBU-1 FF 1936 Oz6837Roberto ClementeNo ratings yet

- De Havilland DH4Document3 pagesDe Havilland DH4RosanaNo ratings yet

- Build and Fly The Fokker D - 8Document8 pagesBuild and Fly The Fokker D - 8Ari SutiknoNo ratings yet

- The Flying Air Warden: Al PardocchiDocument4 pagesThe Flying Air Warden: Al PardocchiJacob PegherNo ratings yet

- 2001 Curtiss P-40M Kittyhwak IIIDocument14 pages2001 Curtiss P-40M Kittyhwak IIIgabrielle dauz0% (1)

- 1938 Guttman Endurdance July 1938 Flying AcesDocument7 pages1938 Guttman Endurdance July 1938 Flying AcesNora MontoyaNo ratings yet

- BD 5 InstructionsDocument13 pagesBD 5 InstructionskokiskoNo ratings yet

- Micro PittsDocument6 pagesMicro Pittsmam73No ratings yet

- Euler DII Oz12376 TranscriptDocument3 pagesEuler DII Oz12376 TranscriptAlessandro Dal BoscoNo ratings yet

- Douglas C-47Document5 pagesDouglas C-47Emerson URNo ratings yet

- Dave Platt Top Flight - Se5a-ManualDocument18 pagesDave Platt Top Flight - Se5a-ManualTerrance TorNo ratings yet

- P-51D Mustang Stahl Oz546 Article PDFDocument3 pagesP-51D Mustang Stahl Oz546 Article PDFEden RaphNo ratings yet

- Sopwith Camel BiplaneDocument8 pagesSopwith Camel BiplaneAviation/Space History LibraryNo ratings yet

- Aeronca Chief TandemDocument7 pagesAeronca Chief TandemAviation/Space History Library100% (1)

- Kiwi - A Free-Flight Model Airplane (Glider)Document4 pagesKiwi - A Free-Flight Model Airplane (Glider)Bob KowalskiNo ratings yet

- Flying Aces StickDocument11 pagesFlying Aces StickFloria BogdanNo ratings yet

- Gyro GliderDocument3 pagesGyro GliderEmerson UR100% (1)

- Vought SBU-1 BomberDocument7 pagesVought SBU-1 BomberAviation/Space History LibraryNo ratings yet

- Full Download Original PDF Advanced Macroeconomics 4Th Edition by David Romer Ebook PDF Docx Kindle Full ChapterDocument22 pagesFull Download Original PDF Advanced Macroeconomics 4Th Edition by David Romer Ebook PDF Docx Kindle Full Chaptermary.grooms166100% (39)

- Full Download Ebook PDF Integrated Advertising Promotion and Marketing Communications Global Edition 11Th Ebook PDF Docx Kindle Full ChapterDocument22 pagesFull Download Ebook PDF Integrated Advertising Promotion and Marketing Communications Global Edition 11Th Ebook PDF Docx Kindle Full Chapterhomer.owens120100% (35)

- Vought V-143 FighterDocument9 pagesVought V-143 FighterAviation/Space History LibraryNo ratings yet

- F-22 Construction Guide-Scratchbuild 13Document14 pagesF-22 Construction Guide-Scratchbuild 13Mar PopNo ratings yet

- Needle Nose! Advanced-Level Paper Airplanes: 4D An Augmented Reading Paper-Folding ExperienceFrom EverandNeedle Nose! Advanced-Level Paper Airplanes: 4D An Augmented Reading Paper-Folding ExperienceNo ratings yet

- Instant Paper Airplanes Ebook: 12 Printable Airplanes You Tape Together and Fly!From EverandInstant Paper Airplanes Ebook: 12 Printable Airplanes You Tape Together and Fly!No ratings yet

- Laptop StandDocument1 pageLaptop Standandres silvestreNo ratings yet

- 3D Engine ModelingDocument16 pages3D Engine Modelingandres silvestreNo ratings yet

- Postal Contest Rules PDFDocument5 pagesPostal Contest Rules PDFandres silvestreNo ratings yet

- 2 Pestillo 132Document1 page2 Pestillo 132andres silvestreNo ratings yet

- f45972552 Edge 540t DXF DXFDocument63 pagesf45972552 Edge 540t DXF DXFandres silvestreNo ratings yet

- 445 035149 1939 WakefieldDocument2 pages445 035149 1939 Wakefieldandres silvestreNo ratings yet

- Bob Angel Spark Ignition Trouble ShootingDocument3 pagesBob Angel Spark Ignition Trouble Shootingandres silvestreNo ratings yet

- Tandy Walker Laser Cut GasketsDocument4 pagesTandy Walker Laser Cut Gasketsandres silvestreNo ratings yet

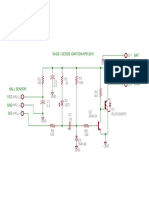

- f43696824 Sage Gedde Ignition SCHDocument1 pagef43696824 Sage Gedde Ignition SCHandres silvestreNo ratings yet

- JayBurkart Speed 400 Motor Replacement 26jul2022-1Document2 pagesJayBurkart Speed 400 Motor Replacement 26jul2022-1andres silvestreNo ratings yet

- Is Now Part ofDocument11 pagesIs Now Part ofandres silvestreNo ratings yet

- Marvv Stern Mark IIIDocument1 pageMarvv Stern Mark IIIandres silvestreNo ratings yet

- ANTIQUE MODELLER Arrow ArticleDocument4 pagesANTIQUE MODELLER Arrow Articleandres silvestreNo ratings yet

- Carbon-Z Yak 54: Instruction Manual Bedienungsanleitung Manuel D'utilisation Manuale Di IstruzioniDocument19 pagesCarbon-Z Yak 54: Instruction Manual Bedienungsanleitung Manuel D'utilisation Manuale Di Istruzioniandres silvestreNo ratings yet

- Fighter Ultralight: Osvaldo DuranaDocument24 pagesFighter Ultralight: Osvaldo Duranaandres silvestreNo ratings yet

- Cap 232 TiledDocument25 pagesCap 232 Tiledandres silvestreNo ratings yet

- PT 40 PlanDocument1 pagePT 40 Planandres silvestreNo ratings yet

- eXTRA TABLITA .46 - Y .60 PDFDocument40 pageseXTRA TABLITA .46 - Y .60 PDFandres silvestreNo ratings yet

- Pilot QB 40S.Document3 pagesPilot QB 40S.andres silvestreNo ratings yet

- Strikemaster ArticleDocument4 pagesStrikemaster Articleandres silvestreNo ratings yet

- 48 Yak54 EXP ManualDocument27 pages48 Yak54 EXP Manualandres silvestreNo ratings yet

- eXTRA 260 - aEROWORK 50CCDocument93 pageseXTRA 260 - aEROWORK 50CCandres silvestreNo ratings yet

- 02flying Models February 1990 PDFDocument101 pages02flying Models February 1990 PDFandres silvestreNo ratings yet

- Extra 260Document26 pagesExtra 260andres silvestreNo ratings yet

- Build Your Own CNC Milling Machine PDFDocument13 pagesBuild Your Own CNC Milling Machine PDFandres silvestreNo ratings yet

- Notes About A320 FCTM by Iman Jafarian and MJ - AzadiDocument47 pagesNotes About A320 FCTM by Iman Jafarian and MJ - Azadimohammad javad AzadiNo ratings yet

- Easa Questions HelicopterDocument83 pagesEasa Questions HelicopterJOEL FONZY S. MANZANONo ratings yet

- Research Article: Aircraft Scheduled Airframe Maintenance and Downtime Integrated Cost ModelDocument13 pagesResearch Article: Aircraft Scheduled Airframe Maintenance and Downtime Integrated Cost ModelAnonymous tdFaNbjNo ratings yet

- Aircraft Design Unit 1Document39 pagesAircraft Design Unit 1Vinoth AeroNo ratings yet

- MasDocument29 pagesMasSyaz AmriNo ratings yet

- Aircraft Weighing Report 2Document29 pagesAircraft Weighing Report 2Edwar ZulmiNo ratings yet

- The Aircraft Design Process: OutlineDocument32 pagesThe Aircraft Design Process: Outlinesmugge juniorNo ratings yet

- Heavy LandingDocument2 pagesHeavy LandingHamdan Merchant100% (2)

- Enemy Engaged - Quick Reference Card - PCDocument2 pagesEnemy Engaged - Quick Reference Card - PCJames YuNo ratings yet

- Contoh Monthly Report PDFDocument4 pagesContoh Monthly Report PDFAchmad Nurr ImanNo ratings yet

- Helicopter Performance: Layton, Donald MDocument287 pagesHelicopter Performance: Layton, Donald MzmajchekNo ratings yet

- WhitepaperDocument15 pagesWhitepaperMasuda AkterNo ratings yet

- Turbocharger Programme 2011 PDFDocument36 pagesTurbocharger Programme 2011 PDFAlexander Akimov100% (1)

- A330 Checklist 2-3-9nDocument1 pageA330 Checklist 2-3-9nHaborymNo ratings yet

- FATechnical KnowledgerevDocument11 pagesFATechnical KnowledgerevhardiprasetiawanNo ratings yet

- The Future of TransportationDocument11 pagesThe Future of TransportationBrandon AckermanNo ratings yet

- 032 - Performance - QuestionsDocument131 pages032 - Performance - QuestionsEASA ATPL Question Bank100% (4)

- Chart Spzo Jul2014Document22 pagesChart Spzo Jul2014oscar2k27No ratings yet

- Wright Flyer AeroplaneDocument14 pagesWright Flyer AeroplaneAviation/Space History LibraryNo ratings yet

- Flight Operations Briefing NotesDocument5 pagesFlight Operations Briefing NotesBilly CostaNo ratings yet

- Mil STD 1523aDocument10 pagesMil STD 1523aNicolasSuchNo ratings yet

- Global Hawk Systems Engineering Case Study PDFDocument103 pagesGlobal Hawk Systems Engineering Case Study PDFAlex BurceaNo ratings yet

- Ad 2011 04 09Document7 pagesAd 2011 04 09bipinupNo ratings yet

- CESSNA172 Normal Procedures 2018Document15 pagesCESSNA172 Normal Procedures 2018VladNo ratings yet

- Alaska Airline ReservationDocument3 pagesAlaska Airline ReservationfarecopyNo ratings yet

- Amap LDocument6 pagesAmap La19952083100% (1)

- Ug - Camo .00006-001 - Easa Part-Camo Approvals - User Guide For Nominated PersonnelDocument30 pagesUg - Camo .00006-001 - Easa Part-Camo Approvals - User Guide For Nominated PersonnelRoshan NundlallNo ratings yet

- Ivchenko ProgressDocument35 pagesIvchenko ProgressIon PopescuNo ratings yet

- Satellite ReportDocument87 pagesSatellite Reportkvk808No ratings yet

Cabinete 2

Cabinete 2

Uploaded by

andres silvestre0 ratings0% found this document useful (0 votes)

22 views4 pages1) The article describes a small gas-powered model airplane called the G.E. "Cabinette" that is easy to build and fly despite its small size.

2) The model can climb quickly and soar high, with one flight carrying the plane out of sight until it was found a week later by a passerby with only minor damage.

3) The plans show how to construct the simple but realistic-looking model using basic materials like balsa wood and paper covering. With a gas engine it can perform well in various weather.

Original Description:

Original Title

cabinete2

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1) The article describes a small gas-powered model airplane called the G.E. "Cabinette" that is easy to build and fly despite its small size.

2) The model can climb quickly and soar high, with one flight carrying the plane out of sight until it was found a week later by a passerby with only minor damage.

3) The plans show how to construct the simple but realistic-looking model using basic materials like balsa wood and paper covering. With a gas engine it can perform well in various weather.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

22 views4 pagesCabinete 2

Cabinete 2

Uploaded by

andres silvestre1) The article describes a small gas-powered model airplane called the G.E. "Cabinette" that is easy to build and fly despite its small size.

2) The model can climb quickly and soar high, with one flight carrying the plane out of sight until it was found a week later by a passerby with only minor damage.

3) The plans show how to construct the simple but realistic-looking model using basic materials like balsa wood and paper covering. With a gas engine it can perform well in various weather.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 4

THE G. E.

"CABINETTE" TAKES WING

A little class A gas job with A big performance -- Easy to build and fly

by FRANK EHLING

WITH a short hop and a bound-this little ship is the frame is not warped and that the whole structure is in

in the air, standing on its tail climbing skyward. A few proper alignment.

seconds later it is a speck in the sky. Be careful to time

the motor for less than twenty seconds or you will spend

more time looking for the ship than it takes to build a

new one.

After many fine flights on a recent trip to the

flying field, the timer stuck and allowed the motor to run

about twenty seconds. The plane kept climbing till it no

longer could be seen, so we went home, sorry that we

made that flight but gratified to know how easily this little

ship can place among contest winners.

One week later a car drove up and out came a

young man with the lost model, the only damage, a

small hole in the wing covering. When offered

compensation for returning the ship he replied, "All I

want is to see that ship perform."

Soon the wing was patched and we started for

the flying field. This fellow had never seen a gas model

fly and he stood breathless when the ship took off into a

steep climb. After a few flights he was a confirmed

model fan, and wanted to build a plane like it. A recent

letter from him tells that he was successful-his plane has

made many fine flights.

This model fulfills the need of a realistic looking

plane that will give a good account of itself when flown in

any kind of weather.

The wing is raised on a high cabin for stability.

The cut-out in its leading edge allows the wing to be

placed nearer the propeller, thus giving the ship a

shorter nose moment arm and added stability.

The plans are shown half size. Any

measurement not given call be determined by merely No larger than some rubber powered models and of simple

doubling the size shown. The whole plan should be construction but with the looks and zip of large planes

drawn up first: this is easily done with a pair of dividers

and ruler. If you prefer, the plans call be enlarged for a

class B ship. One of this size has been built and is

constantly turning in good flights.

Start the construction by assembling the

fuselage sides. The longerons and struts are pinned in

place over the full size drawing, placing the pins on both

sides of the members but not through them. After the

joints are cemented and dry remove the side assembly

from the plan. Make both sides in a similar manner.

Assemble the two sides by cementing the

firewall and the stern post in place; the latter is the

rearmost upright member of the fuselage shown on the

plans. Hold the joints together with pins while they dry.

Next the cross members, top and bottom, can be put in

place; also the cabin structure which is built up with

formers and a keel that runs from its rear to the front of

the fin. While the glue of the joints is drying make sure

Next cement the cabin celluloid windows in place, The stabilizer construction is similar to the wing and

after which the landing gear and motor mounts can be is likewise covered.

properly formed and assembled to the front bulkhead. The The rudder is cut from a balsa sheet and sanded to

ignition then can be installed, located as shown in the a streamline crossection. It is best to dope and finish this

drawings. When this is done sand the whole structure part before it is cemented in the assembly.

lightly. The paper covering may then be applied. The sub-rudder, beneath the fuselage, is made the

When building the wing first cut out all parts to the same as the fin above, except that a wire tail skid is

proper shape, including the spars, ribs, leading and trailing cemented to its lower edge. When these are completed

edges and miscellaneous parts. Assemble half the wing at cement them in place on the fuselage.

a time by mounting the ribs on the spars at the proper Now carefully check over all your work and if

place. completed to your satisfaction apply clear dope to all

Next cement the leading and trailing edges and surfaces. While the dope is still wet check the wing and tail

curved tips in place. When both halves are done join them surfaces for warp, holding them in the correct position until

together with the splices shown in the drawing, making the dope dries.

certain that the wing has the proper dihedral; that is, each The plane may be made very colorful and

wing tip should be raised 2-3/4" from a horizontal line impressive-looking by trimming it with colored dope.

through the leading edge at the wing center. The tips are Flying this little plane is "as easy as eating." First

made from 1/16" sq. bamboo, both tips being made at the glide it, being sure it has correct balance and turns to the

same time to insure uniformity. right in about a 50 ft. circle. This may be regulated by

When all of this is completed cover the center warping the rudder slightly to the right. Test the model by

section and then the leading edge with 1/32" sheet balsa. starting the motor and hand-launching it very gently into the

Sand the whole wing carefully and add a little more cement wind. Do not push it-actually the wind should lift the model

to all joints that may need it. from your grasp. This procedure allows the model to

The wing is now ready for covering. This is done by assume normal flight angle when starting. Adjust the model

cutting the paper with a 3/8" margin all around. Apply to the until flights are satisfactory. Be sure however that in the test

wing by starting at the center and progressively cementing flights the motor runs only for 4 or 5 seconds; after this real

it to each rib as you proceed outward toward the tip. The flights can be made with longer motor runs.

paper should be drawn tightly from center to tip. Then the

leading and trailing edges may be cemented down and the VICT0RY

excessive paper trimmed around the edges.

Scanned from June 1942

Model Airplane News

You might also like

- Hangar Rat PDFDocument5 pagesHangar Rat PDFDarlysson50% (6)

- F-14 Park Jet Construction Guide 2Document23 pagesF-14 Park Jet Construction Guide 2John MondoNo ratings yet

- Marine Capacity Table Hitachi GearboxDocument51 pagesMarine Capacity Table Hitachi Gearboxarieznaval67% (3)

- Taylorcraft L-2 GrasshopperDocument10 pagesTaylorcraft L-2 GrasshopperAviation/Space History Library100% (1)

- Culver Cadet MonoplaneDocument5 pagesCulver Cadet MonoplaneAviation/Space History LibraryNo ratings yet

- The Pacemaker - A Free-Flight Model Airplane (Fuel Engine) (Convert To R/C?)Document11 pagesThe Pacemaker - A Free-Flight Model Airplane (Fuel Engine) (Convert To R/C?)Bob KowalskiNo ratings yet

- The Skyfarer: by Jim NoonanDocument3 pagesThe Skyfarer: by Jim NoonanathrellusNo ratings yet

- Vultee A-31 VengeanceDocument4 pagesVultee A-31 VengeanceAviation/Space History LibraryNo ratings yet

- Baby DurationDocument5 pagesBaby DurationWilmer Chinomes PinzónNo ratings yet

- Interstate Cadet MonoplaneDocument7 pagesInterstate Cadet MonoplaneAviation/Space History LibraryNo ratings yet

- North American BC-1 TrainerDocument7 pagesNorth American BC-1 TrainerAviation/Space History LibraryNo ratings yet

- AirHopper - A Free-Flight Model Airplane (Glider)Document7 pagesAirHopper - A Free-Flight Model Airplane (Glider)Bob KowalskiNo ratings yet

- Tyro 1 - A Free-Flight Model Airplane (Glider)Document4 pagesTyro 1 - A Free-Flight Model Airplane (Glider)Bob KowalskiNo ratings yet

- Taylorcraft O-57 GrasshopperDocument8 pagesTaylorcraft O-57 GrasshopperAviation/Space History Library100% (1)

- The Rocketeer - A Free-Flight Model Airplane (Rocket Engine)Document4 pagesThe Rocketeer - A Free-Flight Model Airplane (Rocket Engine)Bob KowalskiNo ratings yet

- Cessna 195Document2 pagesCessna 195MehdiNo ratings yet

- Dethermalizer - A Free-Flight Model AirplaneDocument4 pagesDethermalizer - A Free-Flight Model AirplaneBob KowalskiNo ratings yet

- Curtiss O-52 - A Free-Flight Model AirplaneDocument5 pagesCurtiss O-52 - A Free-Flight Model AirplaneBob KowalskiNo ratings yet

- Fundamentals of Model Airplane Part 5 PDFDocument6 pagesFundamentals of Model Airplane Part 5 PDFMarian PaunaNo ratings yet

- ERCO 415-A ErcoupeDocument8 pagesERCO 415-A ErcoupeAviation/Space History LibraryNo ratings yet

- Rearwin SportsterDocument7 pagesRearwin SportsterAviation/Space History LibraryNo ratings yet

- High Efficiency Soarer - A Free-Flight Model Airplane (Glider)Document4 pagesHigh Efficiency Soarer - A Free-Flight Model Airplane (Glider)Bob KowalskiNo ratings yet

- The Jersey Albatross - A Free-Flight Model Airplane (Glider)Document4 pagesThe Jersey Albatross - A Free-Flight Model Airplane (Glider)Bob Kowalski100% (1)

- Cessna 140Document18 pagesCessna 140getuliobraiaNo ratings yet

- Republic RC-3 SeabeeDocument4 pagesRepublic RC-3 SeabeeAviation/Space History Library100% (2)

- Building The Fairchild Ranger: by Paul W. LindbergDocument4 pagesBuilding The Fairchild Ranger: by Paul W. LindbergBrunno VasquesNo ratings yet

- Sopwith Camel - A Free-Flight Model AirplaneDocument6 pagesSopwith Camel - A Free-Flight Model AirplaneBob KowalskiNo ratings yet

- The Wisp: by Dan HealdDocument4 pagesThe Wisp: by Dan Healdmuca11No ratings yet

- Bede BD5Document4 pagesBede BD5Alfredo Arnéz Paz SoldánNo ratings yet

- Piper J-3 CubDocument9 pagesPiper J-3 CubAviation/Space History LibraryNo ratings yet

- Rearwin SpeedsterDocument5 pagesRearwin SpeedsterAviation/Space History LibraryNo ratings yet

- Planta de AeronaveDocument18 pagesPlanta de AeronaveKellLuz100% (1)

- Gee Bee Super SportsterDocument8 pagesGee Bee Super SportsterAviation/Space History LibraryNo ratings yet

- Bebe Jodel Oz760 TranscriptDocument3 pagesBebe Jodel Oz760 TranscriptAlessandro Dal BoscoNo ratings yet

- Douglas DB-7 BomberDocument8 pagesDouglas DB-7 BomberAviation/Space History Library50% (2)

- Vought SBU-1 FF 1936 Oz6837Document3 pagesVought SBU-1 FF 1936 Oz6837Roberto ClementeNo ratings yet

- De Havilland DH4Document3 pagesDe Havilland DH4RosanaNo ratings yet

- Build and Fly The Fokker D - 8Document8 pagesBuild and Fly The Fokker D - 8Ari SutiknoNo ratings yet

- The Flying Air Warden: Al PardocchiDocument4 pagesThe Flying Air Warden: Al PardocchiJacob PegherNo ratings yet

- 2001 Curtiss P-40M Kittyhwak IIIDocument14 pages2001 Curtiss P-40M Kittyhwak IIIgabrielle dauz0% (1)

- 1938 Guttman Endurdance July 1938 Flying AcesDocument7 pages1938 Guttman Endurdance July 1938 Flying AcesNora MontoyaNo ratings yet

- BD 5 InstructionsDocument13 pagesBD 5 InstructionskokiskoNo ratings yet

- Micro PittsDocument6 pagesMicro Pittsmam73No ratings yet

- Euler DII Oz12376 TranscriptDocument3 pagesEuler DII Oz12376 TranscriptAlessandro Dal BoscoNo ratings yet

- Douglas C-47Document5 pagesDouglas C-47Emerson URNo ratings yet

- Dave Platt Top Flight - Se5a-ManualDocument18 pagesDave Platt Top Flight - Se5a-ManualTerrance TorNo ratings yet

- P-51D Mustang Stahl Oz546 Article PDFDocument3 pagesP-51D Mustang Stahl Oz546 Article PDFEden RaphNo ratings yet

- Sopwith Camel BiplaneDocument8 pagesSopwith Camel BiplaneAviation/Space History LibraryNo ratings yet

- Aeronca Chief TandemDocument7 pagesAeronca Chief TandemAviation/Space History Library100% (1)

- Kiwi - A Free-Flight Model Airplane (Glider)Document4 pagesKiwi - A Free-Flight Model Airplane (Glider)Bob KowalskiNo ratings yet

- Flying Aces StickDocument11 pagesFlying Aces StickFloria BogdanNo ratings yet

- Gyro GliderDocument3 pagesGyro GliderEmerson UR100% (1)

- Vought SBU-1 BomberDocument7 pagesVought SBU-1 BomberAviation/Space History LibraryNo ratings yet

- Full Download Original PDF Advanced Macroeconomics 4Th Edition by David Romer Ebook PDF Docx Kindle Full ChapterDocument22 pagesFull Download Original PDF Advanced Macroeconomics 4Th Edition by David Romer Ebook PDF Docx Kindle Full Chaptermary.grooms166100% (39)

- Full Download Ebook PDF Integrated Advertising Promotion and Marketing Communications Global Edition 11Th Ebook PDF Docx Kindle Full ChapterDocument22 pagesFull Download Ebook PDF Integrated Advertising Promotion and Marketing Communications Global Edition 11Th Ebook PDF Docx Kindle Full Chapterhomer.owens120100% (35)

- Vought V-143 FighterDocument9 pagesVought V-143 FighterAviation/Space History LibraryNo ratings yet

- F-22 Construction Guide-Scratchbuild 13Document14 pagesF-22 Construction Guide-Scratchbuild 13Mar PopNo ratings yet

- Needle Nose! Advanced-Level Paper Airplanes: 4D An Augmented Reading Paper-Folding ExperienceFrom EverandNeedle Nose! Advanced-Level Paper Airplanes: 4D An Augmented Reading Paper-Folding ExperienceNo ratings yet

- Instant Paper Airplanes Ebook: 12 Printable Airplanes You Tape Together and Fly!From EverandInstant Paper Airplanes Ebook: 12 Printable Airplanes You Tape Together and Fly!No ratings yet

- Laptop StandDocument1 pageLaptop Standandres silvestreNo ratings yet

- 3D Engine ModelingDocument16 pages3D Engine Modelingandres silvestreNo ratings yet

- Postal Contest Rules PDFDocument5 pagesPostal Contest Rules PDFandres silvestreNo ratings yet

- 2 Pestillo 132Document1 page2 Pestillo 132andres silvestreNo ratings yet

- f45972552 Edge 540t DXF DXFDocument63 pagesf45972552 Edge 540t DXF DXFandres silvestreNo ratings yet

- 445 035149 1939 WakefieldDocument2 pages445 035149 1939 Wakefieldandres silvestreNo ratings yet

- Bob Angel Spark Ignition Trouble ShootingDocument3 pagesBob Angel Spark Ignition Trouble Shootingandres silvestreNo ratings yet

- Tandy Walker Laser Cut GasketsDocument4 pagesTandy Walker Laser Cut Gasketsandres silvestreNo ratings yet

- f43696824 Sage Gedde Ignition SCHDocument1 pagef43696824 Sage Gedde Ignition SCHandres silvestreNo ratings yet

- JayBurkart Speed 400 Motor Replacement 26jul2022-1Document2 pagesJayBurkart Speed 400 Motor Replacement 26jul2022-1andres silvestreNo ratings yet

- Is Now Part ofDocument11 pagesIs Now Part ofandres silvestreNo ratings yet

- Marvv Stern Mark IIIDocument1 pageMarvv Stern Mark IIIandres silvestreNo ratings yet

- ANTIQUE MODELLER Arrow ArticleDocument4 pagesANTIQUE MODELLER Arrow Articleandres silvestreNo ratings yet

- Carbon-Z Yak 54: Instruction Manual Bedienungsanleitung Manuel D'utilisation Manuale Di IstruzioniDocument19 pagesCarbon-Z Yak 54: Instruction Manual Bedienungsanleitung Manuel D'utilisation Manuale Di Istruzioniandres silvestreNo ratings yet

- Fighter Ultralight: Osvaldo DuranaDocument24 pagesFighter Ultralight: Osvaldo Duranaandres silvestreNo ratings yet

- Cap 232 TiledDocument25 pagesCap 232 Tiledandres silvestreNo ratings yet

- PT 40 PlanDocument1 pagePT 40 Planandres silvestreNo ratings yet

- eXTRA TABLITA .46 - Y .60 PDFDocument40 pageseXTRA TABLITA .46 - Y .60 PDFandres silvestreNo ratings yet

- Pilot QB 40S.Document3 pagesPilot QB 40S.andres silvestreNo ratings yet

- Strikemaster ArticleDocument4 pagesStrikemaster Articleandres silvestreNo ratings yet

- 48 Yak54 EXP ManualDocument27 pages48 Yak54 EXP Manualandres silvestreNo ratings yet

- eXTRA 260 - aEROWORK 50CCDocument93 pageseXTRA 260 - aEROWORK 50CCandres silvestreNo ratings yet

- 02flying Models February 1990 PDFDocument101 pages02flying Models February 1990 PDFandres silvestreNo ratings yet

- Extra 260Document26 pagesExtra 260andres silvestreNo ratings yet

- Build Your Own CNC Milling Machine PDFDocument13 pagesBuild Your Own CNC Milling Machine PDFandres silvestreNo ratings yet

- Notes About A320 FCTM by Iman Jafarian and MJ - AzadiDocument47 pagesNotes About A320 FCTM by Iman Jafarian and MJ - Azadimohammad javad AzadiNo ratings yet

- Easa Questions HelicopterDocument83 pagesEasa Questions HelicopterJOEL FONZY S. MANZANONo ratings yet

- Research Article: Aircraft Scheduled Airframe Maintenance and Downtime Integrated Cost ModelDocument13 pagesResearch Article: Aircraft Scheduled Airframe Maintenance and Downtime Integrated Cost ModelAnonymous tdFaNbjNo ratings yet

- Aircraft Design Unit 1Document39 pagesAircraft Design Unit 1Vinoth AeroNo ratings yet

- MasDocument29 pagesMasSyaz AmriNo ratings yet

- Aircraft Weighing Report 2Document29 pagesAircraft Weighing Report 2Edwar ZulmiNo ratings yet

- The Aircraft Design Process: OutlineDocument32 pagesThe Aircraft Design Process: Outlinesmugge juniorNo ratings yet

- Heavy LandingDocument2 pagesHeavy LandingHamdan Merchant100% (2)

- Enemy Engaged - Quick Reference Card - PCDocument2 pagesEnemy Engaged - Quick Reference Card - PCJames YuNo ratings yet

- Contoh Monthly Report PDFDocument4 pagesContoh Monthly Report PDFAchmad Nurr ImanNo ratings yet

- Helicopter Performance: Layton, Donald MDocument287 pagesHelicopter Performance: Layton, Donald MzmajchekNo ratings yet

- WhitepaperDocument15 pagesWhitepaperMasuda AkterNo ratings yet

- Turbocharger Programme 2011 PDFDocument36 pagesTurbocharger Programme 2011 PDFAlexander Akimov100% (1)

- A330 Checklist 2-3-9nDocument1 pageA330 Checklist 2-3-9nHaborymNo ratings yet

- FATechnical KnowledgerevDocument11 pagesFATechnical KnowledgerevhardiprasetiawanNo ratings yet

- The Future of TransportationDocument11 pagesThe Future of TransportationBrandon AckermanNo ratings yet

- 032 - Performance - QuestionsDocument131 pages032 - Performance - QuestionsEASA ATPL Question Bank100% (4)

- Chart Spzo Jul2014Document22 pagesChart Spzo Jul2014oscar2k27No ratings yet

- Wright Flyer AeroplaneDocument14 pagesWright Flyer AeroplaneAviation/Space History LibraryNo ratings yet

- Flight Operations Briefing NotesDocument5 pagesFlight Operations Briefing NotesBilly CostaNo ratings yet

- Mil STD 1523aDocument10 pagesMil STD 1523aNicolasSuchNo ratings yet

- Global Hawk Systems Engineering Case Study PDFDocument103 pagesGlobal Hawk Systems Engineering Case Study PDFAlex BurceaNo ratings yet

- Ad 2011 04 09Document7 pagesAd 2011 04 09bipinupNo ratings yet

- CESSNA172 Normal Procedures 2018Document15 pagesCESSNA172 Normal Procedures 2018VladNo ratings yet

- Alaska Airline ReservationDocument3 pagesAlaska Airline ReservationfarecopyNo ratings yet

- Amap LDocument6 pagesAmap La19952083100% (1)

- Ug - Camo .00006-001 - Easa Part-Camo Approvals - User Guide For Nominated PersonnelDocument30 pagesUg - Camo .00006-001 - Easa Part-Camo Approvals - User Guide For Nominated PersonnelRoshan NundlallNo ratings yet

- Ivchenko ProgressDocument35 pagesIvchenko ProgressIon PopescuNo ratings yet

- Satellite ReportDocument87 pagesSatellite Reportkvk808No ratings yet