Professional Documents

Culture Documents

api/resources/file/CH604MM/ATA 100/CH604/AMM/49/AMM49 10 00 04.full

api/resources/file/CH604MM/ATA 100/CH604/AMM/49/AMM49 10 00 04.full

Uploaded by

Rahul VaishnavOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

api/resources/file/CH604MM/ATA 100/CH604/AMM/49/AMM49 10 00 04.full

api/resources/file/CH604MM/ATA 100/CH604/AMM/49/AMM49 10 00 04.full

Uploaded by

Rahul VaishnavCopyright:

Available Formats

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

POWER PLANT - REMOVAL/INSTALLATION

TASK 49−10−00−000−801

1. Removal of the Auxiliary Power Unit (APU) Power Plant

A. Service Bulletin List

SERVICE BULLETIN NO. SERVICE BULLETIN TITLE

604−49−006 Introduction of the 36−150 (CL) Auxillary Power Unit (APU)

B. Reference Information

REFERENCE DESIGNATION

TASK 36−11−07−000−801 Removal of the Auxiliary Power Unit (APU)−Supply

Check−Valve

TASK 49−10−00−910−801 Auxiliary Power Unit (APU) Safety Precautions

TASK 49−11−04−000−801 Removal of the Auxiliary Power Unit (APU)

Enclosure Access Panel (311BZ)

TASK 49−11−04−400−801 Installation of the Auxiliary Power Unit (APU)

Enclosure Access Panel (311BZ)

TASK 49−12−01−000−801 Removal of the Auxiliary Power Unit (APU) Support

Skid Assembly

TASK 49−51−01−000−801 Removal of the Auxiliary Power Unit (APU) Load

Control Valve

TASK 52−41−00−010−801 Open the Aft Equipment−Compartment Door

(311BB)

SPM−MM 20−50−00−000−801 Removal of Lockwire

EFFECTIVITY: ALL

49−10−00 Page 401

Sep 05/2017

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

C. Tools and Equipment

REFERENCE DESIGNATION

GSE 24−00−24 Circuit Breaker Tag − Red

GSE 49−00−01 Kit − APU Removal/Installation

Commercially Available Stand, Mobile

NOTE: Refer to the Illustrated Tool and Equipment Manual to make sure that you use

the correct equipment configuration.

On A/C 5301 to 5630 Pre SB 604−49−006

D. Job Set−Up

(1) Open and tag the circuit breakers that follow:

LOCATION CB NUMBER CB NAME ZONE

CBP−1 L1 APU ECU 221

CBP−1 L2 APU FAULT ANN 221

CBP−1 L3 APU START CONT 221

CBP−1 R5 APU FIRE EXT 221

CBP−1 S3 FUEL SOV APU 221

CBP−2 P4 APU FUEL PUMP 222

(2) Open the aft equipment compartment access−door (311BB)

(TASK 52−41−00−010−801).

(3) Obey all the auxiliary power unit (APU) safety precautions

(TASK 49−10−00−910−801).

(4) Remove the APU enclosure access panel (311BZ) (TASK 49−11−04−000−801).

(5) Remove the lockwire from the electrical connectors (2), (4) and (6)

(SPM−MM 20−50−00−000−801).

(6) Disconnect the electrical connector (2) from the receptacle (3) for the generator

control unit. Install protective covers.

(7) Disconnect the electrical connector (4) from the receptacle (5) of the low

oil−pressure switch for the APU generator adapter. Install the protective covers.

EFFECTIVITY: ALL

49−10−00 Page 402

Mar 14/2022

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

(8) Disconnect the electrical connector (6) from the receptacle (7) of the hot

oil−temperature switch for the APU generator adapter. Install the protective covers.

(9) Disconnect the electrical connector (8) J2KD from the receptacle (9) on the APU

enclosure. Install protective covers.

(10) Loosen the screws (10) and open the clamps (11) that attach the electrical

harness (12) to the APU enclosure.

(11) Temporarily attach the electrical harness (12) to the APU (1).

(12) Remove the parts from the integrated drive generator (13) as follows:

(a) Remove the bolts (14), the washers (69), and the clamp (15) that attach the

terminal block cover (16) to the terminal block (17).

(b) Remove the nuts (18), the washers (19) and the electrical cables (20) from the

terminal lugs (T1, T2, T3, and G) on the terminal block (17).

NOTE: Tag and identify each electrical cable (20) before you remove it.

(c) Loosely install the nuts (18), the washers (19), the terminal block cover (16),

the bolts (14), and the washers (69) on the terminal block (17).

(13) Remove the parts from the starter motor (21) as follow:

(a) Remove the nut (22) and the washer (23) that attaches the electrical cable (24)

to the positive terminal on the starter motor (21).

(b) Remove the nut (87) and the washer (88) that attach the electrical cable (25)

to the negative terminal on the starter motor (21).

NOTE: Tag and identify each of the electrical cables (24) and (25) before the

removal.

(c) Remove the starter cables (24) and (25) from the terminals on the starter

motor (21).

(d) Loosely install the nuts (22) and (87) and the washers (23) and (88) on the

terminals on the starter motor (21).

(14) Remove the exhaust nozzle (26) as follows:

(a) Loosen the coupling (27) that attaches the exhaust nozzle (26) to the exhaust

outlet flange (28).

(b) Remove the exhaust nozzle (26) from the APU (1) and move it into the

exhaust duct (29).

(c) Temporarily attach the coupling (27) to the exhaust nozzle flange (28).

(d) Install protective covers on the exhaust nozzle flange (28).

EFFECTIVITY: ALL

49−10−00 Page 403

Sep 05/2017

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

(15) Remove the APU outlet bleed duct (32) and the APU supply check valve from the

load control valve (31) (TASK 36−11−07−000−801).

(16) Disconnect the APU inlet duct assembly (33) as follows:

(a) Remove the retaining clips (34) that attach the APU inlet bellows

assembly (35) to the flange on the APU inlet duct (36).

(b) Lift the APU inlet bellows assembly (35) and attach it to the hanger bellows

clips (37).

(c) Install a protective cover on the APU inlet duct (36).

CAUTION: USE TWO WRENCHES WHEN YOU REMOVE/TORQUE THE

HOSES/TUBES. USE ONE WRENCH TO HOLD THE FITTING, AND

THE OTHER WRENCH TO LOOSEN/TORQUE THE COUPLING NUT.

IF YOU DO NOT DO THIS, YOU CAN CAUSE DAMAGE TO THE

COMPONENTS.

(17) Disconnect the hoses (38), (39), (41), (43), (44), (46) and (47) as follows:

(a) Disconnect the drain hose (38) at the APU inlet duct (36). Install protective

covers.

(b) Disconnect the drain hose (39) at the tee−fitting (40) for the combustor drains.

Install protective covers.

(c) Disconnect the fuel inlet hose (41) at the generator adapter (42). Install

protective covers.

(d) Disconnect the fuel return hose (43) at the generator adapter (42). Install

protective covers.

(e) Disconnect the fuel supply hose (44) from the fuel control unit (45). Install

protective covers.

(f) Disconnect the drain hose (46) from the fuel control unit (45). Install protective

covers.

(g) Disconnect the vent hose (47) from the vent tube (48) on the generator

adapter (42). Install the protective covers.

(18) Do a visual inspection of the aircraft frame holes where the beam (74) is to be

attached. Make sure the aluminum holes of the frames at FS654.50 and FS700.00

are not damaged.

NOTE: These holes are each protected by a steel doubler.

EFFECTIVITY: ALL

49−10−00 Page 404

Sep 05/2017

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

WARNING: USE ONLY APPROVED LIFTING POINTS WHEN YOU MOVE, LIFT, OR

LOWER THE APU. YOU CAN CAUSE INJURIES TO PERSONS AND

DAMAGE TO THE EQUIPMENT.

MAKE SURE THAT THE APU SLING AND THE APU HOIST IS

ASSEMBLED CORRECTLY. YOU CAN CAUSE INJURIES TO

PERSONS AND DAMAGE TO THE EQUIPMENT.

(19) Install the APU hoist (73), the APU sling (75) and the beam (74) as follows:

(a) Install the beam (74) to the aircraft attaching points at FS654 and FS700.

(b) Install the APU sling cable (82) to the APU upper gearcase adapter (86).

(c) Install the APU sling cable (77) to the APU lifting cable (78) with the bolt (79)

the washer (80) and the nut (81).

(d) Install the APU hoist cable to the APU sling (75) with the shackle (76).

(e) Install the APU hoist (73) to the beam (74).

On A/C 5631 and subs and 5301 to 5630 Post SB 604−49−006

E. Job Set−Up

(1) Open and tag the circuit breakers that follow:

LOCATION CB NUMBER CB NAME ZONE

CBP−1 L1 APU ECU 221

CBP−1 L2 APU FAULT ANN 221

CBP−1 L3 APU START CONT 221

CBP−1 R5 APU FIRE EXT 221

CBP−1 S3 FUEL SOV APU 221

CBP−2 P4 APU FUEL PUMP 222

CBP−5 A2 APU ECU PRIM 311

CBP−5 A3 APU ECU SEC 311

(2) Obey all the auxiliary power unit (APU) safety precautions

(TASK 49−10−00−910−801).

(3) Open the aft equipment compartment access−door (311BB)

(TASK 52−41−00−010−801).

EFFECTIVITY: ALL

49−10−00 Page 405

Sep 05/2017

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

(4) Remove the APU enclosure access panel (311BZ) (TASK 49−11−04−000−801).

(5) Remove the lockwire from the electrical connectors (2), (4) and (6)

(SPM−MM 20−50−00−000−801).

(6) Disconnect the electrical connector (2) from the receptacle (3) for the generator

control unit. Install protective covers.

(7) Disconnect the electrical connector (4) from the receptacle (5) of the low

oil−pressure switch for the APU generator adapter. Install the protective covers.

(8) Disconnect the electrical connector (6) from the receptacle (7) of the hot

oil−temperature switch for the APU generator adapter. Install the protective covers.

(9) Disconnect the electrical connector (8) J2KD from the receptacle (9) on the APU

enclosure. Install protective covers.

(10) Loosen the screws (10) and open the clamps (11) that attach the electrical

harness (12) to the APU enclosure.

(11) Temporarily attach the electrical harness (12) to the APU (1).

(12) Remove the parts from the integrated drive generator (13) as follows:

(a) Remove the screws (14), the washers (15), and the clamp (16) that attach the

terminal block cover (17) to the terminal block (18).

(b) Remove the nuts (19), the washers (20) and the electrical cables (21) from the

terminal lugs (T1, T2, T3, and G) on the terminal block (18).

NOTE: Tag and identify each electrical cable (21) before you remove it.

(c) Loosely install the nuts (19), the washers (20), the terminal block cover (17),

the screws (14), and the washers (15) on the terminal block (18).

(13) Remove the parts from the starter motor (22) as follow:

(a) Remove the nut (23) and the washer (24) that attaches the electrical cable (25)

to the positive terminal on the starter motor (22).

(b) Remove the nut (87) and the washer (88) that attaches the electrical cable (26)

to the negative terminal on the starter motor (22).

NOTE: Tag and identify each of the electrical cables (25) and (26) before

removal.

(c) Remove the starter cables (25) and (26) from the terminals on the starter

motor (22).

(d) Loosely install the nuts (23) and (87) and the washers (24) and (88) on the

terminals on the starter motor (22).

EFFECTIVITY: ALL

49−10−00 Page 406

Sep 05/2017

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

(14) Remove the exhaust nozzle (27) as follows:

(a) Loosen the coupling (28) that attaches the exhaust nozzle (27) to the exhaust

outlet flange (29).

(b) Remove the exhaust nozzle (27) from the APU (1) and move it into the

exhaust duct (30).

(c) Temporarily attach the coupling (28) to the exhaust nozzle flange (29).

(d) Install protective covers on the exhaust nozzle flange (29).

(15) Remove the APU outlet bleed duct (32) and the APU supply check valve from the

load control valve (31) (TASK 36−11−07−000−801).

(16) Disconnect the APU inlet duct assembly (33) as follows:

(a) Remove the retaining clips (34) that attach the APU inlet bellows

assembly (35) to the flange on the APU inlet duct (36).

(b) Lift the APU inlet bellows assembly (35) and attach it to the hanger bellows

clips (37).

(c) Install a protective cover on the APU inlet duct (36).

CAUTION: USE TWO WRENCHES WHEN YOU REMOVE/TORQUE THE

HOSES/TUBES. USE ONE WRENCH TO HOLD THE FITTING, AND

THE OTHER WRENCH TO LOOSEN/TORQUE THE COUPLING NUT.

IF YOU DO NOT DO THIS, YOU CAN CAUSE DAMAGE TO THE

COMPONENTS.

(17) Disconnect the hoses (38), (39), (41), (42) and (45) as follows:

(a) Disconnect the drain hose (38) at the APU inlet duct (36). Install protective

covers.

(b) Disconnect the fuel inlet hose (39) at the generator adapter (40). Install

protective covers.

(c) Disconnect the fuel return hose (41) at the generator adapter (40). Install

protective covers.

(d) Disconnect the fuel supply hose (42) from the fuel control unit (44). Install

protective covers.

(e) Disconnect the drain hose (45) from the fuel control unit (44). Install protective

covers.

EFFECTIVITY: ALL

49−10−00 Page 407

Sep 05/2017

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

CAUTION: USE TWO WRENCHES WHEN YOU REMOVE/TORQUE THE

HOSES/TUBES. USE ONE WRENCH TO HOLD THE FITTING, AND

THE OTHER WRENCH TO LOOSEN/TORQUE THE COUPLING NUT.

IF YOU DO NOT DO THIS, YOU CAN CAUSE DAMAGE TO THE

COMPONENTS.

(18) Disconnect the fuel solenoid tube (53) from the fuel control unit (44). Install

protective covers.

(19) Do a visual inspection of the aircraft frame holes where the beam (74) is to be

attached. Make sure the aluminum holes of the frames at FS654.50 and FS700.00

are not damaged.

NOTE: These holes are each protected by a steel doubler.

WARNING: USE ONLY APPROVED LIFTING POINTS WHEN YOU MOVE, LIFT, OR

LOWER THE APU. YOU CAN CAUSE INJURIES TO PERSONS AND

DAMAGE TO THE EQUIPMENT.

MAKE SURE THAT THE APU SLING AND THE APU HOIST IS

ASSEMBLED CORRECTLY. YOU CAN CAUSE INJURIES TO

PERSONS AND DAMAGE TO THE EQUIPMENT.

(20) Install the beam (74) to the aircraft attaching points at FS654.50 and FS700.00 with

the two lock pins supplied.

(21) Install the APU sling cable (82) to the APU upper gearcase adapter (77).

(22) Install the APU sling cable (77) to the APU lifting cable (78) with the bolt (79) the

washer (80) and the nut (81).

(23) Install the APU hoist cable to the APU sling (75) with the shackle (76).

(24) Install the APU hoist (73) to the beam (74).

On A/C 5301 to 5630 Pre SB 604−49−006

F. Procedure

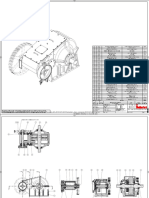

Refer to Figure 401 and Figure 403.

WARNING: MAKE SURE THAT THERE ARE NO PERSONS NEAR THE APU

DURING THE REMOVAL/INSTALLATION. YOU CAN CAUSE INJURIES

TO PERSONS AND DAMAGE TO THE EQUIPMENT.

(1) Put the mobile stand below the aft equipment compartment door.

(2) Remove the bolts (83) and the washers (84) that attach the APU support skid

assembly (85) to the APU enclosure floor.

EFFECTIVITY: ALL

49−10−00 Page 408

Sep 05/2017

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

CAUTION: MAKE SURE THAT THE APU AND ITS COMPONENTS (ESPECIALLY

THE LOAD CONTROL VALVE) DO NOT TOUCH THE SIDES OF THE

APU ENCLOSURE. YOU CAN CAUSE DAMAGE TO THE APU, ITS

COMPONENTS AND THE APU ENCLOSURE.

(3) Carefully operate the hoist to lift the weight of the APU (1) from the APU enclosure.

As the weight of the APU is removed, move the APU out of the APU enclosure.

(4) When the weight of the APU (1) is fully on the APU hoist (73), turn the APU

90 degrees.

(5) Carefully lower the APU (1) through the aft equipment compartment door until it is

clear of the aircraft.

(6) Continue to lower the APU (1) until the APU support skid assembly (85) is on the

mobile stand.

(7) Attach the APU support skid assembly (85) to the mobile stand.

(8) If necessary, remove the APU support skid assembly (85) from the APU (1)

(TASK 49−12−01−000−801).

(9) If necessary, install the APU enclosure access panel (311BZ)

(TASK 49−11−04−400−801).

(10) Remove the APU hoist (73), from the beam (74).

(11) Remove the APU hoist cable from the APU sling (75).

(12) Remove the bolt (79), the washer (80) and the nut (81) that attache the APU sling

cable (77) to the APU lifting cable (78).

(13) Remove the APU sling cable (82) from the APU upper gearcase adapter (86).

(14) Remove the beam (74) from the aircraft attaching points at FS654.00 and

FS700.00.

(15) Do a visual inspection of the aircraft frame holes where the beam (74) was

attached. Make sure the aluminum holes of the frames at FS654.50 and FS700.00

are not damaged.

NOTE: These holes are each protected by a steel doubler.

(16) If the APU (1) will be replaced, remove the parts that follow:

(a) Remove the APU load control valve (31) (TASK 49−51−01−000−801).

(b) Remove the union (49) and the packing (50) from the fuel inlet port (51) on the

generator adapter (42). Install protective covers.

(c) Remove the union (52) and the packing (53) from the fuel return port (54) on

the generator adapter (42). Install protective covers.

EFFECTIVITY: ALL

49−10−00 Page 409

Sep 05/2017

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

(d) Remove the union (55) and the packing (56) from the inlet port (57) on the fuel

control unit (45). Install protective covers.

(e) Remove the union (58) and the packing (59) from the drain port (60) on the

fuel control unit (45). Install protective covers.

(f) Discard the packings (50), (53), (56) and (59).

(g) Remove the drain tubes (61) and (62) from the combustor/plenum drain

valve/orifice fittings (63) and (64). Install protective covers.

(h) Remove the coupling (27) from the exhaust nozzle flange (28).

On A/C 5631 and subs and 5301 to 5630 Post SB 604−49−006

G. Procedure

Refer to Figure 402 and Figure 403.

WARNING: MAKE SURE THAT THERE ARE NO PERSONS NEAR THE APU

DURING THE REMOVAL/INSTALLATION. YOU CAN CAUSE INJURIES

TO PERSONS AND DAMAGE TO THE EQUIPMENT.

(1) Put the mobile stand below the aft equipment compartment door.

(2) Remove the bolts (83) and the washers (84) that attach the APU support skid

assembly (85) to the APU enclosure floor.

CAUTION: MAKE SURE THAT THE APU AND ITS COMPONENTS (ESPECIALLY

THE LOAD CONTROL VALVE) DO NOT TOUCH THE SIDES OF THE

APU ENCLOSURE. YOU CAN CAUSE DAMAGE TO THE APU, ITS

COMPONENTS AND THE APU ENCLOSURE.

(3) Carefully operate the hoist to lift the weight of the APU (1) from the APU enclosure.

As the weight of the APU is removed, move the APU out of the APU enclosure.

(4) When the weight of the APU (1) is fully on the APU hoist (73), turn the APU

90 degrees.

(5) Carefully lower the APU (1) through the aft equipment compartment door until it is

clear of the aircraft.

(6) Continue to lower the APU (1) until the APU support skid assembly (85) is on the

mobile stand.

(7) Attach the APU support skid assembly (85) to the mobile stand.

(8) If necessary, remove the APU support skid assembly (85) from the APU (1)

(TASK 49−12−01−000−801).

(9) If necessary, install the APU enclosure access panel (311BZ)

(TASK 49−11−04−400−801).

EFFECTIVITY: ALL

49−10−00 Page 410

Sep 05/2017

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

(10) Remove the APU hoist (73) from the beam (74).

(11) Remove the APU hoist cable from the APU sling (75).

(12) Remove the bolt (79), the washer (80) and the nut (81) that attache the APU sling

cable (77) to the APU lifting cable (78).

(13) Remove the APU sling cable (82) from the APU upper gearcase adapter (86).

(14) Remove the beam (74) from the aircraft attaching points at FS654.50 and

FS700.00.

(15) Do a visual inspection of the aircraft frame holes where the beam (74) was

attached. Make sure the aluminum holes of the frames at FS654.50 and FS700.00

are not damaged.

NOTE: These holes are each protected by a steel doubler.

(16) If the APU (1) will be replaced, remove the parts that follow:

(a) Remove the APU load control valve (31) (TASK 49−51−01−000−801).

(b) Remove the union (56) and the packing (57) from the fuel inlet port (58) on the

generator adapter (40). Install protective covers.

(c) Remove the union (59) and the packing (60) from the fuel return port (61) on

the generator adapter (40). Install protective covers.

(d) Remove the union (46) and the packing (47) from the inlet port (48) on the fuel

control unit (44). Install protective covers.

(e) Remove the union (49) and the packing (50) from the drain port (51) on the

fuel control unit (44). Install protective covers.

(f) Remove the union (54) and the packing (55) from the drain port (52) on the

fuel control unit (44). Install protective covers.

(g) Discard the packings (47), (50), (55), (57) and (60).

(h) Remove the coupling (28) from the exhaust nozzle flange (29).

EFFECTIVITY: ALL

49−10−00 Page 411

Sep 05/2017

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

33

35 37 34 32

31

FS650.00 43

41 28

3

2 5 27

4

26

29

1

36

22

13

23 87

88

24

25

LMM4910004_001

21

Auxiliary Power Unit (APU) − Removal/Installation− (A/C 5301 to 5630 PRE SB 604−49−006)

Figure 401 (Sheet 1 of 3)

EFFECTIVITY: ALL

49−10−00 Page 412

Sep 05/2017

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

17

16

17

13

20

19

10

18

15

9 8

69

12 7

11 44 6

46

14

16

64

63

62

40

39 61

LMM4910004_002

38

Auxiliary Power Unit (APU) − Removal/Installation− (A/C 5301 to 5630 PRE SB 604−49−006)

Figure 401 (Sheet 2 of 3)

EFFECTIVITY: ALL

49−10−00 Page 413

Sep 05/2017

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

43

41

42

36 13

63

48

61 64

39

47

40 46

62

44

43

52

71

53 45

54 42

60

57 59

41

56 58

49

55

LMM4910004_003

50 46

51

44 72

Auxiliary Power Unit (APU) − Removal/Installation− (A/C 5301 to 5630 PRE SB 604−49−006)

Figure 401 (Sheet 3 of 3)

EFFECTIVITY: ALL

49−10−00 Page 414

Sep 05/2017

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

33

35 37 34 32

31

41

39

29

3

2 5

4 28

27

30

38

LMM4910004_004

Auxiliary Power Unit (APU) − Removal/Installation− (A/C 5301 to 5630 POST SB 604−49−006 and

5631 and SUBS)

Figure 402 (Sheet 1 of 4)

EFFECTIVITY: ALL

49−10−00 Page 415

Sep 05/2017

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

10

16

9 8

11 12 7

43 42 6

21

20

19

15

18

LMM4910004_005

17

14

Auxiliary Power Unit (APU) − Removal/Installation− (A/C 5301 to 5630 POST SB 604−49−006 and

5631 and SUBS)

Figure 402 (Sheet 2 of 4)

EFFECTIVITY: ALL

49−10−00 Page 416

Sep 05/2017

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

13

36

23

24

87

25

88

26

LMM4910004_006

22

Auxiliary Power Unit (APU) − Removal/Installation− (A/C 5301 to 5630 POST SB 604−49−006 and

5631 and SUBS)

Figure 402 (Sheet 3 of 4)

EFFECTIVITY: ALL

49−10−00 Page 417

Sep 05/2017

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

41

59 62

60

61

40

39

56

57 63

58

52

54 55

44

51

53

48

50

47

49

LMM4910004_007

46

45

42

Auxiliary Power Unit (APU) − Removal/Installation− (A/C 5301 to 5630 POST SB 604−49−006 and

5631 and SUBS)

Figure 402 (Sheet 4 of 4)

EFFECTIVITY: ALL

49−10−00 Page 418

Sep 05/2017

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

74

73

75

76

77

86

78

82

79

83

LMM4910004_011

80

81

84

85

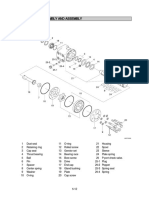

Auxiliary Power Unit (APU) Sling and Hoist − Removal/Installation

Figure 403

EFFECTIVITY: ALL

49−10−00 Page 419

Jun 28/2010

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

TASK 49−10−00−400−801

2. Installation of the Auxiliary Power Unit (APU) Power Plant

A. Service Bulletin List

SERVICE BULLETIN NO. SERVICE BULLETIN TITLE

604−49−006 Introduction of the 36−150 (CL) Auxillary Power Unit (APU)

604−49−003 Improve Leak Resistance and Drainage

B. Reference Information

REFERENCE DESIGNATION

TASK 12−13−49−612−801 Replenishing of the Auxiliary Power Unit (APU) Oil

Supply

TASK 12−13−49−612−802 Replenishing of the Auxiliary Power Unit (APU)

Generator/Adaptor Oil Supply

TASK 36−11−07−400−801 Installation of the Auxiliary Power Unit (APU) Supply

Check−Valve

TASK 49−10−00−710−801 Operational Test of the Auxiliary Power Unit (APU)

TASK 49−10−00−710−802 Operational Test of the Auxiliary Power Unit (APU)

(Loaded)

TASK 49−10−00−790−801 Auxiliary Power Unit (APU) Fuel and Oil Leak Check

TASK 49−10−00−790−802 Auxiliary Power Unit (APU) Bleed Air Leak Check

TASK 49−11−04−000−801 Removal of the Auxiliary Power Unit (APU)

Enclosure Access Panel (311BZ)

TASK 49−11−04−400−801 Installation of the Auxiliary Power Unit (APU)

Enclosure Access Panel (311BZ)

TASK 49−12−01−400−801 Installation of the Auxiliary Power Unit (APU)

Support Skid Assembly

TASK 49−51−01−400−801 Installation of the Auxiliary Power Unit (APU) Load

Control Valve

TASK 49−81−01−400−801 Installation of the Auxiliary Power Unit (APU)

Exhaust Nozzle

TASK 52−41−00−410−801 Close the Aft Equipment−Compartment Door

(311BB)

EFFECTIVITY: ALL

49−10−00 Page 420

May 29/2018

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

REFERENCE DESIGNATION

SPM−MM 20−21−00−910−801 Torquing of Threaded Fasteners

SPM−MM 20−22−00−910−801 Torquing of Plumbing Line Fittings

SPM−MM 20−30−00−910−805 Marman Couplings and V−Band Couplings

SPM−MM 20−50−00−400−801 Installation of Lockwire

SPM−MM 51−23−00−390−809 Wet Installation of Fasteners

CMM 24−22−01 Generator Assembly (UTC Aerospace Systems)

CMM 49−20−00 Engine − Maintenance Manual (Part of CMM

49−21−59) (AlliedSignal / Honeywell International)

CMM 49−21−59 Pneumatic and Shaft Power Gas Turbine Engine

(Alliedsignal Engines)

CMM 49−24−73 Gas Turbine Engine Assembly (Honeywell

International)

CMM 49−24−75 Gas Turbine Engine (Honeywell International)

C. Tools and Equipment

REFERENCE DESIGNATION

GSE 49−00−01 Kit − APU Removal/Installation

Commercially Available Stand, Mobile

Commercially Available Wrench, Torque 18 to 20 lbf in (2.04 to 2.25 Nm)

Commercially Available Wrench, Torque 25 to 30 lbf in (2.83 to 3.38 Nm)

Commercially Available Wrench, Torque 35 to 40 lbf in (3.95 to 4.51 Nm)

Commercially Available Wrench, Torque 40 lbf in (4.52 Nm)

Commercially Available Wrench, Torque 48 to 53 lbf in (5.43 to 5.98 Nm)

Commercially Available Wrench, Torque 70 lbf in (7.91 Nm)

Commercially Available Wrench, Torque 70 to 120 lbf in (7.91 to 13.55 Nm)

Commercially Available Wrench, Torque 75 to 80 lbf in (8.48 to 9.03 Nm)

EFFECTIVITY: ALL

49−10−00 Page 421

Mar 14/2022

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

REFERENCE DESIGNATION

Commercially Available Wrench, Torque 80 lbf in (9.04 Nm)

Commercially Available Wrench, Torque 100 to 250 lbf in (11.30 to

28.24 Nm)

Commercially Available Wrench, Torque 120 lbf in (13.56 Nm)

Commercially Available Wrench, Torque 133 to 147 lbf in (15.03 to

16.60 Nm)

Commercially Available Wrench, Torque 135 to 150 lbf in (15.26 to

16.94 Nm)

Commercially Available Wrench, Torque 17.50 to 35.00 lbf ft (23.73 to

47.45 Nm)

Commercially Available Wrench, Torque 21.42 to 23.66 lbf ft (29.04 to

32.07 Nm)

Commercially Available Wrench, Torque 39.59 to 43.75 lbf ft (53.67 to

59.31 Nm)

NOTE: Refer to the Illustrated Tool and Equipment Manual to make sure that you use

the correct equipment configuration.

D. Consumable Materials

REFERENCE DESIGNATION MANUFACTURERS’ REFERENCE

AND/OR SPECIFICATION

04−024 Petrolatum VV−P−236

05−004 Lockwire, CRES 0.020 in (0.51 mm) MS20995C20

06−070 Sealant, Firewall Dapco 18−4F

Cytec Engineered Materials

06−070B Sealing Compound Aircraft Firewall, Dapco 2200 Type 4

Silicone Cytec Engineered Materials

EFFECTIVITY: ALL

49−10−00 Page 422

Mar 18/2021

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

E. Parts

On A/C 5301 to 5630 Pre SB 604−49−006

REFERENCE NAME OF PART QUANTITY IPC SEQUENCE NO.

1 Unit, Auxiliary Power 1 49−00−01−01−001

49−00−01−01−002

14 Screw 2 24−22−01−01−045

15 Clamp 1 49−13−01−01−030

18 Nut 4 24−22−01−01−055

19 Washer 4 24−22−01−01−060

22 Nut 1 CMM 49−41−04

23 Washer 1 CMM 49−41−04

26 Nozzle, Exhaust 1 49−81−01−01−005

27 Coupling 1 49−81−01−01−010

31 Valve, Auxiliary Power Unit (APU) 1 49−51−01−01−035

Load Control

32 Duct 1 36−11−00−01−346

34 Clip, Retaining 2 49−14−04−01−010

49−14−04−01−015

49 Union 1 49−31−22−01−130

50 Packing 1 49−31−22−01−135

52 Union 1 49−31−22−01−130

53 Packing 1 49−31−22−01−135

55 Union 1 49−31−22−01−120

56 Packing 1 49−31−22−01−125

58 Union 1 49−15−01−01−265

59 Packing 1 49−15−01−01−270

69 Washer 1 24−22−01−01−050

EFFECTIVITY: ALL

49−10−00 Page 423

Sep 05/2017

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

83 Bolt 4 49−12−01−01−135

84 Washer 4 49−12−01−01−140

87 Nut 1 CMM 49−41−04

88 Washer 1 CMM 49−41−04

F. Parts

On A/C 5631 and subs and 5301 to 5630 Post SB 604−49−006

REFERENCE NAME OF PART QUANTITY IPC SEQUENCE NO.

1 Unit, Auxiliary Power 1 49−00−01−01A−001

14 Screw 2 24−22−01−01−045

15 Washer 1 24−22−01−01−050

16 Clamp 1 49−13−01−01A−040

19 Nut 4 24−22−01−01−055

20 Washer 4 24−22−01−01−060

23 Nut 1 CMM 49−41−14

24 Washer 1 CMM 49−41−14

27 Nozzle, Exhaust 1 49−81−01−01B−005

28 Coupling 1 49−81−01−01B−010

31 Valve, Auxiliary Power Unit (APU) 1 49−51−01−01B−020

Load Control

32 Duct 1 36−11−00−01A−355

34 Clip, Retaining 2 49−14−04−01A−010

46 Union 1 49−31−22−01A−115

47 Packing 1 49−31−22−01A−120

49 Union 1 49−15−01−01B−210

50 Packing 1 49−15−01−01B−215

54 Union 1 CMM 49−24−73

EFFECTIVITY: ALL

49−10−00 Page 424

Sep 05/2017

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

55 Packing 1 CMM 49−24−73

56 Union 1 49−31−22−01A−125

57 Packing 1 49−31−22−01A−130

59 Union 1 49−31−22−01A−125

60 Packing 1 49−31−22−01A−130

74 Bolt 4 49−12−01−01A−130

75 Washer 4 49−12−01−01A−135

87 Nut 1 CMM 49−41−14

88 Washer 1 CMM 49−41−14

On A/C 5301 to 5630 Pre SB 604−49−006

G. Job Set−Up

CAUTION: READ THE TORQUE VALUES CAREFULLY. SOME ARE POUND-FORCE

INCHES (LBF IN) AND SOME ARE POUND-FORCE FEET (LBF FT). IF YOU

TORQUE INCORRECTLY, YOU CAN CAUSE DAMAGE TO THE

COMPONENTS.

(1) Make sure the aircraft is in the same configuration as in the removal task.

NOTE: Make sure the mating surfaces are clean with no corrosion, paint, grease

or preservation fluids.

(2) If necessary, remove the APU enclosure access panel (311BZ)

(TASK 49−11−04−000−801).

(3) Do the detailed inspection of the APU enclosure and its components as follows:

(a) Make sure that the exhaust nozzle (26) is in the exhaust duct (29).

(b) Make sure that the APU inlet bellows assembly (35) are attached to the hanger

bellows clips (37).

(c) Make sure that there are no unwanted objects in the APU enclosure.

(d) Make sure that the electrical harnesses and the electrical cables are attached

to the sides of the APU enclosure.

(e) Make sure that the drain, the vent and the fuel hoses/tubes will not prevent the

installation of the APU (1).

EFFECTIVITY: ALL

49−10−00 Page 425

May 29/2018

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

(f) Examine the condition of the gasket (71).

NOTE: Make sure the gasket (71) is installed on the APU enclosure and not

on the flapper door (72).

(4) If the APU (1) was replaced, install the parts that follow:

(a) Lubricate the packings (50), (53), (56) and (59) with petrolatum.

(b) Remove the protective cover. Install the packing (50) and the union (49) on the

fuel inlet port (51) on the generator adapter (42).

(c) Remove the protective cover. Install the packing (53) and the union (52) on the

fuel return port (54) on the generator adapter (42).

(d) Remove the protective cover. Install the packing (56) and the union (55) on the

inlet port (57) on the fuel control unit (45).

(e) Remove the protective cover. Install the packing (59) and the union (58) on the

drain port (60) on the fuel control unit (45).

(f) Remove the protective covers. Install the drain tubes (61) and (62) on the

combustor/plenum drain valve/orifice fittings (63) and (64).

(g) Install the APU load control valve (31) (TASK 49−51−01−400−801).

NOTE: Do not torque the coupling on the APU load control valve (31) at this

time.

(h) Loosely install the coupling (27) on the exhaust nozzle flange (28)

(SPM−MM 20−30−00−910−805).

(5) If the APU (1) was replaced, torque the parts that follow

(SPM−MM 20−22−00−910−801):

(a) Torque the unions (49) and (52) from 39.59 to 43.75 lbf ft (53.67 to 59.31 Nm).

(b) Torque the union (55) from 21.42 to 23.66 lbf ft (29.04 to 32.07 Nm).

(c) Torque the union (58) from 133 to 147 lbf in (15.03 to 16.60 Nm).

(d) Torque the drain tubes (61) and (62) from 135 to 150 lbf in (15.26 to

16.94 Nm).

EFFECTIVITY: ALL

49−10−00 Page 426

Mar 18/2021

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

WARNING: USE ONLY APPROVED LIFTING POINTS WHEN YOU MOVE, LIFT, OR

LOWER THE APU. YOU CAN CAUSE INJURIES TO PERSONS AND

DAMAGE TO THE EQUIPMENT.

MAKE SURE THAT THE APU SLING AND THE APU HOIST IS

ASSEMBLED CORRECTLY. YOU CAN CAUSE INJURIES TO

PERSONS AND DAMAGE TO THE EQUIPMENT.

(6) Install the APU hoist (73), the APU sling (75) and the beam (74) as follows:

(a) Do a visual inspection of the aircraft frame holes where the beam (74) is to be

attached. Make sure the aluminum holes of the frames at FS654.50 and

FS700.00 are not damaged.

NOTE: These holes are each protected by a steel doubler.

(b) Install the beam (74) to the aircraft attaching points at FS654.50 and

FS700.00.

(c) Install the APU sling cable (82) to the APU upper gearcase adapter (86).

(d) Install the APU sling cable (77) to the APU lifting cable (78) with the bolt (79)

the washer (80) and the nut (81).

(e) Attach the APU sling (75) to the shackle (76) on the APU hoist (73).

(f) Attach the APU hoist (73) to the beam (74).

On A/C 5631 and subs and 5301 to 5630 Post SB 604−49−006

H. Job Set−Up

CAUTION: READ THE TORQUE VALUES CAREFULLY. SOME ARE POUND-FORCE

INCHES (LBF IN) AND SOME ARE POUND-FORCE FEET (LBF FT). IF YOU

TORQUE INCORRECTLY, YOU CAN CAUSE DAMAGE TO THE

COMPONENTS.

(1) Make sure the aircraft is in the same configuration as in the removal task.

NOTE: Make sure the mating surfaces are clean with no corrosion, paint, grease

or preservation fluids.

(2) If necessary, remove the APU enclosure access panel (311BZ)

(TASK 49−11−04−000−801).

(3) Do the detailed inspection of the APU enclosure and its components as follows:

(a) Make sure that the exhaust nozzle (27) is in the exhaust duct (30).

(b) Make sure that the APU inlet bellows assembly (35) are attached to the hanger

bellows clips (37).

EFFECTIVITY: ALL

49−10−00 Page 427

May 29/2018

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

(c) Make sure that there are no unwanted objects in the APU enclosure.

(d) Make sure that the electrical harnesses and the electrical cables are attached

to the sides of the APU enclosure.

(e) Make sure that the drain, the vent and the fuel hoses/tubes will not prevent the

installation of the APU (1).

(f) Examine the condition of the gasket (62).

NOTE: Make sure the gasket (62) is installed on the APU enclosure and not

on the flapper door (63).

(4) If the APU (1) was replaced, install the parts that follow:

(a) Lubricate the packings (47), (50), (55), (57) and (60) with petrolatum.

(b) Remove the protective cover. Install the packing (47) and the union (46) on the

fuel inlet port (48) on the generator adapter (44).

(c) Remove the protective cover. Install the packing (50) and the union (49) on the

fuel return port (51) on the generator adapter (44).

(d) Remove the protective cover. Install the packing (55) and the union (54) on the

inlet port (52) on the fuel control unit (44).

(e) Remove the protective cover. Install the packing (57) and the union (56) on the

drain port (58) on the fuel control unit (40).

(f) Remove the protective cover. Install the packing (60) and the union (59) on the

drain port (61) on the fuel control unit (40).

(g) Install the APU load control valve (31) (TASK 49−51−01−400−801).

NOTE: Do not torque the coupling on the APU load control valve (31) at this

time.

(h) Loosely install the coupling (28) on the exhaust nozzle flange (27)

(SPM−MM 20−30−00−910−805).

(5) If the APU (1) was replaced, torque the parts that follow

(SPM−MM 20−22−00−910−801):

(a) Torque the unions (56) and (59) from 39.59 to 43.75 lbf ft (53.67 to 59.31 Nm).

(b) Torque the union (46) from 21.42 to 23.66 lbf ft (29.04 to 32.07 Nm).

(c) Torque the union (49) from 133 to 147 lbf in (15.03 to 16.60 Nm).

(d) Torque the union (54) to 70 lbf in (7.91 Nm) (CMM 49−24−75).

EFFECTIVITY: ALL

49−10−00 Page 428

Mar 14/2022

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

WARNING: USE ONLY APPROVED LIFTING POINTS WHEN YOU MOVE, LIFT, OR

LOWER THE APU. YOU CAN CAUSE INJURIES TO PERSONS AND

DAMAGE TO THE EQUIPMENT.

MAKE SURE THAT THE APU SLING AND THE APU HOIST IS

ASSEMBLED CORRECTLY. YOU CAN CAUSE INJURIES TO

PERSONS AND DAMAGE TO THE EQUIPMENT.

(6) Install the APU hoist (73), the APU sling (75) and the beam (74) as follows:

(a) Do a visual inspection of the aircraft frame holes where the beam (74) is to be

attached. Make sure the aluminum holes of the frames at FS654.50 and

FS700.00 are not damaged.

NOTE: These holes are each protected by a steel doubler.

(b) Install the beam (74) to the aircraft attaching points at FS654.50 and FS700.00

with the two lock pins supplied.

(c) Install the APU sling cable (82) to the APU upper gearcase adapter (77).

(d) Install the APU sling cable (77) to the APU lifting cable (78) with the bolt (79)

the washer (80) and the nut (81).

(e) Attach the APU sling (75) to the shackle (76) on the APU hoist (73).

(f) Attach the APU hoist (73) to the beam (75).

On A/C 5301 to 5630 Pre SB 604−49−006

I. Procedure

Refer to Figure 401 and Figure 403.

WARNING: MAKE SURE THAT THERE ARE NO PERSONS NEAR THE APU

DURING THE REMOVAL/INSTALLATION. YOU CAN CAUSE INJURIES

TO PERSONS AND DAMAGE TO THE EQUIPMENT.

(1) Put the mobile stand below the aft equipment compartment door (311BB).

(2) Remove the fasteners that attach the APU support skid assembly (85) to the mobile

stand.

(3) Carefully operate the APU hoist (73) to lift the APU (1) off of the mobile stand.

(4) If removed, install the APU support skid assembly (85) on the APU (1)

(TASK 49−12−01−400−801).

(5) Carefully operate the APU hoist (73) to lift the APU (1) through the aft equipment

compartment door (311BB).

(6) Turn the APU (1) 90 degrees.

EFFECTIVITY: ALL

49−10−00 Page 429

May 29/2018

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

CAUTION: MAKE SURE THAT THE APU AND ITS COMPONENTS (ESPECIALLY

THE LOAD CONTROL VALVE) DO NOT TOUCH THE SIDES OF THE

APU ENCLOSURE. YOU CAN CAUSE DAMAGE TO THE APU, ITS

COMPONENTS AND THE APU ENCLOSURE.

(7) Carefully operate the APU hoist (73) to lower the APU (1) into the APU enclosure.

As the APU is lowered, push the APU into the APU enclosure.

(8) Align the holes in the APU support skid assembly (85) with the holes in the floor of

the APU enclosure.

On A/C 5301 to 5399 Pre SB 604−49−003

(9) Attach the APU support skid (85) to the APU enclosure floor with the bolts (83) and

the washers (84).

On A/C 5400 and subs and 5301 to 5399 Post SB 604−49−003

(10) Wet install the bolts (83) and the washers (84) that attach the APU support skid

assembly (85) to the APU enclosure floor (SPM−MM 51−23−00−390−809).

(11) Torque the bolts (83) from 25 to 30 lbf in (2.83 to 3.38 Nm) and add running torque

(SPM−MM 20−21−00−910−801).

(12) Remove the APU hoist (73), the APU sling (75) and the beam (74) as follows:

(a) Remove the APU hoist (73) from the beam (74).

(b) Remove the APU sling (75) from the shackle (76) on the APU hoist (73).

(c) Remove the bolt (79), the washer (80) and the nut (81) that attache the APU

sling cable (77) to the APU lifting cable (78).

(d) Remove the APU sling cable (82) from the APU upper gearcase adapter (86).

(e) Remove the beam (74) from the aircraft attaching points at FS654.50 and

FS700.00.

(f) Do a visual inspection of the aircraft frame holes where the beam (74) was

attached. Make sure the aluminum holes of the frames at FS654.50 and

FS700.00 are not damaged.

NOTE: These holes are each protected by a steel doubler.

(13) Connect the drain, the vent and the fuel hoses/tubes as follows:

(a) Remove the protective covers from the hoses/tubes (38), (39), (41), (43), (44),

(46), (47) and (48).

(b) Connect the vent hose (47) to the vent tube (48) on the generator adapter (42).

EFFECTIVITY: ALL

49−10−00 Page 430

Sep 05/2017

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

(c) Connect the fuel return hose (43) to the union (52) on the generator

adapter (42).

NOTE: Make sure that the fuel return hose (43) does not touch the ignition

unit, its electrical harness or the ignition lead.

(d) Connect the fuel inlet hose (41) to the union (49) on the generator

adapter (42).

NOTE: Make sure that the fuel inlet hose (41) does not touch the ignition

unit, its electrical harness or the ignition lead.

(e) Connect the fuel supply hose (44) to the union (55) on the fuel control

unit (45).

(f) Connect the drain hose (46) to the union (58) the fuel control unit (45).

(g) Connect the drain hose (38) to the APU inlet duct (36).

(h) Connect the drain hose (39) to the tee−fitting (40) for the combustor drains.

CAUTION: USE TWO WRENCHES WHEN YOU REMOVE/TORQUE THE

HOSES/TUBES. USE ONE WRENCH TO HOLD THE FITTING, AND

THE OTHER WRENCH TO LOOSEN/TORQUE THE COUPLING NUT.

IF YOU DO NOT DO THIS, YOU CAN CAUSE DAMAGE TO THE

COMPONENTS.

(14) Torque the fittings that follow (SPM−MM 20−22−00−910−801):

(a) Torque the vent hose (47) from 70 to 120 lbf in (7.91 to 13.55 Nm).

(b) Torque the fuel return hose (43) from 17.50 to 35.00 lbf ft (23.73 to 47.45 Nm).

(c) Torque the fuel inlet hose (41) from 17.50 to 35.00 lbf ft (23.73 to 47.45 Nm).

(d) Torque the fuel supply hose (44) from 100 to 250 lbf in (11.30 to 28.24 Nm).

(e) Torque the drain hose (46) from 70 to 120 lbf in (7.91 to 13.55 Nm).

(f) Torque the drain hose (38) from 70 to 120 lbf in (7.91 to 13.55 Nm).

(g) Torque the drain hose (39) from 70 to 120 lbf in (7.91 to 13.55 Nm).

(15) Install the APU outlet bleed duct (32) and the APU check valve

(TASK 36−11−07−400−801)

Connect the load control valve (31) as follows:

NOTE: At this moment, check the distance between the APU load control valve

and the APU enclosure then torque the APU LCV V−band coupling

(SPM−MM 20−30−00−910−805).

EFFECTIVITY: ALL

49−10−00 Page 431

May 29/2018

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

(16) Install the exhaust nozzle (26) (TASK 49−81−01−400−801).

(17) Connect the APU inlet duct assembly (33) as follows:

(a) Remove the protective cover from the APU inlet duct (36).

(b) Remove the APU inlet bellows assembly (35) from the hanger bellows

clips (37).

(c) Attach the APU inlet bellows assembly (35) to the flange on the APU inlet

duct (36) with the retaining clips (34).

(18) Install the parts on the starter motor (21) as follow:

(a) Remove the nuts (22) and (87) and the washers (23) and (88) from the

terminals on the starter motor (21).

(b) Attach the starter cable (24) to the positive terminal on the starter motor (21)

with the washer (23) and the nut (22).

(c) Attach the starter cable (25) to the negative terminal on the starter motor (21)

with the washer (88) and the nut (87).

(d) Torque the nut (22) on the positive terminal from 35 to 40 lbf in

(3.95 to 4.51 Nm) (CMM 49−21−59) and (SPM−MM 20−21−00−910−801).

(e) Torque the nut (87) on the negative terminal from 75 to 80 lbf in

(8.48 to 9.03 Nm) (CMM 49−21−59) and (SPM−MM 20−21−00−910−801).

(19) Install the parts on the integrated drive generator (13) as follow:

(a) Remove the screws (14), the washers (69), the terminal block cover (16), the

nuts (18) and the washers (19) from the terminal block (17).

(b) Install the electrical cables (20) on the terminal lugs (T1, T2, T3 and G) on the

terminal block (17).

(c) Attach the electrical cables (20) to the terminal lugs (T1, T2, T3 and G) on the

terminal block (17) with the washers (19) and the nuts (18).

(d) Torque the nuts (18) from 48 to 53 lbf in (5.43 to 5.98 Nm)

(SPM−MM 20−21−00−910−801).

(e) Attach the clamp (15) and the terminal block cover (16) to the terminal

block (17) with the screws (14) and washers (69).

(f) Torque the screws (14) from 18 to 20 lbf in (2.04 to 2.25 Nm)

(CMM 24−22−01) and (SPM−MM 20−21−00−910−801).

EFFECTIVITY: ALL

49−10−00 Page 432

Mar 14/2022

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

(20) Connect the electrical connectors that follow:

(a) Attach the electrical harness (12) to the APU enclosure with the screws (10)

and the clamps (11).

(b) Remove the protective covers from the electrical connectors and their

receptacles.

(c) Connect the electrical connector (2) to the receptacle (3).

(d) Connect the electrical connector (4) to the receptacle (5).

(e) Connect the electrical connector (6) to the receptacle (7).

(f) Connect the electrical connector (8) J2KD to the receptacle (9).

(21) Safety the electrical connectors (2), (4) and (6) with lockwire

(SPM−MM 20−50−00−400−801).

(22) Remove the tags and close the circuit breakers that follow:

LOCATION CB NUMBER CB NAME ZONE

CBP−1 L1 APU ECU 221

CBP−1 L2 APU FAULT ANN 221

CBP−1 L3 APU START CONT 221

CBP−1 R5 APU FIRE EXT 221

CBP−1 S3 FUEL SOV APU 221

CBP−2 P4 APU FUEL PUMP 222

(23) Do the servicing of the APU as follows:

(a) If a new APU is installed or the APU has been preserved, do the Prepare the

APU for Service procedure (CMM 49−20−00).

(b) Do the replenishing of the APU oil tank (TASK 12−13−49−612−801).

(c) Do the replenishing of the APU generator/adaptor

(TASK 12−13−49−612−802).

(24) Install the APU enclosure access panel (311BZ) (TASK 49−11−04−400−801)

(25) If you installed a new APU, do the tests that follow:

(a) Do the operational test of the APU (loaded) (TASK 49−10−00−710−802).

EFFECTIVITY: ALL

49−10−00 Page 433

May 29/2018

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

(b) Do the APU fuel and oil leak check (TASK 49−10−00−790−801).

(c) Do the APU bleed air leak check (TASK 49−10−00−790−802).

(26) If you installed the same APU, do the tests that follow:

(a) Do the operational test of the APU (TASK 49−10−00−710−801).

(b) Do the APU fuel and oil leak check (TASK 49−10−00−790−801).

(c) Do the APU bleed air leak check (TASK 49−10−00−790−802).

On A/C 5631 and subs and 5301 to 5630 Post SB 604−49−006

J. Procedure

Refer to Figure 402 and Figure 403.

WARNING: MAKE SURE THAT THERE ARE NO PERSONS NEAR THE APU

DURING THE REMOVAL/INSTALLATION. YOU CAN CAUSE INJURIES

TO PERSONS AND DAMAGE TO THE EQUIPMENT.

(1) Put the mobile stand below the aft equipment compartment door (311BB).

(2) Remove the fasteners that attach the APU support skid assembly (85) to the mobile

stand.

(3) Carefully operate the APU hoist (73) to lift the APU (1) off of the mobile stand.

(4) If removed, install the APU support skid assembly (85) on the APU (1)

(TASK 49−12−01−400−801).

(5) Carefully operate the APU hoist (73) to lift the APU (1) through the aft equipment

compartment door (311BB).

(6) Turn the APU (1) 90 degrees.

CAUTION: MAKE SURE THAT THE APU AND ITS COMPONENTS (ESPECIALLY

THE LOAD CONTROL VALVE) DO NOT TOUCH THE SIDES OF THE

APU ENCLOSURE. YOU CAN CAUSE DAMAGE TO THE APU, ITS

COMPONENTS AND THE APU ENCLOSURE.

(7) Carefully operate the APU hoist (73) to lower the APU (1) into the APU enclosure.

As the APU is lowered, push the APU into the APU enclosure.

(8) Align the holes in the APU support skid assembly (85) with the holes in the floor of

the APU enclosure.

(9) Wet install the bolts (83) with firewall silicon sealant and the washers (84) that

attach the APU support skid assembly (85) to the APU enclosure floor

(SPM−MM 51−23−00−390−809).

EFFECTIVITY: ALL

49−10−00 Page 434

May 29/2018

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

(10) Torque the bolts (83) from 25 to 30 lbf in (2.83 to 3.38 Nm) and add running torque

(SPM−MM 20−21−00−910−801).

(11) Remove the APU hoist (73), the APU sling (75) and the beam (65) as follows:

(a) Remove the APU hoist (73) from the beam (74).

(b) Remove the APU sling (76) from the shackle (77) on the APU hoist (73).

(c) Remove the bolt (79), the washer (80) and the nut (81) that attache the APU

sling cable (77) to the APU lifting cable (78).

(d) Remove the APU sling cable (82) from the APU upper gearcase adapter (86).

(e) Remove the beam (74) from the aircraft attaching points at FS654.50 and

FS700.00.

(f) Do a visual inspection of the aircraft frame holes where the beam (74) was

attached. Make sure the aluminum holes of the frames at FS654.50 and

FS700.00 are not damaged.

NOTE: These holes are each protected by a steel doubler.

(12) Connect the drain, the vent and the fuel hoses/tubes as follows:

(a) Remove the protective covers from the hoses/tubes (38), (39), (41), (42),

and (43).

(b) Connect the fuel return hose (41) to the union (60) on the generator

adapter (40).

NOTE: Make sure that the fuel return hose (43) does not touch the ignition

unit, its electrical harness or the ignition lead.

(c) Connect the fuel inlet hose (39) to the union (56) on the generator

adapter (40).

NOTE: Make sure that the fuel inlet hose (39) does not touch the ignition

unit, its electrical harness or the ignition lead.

(d) Connect the fuel supply hose (42) to the union (46) on the fuel control

unit (44).

(e) Connect the drain hose (45) to the union (49) the fuel control unit (44).

(f) Connect the fuel solenoid tube (53) to the union (54) the fuel control unit (44).

(g) Connect the drain hose (38) to the APU inlet duct (36).

EFFECTIVITY: ALL

49−10−00 Page 435

Sep 05/2017

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

CAUTION: USE TWO WRENCHES WHEN YOU REMOVE/TORQUE THE

HOSES/TUBES. USE ONE WRENCH TO HOLD THE FITTING, AND

THE OTHER WRENCH TO LOOSEN/TORQUE THE COUPLING NUT.

IF YOU DO NOT DO THIS, YOU CAN CAUSE DAMAGE TO THE

COMPONENTS.

(13) Torque the fittings that follow (SPM−MM 20−22−00−910−801):

(a) Torque the fuel return hose (41) from 17.50 to 35.00 lbf ft (23.73 to 47.45 Nm).

(b) Torque the fuel inlet hose (39) from 17.50 to 35.00 lbf ft (23.73 to 47.45 Nm).

(c) Torque the fuel supply hose (42) from 100 to 250 lbf in (11.30 to 28.24 Nm).

(d) Torque the drain hose (45) from 70 to 120 lbf in (7.91 to 13.55 Nm).

(e) Torque the fuel solenoid tube (53) to 120 lbf in (13.56 Nm) (CMM 49−24−75).

(f) Torque the drain hose (38) from 70 to 120 lbf in (7.91 to 13.55 Nm).

(14) Connect the load control valve (31) as follows:

(a) At this moment, check the distance between the APU load control valve (31)

and the APU enclosure and torque the V−band coupling

(SPM−MM 20−30−00−910−805).

(b) Install the APU outlet bleed duct (32) and the APU check valve

(TASK 36−11−07−400−801)

(15) Install the exhaust nozzle (27) (TASK 49−81−01−400−801).

(16) Connect the APU inlet duct assembly (33) as follows:

(a) Remove the protective cover from the APU inlet duct (36).

(b) Remove the APU inlet bellows assembly (35) from the hanger bellows

clips (37).

(c) Attach the APU inlet bellows assembly (35) to the flange on the APU inlet

duct (36) with the retaining clips (34).

(17) Install the parts on the starter motor (22) as follow:

(a) Remove the nuts (23) and (87) and the washers (24) and (88) from the

terminals on the starter motor (22).

(b) Attach the starter cable (25) to the positive terminal on the starter motor (22)

with the washer (24) and the nut (23).

(c) Attach the starter cable (26) to the negative terminal on the starter motor (22)

with the washer (88) and the nut (87).

EFFECTIVITY: ALL

49−10−00 Page 436

Mar 14/2022

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

(d) Torque the nut (23) on the positive terminal to 40 lbf in (4.52 Nm)

(CMM 49−24−75) and (SPM−MM 20−21−00−910−801).

(e) Torque the nut (87) on the negative terminal to 80 lbf in (9.04 Nm)

(CMM 49−24−75) and (SPM−MM 20−21−00−910−801).

(18) Install the parts on the integrated drive generator (13) as follow:

(a) Remove the screws (14), the washers (15), the terminal block cover (17), the

nuts (19) and the washers (20) from the terminal block (18).

(b) Install the electrical cables (21) on the terminal lugs (T1, T2, T3 and G) on the

terminal block (18).

(c) Attach the electrical cables (21) to the terminal lugs (T1, T2, T3 and G) on the

terminal block (18) with the washers (20) and the nuts (19).

(d) Torque the nuts (19) from 48 to 53 lbf in (5.43 to 5.98 Nm)

(SPM−MM 20−21−00−910−801).

(e) Attach the clamp (16) and the terminal block cover (17) to the terminal

block (18) with the screws (14) and washers (15).

(f) Torque the screws (14) from 18 to 20 lbf in (2.04 to 2.25 Nm)

(CMM 24−22−01) and (SPM−MM 20−21−00−910−801).

(19) Connect the electrical connectors that follow:

(a) Attach the electrical harness (12) to the APU enclosure with the screws (10)

and the clamps (11).

(b) Remove the protective covers from the electrical connectors and their

receptacles.

(c) Connect the electrical connector (2) to the receptacle (3).

(d) Connect the electrical connector (4) to the receptacle (5).

(e) Connect the electrical connector (6) to the receptacle (7).

(f) Connect the electrical connector (8) J2KD to the receptacle (9).

(20) Safety the electrical connectors (2), (4) and (6) with lockwire

(SPM−MM 20−50−00−400−801).

EFFECTIVITY: ALL

49−10−00 Page 437

Mar 14/2022

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

(21) Remove the tags and close the circuit breakers that follow:

LOCATION CB NUMBER CB NAME ZONE

CBP−1 L1 APU ECU 221

CBP−1 L2 APU FAULT ANN 221

CBP−1 L3 APU START CONT 221

CBP−1 R5 APU FIRE EXT 221

CBP−1 S3 FUEL SOV APU 221

CBP−2 P4 APU FUEL PUMP 222

CBP−5 A2 APU ECU PRIM 311

CBP−5 A3 APU ECU SEC 311

(22) Do the servicing of the APU as follows:

(a) If a new APU is installed or the APU has been preserved, do the Prepare the

APU for Service procedure (CMM 49−24−75).

(b) Do the replenishing of the APU oil tank (TASK 12−13−49−612−801).

(c) Do the replenishing of the APU generator/adaptor

(TASK 12−13−49−612−802).

(23) Install the APU enclosure access panel (311BZ) (TASK 49−11−04−400−801)

(24) If you installed a new APU, do the tests that follow:

(a) Do the operational test of the APU (loaded) (TASK 49−10−00−710−802).

(b) Do the APU fuel and oil leak check (TASK 49−10−00−790−801).

(c) Do the APU bleed air leak check (TASK 49−10−00−790−802).

(25) If you installed the same APU, do the tests that follow:

(a) Do the operational test of the APU (TASK 49−10−00−710−801).

(b) Do the APU fuel and oil leak check (TASK 49−10−00−790−801).

(c) Do the APU bleed air leak check (TASK 49−10−00−790−802).

EFFECTIVITY: ALL

49−10−00 Page 438

May 29/2018

CL−604 AIRCRAFT MAINTENANCE MANUAL − PART II

K. Close Out

(1) Remove all tools, equipment, and unwanted materials from the work area.

(2) Close the aft equipment compartment access−door (311BB)

(TASK 52−41−00−410−801).

EFFECTIVITY: ALL

49−10−00 Page 439

Sep 05/2017

You might also like

- Zexel Rhd6 & Rhd10 Service Manual GovernorDocument0 pagesZexel Rhd6 & Rhd10 Service Manual GovernorAbsar Mamun83% (6)

- Caterpillar Cat 315C EXCAVATOR (Prefix CFL) Service Repair Manual (CFL00001 and Up)Document27 pagesCaterpillar Cat 315C EXCAVATOR (Prefix CFL) Service Repair Manual (CFL00001 and Up)kfm8seuudu67% (3)

- 1 3900169 PDFDocument509 pages1 3900169 PDFHussain Shah100% (1)

- TASK 71-00-00-000-042-A Removal of The Power PlantDocument24 pagesTASK 71-00-00-000-042-A Removal of The Power PlantVijai PrakashNo ratings yet

- Caterpillar Cat 303.5 Mini Hydraulic Excavator (Prefix AFW) Service Repair Manual (AFW00001 and Up) PDFDocument23 pagesCaterpillar Cat 303.5 Mini Hydraulic Excavator (Prefix AFW) Service Repair Manual (AFW00001 and Up) PDFfkdmma100% (1)

- Spare Part Manual bp350d Part 2 PDFDocument35 pagesSpare Part Manual bp350d Part 2 PDFnirmalNo ratings yet

- S50me-C8 5Document387 pagesS50me-C8 5Cuit Tru Lala50% (2)

- Transmission Powershift HL760-9SDocument44 pagesTransmission Powershift HL760-9SLhsan Rajawi100% (7)

- Trocoide Thurman PDFDocument4 pagesTrocoide Thurman PDFmgualdiNo ratings yet

- SSP 303 v10 Tdi EngineDocument22 pagesSSP 303 v10 Tdi Engineabonatuconnex8926100% (1)

- TR deDocument9 pagesTR deRameswar PradhanNo ratings yet

- CPA - A330 - AMM - FSN - 752 - 01-Oct-2022 - 36-11-55-000-804-A - Removal of The Bleed Valve Control SolenoidDocument6 pagesCPA - A330 - AMM - FSN - 752 - 01-Oct-2022 - 36-11-55-000-804-A - Removal of The Bleed Valve Control SolenoidMARCO CHANNo ratings yet

- Skid Control Ecu Assy (LHD) : ReplacementDocument2 pagesSkid Control Ecu Assy (LHD) : ReplacementMichael EmsleyNo ratings yet

- Leap FMUDocument10 pagesLeap FMURameswar PradhanNo ratings yet

- Electrical Power Ac Generation Cabin 115 Vac Inverter System Maintenance PracticesDocument8 pagesElectrical Power Ac Generation Cabin 115 Vac Inverter System Maintenance Practicessarvesh_ame2011No ratings yet

- AMM Deactivation of The Thrust Reverser SystemDocument11 pagesAMM Deactivation of The Thrust Reverser Systemmantenimientotalmaoma032No ratings yet

- Subaru-Legacy 2005 EN Manual de Taller Control de Emisiones 17fbaf51b7Document9 pagesSubaru-Legacy 2005 EN Manual de Taller Control de Emisiones 17fbaf51b7miguelNo ratings yet

- Aircraft Maintenance ManualDocument6 pagesAircraft Maintenance Manualom prakash patelNo ratings yet

- Power Turbine (Power Turbine Module)Document4 pagesPower Turbine (Power Turbine Module)Andrés AlbaNo ratings yet

- AMM32 51 31 04.fullDocument6 pagesAMM32 51 31 04.fullTarek ElghazzalyNo ratings yet

- 74-20-00 Igniters and Ignition Cables - Maintenance PracticesDocument15 pages74-20-00 Igniters and Ignition Cables - Maintenance PracticesAndres GuerreroNo ratings yet

- EXT Eva Air: Job CardDocument19 pagesEXT Eva Air: Job CardLê Viết DũngNo ratings yet

- Powerplant Build Manual 71-10-06-4Document21 pagesPowerplant Build Manual 71-10-06-4Wong BennyNo ratings yet

- Borescope Inspection of The Inner Cowl Bolts of The Combustion ChamberDocument3 pagesBorescope Inspection of The Inner Cowl Bolts of The Combustion Chamber尹兴旺No ratings yet

- Pneumatic Ducts Removal in Wing Leading Edge Ata 36Document17 pagesPneumatic Ducts Removal in Wing Leading Edge Ata 36Luis AbrilNo ratings yet

- TM 10-3930-669-20 Forklift Truck 6K Drexel MDL R60SL-DC Part 3Document277 pagesTM 10-3930-669-20 Forklift Truck 6K Drexel MDL R60SL-DC Part 3AdvocateNo ratings yet

- AMM - 01-Aug-2019 - 79-21-10-000-004-A - Removal of The Lubrication UnitDocument10 pagesAMM - 01-Aug-2019 - 79-21-10-000-004-A - Removal of The Lubrication UnitIrfan05100% (1)

- Autopilot Servo - Maintenance PracticesDocument16 pagesAutopilot Servo - Maintenance PracticesEleazarNo ratings yet

- Electric Lost Motion Actuator Instructions For Conversion From 115V, 60 HZ To 220V, 50 HZDocument3 pagesElectric Lost Motion Actuator Instructions For Conversion From 115V, 60 HZ To 220V, 50 HZAlexis SánchezNo ratings yet

- AMM Operational Test of The Thrust Reverser SystemDocument7 pagesAMM Operational Test of The Thrust Reverser Systemmantenimientotalmaoma032No ratings yet

- Power Steering Ecu Assy: ReplacementDocument22 pagesPower Steering Ecu Assy: ReplacementMusat Catalin-MarianNo ratings yet

- Thrust Reverser System Control - Deactivation-ReactivationDocument10 pagesThrust Reverser System Control - Deactivation-Reactivationphuong leNo ratings yet

- (V) KR 6 KS (V) KR 16 KS ... - 2 KS: RepairDocument31 pages(V) KR 6 KS (V) KR 16 KS ... - 2 KS: RepairluckesmanNo ratings yet

- Removal: 2Az-Fe Engine Mechanical - Engine AssemblyDocument8 pagesRemoval: 2Az-Fe Engine Mechanical - Engine AssemblyViệt Anh PhạmNo ratings yet

- AMM Operational Test of The FADEC On The Ground (With Engine Non Motoring)Document6 pagesAMM Operational Test of The FADEC On The Ground (With Engine Non Motoring)mantenimientotalmaoma032No ratings yet

- Skid Control Ecu Assy (RHD) : ReplacementDocument1 pageSkid Control Ecu Assy (RHD) : ReplacementMichael EmsleyNo ratings yet

- GVI Brake Units - 32-40-00-210-801-A PDFDocument4 pagesGVI Brake Units - 32-40-00-210-801-A PDFpannNo ratings yet

- Henry Yaris 3Document4 pagesHenry Yaris 3Miguel AngelNo ratings yet

- 320c Excavadora Cat Desarmado y Armado Bombas HidraulicasDocument20 pages320c Excavadora Cat Desarmado y Armado Bombas HidraulicasJuan camilo Cárdenas garciaNo ratings yet

- SB 27 132 00Document30 pagesSB 27 132 00Bony KlausNo ratings yet

- Gulfstream G650ErDocument6 pagesGulfstream G650ErAdrian LauNo ratings yet

- Automatic Transmission AssemblyDocument6 pagesAutomatic Transmission Assemblyseancampbell84100% (1)

- ML C 650 c65mm716Document8 pagesML C 650 c65mm716operacionesNo ratings yet

- Fault Isolation Manual: Print Date: 2021-05-27Document20 pagesFault Isolation Manual: Print Date: 2021-05-27Mahbub RahmanNo ratings yet

- AR01.10-B-2400I.fm Removing and Installing The Engine 10.10.01Document9 pagesAR01.10-B-2400I.fm Removing and Installing The Engine 10.10.01LUKASNo ratings yet

- Desmontage de MotorDocument26 pagesDesmontage de MotorjaimeNo ratings yet

- Intake Manifold-Lower: Special Tool(s)Document16 pagesIntake Manifold-Lower: Special Tool(s)William Y. OspinaNo ratings yet

- Bomba 330CDocument11 pagesBomba 330CjulianmatabajoyNo ratings yet

- MM32-30-31-02.full - Selector Valve - PracticesDocument4 pagesMM32-30-31-02.full - Selector Valve - PracticesIng NavaNo ratings yet

- Operational Test of The ENG 1 (2) LP Fuel ValveDocument9 pagesOperational Test of The ENG 1 (2) LP Fuel Valvemantenimientotalmaoma032No ratings yet

- ML B 200 b200fmm1035Document11 pagesML B 200 b200fmm1035Marco Antonio PrietoNo ratings yet

- Honda CR V 2007 2009 Engine Mechanical Service Repair ManualDocument10 pagesHonda CR V 2007 2009 Engine Mechanical Service Repair Manuallisa100% (47)

- ControlsDocument10 pagesControlsmonukumar98375No ratings yet

- 78 00 00 RiDocument78 pages78 00 00 RiÜmit KazanNo ratings yet

- Golf5 Airbag Srs 1Document4 pagesGolf5 Airbag Srs 1Boris KopetschekNo ratings yet

- Aftercooler - Remove Removal Procedure: Shutdown SIS Previous ScreenDocument3 pagesAftercooler - Remove Removal Procedure: Shutdown SIS Previous ScreenTASHKEELNo ratings yet

- Bomba Hyd Vibro CS563Document16 pagesBomba Hyd Vibro CS563Ingemak Urbano100% (1)

- ML C Ser c206hmm225Document15 pagesML C Ser c206hmm225mantenimientoaerosarayakuNo ratings yet

- TEST1Document16 pagesTEST1Lender VegaNo ratings yet

- Deactivation of The Bleed Pressure Regulating Valve (PRV)Document44 pagesDeactivation of The Bleed Pressure Regulating Valve (PRV)mantenimientotalmaoma032No ratings yet

- Thakur Institute of Aviation TechnologyDocument16 pagesThakur Institute of Aviation Technologygupta3070No ratings yet

- 3gr-Fse-Em21-Engine Assembly-RemovalDocument12 pages3gr-Fse-Em21-Engine Assembly-RemovalHuỳnh Minh ĐứcNo ratings yet

- SHROUDDocument7 pagesSHROUD尹兴旺No ratings yet

- AMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: VT-ILN - 10151 - 431Document5 pagesAMM - IGO - A318/A319/A320/A321 REV DATE: Aug 01/2021 Tail Number - MSN - FSN: VT-ILN - 10151 - 431Rameswar PradhanNo ratings yet

- Automatic Transaxle2 PDFDocument11 pagesAutomatic Transaxle2 PDFluisNo ratings yet

- @A318/A319/A320/A321: Chapter 49 - Airborne Auxiliary PowerDocument31 pages@A318/A319/A320/A321: Chapter 49 - Airborne Auxiliary PowerFabian Andres Soto Lineros (LATAM)No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- QSK60 Starting SystemDocument4 pagesQSK60 Starting Systemagvass100% (1)

- Parts Catalog Cummins, 6LTAA8.9G2 - ESN 82312099 - CPL 3079-65Document1 pageParts Catalog Cummins, 6LTAA8.9G2 - ESN 82312099 - CPL 3079-65Hardiansyah SimarmataNo ratings yet

- Engine Overhaul Minggu 11Document63 pagesEngine Overhaul Minggu 11Renaldi Ardiansyah100% (1)

- Hydril PDFDocument5 pagesHydril PDFAyoub PoloNo ratings yet

- Removal, Installation and Adjustment: Section 2A - All ModelsDocument40 pagesRemoval, Installation and Adjustment: Section 2A - All ModelsАлександр ГершукNo ratings yet

- Manual HobartDocument39 pagesManual HobartВолодимир БроNo ratings yet

- 4-STROKE DIESEL ENGINE CYCLE - HTMLDocument9 pages4-STROKE DIESEL ENGINE CYCLE - HTMLJesua Mañalac OlaybarNo ratings yet

- Kayaba B0240-18027 - 2Document4 pagesKayaba B0240-18027 - 2TSPSRL Import ExportNo ratings yet

- 912 ReducerDocument2 pages912 ReducerAndrea VarasNo ratings yet

- Sidel Matriz Parte 2Document250 pagesSidel Matriz Parte 2Fernando RosaNo ratings yet

- XVS1300A Service ManualDocument421 pagesXVS1300A Service Manualabstraction38100% (1)

- WM90-Parts Manual CompressedDocument66 pagesWM90-Parts Manual CompressedDuala MaquinariaNo ratings yet

- LM Assembly THKDocument14 pagesLM Assembly THKAmudha BoobalanNo ratings yet

- Instruction Manual (Window Wiper)Document15 pagesInstruction Manual (Window Wiper)Arlindo J LopesNo ratings yet

- Lull Parts2 ManguerasDocument365 pagesLull Parts2 ManguerassolserengsaNo ratings yet

- P48GSI: VGF Series Gas EngineDocument2 pagesP48GSI: VGF Series Gas EngineferyNo ratings yet

- Butterfly Emb Single Head Machine Parts BookDocument30 pagesButterfly Emb Single Head Machine Parts BookCambridge GTNo ratings yet

- Power Steering Pump (Bus) Mercedes OM 926 LA: (Europa) (Engine)Document4 pagesPower Steering Pump (Bus) Mercedes OM 926 LA: (Europa) (Engine)Karthii AjuNo ratings yet

- Engineering-Info-Helical-Gears ParametersDocument3 pagesEngineering-Info-Helical-Gears ParametersalbertoNo ratings yet

- 5-3 Group 3 Disassembly and AssemblyDocument25 pages5-3 Group 3 Disassembly and Assemblystefan corjucNo ratings yet

- Joywell TRANSMISSION BDocument59 pagesJoywell TRANSMISSION BЕкатерина КалашниковаNo ratings yet

- Fiat Bogie PresentationDocument53 pagesFiat Bogie PresentationRitesh KumarNo ratings yet

- Tinnerman NutDocument1 pageTinnerman NutAhmad ShazaNo ratings yet