Professional Documents

Culture Documents

pm377 GBR

pm377 GBR

Uploaded by

jsanmiguelOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

pm377 GBR

pm377 GBR

Uploaded by

jsanmiguelCopyright:

Available Formats

Data Sheet

CreaGlas Fabric Adhesive

ELF 377

Low-emission, solvent- and plasticizer-free, special adhesive for

CreaGlas Fabric, for indoors

Field of Application

For gluing CreaGlas Fabric or Nonwoven and wall coverings in interior

applications. On load-bearing substrates, e.g., interior plaster

(depending on the compressive strength), concrete, gypsum plaster

boards, intact dispersion paint coats.

Properties

- ELF = low emission, solvent and plasticizer-free

- Water-dilutable emulsion adhesive

- Also for use with wallpaper pasting and Airless units

- With good initial adhesion and long open time

- Good spreadability

- In system build-up with CreaGlas Fabric "schwerentflammbar" B1

(flame-retardant) or "nichtbrennbar" A2 (non-combustible)

- In system build-up with Rapid Nonwoven 1525 and Light Nonwoven

130 "schwerentflammbar" B1 (flame-retardant)

- Dries transparently

- Diffusible

- For indoors

Material description

Color transparent when dry

Gloss grade matt

Base material polyvinyl acetate polymer

Density approx. 1.02 g/cm³

Packaging 18 kg

Page 1 of 5 Data Sheet 377 en Date: 08.09.2020

Use

Thinning For roller application, dilute with water as required, depending on the

substrate absorbency, design and situation on site. For fine CreaGlas

designs, e.g. 2311 Fine and 2111 VG Fine as well as for nonwovens,

dilute approx. 15% with water.

For airless application, dilute approx. 10% with water.

For application with wallpaper device, dilute approx. 25% with water.

Tinting Do not tint.

Compatibility Do not mix with other types of material.

Application Roller and airless application

For gluing CreaGlas Fabric and Nonwoven apply an adequate quantity

of CreaGlas Fabric Adhesive ELF 377 (2 to 3 widths, depending on the

design) directly on the substrate using a lamb’s wool roller or the airless

spray device. When applying the adhesive using an airless spray

method, we recommend re-rolling the applied glue using a lamb’s wool

roller to ensure an even distribution and quantity of the adhesive.

Apply or re-roll the glue with a short-pile lamswool roller and allow

sufficient flash-off time.

Lay the cut CreaGlas Fabric or Nonwoven in the wet adhesive edge to

edge and press out any bubbles with the Fabric Smoother 1323.

Avoid adhesive contamination on the surface. Carefully remove any

contamination with a damp sponge.

Application using a wallpaper pasting machine

In addition to that, almost all CreaGlas Fabric Profession and VG

(precoated) designs can be applied using a wallpaper pasting machine.

For further information on that, refer to Data Sheets cg20 CreaGlas

Fabric Profession and cg21 CreaGlas Fabric VG (precoated). For

application using a wallpaper pasting machine dilute CreaGlas Fabric

Adhesive ELF 377 approx. 25 % with water. When pulling through the

CreaGlas Fabric, make sure, the adhesive is applied evenly. Apply the

Fabric immediately. The Fabric is more difficult to apply if soaked for too

long and should be avoided. Continue the application as described

above.

Note the information on Data Sheets for CreaGlas Fabric Profession

cg20, CreaGlas Fabric VG pre-primed cg21, Xtra Nonwoven 1725,

Rapid Nonwoven 1525 and Light Nonwoven 130 when gluing wall

coverings.

Consumption For gluing CreaGlas Fabric, approx. 150–300 g/m², depending on

design and substrate.

For gluing non-woven wall coverings, e.g. CreaGlas Nonwoven VG

1000 and 1001, Xtra Nonwoven 1725, Rapid Nonwoven 1525 and Light

Nonwoven 130, ca. 150 g/m².

Determine exact consumption by means of a test application on the

object to be coated.

Application temperature Do not apply if air or object temperature is under +8 °C.

Recommended air and object temperature for application: +15 °C to

+25 °C.

Tool cleaning Clean tools immediately after use with water.

Page 2 of 5 Data Sheet 377

Use

Spray data

Spray system Nozzle Spraying angle Pressure Thinning

Airless 0.023 inch 40°–50° 180–200 bar Approx. 10%

Drying (+20 °C, 65 % relative humidity)

After the adhesive is dry, further coatings can be applied on the wall

covering.

Storage

Store in a cool and frost-free place. Reseal opened containers tightly.

Declaration

Note Contains preservatives.

Product code BSW20.

Comply with the specifications in the current Safety Data Sheet.

System build-up

Substrate preparation The substrate must be level, solid, dry, clean, load-bearing and free

from efflorescence, sinter layers, separating agents, corrosion-

promoting components or other intermediate layers affecting the

adhesion. Check existing coatings for their suitability, load-bearing

capacity and adhesive properties. Remove defective and unsuitable

coatings thoroughly and dispose of them in accordance with the

applicable regulations. Thoroughly wash off limepaint. Wash down intact

coats of oil paints and varnishes with an alkaline solution, sand down

well and clean. Remove any wall coverings, including any paste or wall-

glue residue. Treat replastered areas with a fluorine primer. Rough

surface, damaged areas should be levelled out with e.g. Briplast Mineral

Hand Applying Filler Light ELF 1886 before applying the paint. Apply a

prime and/or intermediate coat to the substrate as required. Also see

VOB Part C, DIN 18363, Section 3.

Page 3 of 5 Data Sheet 377

System build-up

Filling and

Substrates Primer Gluing Coating 4)

priming 3)

Gypsum plasterboard,

gypsum wall panels,

gypsum fiber board -

filled CreaGlas Fabric or

Nonwoven with

Optional 2)

Gypsum lime mortar 1) topcoats from the

Lacryl Deep

CreaGlas Fabric CreaGlas Fabric

Normally absorbent Penetrating Primer

and System or Xtra

substrates, e.g. ELF 595 or Lacryl

nonwoven wall Nonwoven 1725,

interior plaster Hydro-Gel ELF 695

As required, 1 – 2x coverings, Rapid Nonwoven

(lime/cement mortar with, e.g., Briplast e.g. CreaGlas 1525 or Light

1)), concrete, precision

Mineral Hand Nonwoven VG 1000 Nonwoven 130,

stone masonry, matt Applying Light Filler or 1001, Xtra depending on

emulsion paint coats ELF 1886 and Nonwoven 1725, degree of exposure

priming with Lacryl Rapid Nonwoven of the surface,

Smooth, non- Deep Penetrating 1525 or Light requirements and

absorbent and glossy Primer ELF 595 Nonwoven 130, gloss grade with

substrates, e.g. intact, Adhesion Primer glued with CreaGlas emulsion paints of

glossy emulsion ELF 3720 Fabric Adhesive at least wet

coatings, oil and ELF 377 abrasion resistance

enamel paints class 2 in

accordance with

DIN 13300

2K-EP Varioprimer

Non-ferrous metals or

865 or 2K-EP

plastic

Varioprimer S 864

1) Minimum compressive strength > 2.0 N/mm² (Compressive strength class CS II, CS III, CS IV as well as B1–

B7)

2) Required if no further surface filling is to take place.

3) The need for and scope of filling depends on the expectations on the final surface finish. For smooth, even

surfaces, the substrate should generally correspond to at least surface quality Q3 for gypsum plaster or

gypsum plasterboard substrates. All other substrates should be prepared in the same way, using this as a

basis.

4) To achieve a uniform surface appearance, especially on critically illuminated surfaces, coats must be

consistently applied wet in wet and with uniform smoothing.

Page 4 of 5 Data Sheet 377

Notes

Application on gypsum fillers Gypsum fillers recommended by gypsum plaster board manufacturers

may be particularly sensitive to moisture impact; this may result in

swelling, bubble formation and flaking (refer also to leaflet

2„Verspachtelung von Gipskarton“ (Using Fillers on Gypsum

Plasterboard) Bundesverband der Gips- und Gipsbauplattenindustrie

e.V. (German Association of Gypsum and Plasterboard Industry). For

rapid drying, ensure that the ventilation and temperature are adequate.

Adhesive application and Take care to apply the correct quantity of adhesive and to distribute it

distribution evenly. Applying too much adhesive can result in adhesive clumping,

causing disruptions in the surface appearance as well as seam

markings due to open seams that arise in the course of drying.

Further specifications Follow the instructions on the Data Sheets of the products used, the

CreaGlas Fabric System and the different CreaGlas fabric types.

Remark

This Data Sheet is based on extensive development work and years of

practical experience. The translation corresponds to the current German

version, in compliance with the German laws, regulations, standards

and guidelines. Its content does not constitute a contractual legal

relationship. The user/buyer is not released from the responsibility of

checking our products to ensure they are suitable for the intended

application. In addition, our general terms of business apply.

When a new version of this Data Sheet with updated information is

published, the previous version no longer applies. The current version is

available on our website.

Brillux

Weseler Straße 401

48163 Münster

GERMANY

Phone +49 251 7188-0

Fax +49 251 7188-105

info@brillux.de

www.brillux.com

Page 5 of 5 Data Sheet 377

You might also like

- MasterProtect 1891Document2 pagesMasterProtect 1891SHAIK ASIMUDDINNo ratings yet

- B 64483EN 2 - 03 Fanuc Dual Check SafetyDocument240 pagesB 64483EN 2 - 03 Fanuc Dual Check SafetyDmitry100% (4)

- Quakebond J333Sr: The Infrastructure InnovatorsDocument2 pagesQuakebond J333Sr: The Infrastructure Innovatorskhoirul ramadhanNo ratings yet

- H. V. NC: Matt ClearDocument1 pageH. V. NC: Matt Clearمحمد عزتNo ratings yet

- TDS - TERRAWET Primer G 9 - 733 Inline - 060 - enDocument2 pagesTDS - TERRAWET Primer G 9 - 733 Inline - 060 - enJavier Martinez CañalNo ratings yet

- Araco Ac Putty - TDSDocument2 pagesAraco Ac Putty - TDSEGO AnimationNo ratings yet

- Eco-Flex C/G™: Fire Resistant CoatingDocument4 pagesEco-Flex C/G™: Fire Resistant CoatingMarcus RashfordNo ratings yet

- Technical Information: Kiwobond 930Document2 pagesTechnical Information: Kiwobond 930Hendrawan Setya PNo ratings yet

- Flex-Pro Pu: Technical Data SheetDocument4 pagesFlex-Pro Pu: Technical Data SheetKenneth CabacunganNo ratings yet

- PDS - AFTEK Flex-Pro PU Sealant PDFDocument4 pagesPDS - AFTEK Flex-Pro PU Sealant PDFLexyNo ratings yet

- X-Tech CrystalClear 3Document2 pagesX-Tech CrystalClear 3EGO AnimationNo ratings yet

- Dust Control Joint Compound: Usg Sheetrock BrandDocument2 pagesDust Control Joint Compound: Usg Sheetrock BrandHoracio PadillaNo ratings yet

- d2) Epilux218 4267Document2 pagesd2) Epilux218 4267Syed FaridNo ratings yet

- H. V. NC Sanding Sealer: ClearDocument1 pageH. V. NC Sanding Sealer: Clearمحمد عزتNo ratings yet

- Wrb-Air Barrier - Parex Usa Weatherseal Spray and Roll OnDocument3 pagesWrb-Air Barrier - Parex Usa Weatherseal Spray and Roll Onsaffronbuilders9No ratings yet

- 14 - TDS - Concresive 2020Document2 pages14 - TDS - Concresive 2020aahtagoNo ratings yet

- Sarnacol®-2170: Product Data SheetDocument3 pagesSarnacol®-2170: Product Data SheetAhmed MontashNo ratings yet

- X-Shield SF PrimerDocument2 pagesX-Shield SF Primernader enanyNo ratings yet

- All Purpose Joint Compound: Usg Sheetrock BrandDocument2 pagesAll Purpose Joint Compound: Usg Sheetrock BrandG. TorresNo ratings yet

- Ampreg 21Document6 pagesAmpreg 21Cinthya Felipe LópezNo ratings yet

- Alpha Dry Adhesive Tds 843706Document2 pagesAlpha Dry Adhesive Tds 843706aruncg2No ratings yet

- Bostik DIY Philippines NoMoreNails Technical Data SheetDocument2 pagesBostik DIY Philippines NoMoreNails Technical Data SheetStephen Megs Booh MantizaNo ratings yet

- Flexseal GA777Document2 pagesFlexseal GA777osama mohNo ratings yet

- Dlc-Grout C100: General Purpose, High Strength, Non-Shrink Cementitious GroutDocument4 pagesDlc-Grout C100: General Purpose, High Strength, Non-Shrink Cementitious Grout4919404No ratings yet

- 25 KG Gyproc Elite 100 One Coat Gypsum PlasterDocument3 pages25 KG Gyproc Elite 100 One Coat Gypsum Plastersyedaliabl2023No ratings yet

- X-Shield AcrylCoatDocument2 pagesX-Shield AcrylCoatEGO AnimationNo ratings yet

- Technical Information: Mga Special Heatresist Semi Matt 58MGA2106Document3 pagesTechnical Information: Mga Special Heatresist Semi Matt 58MGA2106Javier Martinez CañalNo ratings yet

- IJM700 v01Document2 pagesIJM700 v01j.saiyathNo ratings yet

- TDS-EN-Conflex PS - Rev 016-Aug21Document2 pagesTDS-EN-Conflex PS - Rev 016-Aug21LONG LASTNo ratings yet

- Dura Grout: A.B.E. Construction ChemicalsDocument3 pagesDura Grout: A.B.E. Construction ChemicalsVirah Sammy ChandraNo ratings yet

- Decofill PDFDocument2 pagesDecofill PDFArun KumarNo ratings yet

- 4 Rockgrip 27 en Prep Plaster Primer WB 2022 Rev1Document5 pages4 Rockgrip 27 en Prep Plaster Primer WB 2022 Rev1yoxan25808No ratings yet

- VA4216 PE85 Top Trans S692N BG40 ImpDocument1 pageVA4216 PE85 Top Trans S692N BG40 Impbalaji nobelNo ratings yet

- 8 Bergermaster 00 en Intext WB Plaster Primer 2022 Rev5Document5 pages8 Bergermaster 00 en Intext WB Plaster Primer 2022 Rev5yoxan25808No ratings yet

- Capgel: S R F CDocument1 pageCapgel: S R F CEng-Medrar AlkateryNo ratings yet

- j6) Autocareenamel 3087Document2 pagesj6) Autocareenamel 3087vinodNo ratings yet

- Araco WPR 78Document2 pagesAraco WPR 78Georges BaderNo ratings yet

- Sigmaguard CSF 575Document6 pagesSigmaguard CSF 575Erdi ErdoganNo ratings yet

- Sikadur®-53: Product Data SheetDocument3 pagesSikadur®-53: Product Data Sheetjet toledoNo ratings yet

- Probuild GP100Document2 pagesProbuild GP100osama mohNo ratings yet

- Timeless InstallationDocument12 pagesTimeless Installationdanny01No ratings yet

- CrystorDocument2 pagesCrystorryanNo ratings yet

- Altuglas S2002Document2 pagesAltuglas S2002White SwanNo ratings yet

- Probuild JC100Document2 pagesProbuild JC100osama mohNo ratings yet

- Polymastic: Single Component Acrylic Co-Polymer MasticDocument2 pagesPolymastic: Single Component Acrylic Co-Polymer MasticaahtagoNo ratings yet

- Congrout Padding MortarDocument1 pageCongrout Padding MortarVietpapayaNo ratings yet

- PDS Gyproc Moisture Resistant PDFDocument2 pagesPDS Gyproc Moisture Resistant PDFRATHEESH P.KNo ratings yet

- X - Pruf RBEDocument2 pagesX - Pruf RBEAmr RagabNo ratings yet

- Quickmast 341Document2 pagesQuickmast 341osama mohNo ratings yet

- Garlock GSK 3-86 Strainer Gasket 04.2017 en-NADocument2 pagesGarlock GSK 3-86 Strainer Gasket 04.2017 en-NAAbuhurairah MunshiNo ratings yet

- Buffa Datasheet COPER EVOLUZIONE PDFDocument2 pagesBuffa Datasheet COPER EVOLUZIONE PDFJurgen VassalloNo ratings yet

- Product Data Sheet: Thistle® One Coat PlasterDocument6 pagesProduct Data Sheet: Thistle® One Coat PlastergowthamNo ratings yet

- Marco Data Sheet e 2205ctgDocument2 pagesMarco Data Sheet e 2205ctgKhoa NguyễnNo ratings yet

- Acrylic Sunscreen Sealer: Technical Data SheetDocument1 pageAcrylic Sunscreen Sealer: Technical Data SheetShaijan JosephNo ratings yet

- TALYEES-G100 Data SheetDocument3 pagesTALYEES-G100 Data SheetChristos LeptokaridisNo ratings yet

- Epocote WBDocument2 pagesEpocote WBArya PratamaNo ratings yet

- Pds-Cpd-Sikaflex Mortar Fix-UsDocument2 pagesPds-Cpd-Sikaflex Mortar Fix-UsBudhi KurniawanNo ratings yet

- Mastertop 1255: Decorative Aggregate-Based Resin Flooring SystemDocument3 pagesMastertop 1255: Decorative Aggregate-Based Resin Flooring SystemFrancois-No ratings yet

- s1 Berger Gloss 7 - 2282Document2 pagess1 Berger Gloss 7 - 2282tunlajiNo ratings yet

- AWAZEL WB SubmittalDocument26 pagesAWAZEL WB SubmittalAbdel Mongy AhmedNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Sensitivity Analysis of Entrance Design Parameters of A Backward-Inclined Centrifugal Fan Using DOE Method and CFD CalculationsDocument8 pagesSensitivity Analysis of Entrance Design Parameters of A Backward-Inclined Centrifugal Fan Using DOE Method and CFD CalculationsHüseyin Atakan BaytaşNo ratings yet

- Lesson Plan in EnglishDocument4 pagesLesson Plan in EnglishMary Jane MiravallesNo ratings yet

- STUD ADHESIVE BONDED M10x50mm PDFDocument61 pagesSTUD ADHESIVE BONDED M10x50mm PDFEd2sverissimoNo ratings yet

- The Python Quiz Book Michael Driscoll Full ChapterDocument67 pagesThe Python Quiz Book Michael Driscoll Full Chaptersaul.sumbry682100% (7)

- Soil Spectroscopy: Training MaterialDocument28 pagesSoil Spectroscopy: Training MaterialAgustín DeviaNo ratings yet

- ISTA PCG 01 Reusable Passive Thermal Packaging System Best Practice GuidelineDocument31 pagesISTA PCG 01 Reusable Passive Thermal Packaging System Best Practice GuidelinealexNo ratings yet

- Iranian Ice Repositories - An Example of Traditional Indigenous ArchitectureDocument12 pagesIranian Ice Repositories - An Example of Traditional Indigenous Architectureadekpadek100% (1)

- Activity Guide and Evaluation Rubric - Task 4 - Final ExamDocument4 pagesActivity Guide and Evaluation Rubric - Task 4 - Final ExamEnith Alexandra Jaimes VeraNo ratings yet

- IEEE - 0446 - 1995 (Orange) Emergency and Standby Power SystemsDocument319 pagesIEEE - 0446 - 1995 (Orange) Emergency and Standby Power SystemsJOHAN ARLEY DELGADO VARGAS100% (3)

- Interaksi Varanus Salvator (Interaction of Varanus Salvator) : Prey, Predator, Atau DETRIVORE? (Varanus Salvato..Document12 pagesInteraksi Varanus Salvator (Interaction of Varanus Salvator) : Prey, Predator, Atau DETRIVORE? (Varanus Salvato..Anggi jayadi RiwuNo ratings yet

- Articles On Caste and Class in Early India 2016Document210 pagesArticles On Caste and Class in Early India 2016Aquib RahmaniNo ratings yet

- Corporate Citizenship and Higher Education: Morgan R. ClevengerDocument281 pagesCorporate Citizenship and Higher Education: Morgan R. ClevengerVictóriaVittideLaurentizNo ratings yet

- 24 Lampu Sorot Taman (PHILIPS)Document2 pages24 Lampu Sorot Taman (PHILIPS)hafinNo ratings yet

- Green BuildingDocument69 pagesGreen BuildingBS EntertainmentNo ratings yet

- 2305 10510Document12 pages2305 10510avillenaNo ratings yet

- Godrej and Boyce Corporate ProfileDocument2 pagesGodrej and Boyce Corporate ProfileSahili SalveNo ratings yet

- Pittclad 316S PDS 7.13.21Document4 pagesPittclad 316S PDS 7.13.21MassimoPartipiloNo ratings yet

- HRM Notes Part 2Document34 pagesHRM Notes Part 2Vanessa BatallaNo ratings yet

- Sbs Mathematics Statistics and Operational Research 23Document37 pagesSbs Mathematics Statistics and Operational Research 23YNo ratings yet

- Dark Heresy Character Sheet - Ace Character (Unfinished)Document2 pagesDark Heresy Character Sheet - Ace Character (Unfinished)Alasdair GoudieNo ratings yet

- Bridge Ergonomic Design A ReviewDocument7 pagesBridge Ergonomic Design A ReviewLibrary Jasaan CampusNo ratings yet

- DeGuzman Joshua Rae PayrollDocument6 pagesDeGuzman Joshua Rae PayrollHero CourseNo ratings yet

- Etp Progress Report - g70Document18 pagesEtp Progress Report - g70EeHuey ChooNo ratings yet

- Lee Moi Wong Chief Research Officer Kuala LumpurDocument2 pagesLee Moi Wong Chief Research Officer Kuala LumpurTony MathewNo ratings yet

- Anatomy and Physiology: Bojo Suasa, RN Pamantasan NG Lungsod NG Maynila College of NursingDocument38 pagesAnatomy and Physiology: Bojo Suasa, RN Pamantasan NG Lungsod NG Maynila College of NursingVernice OrtegaNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityBhavesh PatelNo ratings yet

- FP1 Listening Skills 2Document2 pagesFP1 Listening Skills 2Jordi Sánchez RodríguezNo ratings yet

- 24-12-2021 - Hand Written Notes - Shankar IAS AcademyDocument13 pages24-12-2021 - Hand Written Notes - Shankar IAS AcademyThakre ShubhamNo ratings yet

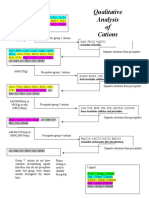

- Qualitative Analysis of Cations: Insoluble ChloridesDocument1 pageQualitative Analysis of Cations: Insoluble Chlorideskemhar jaminulNo ratings yet