Professional Documents

Culture Documents

GC Hy CNG 400C QC Qap 001

GC Hy CNG 400C QC Qap 001

Uploaded by

mech1Copyright:

Available Formats

You might also like

- ITP For PV Mounting Structure and Module Installation-2023!05!19Document3 pagesITP For PV Mounting Structure and Module Installation-2023!05!19Mohammad BayisNo ratings yet

- PC78UU-6 NhoDocument123 pagesPC78UU-6 NhoFris Ainur100% (1)

- Inspection and Test Plan For Gas Turbine PDFDocument5 pagesInspection and Test Plan For Gas Turbine PDFreza ebrahimi100% (1)

- Cargo Operating ManualDocument309 pagesCargo Operating Manualbatizap batizap0% (1)

- ITP For Safety Relief Valve (Reviwed by Galfar QC)Document2 pagesITP For Safety Relief Valve (Reviwed by Galfar QC)anon_585140390No ratings yet

- Quality Assurance Protocol: Raw MaterialDocument2 pagesQuality Assurance Protocol: Raw MaterialShah Newaz Kabir100% (1)

- Valve Inspection and Test PlanDocument1 pageValve Inspection and Test PlanClarkFedele27100% (1)

- KSB Etanorm CurvesDocument83 pagesKSB Etanorm CurvesEric Fabro100% (5)

- TH360B TH560B - CAT - Hydr System.Document2 pagesTH360B TH560B - CAT - Hydr System.Zeck33% (3)

- QAP - Filter Press FinalDocument1 pageQAP - Filter Press FinalStepworthNo ratings yet

- Final - Pump - QAP - 5P0312ABCD - Antico - Code 4 PDFDocument1 pageFinal - Pump - QAP - 5P0312ABCD - Antico - Code 4 PDFRishabh VermaNo ratings yet

- ITP For Profibus CABLE (YJ72759)Document1 pageITP For Profibus CABLE (YJ72759)Meng PamplonaNo ratings yet

- ITP For Sprinkler and Spary SystemDocument6 pagesITP For Sprinkler and Spary System梁奇龙100% (2)

- SR No Activity Characteristics To Be Checked Quantum of Check Inspection / SignDocument1 pageSR No Activity Characteristics To Be Checked Quantum of Check Inspection / SignAlpine ProjectsNo ratings yet

- KBR Inspection Test Plan For Shop Fabricated PipingDocument4 pagesKBR Inspection Test Plan For Shop Fabricated PipingSyafril AkbarNo ratings yet

- HVAC Systems List of Tests - LCETEDDocument4 pagesHVAC Systems List of Tests - LCETEDjon aquinoNo ratings yet

- Jeritp P 170300Document1 pageJeritp P 170300NicolaMasteNo ratings yet

- ITP For Non-Fire Resistant CI CableDocument1 pageITP For Non-Fire Resistant CI CableMeng PamplonaNo ratings yet

- Contoh Itp Mechanical PltuDocument2 pagesContoh Itp Mechanical PltuwawanNo ratings yet

- Contoh Itp Mechanical PltuDocument2 pagesContoh Itp Mechanical PltuyusufNo ratings yet

- Vishwabalaa Engineering Private Limited, Thirumazhisai, Chennai - 600124Document2 pagesVishwabalaa Engineering Private Limited, Thirumazhisai, Chennai - 600124sanil50% (2)

- Amiitp G 310500 - 2Document4 pagesAmiitp G 310500 - 2wangkai01.sneiNo ratings yet

- Revised QAP - Sluice ValveDocument1 pageRevised QAP - Sluice Valvevijaivirajackie mNo ratings yet

- Inspection Check List Clarification StationDocument33 pagesInspection Check List Clarification StationSepong BebNo ratings yet

- Tank Maintenance ITPDocument24 pagesTank Maintenance ITPthomas varugheseNo ratings yet

- PSI-Origin Energy-Basic Land Rig Inspection CriteriaDocument3 pagesPSI-Origin Energy-Basic Land Rig Inspection CriteriaKBNo ratings yet

- List of Hydro Test - WartsilaDocument1 pageList of Hydro Test - WartsilaSadia HasanNo ratings yet

- Programa de Mantenimiento Preventivo ACS880Document2 pagesPrograma de Mantenimiento Preventivo ACS880JaimeNo ratings yet

- ICL Pump QAP RPS 40-32 T3A AWC - ICL - ITPDocument2 pagesICL Pump QAP RPS 40-32 T3A AWC - ICL - ITPalokgoel_2006No ratings yet

- Qap - Oil Cooler For 82.1 KW & 16 KWDocument1 pageQap - Oil Cooler For 82.1 KW & 16 KWHEPL VATVANo ratings yet

- Flowdyne Enterprises, Mumbai Quality Assurance PlanDocument1 pageFlowdyne Enterprises, Mumbai Quality Assurance PlanRv JmNo ratings yet

- Inspection & Test Plan (Itp) - Iso 5167 - Fittings (SC / DC)Document1 pageInspection & Test Plan (Itp) - Iso 5167 - Fittings (SC / DC)Guru DevaNo ratings yet

- ITP (Can Gas)Document1 pageITP (Can Gas)Kemas Muhandis MancapaniNo ratings yet

- Section 7 Test and InspectionDocument12 pagesSection 7 Test and InspectionThaigroup CementNo ratings yet

- Sangeetha Engineering Works (P) LTD.: Ernakulam - 682 305 B-NO:14/107A, Near Agastya Ashram, Kureekkad, ThripunithuraDocument2 pagesSangeetha Engineering Works (P) LTD.: Ernakulam - 682 305 B-NO:14/107A, Near Agastya Ashram, Kureekkad, ThripunithuraSANGEETHANo ratings yet

- Itp PRDSDocument3 pagesItp PRDSDwi Mulyanti Dwimulyantishop100% (1)

- ACS880-107, - 207, - 307, - 607, - 907, - 1607 Multidrive: Maintenance ScheduleDocument4 pagesACS880-107, - 207, - 307, - 607, - 907, - 1607 Multidrive: Maintenance Scheduleafadsfd asfadfNo ratings yet

- ITP Arrester SulselbarruDocument14 pagesITP Arrester SulselbarruDaniel ChristianNo ratings yet

- AIP-Shed-week One-Inspection ReportDocument15 pagesAIP-Shed-week One-Inspection Reportyibelta abebeNo ratings yet

- ITP Piping DPPU Lampung Rev.1Document1 pageITP Piping DPPU Lampung Rev.1Steve WawukNo ratings yet

- Hydrotest Reports ORR 8inch KM 06-10 REALDocument47 pagesHydrotest Reports ORR 8inch KM 06-10 REALMAS CONSTRUCTIONSNo ratings yet

- RBCAPQPPPAPPackDocument60 pagesRBCAPQPPPAPPackAbdelilah KadriNo ratings yet

- 01 - A - I Test PlanDocument1 page01 - A - I Test Planrahmath nawazNo ratings yet

- Mar HM 18.06.22Document302 pagesMar HM 18.06.22özgen bölükNo ratings yet

- Ruelco CatalogDocument264 pagesRuelco CatalogJosé Uriel Javier TorresNo ratings yet

- Đính Kèm - HGBP - ITP For MV & LV SWGR (Project Format)Document9 pagesĐính Kèm - HGBP - ITP For MV & LV SWGR (Project Format)The GunnersNo ratings yet

- Inspection and Test Plan For Fan and Blower PDFDocument5 pagesInspection and Test Plan For Fan and Blower PDFAulia RahmanNo ratings yet

- 41.water Cum Foam Monitor-Trailer MountedDocument2 pages41.water Cum Foam Monitor-Trailer MountedSimbu ArasanNo ratings yet

- Inspection and Test Plan For Gas TurbineDocument5 pagesInspection and Test Plan For Gas TurbineLiu YangtzeNo ratings yet

- Quality Management - Inspection and Test PlanDocument1 pageQuality Management - Inspection and Test PlanVIKASH RAINo ratings yet

- Inspection and Test Plan (Itp) :: Floating Ball ValvesDocument1 pageInspection and Test Plan (Itp) :: Floating Ball ValvesDeepak UpadhyayNo ratings yet

- Inspection and Test Plan For Line PipeDocument4 pagesInspection and Test Plan For Line PipeMohamed BencharifNo ratings yet

- 2.3 Table of ContentDocument1 page2.3 Table of ContentEr Md AamirNo ratings yet

- F&G Devices Inspection and Test PlanDocument3 pagesF&G Devices Inspection and Test PlanaliNo ratings yet

- ACS580MV: Preventive Maintenance ScheduleDocument2 pagesACS580MV: Preventive Maintenance Schedulealok pratap singhNo ratings yet

- C1230D Intercooler SpecificationsDocument31 pagesC1230D Intercooler Specificationsprimeengineers444No ratings yet

- Manufacturing Inspection Test Plan: 1. Fabrication & Pre RequisitesDocument1 pageManufacturing Inspection Test Plan: 1. Fabrication & Pre RequisitesAlesol EquipmentNo ratings yet

- Asorc-Qcp 1652 ModifiedDocument22 pagesAsorc-Qcp 1652 ModifiedalkhiatNo ratings yet

- DCS No 15 - AC Not Working - Less EffecctiveDocument2 pagesDCS No 15 - AC Not Working - Less Effecctiveservicemanager.bkdNo ratings yet

- Itp For Tank Fabrication Installation Work1 Rev02 PDFDocument22 pagesItp For Tank Fabrication Installation Work1 Rev02 PDFMichelNo ratings yet

- Maintenance Schedule ACS580 ACH580 ACQ580 DrivesDocument2 pagesMaintenance Schedule ACS580 ACH580 ACQ580 DrivesDorinaDraganNo ratings yet

- 01-Ge-Aqa-9600 Itp DMF FRP Water Trough r2Document29 pages01-Ge-Aqa-9600 Itp DMF FRP Water Trough r2Eljo AndsNo ratings yet

- Inspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak RiauDocument4 pagesInspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak Riauanang_priNo ratings yet

- Curve (Slop Oil)Document1 pageCurve (Slop Oil)mech1No ratings yet

- Hindustan Petroleum Corporation LTDDocument217 pagesHindustan Petroleum Corporation LTDmech1No ratings yet

- SS SS Tubing Pid-3Document1 pageSS SS Tubing Pid-3mech1No ratings yet

- SS SS Tubing Pid-2Document1 pageSS SS Tubing Pid-2mech1No ratings yet

- 17-10 CDTPDocument14 pages17-10 CDTPmech1No ratings yet

- Series Series Series Series: Control Control Ball BallDocument4 pagesSeries Series Series Series: Control Control Ball BallEmi MariniNo ratings yet

- Skid Weight Calculation HHI-RAR-SD-SCAL-004. REV.BDocument8 pagesSkid Weight Calculation HHI-RAR-SD-SCAL-004. REV.BAgus MarpaungNo ratings yet

- Diagrama Hidraulico 420E CATERPILLAR PDFDocument4 pagesDiagrama Hidraulico 420E CATERPILLAR PDFWilmer0% (1)

- 345B and 345B II Excavators Hydraulic System - Attachment: Fluid Power SymbolsDocument2 pages345B and 345B II Excavators Hydraulic System - Attachment: Fluid Power SymbolsricardoNo ratings yet

- What Are The Safe Practices in Operating A Purifier As Per Operating Manual Instruction?Document4 pagesWhat Are The Safe Practices in Operating A Purifier As Per Operating Manual Instruction?Cj MañugoNo ratings yet

- ProductCatalog Cyrus Shank PSVDocument95 pagesProductCatalog Cyrus Shank PSVmramos4191No ratings yet

- Siemens: ASK DDocument1 pageSiemens: ASK DMurilo MonteiroNo ratings yet

- Easa 66Document5 pagesEasa 66BETHWELNo ratings yet

- D6M Track-Type Tractor Hydraulic System: 9ZM1-UP 2RN1-UP 3WN1-UP 4JN1-UP 5NR1-UP 5WR1-UP 6LR1-UP 2YS1-UP 4GS1-UP 4HS1-UPDocument2 pagesD6M Track-Type Tractor Hydraulic System: 9ZM1-UP 2RN1-UP 3WN1-UP 4JN1-UP 5NR1-UP 5WR1-UP 6LR1-UP 2YS1-UP 4GS1-UP 4HS1-UPElectronica Mecatronica RasmusNo ratings yet

- MM 1202 Av PDFDocument2 pagesMM 1202 Av PDFGarryNo ratings yet

- Pipes - CIFDocument13 pagesPipes - CIFsolebNo ratings yet

- Section 4 Brake System: Group 1 Structure and FunctionDocument22 pagesSection 4 Brake System: Group 1 Structure and FunctionREMZONANo ratings yet

- Features: Micropac® MC Compact Single Speed Hand PumpDocument3 pagesFeatures: Micropac® MC Compact Single Speed Hand PumpShankar BhardwajNo ratings yet

- Nirogen Rejection in Natural GasDocument10 pagesNirogen Rejection in Natural GasChukwuma OnukuNo ratings yet

- Dry Running PumpsDocument9 pagesDry Running Pumpsabo yossefNo ratings yet

- Serie 101 RTC CouplingsDocument10 pagesSerie 101 RTC CouplingsHIDRAFLUIDNo ratings yet

- Compressible Fluid Flow Oosthuizen SolutDocument105 pagesCompressible Fluid Flow Oosthuizen Solutam sachinNo ratings yet

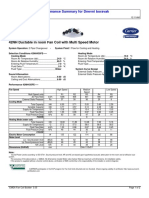

- Performance Summary For Dnevni Boravak: 42NH Ductable in Room Fan Coil With Multi Speed MotorDocument2 pagesPerformance Summary For Dnevni Boravak: 42NH Ductable in Room Fan Coil With Multi Speed Motorvelikimag87No ratings yet

- Rice List Of: An ISO 9001 CompanyDocument16 pagesRice List Of: An ISO 9001 Company555dddaaaaNo ratings yet

- SM SAA6D170E-5.pdf-68-79 PDFDocument12 pagesSM SAA6D170E-5.pdf-68-79 PDFBalikpapan CityNo ratings yet

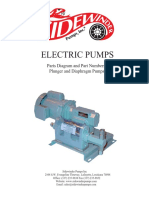

- Electric Pumps: Parts Diagram and Part Numbers Plunger and Diaphragm PumpsDocument24 pagesElectric Pumps: Parts Diagram and Part Numbers Plunger and Diaphragm PumpsCARLITOS 25No ratings yet

- 03-04-45-03 6081H Nao ParteDocument2 pages03-04-45-03 6081H Nao Partefranc.silveiNo ratings yet

- Sales and Engineering Data: Pd03P-Xxs-Xxx and Pe03P-Xxs-Xxx 10 - 100 1:1Document4 pagesSales and Engineering Data: Pd03P-Xxs-Xxx and Pe03P-Xxs-Xxx 10 - 100 1:1jarosNo ratings yet

- WPS 1013-2011Document27 pagesWPS 1013-2011alexander100% (1)

- Nozzle Load CheckDocument4 pagesNozzle Load CheckpipestressNo ratings yet

- GIS 14a - Purging Natural Gas Installation Volumes Between 0.03 m3 To 1.0 m3 - Energy Safe VictoriaDocument11 pagesGIS 14a - Purging Natural Gas Installation Volumes Between 0.03 m3 To 1.0 m3 - Energy Safe VictoriaArash FatehnezhadNo ratings yet

GC Hy CNG 400C QC Qap 001

GC Hy CNG 400C QC Qap 001

Uploaded by

mech1Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GC Hy CNG 400C QC Qap 001

GC Hy CNG 400C QC Qap 001

Uploaded by

mech1Copyright:

Available Formats

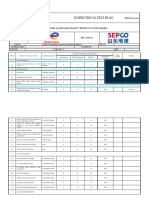

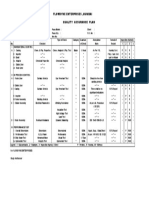

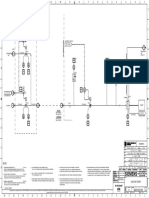

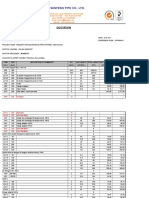

QUALITY ASSURANCE PLAN GASCOMP FUELTECH(INDIA) PVT LTD

PLOT NO:- 219 GIDC- RANOLI, VADODARA, GUJARAT-391350

Product Name : CNG Hydraulic Booster Compressor -400SCMH Customer Name:- HPCL QAP NO:- GC-HY-CNG-400C-QC-QAP-001 REV. - 00

Project No:- GC-HY-CNG-400C-LAB/3517868/5,6 Project Name:- SUPPLY OF 400 SCMH CNG BOOSTER COMPRESSOR DATE - 15-12-2023

Sr. No. Component Operation Characteristics Frequency Scope Of TPI CA Remarks

A:-Bought Out Material

1 Frame (Compressor Body) Visual 100% W W/R

2 Intensifier Visual, Hydro test 100% R R

3 Actuator Visual, Test Certificates 100% R R

4 Ball Valve Visual, Test Certificates 100% R R

5 Safety Valve (SRV) Visual, Test Certificates 100% R R

6 NRV Visual, Test Certificates 100% R R

7 Solenoid Valve Visual, Test Certificates 100% R R

8 SS Fittings Visual, Test Certificates 100% R R

9 SS Tubing's Visual, Test Certificates 100% R R

10 Gas Cooler & Oil Cooler Visual, Hydro test 100% R R

11 Pressure Gauge Visual, Test Certificates 100% R R

12 Pressure Transmitter Visual, Test Certificates 100% R R

13 Temperature Transmitter Visual, Test Certificates 100% R R

14 Mass Flow Meter Visual, Test Certificates 100% R R

15 FLP Electrical Control Panel Enclosure Visual, Test Certificates 100% R R

16 Water Pump Visual, Test Certificates 100% R R

17 Main Motor & Aux. Motor Visual, Test Certificates 100% R R

18 Flame Detector Visual, Test Certificates 100% R R

19 Gas Detector Visual, Test Certificates 100% R R

20 CO2 Flooding System Visual, Test Certificates 100% R R

21 Stability Certificate Visual, Stability Certificate 100% R R

22 LCV Filling Hose Visual, Test Certificates 100% R R

23 Breakaway Visual, Test Certificates 100% R R

24 QRC Visual, Test Certificates 100% R R

25 Needle Valve Visual, Test Certificates 100% R R

26 Door Limit Switch Visual, Test Certificates 100% R R

27 Juction Box Visual, Test Certificates 100% R R

28 FLP Tub light Visual, Test Certificates 100% R R

29 Hooter Visual, Test Certificates 100% R R

30 Hydraulic Hoses Visual, Test Certificates 100% R R

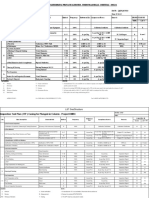

QUALITY ASSURANCE PLAN GASCOMP FUELTECH(INDIA) PVT LTD

PLOT NO:- 219 GIDC- RANOLI, VADODARA, GUJARAT-391350

Product Name : CNG Hydraulic Booster Compressor -400SCMH Customer Name:- HPCL QAP NO:- GC-HY-CNG-400C-QC-QAP-001 REV. - 00

Project No:- GC-HY-CNG-400C-LAB/3517868/5,6 Project Name:- SUPPLY OF 400 SCMH CNG BOOSTER COMPRESSOR DATE - 15-12-2023

Sr. No. Component Operation Characteristics Frequency Scope Of TPI CA Remarks

B Test : Final Inspection (for complete assembly)

1 Leak Test @200 Bar Functional Test 100% W W/R

2 Main Motor Overload Relay (Simulation) Functional Test 100% W W/R

3 Cooling Fan Motor Overload Relay (Simulation) Functional Test 100% W W/R

Oil Temperature Transmitter Functional Test 100% W W/R

4

(Simulation)

5 Gas Detector Functional Test 100% W W/R

6 Flame Detector Functional Test 100% W W/R

7 CO2 Alarm Functional Test 100% W W/R

8 Check for High Suction Pressure Alarm (Simulation) Functional Test 100% W W/R

9 Check for Low Suction Pressure Alarm (Simulation) Functional Test 100% W W/R

10 High Voltage Alarm Functional Test 100% W W/R

11 Low Voltage Alarm Functional Test 100% W W/R

12 High Discharge Pressure Functional Test 100% W W/R

13 High Water Temperature Alarm Functional Test 100% W W/R

14 Electrical Panel Functional Test 100% W W/R

15 Canopy Painting Visual 100% W W/R

16 Final mock-up Assembly of the package (As per GAD) Visual 100% W W/R

17 P&ID Check Visual 100% W W/R

18 Wiring Diagram Check Visual 100% W W/R

19 Dimensional Inspection (As per approved GAD, PID) Visual 100% W R

20 Priority Panel Visual 100% W R

21 HV Continuity, Mass mode Function Functional Test 100% W W/R

QUALITY ASSURANCE PLAN GASCOMP FUELTECH(INDIA) PVT LTD

PLOT NO:- 219 GIDC- RANOLI, VADODARA, GUJARAT-391350

Product Name : CNG Hydraulic Booster Compressor -400SCMH Customer Name:- HPCL QAP NO:- GC-HY-CNG-400C-QC-QAP-001 REV. - 00

Project No:- GC-HY-CNG-400C-LAB/3517868/5,6 Project Name:- SUPPLY OF 400 SCMH CNG BOOSTER COMPRESSOR DATE - 15-12-2023

Sr. No. Component Operation Characteristics Frequency Scope Of TPI CA Remarks

C Mechanical Run Test/ String Test (In Continuous of 4 hours without Breakdown)

1 Delivery Test (200 bar) Performance Test 100% W W/R

Media NITROGEN/ CNG

2 Suction pressure Performance Test 100% W W/R

(Kg/cm2)@30

3 Discharge Pressure Performance Test 100% W W/R

(Kg/cm2)@250 (As per client Requirements)

4 Unit in KWH Performance Test 100% W W/R

5 HMR Performance Test 100% W W/R

6 Discharge Unit Performance Test 100% W W/R

7 Flow Unit (KG/hr) Performance Test 100% W W/R

Average

8 Noise and vibration Performance Test 100% R

9 Name Plate, Tagging, Client Logo Visual 100% R

D Site Performance Test (Field trails run test @72Hours (MFR - P) 100% W/R

NOTE: 1. All the Electrical instruments PESO Certificate will also be reviewed by TPI.

2. T4S Annexure shall be checked and stamped by TPIA,Anneture Compliance signed with remarks from TPIA shall be given with IRN.

NOTE :

1. LEGENDS , W - Witness , R- Review , P- Perform

2. CA - Owner / Owner's Representative (VCS/HPCL)

PREPARED BY (GASCOMP) APPROVED BY

-OEM shall follow the Typ. QAP as per mentioned in tender documents.

-QAP shall covers all triping and alarms list.

You might also like

- ITP For PV Mounting Structure and Module Installation-2023!05!19Document3 pagesITP For PV Mounting Structure and Module Installation-2023!05!19Mohammad BayisNo ratings yet

- PC78UU-6 NhoDocument123 pagesPC78UU-6 NhoFris Ainur100% (1)

- Inspection and Test Plan For Gas Turbine PDFDocument5 pagesInspection and Test Plan For Gas Turbine PDFreza ebrahimi100% (1)

- Cargo Operating ManualDocument309 pagesCargo Operating Manualbatizap batizap0% (1)

- ITP For Safety Relief Valve (Reviwed by Galfar QC)Document2 pagesITP For Safety Relief Valve (Reviwed by Galfar QC)anon_585140390No ratings yet

- Quality Assurance Protocol: Raw MaterialDocument2 pagesQuality Assurance Protocol: Raw MaterialShah Newaz Kabir100% (1)

- Valve Inspection and Test PlanDocument1 pageValve Inspection and Test PlanClarkFedele27100% (1)

- KSB Etanorm CurvesDocument83 pagesKSB Etanorm CurvesEric Fabro100% (5)

- TH360B TH560B - CAT - Hydr System.Document2 pagesTH360B TH560B - CAT - Hydr System.Zeck33% (3)

- QAP - Filter Press FinalDocument1 pageQAP - Filter Press FinalStepworthNo ratings yet

- Final - Pump - QAP - 5P0312ABCD - Antico - Code 4 PDFDocument1 pageFinal - Pump - QAP - 5P0312ABCD - Antico - Code 4 PDFRishabh VermaNo ratings yet

- ITP For Profibus CABLE (YJ72759)Document1 pageITP For Profibus CABLE (YJ72759)Meng PamplonaNo ratings yet

- ITP For Sprinkler and Spary SystemDocument6 pagesITP For Sprinkler and Spary System梁奇龙100% (2)

- SR No Activity Characteristics To Be Checked Quantum of Check Inspection / SignDocument1 pageSR No Activity Characteristics To Be Checked Quantum of Check Inspection / SignAlpine ProjectsNo ratings yet

- KBR Inspection Test Plan For Shop Fabricated PipingDocument4 pagesKBR Inspection Test Plan For Shop Fabricated PipingSyafril AkbarNo ratings yet

- HVAC Systems List of Tests - LCETEDDocument4 pagesHVAC Systems List of Tests - LCETEDjon aquinoNo ratings yet

- Jeritp P 170300Document1 pageJeritp P 170300NicolaMasteNo ratings yet

- ITP For Non-Fire Resistant CI CableDocument1 pageITP For Non-Fire Resistant CI CableMeng PamplonaNo ratings yet

- Contoh Itp Mechanical PltuDocument2 pagesContoh Itp Mechanical PltuwawanNo ratings yet

- Contoh Itp Mechanical PltuDocument2 pagesContoh Itp Mechanical PltuyusufNo ratings yet

- Vishwabalaa Engineering Private Limited, Thirumazhisai, Chennai - 600124Document2 pagesVishwabalaa Engineering Private Limited, Thirumazhisai, Chennai - 600124sanil50% (2)

- Amiitp G 310500 - 2Document4 pagesAmiitp G 310500 - 2wangkai01.sneiNo ratings yet

- Revised QAP - Sluice ValveDocument1 pageRevised QAP - Sluice Valvevijaivirajackie mNo ratings yet

- Inspection Check List Clarification StationDocument33 pagesInspection Check List Clarification StationSepong BebNo ratings yet

- Tank Maintenance ITPDocument24 pagesTank Maintenance ITPthomas varugheseNo ratings yet

- PSI-Origin Energy-Basic Land Rig Inspection CriteriaDocument3 pagesPSI-Origin Energy-Basic Land Rig Inspection CriteriaKBNo ratings yet

- List of Hydro Test - WartsilaDocument1 pageList of Hydro Test - WartsilaSadia HasanNo ratings yet

- Programa de Mantenimiento Preventivo ACS880Document2 pagesPrograma de Mantenimiento Preventivo ACS880JaimeNo ratings yet

- ICL Pump QAP RPS 40-32 T3A AWC - ICL - ITPDocument2 pagesICL Pump QAP RPS 40-32 T3A AWC - ICL - ITPalokgoel_2006No ratings yet

- Qap - Oil Cooler For 82.1 KW & 16 KWDocument1 pageQap - Oil Cooler For 82.1 KW & 16 KWHEPL VATVANo ratings yet

- Flowdyne Enterprises, Mumbai Quality Assurance PlanDocument1 pageFlowdyne Enterprises, Mumbai Quality Assurance PlanRv JmNo ratings yet

- Inspection & Test Plan (Itp) - Iso 5167 - Fittings (SC / DC)Document1 pageInspection & Test Plan (Itp) - Iso 5167 - Fittings (SC / DC)Guru DevaNo ratings yet

- ITP (Can Gas)Document1 pageITP (Can Gas)Kemas Muhandis MancapaniNo ratings yet

- Section 7 Test and InspectionDocument12 pagesSection 7 Test and InspectionThaigroup CementNo ratings yet

- Sangeetha Engineering Works (P) LTD.: Ernakulam - 682 305 B-NO:14/107A, Near Agastya Ashram, Kureekkad, ThripunithuraDocument2 pagesSangeetha Engineering Works (P) LTD.: Ernakulam - 682 305 B-NO:14/107A, Near Agastya Ashram, Kureekkad, ThripunithuraSANGEETHANo ratings yet

- Itp PRDSDocument3 pagesItp PRDSDwi Mulyanti Dwimulyantishop100% (1)

- ACS880-107, - 207, - 307, - 607, - 907, - 1607 Multidrive: Maintenance ScheduleDocument4 pagesACS880-107, - 207, - 307, - 607, - 907, - 1607 Multidrive: Maintenance Scheduleafadsfd asfadfNo ratings yet

- ITP Arrester SulselbarruDocument14 pagesITP Arrester SulselbarruDaniel ChristianNo ratings yet

- AIP-Shed-week One-Inspection ReportDocument15 pagesAIP-Shed-week One-Inspection Reportyibelta abebeNo ratings yet

- ITP Piping DPPU Lampung Rev.1Document1 pageITP Piping DPPU Lampung Rev.1Steve WawukNo ratings yet

- Hydrotest Reports ORR 8inch KM 06-10 REALDocument47 pagesHydrotest Reports ORR 8inch KM 06-10 REALMAS CONSTRUCTIONSNo ratings yet

- RBCAPQPPPAPPackDocument60 pagesRBCAPQPPPAPPackAbdelilah KadriNo ratings yet

- 01 - A - I Test PlanDocument1 page01 - A - I Test Planrahmath nawazNo ratings yet

- Mar HM 18.06.22Document302 pagesMar HM 18.06.22özgen bölükNo ratings yet

- Ruelco CatalogDocument264 pagesRuelco CatalogJosé Uriel Javier TorresNo ratings yet

- Đính Kèm - HGBP - ITP For MV & LV SWGR (Project Format)Document9 pagesĐính Kèm - HGBP - ITP For MV & LV SWGR (Project Format)The GunnersNo ratings yet

- Inspection and Test Plan For Fan and Blower PDFDocument5 pagesInspection and Test Plan For Fan and Blower PDFAulia RahmanNo ratings yet

- 41.water Cum Foam Monitor-Trailer MountedDocument2 pages41.water Cum Foam Monitor-Trailer MountedSimbu ArasanNo ratings yet

- Inspection and Test Plan For Gas TurbineDocument5 pagesInspection and Test Plan For Gas TurbineLiu YangtzeNo ratings yet

- Quality Management - Inspection and Test PlanDocument1 pageQuality Management - Inspection and Test PlanVIKASH RAINo ratings yet

- Inspection and Test Plan (Itp) :: Floating Ball ValvesDocument1 pageInspection and Test Plan (Itp) :: Floating Ball ValvesDeepak UpadhyayNo ratings yet

- Inspection and Test Plan For Line PipeDocument4 pagesInspection and Test Plan For Line PipeMohamed BencharifNo ratings yet

- 2.3 Table of ContentDocument1 page2.3 Table of ContentEr Md AamirNo ratings yet

- F&G Devices Inspection and Test PlanDocument3 pagesF&G Devices Inspection and Test PlanaliNo ratings yet

- ACS580MV: Preventive Maintenance ScheduleDocument2 pagesACS580MV: Preventive Maintenance Schedulealok pratap singhNo ratings yet

- C1230D Intercooler SpecificationsDocument31 pagesC1230D Intercooler Specificationsprimeengineers444No ratings yet

- Manufacturing Inspection Test Plan: 1. Fabrication & Pre RequisitesDocument1 pageManufacturing Inspection Test Plan: 1. Fabrication & Pre RequisitesAlesol EquipmentNo ratings yet

- Asorc-Qcp 1652 ModifiedDocument22 pagesAsorc-Qcp 1652 ModifiedalkhiatNo ratings yet

- DCS No 15 - AC Not Working - Less EffecctiveDocument2 pagesDCS No 15 - AC Not Working - Less Effecctiveservicemanager.bkdNo ratings yet

- Itp For Tank Fabrication Installation Work1 Rev02 PDFDocument22 pagesItp For Tank Fabrication Installation Work1 Rev02 PDFMichelNo ratings yet

- Maintenance Schedule ACS580 ACH580 ACQ580 DrivesDocument2 pagesMaintenance Schedule ACS580 ACH580 ACQ580 DrivesDorinaDraganNo ratings yet

- 01-Ge-Aqa-9600 Itp DMF FRP Water Trough r2Document29 pages01-Ge-Aqa-9600 Itp DMF FRP Water Trough r2Eljo AndsNo ratings yet

- Inspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak RiauDocument4 pagesInspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak Riauanang_priNo ratings yet

- Curve (Slop Oil)Document1 pageCurve (Slop Oil)mech1No ratings yet

- Hindustan Petroleum Corporation LTDDocument217 pagesHindustan Petroleum Corporation LTDmech1No ratings yet

- SS SS Tubing Pid-3Document1 pageSS SS Tubing Pid-3mech1No ratings yet

- SS SS Tubing Pid-2Document1 pageSS SS Tubing Pid-2mech1No ratings yet

- 17-10 CDTPDocument14 pages17-10 CDTPmech1No ratings yet

- Series Series Series Series: Control Control Ball BallDocument4 pagesSeries Series Series Series: Control Control Ball BallEmi MariniNo ratings yet

- Skid Weight Calculation HHI-RAR-SD-SCAL-004. REV.BDocument8 pagesSkid Weight Calculation HHI-RAR-SD-SCAL-004. REV.BAgus MarpaungNo ratings yet

- Diagrama Hidraulico 420E CATERPILLAR PDFDocument4 pagesDiagrama Hidraulico 420E CATERPILLAR PDFWilmer0% (1)

- 345B and 345B II Excavators Hydraulic System - Attachment: Fluid Power SymbolsDocument2 pages345B and 345B II Excavators Hydraulic System - Attachment: Fluid Power SymbolsricardoNo ratings yet

- What Are The Safe Practices in Operating A Purifier As Per Operating Manual Instruction?Document4 pagesWhat Are The Safe Practices in Operating A Purifier As Per Operating Manual Instruction?Cj MañugoNo ratings yet

- ProductCatalog Cyrus Shank PSVDocument95 pagesProductCatalog Cyrus Shank PSVmramos4191No ratings yet

- Siemens: ASK DDocument1 pageSiemens: ASK DMurilo MonteiroNo ratings yet

- Easa 66Document5 pagesEasa 66BETHWELNo ratings yet

- D6M Track-Type Tractor Hydraulic System: 9ZM1-UP 2RN1-UP 3WN1-UP 4JN1-UP 5NR1-UP 5WR1-UP 6LR1-UP 2YS1-UP 4GS1-UP 4HS1-UPDocument2 pagesD6M Track-Type Tractor Hydraulic System: 9ZM1-UP 2RN1-UP 3WN1-UP 4JN1-UP 5NR1-UP 5WR1-UP 6LR1-UP 2YS1-UP 4GS1-UP 4HS1-UPElectronica Mecatronica RasmusNo ratings yet

- MM 1202 Av PDFDocument2 pagesMM 1202 Av PDFGarryNo ratings yet

- Pipes - CIFDocument13 pagesPipes - CIFsolebNo ratings yet

- Section 4 Brake System: Group 1 Structure and FunctionDocument22 pagesSection 4 Brake System: Group 1 Structure and FunctionREMZONANo ratings yet

- Features: Micropac® MC Compact Single Speed Hand PumpDocument3 pagesFeatures: Micropac® MC Compact Single Speed Hand PumpShankar BhardwajNo ratings yet

- Nirogen Rejection in Natural GasDocument10 pagesNirogen Rejection in Natural GasChukwuma OnukuNo ratings yet

- Dry Running PumpsDocument9 pagesDry Running Pumpsabo yossefNo ratings yet

- Serie 101 RTC CouplingsDocument10 pagesSerie 101 RTC CouplingsHIDRAFLUIDNo ratings yet

- Compressible Fluid Flow Oosthuizen SolutDocument105 pagesCompressible Fluid Flow Oosthuizen Solutam sachinNo ratings yet

- Performance Summary For Dnevni Boravak: 42NH Ductable in Room Fan Coil With Multi Speed MotorDocument2 pagesPerformance Summary For Dnevni Boravak: 42NH Ductable in Room Fan Coil With Multi Speed Motorvelikimag87No ratings yet

- Rice List Of: An ISO 9001 CompanyDocument16 pagesRice List Of: An ISO 9001 Company555dddaaaaNo ratings yet

- SM SAA6D170E-5.pdf-68-79 PDFDocument12 pagesSM SAA6D170E-5.pdf-68-79 PDFBalikpapan CityNo ratings yet

- Electric Pumps: Parts Diagram and Part Numbers Plunger and Diaphragm PumpsDocument24 pagesElectric Pumps: Parts Diagram and Part Numbers Plunger and Diaphragm PumpsCARLITOS 25No ratings yet

- 03-04-45-03 6081H Nao ParteDocument2 pages03-04-45-03 6081H Nao Partefranc.silveiNo ratings yet

- Sales and Engineering Data: Pd03P-Xxs-Xxx and Pe03P-Xxs-Xxx 10 - 100 1:1Document4 pagesSales and Engineering Data: Pd03P-Xxs-Xxx and Pe03P-Xxs-Xxx 10 - 100 1:1jarosNo ratings yet

- WPS 1013-2011Document27 pagesWPS 1013-2011alexander100% (1)

- Nozzle Load CheckDocument4 pagesNozzle Load CheckpipestressNo ratings yet

- GIS 14a - Purging Natural Gas Installation Volumes Between 0.03 m3 To 1.0 m3 - Energy Safe VictoriaDocument11 pagesGIS 14a - Purging Natural Gas Installation Volumes Between 0.03 m3 To 1.0 m3 - Energy Safe VictoriaArash FatehnezhadNo ratings yet