Professional Documents

Culture Documents

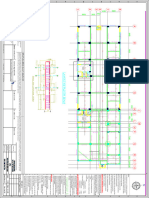

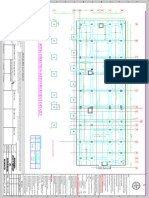

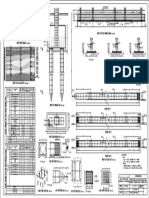

Raft Slab Bottom Long Bars Details

Raft Slab Bottom Long Bars Details

Uploaded by

DINESH M.NOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Raft Slab Bottom Long Bars Details

Raft Slab Bottom Long Bars Details

Uploaded by

DINESH M.NCopyright:

Available Formats

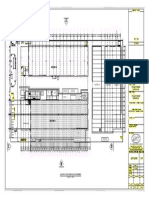

N

J M

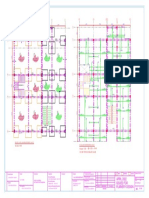

A B C D E F G H E L N P Q R S T U

1020 1200

9900 9900 4000 2660 9900 9830 1850 4500 2420 2580 7250 6600 3450

3240

86300 Notes:

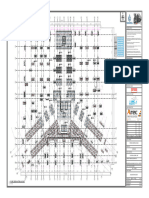

1.All dimensions are in millimeters and levels

1150

are in meters unless otherwise specified.

Y16 @200C/C ALONG `X' DIR

2.Drawing shall not be scaled, only written

8 1050

B1 B1 B1 B1 B1 B1 B1 B1 B1 B1

dimensions to be followed.

P1 P1 P1 P1 P1 P1 P1 P1 P1 P1 P1 3.Any Error or Discrepancies in the

Drawings are to be brought to the notice.

9250

6900

of the Architect/ Engineers.

B1

B1

B1

B1

B1

B1

B1

B1

B1

B1

4. This drawings shall not be used other than

B1

the purpose marked/issued specified.

5. The drawings to be read with conjuction

7 B1 B1 B1 B1 B1 B1 B1 B1 B1 B1

Y25+Y25 @100C/C- ALONG `X' DIR

P4 P1 P1

P1

P1

with structural drawings.

P1 P2 P1 P1 P1 P1

Y16 @200C/C ALONG `X' DIR

6. All the drawings prepared by Design

4250

and structural consultants are as per

B4

10325

NBC norms and guidelines.

6

Y32 @100-2 LAYERS IN `X' DIR

Y32 @100-2 LAYERS IN `X' DIR

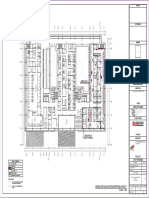

REMOVAL OF FORMWORK(SHUTTERING) :

B2

B2

B2

B2

B1

B1

B1

B1

27500

S.W2

2000

Shuttering of any part of the structure shall not be

5 Y16 @200 IN `Y' DIR removed until the concrete attains 70% of the specified

strength of concrete however the following minimum

period (after final pour ) shall be allowed before

B4

3650

P1

removal of shuttering as per clause 11.3.1, is 456:2000

A. Vertical side of shuttering of columns,walls & beams

4

Y16 @200C/C- ALONG `X' DIR

Y16 @200C/C- ALONG `X' DIR

B2 B2 B2 B2 B2 B3 B3 B3 B1 - 24 hours

P1 B. Bottom shuttering of slabs (keeping the props)

P2 P2 P2 P2 P1 P1 - 3 days

C. Bottom shuttering of beams (keeping the props)

Y16 @200 `X' DIR

- 7 day

B1

B1

B4

6900

B1

D. Props to slabs :

B1

B4

B4

B4

B4

B4

i .spanning upto 4.5 m - 7 days

9250

i i .spanning over 4.5 m - 14 days

P1 E. Props to beams & arches :

B1 B1 B4 B4 B1 i .spanning upto 6 m - 14 days

3 P2 B2

P4

B4 B4 B4

P1

i i.spanning over 6 m - 21 days

RAFT LINE LAP JOINTS FOR REINFORCEMENT BARS :

3290

1. At any cross section of the member,not more than

50% of the bars shall be lapped.

2 2. Laps shall be staggered with a minimum centre to

centre distance of 1.3 times lap length of the bar for

PCC LINE

tension & compression members.

NF2 NF1 NF1 NF1 NF2 3. Development length (ld) shall be as per (sp:34-1999)

NF1 NF1 NF1

table below:

a) Development length for column bars - 40d

b) Development length for beam bars - 50d

4. Laps in columns shall be provided at mid height of

11105

floor and not at slab level .

5. Laps in beams and slabs shall be provided at the

point of contraflexure.

3000 6. Welding of bars shall be done as a stitch weld for 5

2700

1500 times diameter of bar and a gap of 5 times higher

1350

diameter bar and again welding for another 5 times

diameter of bar using arc welding and special

1350

electrodes after obtaining prior written approval from

1

3000

2700

the structural designer.

7. Detailing of rebars shall confirm to sp-34 & is 13920.

M-35 GRADE CONCRETE

GENERAL NOTES:

NF2 NF1 NF1 NF1 NF1 NF1 NF2 1. Concrete grade shall be M35(design mix) confirming to

is 456:2000

2. Minimum cement content = 380 kg/m3.

3. Min.grade of reinforcement marked thus (y) shall be Fe

550D confirming to IS 1786-1985

4. Clear cover for reinforcement

a) Column = 40mm d) Raft slab bottom = 75mm

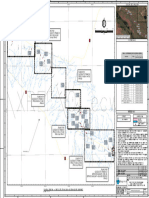

FOOTING SCHEDULE : e) Raft slab top = 50mm

BOTTOM - SHORT BAR DIRECTION-REINFORCEMENT DETAILS

b) R.C wall = 40mm

c) Shear wall = 40mm

FOOTING

SI. FOOTING REINFORCEMENT This drg. read in conjection with arch.drgs.

NO OF

NO. NAME FOOTING SIZE X = LONGER DIRECTION 5. Raft & Columns are designed for Ground + Mezzanine +

FOOTING

Y = SHORTER DIRECTION Four floor loads only.

Y20 @ 125 C/C 6. SBC of the soil is taken as 320kN / sqm. @ 2.40m below

01 NF1 2000 x 2000 BOTTOM - 14

BOTHWAYS from N.G.L. as per soil report.

D = 750 Y16 @ 150 C/C 7. Spacer bar - 25mm dia to be provided in between two

TOP - BOTHWAYS layer of reinforcement at every 750mm c/c

8. Structural engineer responsibility is limited to design &

issual of structural drawing only

9. Onus of construction lies with contractor/owner

10. For concreting water cement ratio should be (0.45) (for

1bag cement= max-25 lit of water only to be added.)

NOTES STRUCTURAL DESIGN QUALITY ASSURANCE

REVISIONS

Notice of no objection from Southern Railways Katpadi is being accorded for design principles based on the The drawing has been prepared based on actual site survey and other terms and conditions of the EPC Agreement. Responsibility of accuracy, correctness , This drawing including its design and detailing has been checked in accordance with the requirements of EPC Agreement and found

recommendations of the Architect/Lead Designer and proposal by the Contractor. However, the completeness, integrity and full compliance with byelaws, standards, statutory, regulations of relevant Codes & Manuals/ Rules and as per EPC Agreement suitable for the execution purpose. The overall responsibility of correctness of design,detailing and compliance with EPC agreement R.NO DATE DESCRIPTION

overall responsibility and design accuracy lies with the contractor (Engineering Projects (india) Pvt Ltd) provisions, rests with the Design Consultants and the Contractor without any financial implications. rests with the Structural Design Consultant and Contractor.

CLIENT: PROJECT: EPC Contractor: DESIGN CONSULTANT Authority Engineer (PMS) AXEN CN/MAS DY. CE CN/MAS CE CN/MAS

Drawing Title :

SOUTHERN RAILWAYS, REDEVELOPMENT OF ENGINEERING PROJECTS M/S VOYANTS SOLUTIONS PVT. LTD.

KATPADI. KATPADI JUNCTION (INDIA) LTD-CHENNAI Drawing Type :

Drawing No.: Scale: 1:100 Date: 12.12.23

Drawing Purpose: Sheet Size: A2 Rev. No: R0

AGM DESIGN DIRECTOR TEAM LEADER LEAD DESIGNER

You might also like

- Plinth Beam LayoutDocument1 pagePlinth Beam LayoutDINESH M.NNo ratings yet

- Raft Slab LayoutDocument1 pageRaft Slab LayoutDINESH M.NNo ratings yet

- Raft Slab Top Bars DetailsDocument1 pageRaft Slab Top Bars DetailsDINESH M.NNo ratings yet

- Lighting 4Document1 pageLighting 4jpsablan.gccmNo ratings yet

- Foundation Plan Roof Beam Plan: Jomar R. MercialesDocument1 pageFoundation Plan Roof Beam Plan: Jomar R. MercialesJaypee MoradaNo ratings yet

- Document 1Document1 pageDocument 1MUQEET ahmedNo ratings yet

- TIC Pre-Fab Shed 20.12.17-Model - PDF A-1Document1 pageTIC Pre-Fab Shed 20.12.17-Model - PDF A-1Habibur RahmanNo ratings yet

- Raft Slab Bottom Short Bars DetailsDocument1 pageRaft Slab Bottom Short Bars DetailsDINESH M.NNo ratings yet

- FP SDP 20X30 PalanogbirthinghomeDocument1 pageFP SDP 20X30 Palanogbirthinghomeflor johnNo ratings yet

- A B C D E F G: Northern IloiloDocument1 pageA B C D E F G: Northern IloiloDan Ney HuboNo ratings yet

- SM 02Document1 pageSM 02MUBASHIRNo ratings yet

- Denah Instalasi Sistem Antrian R1-LT 1Document1 pageDenah Instalasi Sistem Antrian R1-LT 1Jafar SidiqNo ratings yet

- Denah Instalasi Sistem Antrian R1-LT 2Document1 pageDenah Instalasi Sistem Antrian R1-LT 2Jafar SidiqNo ratings yet

- 1st Floor Duct-ModelDocument1 page1st Floor Duct-Modelاحمد خليفة خليفةNo ratings yet

- 03A Clasificación Del Suelo Vista GeneralDocument1 page03A Clasificación Del Suelo Vista GeneralANGIE D. ZAMBRANO C.No ratings yet

- A2 PDFDocument1 pageA2 PDFCRISCHOUEL ALIMORONGNo ratings yet

- Mapa SNT Septiembre 2021 A1Document1 pageMapa SNT Septiembre 2021 A1Jairo DumanNo ratings yet

- Ground Floor Plan Ground Floor Plan: A B C A B C 3 A B C A B C 3Document1 pageGround Floor Plan Ground Floor Plan: A B C A B C 3 A B C A B C 3Jem CapistranoNo ratings yet

- La Palmira-1Document1 pageLa Palmira-1Carlos orozcoNo ratings yet

- Mgc-rl2-Sds-cvl-022 Rev.00 - Glass Balustrade Handrail at First Floor - Th43Document4 pagesMgc-rl2-Sds-cvl-022 Rev.00 - Glass Balustrade Handrail at First Floor - Th43jijinsNo ratings yet

- Backup Assignment Working Drawing 2 1211267Document1 pageBackup Assignment Working Drawing 2 1211267Nabil SyadiqNo ratings yet

- StandDocument1 pageStandPnashe MapongaNo ratings yet

- HNK - Ground Floor Structural Drawings 13-09-2023 - r3Document10 pagesHNK - Ground Floor Structural Drawings 13-09-2023 - r3Karan KumarNo ratings yet

- Vie Pc01 STN DWG MP Ppa 01108 0Document1 pageVie Pc01 STN DWG MP Ppa 01108 0Ashish BhartiNo ratings yet

- Victoria Shanghai Academy School Building 9/F Blueprint PlanDocument1 pageVictoria Shanghai Academy School Building 9/F Blueprint PlanZwaaknqNo ratings yet

- 201853C 509 DW 1841 0005 Rev 2Document1 page201853C 509 DW 1841 0005 Rev 2Suman JanaNo ratings yet

- Redes Acueducto Plancha: Rio BogotaDocument1 pageRedes Acueducto Plancha: Rio BogotaJOSE RODRIGO TORRES CORREANo ratings yet

- Ar-1.0 - Grand Parkplace Lower Ground Floor Plan W Column - Option 2Document1 pageAr-1.0 - Grand Parkplace Lower Ground Floor Plan W Column - Option 2Gelsey UyNo ratings yet

- Air KotorDocument1 pageAir KotorAsep fauzanNo ratings yet

- Sy Res Sanjuan BatangasDocument5 pagesSy Res Sanjuan BatangasSecond Floor ConstructionNo ratings yet

- Compressor ShelterDocument3 pagesCompressor ShelterHUSSEIN FNEISHNo ratings yet

- Dau Noi Nuoc MưaDocument4 pagesDau Noi Nuoc Mưaha ducNo ratings yet

- Yas MZ Acm ST C40 B1 DT 06001 (A)Document1 pageYas MZ Acm ST C40 B1 DT 06001 (A)hemanthsridharaNo ratings yet

- WTC-MQ-XAR-AR-EL-00201 (C) - West Elevation - 02Document1 pageWTC-MQ-XAR-AR-EL-00201 (C) - West Elevation - 02xyzhynNo ratings yet

- Ref1 CD - DIZ BDCDocument22 pagesRef1 CD - DIZ BDCBryan Nicolas IbeNo ratings yet

- 01-04-2024 Layout Sinotrans (Rev 4)Document1 page01-04-2024 Layout Sinotrans (Rev 4)Hans HendryanNo ratings yet

- 01 - Oleod. Tramo III - Plano 01Document1 page01 - Oleod. Tramo III - Plano 01benjamin Diaz BenincampiNo ratings yet

- Warehouse - Level 01 Columns & Walls Setting Out Plan - Part-1 1Document1 pageWarehouse - Level 01 Columns & Walls Setting Out Plan - Part-1 1projects sureshNo ratings yet

- C.7wy0.wh.74.31.20201.uag Eiz100 S01 R00Document1 pageC.7wy0.wh.74.31.20201.uag Eiz100 S01 R00JC DC AcostaNo ratings yet

- Fire Alarm Second Floor Plan. - 20.12.23-FaDocument1 pageFire Alarm Second Floor Plan. - 20.12.23-FaAtish SinghNo ratings yet

- CAHUACONATRAMO I-ModelDocument1 pageCAHUACONATRAMO I-ModelSiles Melanio Izquierdo ValdezNo ratings yet

- Water Supply Pressure TestDocument3 pagesWater Supply Pressure TestarlanNo ratings yet

- Factory 2: A2 B2 C2 D2 E2 F2 G2 H2 I2 J2 K2 L2 M2 N2 O2 P2 Q2 R2 A3 B3 A4 B4 C4 D4 E4 G4 H4 F4Document1 pageFactory 2: A2 B2 C2 D2 E2 F2 G2 H2 I2 J2 K2 L2 M2 N2 O2 P2 Q2 R2 A3 B3 A4 B4 C4 D4 E4 G4 H4 F4Eddy Shaka AMTNo ratings yet

- SJGC - 26.04.2021 - Tender Drawings - HVACDocument5 pagesSJGC - 26.04.2021 - Tender Drawings - HVACwaz ahmedNo ratings yet

- Toilet: Block ADocument1 pageToilet: Block Aidesign advertisingNo ratings yet

- Festival Mall - Asbuilt PlanDocument1 pageFestival Mall - Asbuilt PlanArmando RodriguezNo ratings yet

- 1251 A 301 Sections A 3011410933459381Document1 page1251 A 301 Sections A 3011410933459381Fadi AlatrashNo ratings yet

- Dormitory - Koordinat BorepileDocument3 pagesDormitory - Koordinat BorepilehadipurnomoputraNo ratings yet

- Nenmong Tranphucduy FinallyDocument1 pageNenmong Tranphucduy FinallyPhúc DuyNo ratings yet

- R4 Footing Lay-OutDocument1 pageR4 Footing Lay-OutKaran KumarNo ratings yet

- 04 - General Layout Plan (Endorsed Copy)Document1 page04 - General Layout Plan (Endorsed Copy)jae shen simNo ratings yet

- A1Document1 pageA1Mary FelicianoNo ratings yet

- Yas MZ Acm ST C40 B1 DT 06002 (A)Document1 pageYas MZ Acm ST C40 B1 DT 06002 (A)hemanthsridharaNo ratings yet

- 319 - OCM3000ti-OMH3000Document6 pages319 - OCM3000ti-OMH3000Bidu BiduNo ratings yet

- Ar-1.0 - Grand Parkplace Floor Plan W Column - Option 1Document1 pageAr-1.0 - Grand Parkplace Floor Plan W Column - Option 1Gelsey UyNo ratings yet

- A B C D E F G H J: Jumeirah VillageDocument1 pageA B C D E F G H J: Jumeirah VillageMUBASHIRNo ratings yet

- Grma Final Structural Detaling-001Document1 pageGrma Final Structural Detaling-001migbaru aberaNo ratings yet

- 2NDFLOOR CVMC MAIN-mergedDocument4 pages2NDFLOOR CVMC MAIN-mergedRafaela VillanuevaNo ratings yet

- Sub Soil With Raft Layout-ModelDocument1 pageSub Soil With Raft Layout-ModelKaran KumarNo ratings yet

- LEVEL III - ATA 45 Onboard Maintenance SystemDocument186 pagesLEVEL III - ATA 45 Onboard Maintenance Systemwagdi100% (3)

- Ras 13ykv e PDFDocument79 pagesRas 13ykv e PDFaxisNo ratings yet

- SCLMDocument45 pagesSCLMkeerthana chandrasekarNo ratings yet

- Raisecom RC002-16Document2 pagesRaisecom RC002-16Eka RatnaNo ratings yet

- Entity Relationship ModelDocument41 pagesEntity Relationship ModelaziNo ratings yet

- C-Zone SDN BHD: WWW - Czone.myDocument2 pagesC-Zone SDN BHD: WWW - Czone.myFirman SyahNo ratings yet

- SKF GE 200 ES-2RS SpecificationDocument5 pagesSKF GE 200 ES-2RS SpecificationvishnuNo ratings yet

- CSC232 - Chp4 Computer ArithmeticDocument71 pagesCSC232 - Chp4 Computer ArithmeticHassan HassanNo ratings yet

- Abeba DebruDocument90 pagesAbeba Debruabera alemayehuNo ratings yet

- M Tech Dissertation Computer ScienceDocument4 pagesM Tech Dissertation Computer ScienceWriteMyPsychologyPaperCanada100% (1)

- WD My Cloud EX2 Ultra NAS Product DatasheetDocument2 pagesWD My Cloud EX2 Ultra NAS Product DatasheetRayyana AsmanNo ratings yet

- 02 - RA22742EN01GLA00 - Flexi - MR - BTS - Licensed - Feat - & - SW - Comp PDFDocument29 pages02 - RA22742EN01GLA00 - Flexi - MR - BTS - Licensed - Feat - & - SW - Comp PDFICCB2006No ratings yet

- Online Voting SystemDocument26 pagesOnline Voting SystemVenkatesh Hanumandla96% (27)

- Winodws 11 Kako InstaliratiDocument9 pagesWinodws 11 Kako InstaliratiFaćko Iz Dubokog PotokaNo ratings yet

- COMANDOSDocument13 pagesCOMANDOSLiaNo ratings yet

- V033e1-5 NT620S+NT620CDocument337 pagesV033e1-5 NT620S+NT620CMERTAL JAYA ABADINo ratings yet

- DevOps Brochure AS USENDocument5 pagesDevOps Brochure AS USENmd imranNo ratings yet

- How To Install DockerDocument5 pagesHow To Install DockerfaeemNo ratings yet

- ML Module 5 2022 PDFDocument31 pagesML Module 5 2022 PDFjanuary100% (1)

- Снимок экрана 2024-03-19 в 12.42.42Document1 pageСнимок экрана 2024-03-19 в 12.42.42gpv44nczhsNo ratings yet

- Smart Dustbin Vigilant System Using GSM and Arduino UnoDocument4 pagesSmart Dustbin Vigilant System Using GSM and Arduino UnoClean 91No ratings yet

- Octal Bus Transceiver (3-State) : Order CodesDocument10 pagesOctal Bus Transceiver (3-State) : Order CodesSero StivNo ratings yet

- "The Web Development Glossary": A New Reference Book Covering 2,000 Terms in Web Development and DesignDocument2 pages"The Web Development Glossary": A New Reference Book Covering 2,000 Terms in Web Development and DesignPR.comNo ratings yet

- Executing Shell Commands With PythonDocument12 pagesExecuting Shell Commands With PythonHbsodndkNo ratings yet

- Datasheet - Trimble TDC600 Handheld - English (US)Document2 pagesDatasheet - Trimble TDC600 Handheld - English (US)Vithakone SITTHIDETHNo ratings yet

- Business Name Street LocalityDocument62 pagesBusiness Name Street LocalityJoseph MolenkoNo ratings yet

- Geriatric-Medi BotDocument38 pagesGeriatric-Medi Bot4402 Ajesh RNo ratings yet

- Factor Analysis: Warning: Very Mathematical!Document84 pagesFactor Analysis: Warning: Very Mathematical!Dr Arif AnwarNo ratings yet

- Voltage Follower Part II Circuit IntuitionsDocument3 pagesVoltage Follower Part II Circuit IntuitionsfofokxidNo ratings yet

- Cisco APIC REST API Configuration Guide 42xDocument56 pagesCisco APIC REST API Configuration Guide 42xTrương Văn HuyNo ratings yet