Professional Documents

Culture Documents

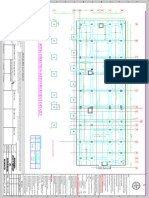

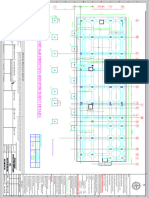

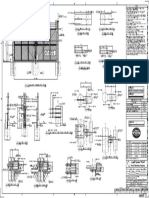

RC Wall Layout

RC Wall Layout

Uploaded by

DINESH M.NOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RC Wall Layout

RC Wall Layout

Uploaded by

DINESH M.NCopyright:

Available Formats

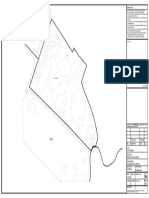

N

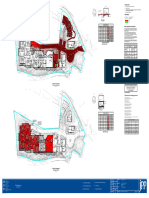

J M Notes:

1.All dimensions are in millimeters and levels

A B C D E F G H E L N P Q R S T U are in meters unless otherwise specified.

2.Drawing shall not be scaled, only written

1020 1850 1200 dimensions to be followed.

9900 9900 3240 4000 2660 9900 9830 4500 2420 2580 7250 6600 3300 2200 3450 3.Any Error or Discrepancies in the

Drawings are to be brought to the notice.

of the Architect/ Engineers.

4. This drawings shall not be used other than

the purpose marked/issued specified.

5. The drawings to be read with conjuction

8 with structural drawings.

6. All the drawings prepared by Design

and structural consultants are as per

6900

NBC norms and guidelines.

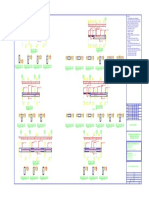

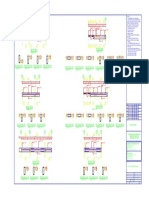

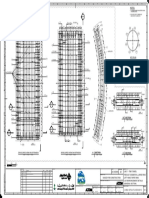

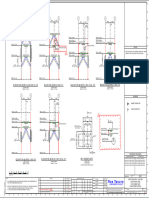

REMOVAL OF FORMWORK(SHUTTERING) :

Shuttering of any part of the structure shall not be

removed until the concrete attains 70% of the specified

7 strength of concrete however the following minimum

period (after final pour ) shall be allowed before

4250

removal of shuttering as per clause 11.3.1, is 456:2000

A. Vertical side of shuttering of columns,walls & beams

- 24 hours

B. Bottom shuttering of slabs (keeping the props)

6

2000

- 3 days

LIFT

CUTOUT C. Bottom shuttering of beams (keeping the props)

5 - 7 day

D. Props to slabs :

i .spanning upto 4.5 m - 7 days

3650

i i .spanning over 4.5 m - 14 days

E. Props to beams & arches :

i .spanning upto 6 m - 14 days

4 i i.spanning over 6 m - 21 days

LAP JOINTS FOR REINFORCEMENT BARS :

1. At any cross section of the member,not more than

6900

50% of the bars shall be lapped.

2. Laps shall be staggered with a minimum centre to

centre distance of 1.3 times lap length of the bar for

tension & compression members.

3. Development length (ld) shall be as per (sp:34-1999)

table below:

3 a) Development length for column bars - 40d

b) Development length for beam bars - 50d

4. Laps in columns shall be provided at mid height of

floor and not at slab level .

5. Laps in beams and slabs shall be provided at the

point of contraflexure.

6. Welding of bars shall be done as a stitch weld for 5

times diameter of bar and a gap of 5 times higher

diameter bar and again welding for another 5 times

diameter of bar using arc welding and special

electrodes after obtaining prior written approval from

the structural designer.

7. Detailing of rebars shall confirm to sp-34 & is 13920.

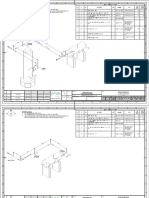

RCC WALL LAYOUT

GENERAL NOTES:

1. Concrete grade shall be M35(design mix) confirming to

is 456:2000

2. Minimum cement content = 380 kg/m3.

3. Min.grade of reinforcement marked thus (y) shall be Fe

550D confirming to IS 1786-1985

4. Clear cover for reinforcement

a) Column = 40mm d) Raft slab bottom = 75mm

b) R.C wall = 40mm e) Raft slab top = 50mm

c) Shear wall = 40mm

This drg. read in conjection with arch.drgs.

5. Raft & Columns are designed for Ground + Mezzanine +

Four floor loads only.

6. SBC of the soil is taken as 320kN / sqm. @ 2.40m below

from N.G.L. as per soil report.

7. Spacer bar - 25mm dia to be provided in between two

layer of reinforcement at every 750mm c/c

8. Structural engineer responsibility is limited to design &

issual of structural drawing only

9. Onus of construction lies with contractor/owner

10. For concreting water cement ratio should be (0.45) (for

1bag cement= max-25 lit of water only to be added.)

NOTES STRUCTURAL DESIGN QUALITY ASSURANCE

REVISIONS

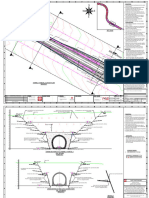

Notice of no objection from Southern Railways Katpadi is being accorded for design principles based on the The drawing has been prepared based on actual site survey and other terms and conditions of the EPC Agreement. Responsibility of accuracy, correctness , This drawing including its design and detailing has been checked in accordance with the requirements of EPC Agreement and found

recommendations of the Architect/Lead Designer and proposal by the Contractor. However, the completeness, integrity and full compliance with byelaws, standards, statutory, regulations of relevant Codes & Manuals/ Rules and as per EPC Agreement suitable for the execution purpose. The overall responsibility of correctness of design,detailing and compliance with EPC agreement R.NO DATE DESCRIPTION

overall responsibility and design accuracy lies with the contractor (Engineering Projects (india) Pvt Ltd) provisions, rests with the Design Consultants and the Contractor without any financial implications. rests with the Structural Design Consultant and Contractor.

CLIENT: PROJECT: EPC Contractor: DESIGN CONSULTANT Authority Engineer (PMS) AXEN CN/MAS DY. CE CN/MAS CE CN/MAS

Drawing Title :

SOUTHERN RAILWAYS, REDEVELOPMENT OF ENGINEERING PROJECTS M/S VOYANTS SOLUTIONS PVT. LTD.

KATPADI. KATPADI JUNCTION (INDIA) LTD-CHENNAI Drawing Type :

Drawing No.: Scale: 1:100 Date: 12.12.23

Drawing Purpose: Sheet Size: A2 Rev. No: R0

AGM DESIGN DIRECTOR TEAM LEADER LEAD DESIGNER

You might also like

- MINI Cooper Service Manual: 2002-2006 - Complete IndexDocument11 pagesMINI Cooper Service Manual: 2002-2006 - Complete IndexBentley Publishers14% (14)

- Raft Slab LayoutDocument1 pageRaft Slab LayoutDINESH M.NNo ratings yet

- Raft Slab Top Bars DetailsDocument1 pageRaft Slab Top Bars DetailsDINESH M.NNo ratings yet

- Raft Slab Bottom Short Bars DetailsDocument1 pageRaft Slab Bottom Short Bars DetailsDINESH M.NNo ratings yet

- THD-0500-ARC-GF-PL-8404 Ground Floor Wet Area Waterproofing Works Layout Code B Approved As NotedDocument2 pagesTHD-0500-ARC-GF-PL-8404 Ground Floor Wet Area Waterproofing Works Layout Code B Approved As NotedQAQC GCCNo ratings yet

- Op Block Ground FloorDocument1 pageOp Block Ground Floorvenkat rajuNo ratings yet

- Plinth Beam LayoutDocument1 pagePlinth Beam LayoutDINESH M.NNo ratings yet

- KATEDAN, COLUMNS, PLINTH, ROOF LAYOUTS Throug Mail On 30.07.18Document1 pageKATEDAN, COLUMNS, PLINTH, ROOF LAYOUTS Throug Mail On 30.07.18nikita meshramNo ratings yet

- S-14 - Roof Framing PlanDocument1 pageS-14 - Roof Framing PlanJames PittsNo ratings yet

- Ndwiga 2 Bedroom Apartments in Chokaa PDFDocument1 pageNdwiga 2 Bedroom Apartments in Chokaa PDFRooney mutetiNo ratings yet

- Box Culvert 2X2Document6 pagesBox Culvert 2X2abhishek singhNo ratings yet

- Raft Slab Bottom Long Bars DetailsDocument1 pageRaft Slab Bottom Long Bars DetailsDINESH M.NNo ratings yet

- Beam 1st Floor - 1Document1 pageBeam 1st Floor - 1danokrayNo ratings yet

- Beam 1st Floor - 1Document1 pageBeam 1st Floor - 1danokrayNo ratings yet

- Beam 1st Floor - 1Document1 pageBeam 1st Floor - 1danokrayNo ratings yet

- Beam 1st Floor - 1Document1 pageBeam 1st Floor - 1danokrayNo ratings yet

- General Notes 1Document1 pageGeneral Notes 1محمد ابراهيمNo ratings yet

- Sa128563 0006 0003 PDFDocument1 pageSa128563 0006 0003 PDFGavriel NgNo ratings yet

- Anexo 3Document1 pageAnexo 3Vagner TimbaNo ratings yet

- Faith Chogo Two BedroomDocument1 pageFaith Chogo Two BedroomBrian KibetNo ratings yet

- Faith Chogo Two BedroomDocument1 pageFaith Chogo Two BedroomBrian KibetNo ratings yet

- Pile Cap of Abutment A1 & A2 (Takarma) - 1Document1 pagePile Cap of Abutment A1 & A2 (Takarma) - 1Nilay GandhiNo ratings yet

- Admission TextDocument1 pageAdmission TextSwati DhurpateNo ratings yet

- T1 P2 Exc. and Support Portal DrawingDocument3 pagesT1 P2 Exc. and Support Portal Drawinggoutampatra.official.91No ratings yet

- SR Description Unit Weight: Praj Industries LTDDocument6 pagesSR Description Unit Weight: Praj Industries LTDviveksharmalove77No ratings yet

- A B C D E F G: Ground Floor PlanDocument1 pageA B C D E F G: Ground Floor PlanNPCC MawsynramNo ratings yet

- KKR RKD ZZ 06 DR A 1136 6th Floor Partition Types Plan 1Document1 pageKKR RKD ZZ 06 DR A 1136 6th Floor Partition Types Plan 1Cos CostyNo ratings yet

- Pdch14-Gaj-Dwg-000-Xxx-Arc-31111-Pdf (T01) - Window Locations - Apartments Upper LevelsDocument1 pagePdch14-Gaj-Dwg-000-Xxx-Arc-31111-Pdf (T01) - Window Locations - Apartments Upper LevelsZaido Al HalabiNo ratings yet

- Refer To Drawing No.: 620620 SH-002 Refer To Drawing No.: 620620 SH-003Document1 pageRefer To Drawing No.: 620620 SH-002 Refer To Drawing No.: 620620 SH-003muthuvelaaNo ratings yet

- Kitchen-Model ShiDocument1 pageKitchen-Model ShiSHIVAM RAVALNo ratings yet

- Attachment 2 Work LocationDocument1 pageAttachment 2 Work LocationAqueel AzharNo ratings yet

- Proposed Gentle Shepherd Classrooms BlockDocument9 pagesProposed Gentle Shepherd Classrooms BlockerickNo ratings yet

- Approved For Construction: D A D ADocument1 pageApproved For Construction: D A D AamirNo ratings yet

- M BD2 100tu0 Ctli Edr 000112Document1 pageM BD2 100tu0 Ctli Edr 000112Sanjoy SanyalNo ratings yet

- C200-Standard Details-C200Document1 pageC200-Standard Details-C200Emson ChitsungoNo ratings yet

- DHQC Cecb MB Ti Ar DW ML 02 80507Document1 pageDHQC Cecb MB Ti Ar DW ML 02 80507Kumudu PereraNo ratings yet

- Pm210011-Nui900-Rd2-00025 - 01 - Raft Foundation Section, Column & Wall Deta...Document1 pagePm210011-Nui900-Rd2-00025 - 01 - Raft Foundation Section, Column & Wall Deta...MOHAMMAD JAKARIA HASANNo ratings yet

- First Floor Plan: General NotesDocument1 pageFirst Floor Plan: General NotesAmadi HenryNo ratings yet

- Amrapali Leisure Park: NBCC (India) LimitedDocument1 pageAmrapali Leisure Park: NBCC (India) LimitedPlanning vclgroupNo ratings yet

- D E F G H: Grating SpecificationsDocument1 pageD E F G H: Grating SpecificationssivagnanamNo ratings yet

- R03 C07B01 IKP 01 GF SDW AR 10005 - Comments1Document1 pageR03 C07B01 IKP 01 GF SDW AR 10005 - Comments1Eleazar SacloloNo ratings yet

- 9946Z - 0657-SP-SL-PL-C-G12-005 (B) - Cut & Fill AnalysisDocument1 page9946Z - 0657-SP-SL-PL-C-G12-005 (B) - Cut & Fill Analysisjmdavies.isNo ratings yet

- Victoria Shanghai Academy School Building 9/F Blueprint PlanDocument1 pageVictoria Shanghai Academy School Building 9/F Blueprint PlanZwaaknqNo ratings yet

- A7120 94 A10 S XXX9400Document1 pageA7120 94 A10 S XXX9400Faisal MuhammadNo ratings yet

- JNDocument38 pagesJNcristianNo ratings yet

- Reset 1 D 0 0 1 EL ST: A B C B' A'Document1 pageReset 1 D 0 0 1 EL ST: A B C B' A'dawitgggNo ratings yet

- Apcu & Emergency First FloorDocument1 pageApcu & Emergency First Floorvenkat rajuNo ratings yet

- Contour Map - 1Document1 pageContour Map - 1mffareed70No ratings yet

- Building Construction - Viii: Large Span Roof Plan 1 Large Span Roof Isometric 3Document1 pageBuilding Construction - Viii: Large Span Roof Plan 1 Large Span Roof Isometric 3Vinita KumariNo ratings yet

- Large Roof Span Structure - Pankaj PrabhakarDocument1 pageLarge Roof Span Structure - Pankaj PrabhakarVinita KumariNo ratings yet

- M BD3 1F8000 Cutl Edr 000202Document1 pageM BD3 1F8000 Cutl Edr 000202ahmed.abdelmegeed78No ratings yet

- Paint Specifications 27-05-2020Document1 pagePaint Specifications 27-05-2020Vinod MasaniNo ratings yet

- Tagaytay As-Built 5Document6 pagesTagaytay As-Built 5Alvin Jan FranciscoNo ratings yet

- WTC-MQ-XAR-AR-EL-00201 (C) - West Elevation - 02Document1 pageWTC-MQ-XAR-AR-EL-00201 (C) - West Elevation - 02xyzhynNo ratings yet

- MEUK-TW-001-DRAWS-1-2016-28-01 Rev DDocument1 pageMEUK-TW-001-DRAWS-1-2016-28-01 Rev DbgygNo ratings yet

- Cyclone Raw MillDocument1 pageCyclone Raw MillADOFSLNo ratings yet

- Elevation at Grid Line 102 & 103 Elevation at Grid Line 104 Elevation at Grid Line 099 & 100 Elvation at Grid Line 101Document1 pageElevation at Grid Line 102 & 103 Elevation at Grid Line 104 Elevation at Grid Line 099 & 100 Elvation at Grid Line 101schhittarkaNo ratings yet

- Tensile Fabric Details 3Document1 pageTensile Fabric Details 3FRANKLYN SPENCERNo ratings yet

- Notes:: For ConstructionDocument1 pageNotes:: For ConstructionDAVID SOTONo ratings yet

- M BD2 100tu0 Ctli Edr 000116Document1 pageM BD2 100tu0 Ctli Edr 000116Sanjoy SanyalNo ratings yet

- Fema f2Document2 pagesFema f2santoshkumar86No ratings yet

- Cables: June 2015Document27 pagesCables: June 2015Gaurav NeermulNo ratings yet

- Literature ReviewDocument3 pagesLiterature Reviewsheen100No ratings yet

- Passive Cooling 1Document15 pagesPassive Cooling 11SI17AT024 MOHAMMED AASIM ATIQNo ratings yet

- Module 4 - Organization and Management AspectDocument3 pagesModule 4 - Organization and Management AspectYolly DiazNo ratings yet

- Classification of Android Apps and Malware Using Deep Neural NetworksDocument8 pagesClassification of Android Apps and Malware Using Deep Neural NetworksAbhishek ChattopadhyayNo ratings yet

- FDP Reading MaterialDocument135 pagesFDP Reading MaterialSyam MohanNo ratings yet

- Usbn B.ing 2019 - BDocument9 pagesUsbn B.ing 2019 - BAgus WuryantoNo ratings yet

- Vision of Narayana Murthy For A Better IndiaDocument2 pagesVision of Narayana Murthy For A Better IndiadushyantNo ratings yet

- Terrermix Ramadhan RecipesDocument50 pagesTerrermix Ramadhan Recipesfirdaus hadzwanNo ratings yet

- Amit - CSV Compliance - 2024Document4 pagesAmit - CSV Compliance - 2024eyamit.patilNo ratings yet

- JBL Oodinol 1000Document5 pagesJBL Oodinol 1000joannejinxNo ratings yet

- Zaremby - BKRVW - Turner's European Intellectual History - TNC - 2015.11Document3 pagesZaremby - BKRVW - Turner's European Intellectual History - TNC - 2015.11Alvino-Mario FantiniNo ratings yet

- Form 02 QuestionsDocument7 pagesForm 02 QuestionsMagomed KitaevNo ratings yet

- Inv617 - Jba2514b - Sovereign Bond Spreads - Nurul Ain Nabila BT Mohd SabriDocument4 pagesInv617 - Jba2514b - Sovereign Bond Spreads - Nurul Ain Nabila BT Mohd SabriAin Nabila000No ratings yet

- Aganan Cpar M6Document4 pagesAganan Cpar M6John Dave DeriloNo ratings yet

- 35kV AL 133% TRXLPE One-Third Neutral LLDPE Primary UD: SPEC 81252Document5 pages35kV AL 133% TRXLPE One-Third Neutral LLDPE Primary UD: SPEC 81252Anonymous hxyW3v5QqVNo ratings yet

- Vo Dai Quang Semantics - Lectures in Broad OutlineDocument89 pagesVo Dai Quang Semantics - Lectures in Broad OutlineThu PhạmNo ratings yet

- CS 507 Mid TermDocument10 pagesCS 507 Mid TermMuddsir AmanNo ratings yet

- Ehs Hospital List For Both TG & ApDocument43 pagesEhs Hospital List For Both TG & ApAvulaHarikrishnaYadavNo ratings yet

- Introduction To CRMDocument20 pagesIntroduction To CRMflaviagonNo ratings yet

- The Readiness LearningDocument24 pagesThe Readiness Learningcss_saidNo ratings yet

- Dual Stack 10G Ethernet Routing Fiber Switch: AP6500E-16X-4XG-RDocument4 pagesDual Stack 10G Ethernet Routing Fiber Switch: AP6500E-16X-4XG-RManojit SahaNo ratings yet

- Ford Half ShaftDocument10 pagesFord Half Shaftsuysuy00No ratings yet

- CTEKS 12-14 X 50 HGSDocument2 pagesCTEKS 12-14 X 50 HGSPT SHS Garasi GempolNo ratings yet

- Key Answer Org DevDocument15 pagesKey Answer Org DevSheennah Lee LimNo ratings yet

- Module4 VirtualnetworkingDocument33 pagesModule4 VirtualnetworkingNithin krishnaNo ratings yet

- Advanced DirectiveDocument11 pagesAdvanced DirectivecaseyscribdNo ratings yet

- Fresh VisionDocument2 pagesFresh VisionTerry DehartNo ratings yet