Professional Documents

Culture Documents

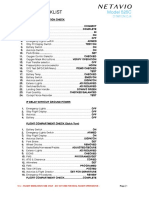

Take Off Rotation 1706452976

Take Off Rotation 1706452976

Uploaded by

marroco13Copyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- Case Study Pack - May 2024 - Before One PLC 2Document61 pagesCase Study Pack - May 2024 - Before One PLC 2Mark ChangNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- JMB VL3 915 PohDocument51 pagesJMB VL3 915 PohnaindejardinNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- ATR Aircraft Performance 2Document160 pagesATR Aircraft Performance 2Nicky Holden100% (9)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Weight & Balance Pa - 28 - 181 Archer Ii PDFDocument1 pageWeight & Balance Pa - 28 - 181 Archer Ii PDFAndres Santiago OrtizNo ratings yet

- C550 Bravo AFM Sec.4&7Document478 pagesC550 Bravo AFM Sec.4&7German RebollarNo ratings yet

- Normal Checklist: Model 525CDocument5 pagesNormal Checklist: Model 525CJose Otero De SantiagoNo ratings yet

- Airport Runway DesignDocument20 pagesAirport Runway DesignAryan AroraNo ratings yet

- Cls Boeing 747 Operations ManualDocument50 pagesCls Boeing 747 Operations ManualMatias Carranza100% (2)

- Falcon 20 Study GuideDocument13 pagesFalcon 20 Study GuidemacvsogchingaNo ratings yet

- Mastering Physics CH 02 HW College Physics I LCCCDocument33 pagesMastering Physics CH 02 HW College Physics I LCCCSamuel80% (15)

- Klaxksfo PDF 1652788062Document32 pagesKlaxksfo PDF 1652788062Mark ChangNo ratings yet

- Omaalfbo PDF 1654875755Document133 pagesOmaalfbo PDF 1654875755Mark ChangNo ratings yet

- Lgavlszh PDF 1653730453Document85 pagesLgavlszh PDF 1653730453Mark ChangNo ratings yet

- Lgav03r LSZH14Document7 pagesLgav03r LSZH14Mark ChangNo ratings yet

- Rjaarjbb PDF 1652968671Document106 pagesRjaarjbb PDF 1652968671Mark ChangNo ratings yet

- Klax25r Ksfo28lDocument5 pagesKlax25r Ksfo28lMark ChangNo ratings yet

- Klaxksfo PDF 1653719538Document31 pagesKlaxksfo PDF 1653719538Mark ChangNo ratings yet

- Eddmengm PDF 1652599893Document36 pagesEddmengm PDF 1652599893Mark ChangNo ratings yet

- Ltfmepwa PDF 1653309716Document108 pagesLtfmepwa PDF 1653309716Mark ChangNo ratings yet

- Eddm08r Engm01lDocument8 pagesEddm08r Engm01lMark ChangNo ratings yet

- Lfboyssy PDF 1655909324Document253 pagesLfboyssy PDF 1655909324Mark ChangNo ratings yet

- LTFM35R Epwa33Document11 pagesLTFM35R Epwa33Mark ChangNo ratings yet

- Safely Flying Non Precision Instrument ApproachesDocument9 pagesSafely Flying Non Precision Instrument ApproachesMark ChangNo ratings yet

- 01 - General Question 1 of 109: Question: Which of The Following Statements Is Correct ?Document118 pages01 - General Question 1 of 109: Question: Which of The Following Statements Is Correct ?Yahya Yıldırım100% (4)

- High Lift DevicesDocument33 pagesHigh Lift DevicesNitsugaNo ratings yet

- Avionics Training Systems by Len Buckwalter2 PDFDocument150 pagesAvionics Training Systems by Len Buckwalter2 PDFDeepak ShuklaNo ratings yet

- Free Fall Sample Problem With SolutionDocument8 pagesFree Fall Sample Problem With Solutionmark jason perezNo ratings yet

- 15 WindshearDocument5 pages15 WindshearearlNo ratings yet

- Argumentation Final Essay - Alfredo JaimeDocument7 pagesArgumentation Final Essay - Alfredo JaimeAlfredo R JaimeNo ratings yet

- MEmory Items For The LEarjet 35ADocument3 pagesMEmory Items For The LEarjet 35ABrendanRatchfordNo ratings yet

- Uav 1Document130 pagesUav 1Tufel NooraniNo ratings yet

- JDK Procedures - SummaryDocument8 pagesJDK Procedures - SummaryEthan PoonNo ratings yet

- Pilots HandbookDocument43 pagesPilots HandbookPaul TurnetNo ratings yet

- Normal Procedures Checklist RTS Seneca V 2016 13062016 PDFDocument14 pagesNormal Procedures Checklist RTS Seneca V 2016 13062016 PDFboero115No ratings yet

- Chapter I: B777: Aircraft Handling ManualDocument12 pagesChapter I: B777: Aircraft Handling Manualapi-3705891100% (3)

- Section 5 - PerformanceDocument124 pagesSection 5 - PerformanceflorentNo ratings yet

- Typhoon H User Manual T1Document29 pagesTyphoon H User Manual T1matra08No ratings yet

- Force Plates Vertical JumpsDocument10 pagesForce Plates Vertical JumpsPatricio Fernandez EtchemendiNo ratings yet

- Partenavia P.68Document4 pagesPartenavia P.68Shibin JohneyNo ratings yet

- AirplanesDocument2 pagesAirplanesJuliet BarbonNo ratings yet

- The Importance of Proper Rotation TechniqueDocument2 pagesThe Importance of Proper Rotation Techniqueaske7sp8055No ratings yet

- Cessna Stationair U206G POH - 1981Document452 pagesCessna Stationair U206G POH - 1981jwzumwalt100% (14)

- AE19402 - Aircraft Performance - Question BankDocument6 pagesAE19402 - Aircraft Performance - Question BankThejeshwarrNo ratings yet

Take Off Rotation 1706452976

Take Off Rotation 1706452976

Uploaded by

marroco13Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Take Off Rotation 1706452976

Take Off Rotation 1706452976

Uploaded by

marroco13Copyright:

Available Formats

A Focus on the

Takeoff Rotation

An appropriate takeoff rotation maneuver is a balance

between good takeoff performance and sufficient margin

versus tail strike, stall speed, and minimum control speeds.

Applying the 3°/s rotation rate requested in the SOPs is the

key to ensure that the aircraft meets the expected takeoff

performance. Flight data monitoring shows that the rotation

rate values in service vary and a lower rotation rate is

observed in some cases with the associated degradation of

takeoff performance. This article describes both the takeoff

rotation laws available on Airbus Fly-by-Wire (FBW) aircraft

and the recommended rotation techniques that will enable

flight crew to achieve consistent takeoff rotations at the

requested rotation rate.

This article is also available on safetyfirst.airbus.com and on the Safety

first app for iOS and Android devices.

Safety first - January 2021 Page 1/11

CASE STUDY: A340 LONG TAKEOFF

Event Description

A takeoff from a high altitude airport (8360 ft)

An A340-300 was performing a takeoff from a high altitude airport. A TOGA thrust

takeoff in CONF2 was selected. The takeoff performance was calculated for a 4 kt

tailwind and was limited by the runway length (takeoff run in One Engine

Inoperative (OEI) condition). The gross weight of the aircraft was 236.9 t and was

close to the Maximum Takeoff Weight of 237 t in the conditions of the day.

An uneventful takeoff roll

The aircraft reached V1 (128 kt) 54 s after brake release and TOGA thrust

application. ① The Pilot Flying (PF) then initiated the rotation close to VR. The

nose landing gear lifted off the ground 1 s later and the pitch began to increase.

A late liftoff

② V2 (149 kt) was reached with the aircraft still on the ground. The main landing

gear was still compressed and the aircraft had a pitch of 4° up. ③ Liftoff occurred

11 s after rotation initiation at 155 kt, and at only 140 m from the runway end with (fig.1) Sequence of

a recorded pitch of 9° up. events from VR to liftoff

Runway end overflown at 6 ft radio altitude

④ The aircraft flew over the runway end at 6 ft Radio Altitude (RA), and then ⑤

overflew the end of the clearway at 20 ft RA and avoided the LOC antennas by

only 12 ft. ⑥ The aircraft eventually reached 35 ft RA 550 m after the runway end.

The landing gear was selected up 3 s later at 135 ft RA with a vertical speed of

1300 ft/min, pitch at 12°, and speed at 160 kt. The aircraft continued its climb and

completed its flight uneventfully.

Despite what seemed to be a standard takeoff roll, the aircraft lifted off the runway (fig.2) Sequence of

very late, overflying the LOC antennas located at the end of the clearway with events from runway

very little clearance. How did this happen? threshold to 35 ft RA

Safety first - January 2021 Page 2/11

Event Analysis

A nominal aircraft acceleration performance until VR

The analysis of the DFDR data showed that the aircraft acceleration was in

accordance with the expected performance in the conditions of the day reported

as wet runway with 4 kt tailwind.

A slow rotation rate during takeoff

The sidestick inputs ordered by the PF during the rotation resulted in an average

rotation rate of 1°/sec. Airbus SOPs request a 3°/s rotation rate. This slow rotation

rate resulted in degraded takeoff performance leading to a significant increase in

the takeoff distance.

THE REQUESTED TAKEOFF ROTATION

RATE VALUE

The origin of the requested rotation rate “The requested

The rotation rate that is used to compute the takeoff performance was determined 3°/s rotation rate

during the takeoff performance flight test campaign together with the Airworthiness was the value

Authorities. This value is the average of the rotation rates recorded during all of

the test aircraft takeoffs performed in a variety of operating conditions. selected and is

applicable to all

The requested 3°/s rotation rate was the value selected and is applicable to all

Airbus aircraft except for the A220, which has a 3 to 5°/s rate requested in its Airbus aircraft

FCOM. This value ensured that the actual takeoff distance is closest to the except for the

computed distance. If the PF applies a rotation rate that is lower than the

requested rotation rate, the aircraft may not take off according to the computed A220, which has

performance, leading to an increased takeoff distance and a decreased obstacle a 3 to 5°/s rate

clearance.

requested in its

Rotation rate too low in some takeoffs FCOM.”

Flight data monitoring shows that the rotation rate values recorded in service vary.

A low rotation rate with an associated takeoff performance degradation was

observed in some cases. Safety margins used in takeoff performance computation

prevent any significant problems in most cases. However, these margins may not

be sufficient in certain situations as can be seen in the event described above. It is

why flight crews should always perform the takeoff rotation at a rate as close as

possible to the requested rotation rate, and this is especially important in

conditions where performance is limited by runway length or obstacle clearance.

Safety first - January 2021 Page 3/11

A significant impact on takeoff performance

(fig.3) Impact of a lower

A rotation rate lower than the requested 3°/s in the SOPs significantly increases rotation rate on the takeoff

the takeoff distance. For example, a takeoff performed with a 2°/s rotation rate distance

increases the takeoff distance by approximately 300 m (1000 ft) compared to a

3°/s rotation rate.

Takeoff Distance (TOD) margins

The regulatory Takeoff Distance (TOD) on a dry runway is calculated by taking

the greatest value of:

- the TOD computed with one engine failure happening just prior to

reaching V1 (TODN-1), or

- the TOD computed with all engines operative (TODN) with an additional

margin of 15 %.

TODdry = max of { TODN-1 ; 1.15 x TODN }

Twin-engine aircraft

On a twin-engine aircraft, the TOD is often provided by the TODN-1 because the

loss of half of its thrust strongly impacts the takeoff distance. This calculation

provides additional margin for a takeoff with both engines operative.

While the PF should perform the requested rotation rate of 3°/s in all conditions, it (fig.4) Example of a TOD

is even more important in case of engine failure during takeoff, because there is computation for a

no additional margin for the calculated TOD. twin-engine aircraft

Safety first - January 2021 Page 4/11

Four-engine aircraft

On a four-engine aircraft, the TOD is often sized by the factored TODN because

the TODN-1 is often the shortest as it is computed with a loss of thrust limited to a

quarter of the total available thrust.

Achieving the requested rotation rate of 3°/s is especially important in daily

operations (i.e. when all four engines are operative), because this condition is (fig.5) Example of a TOD

usually the sizing one, and therefore, does not provide additional margin on top of computation for a

the 1.15 factor. twin-engine aircraft

TAKEOFF ROTATION LAWS AVAILABLE ON

FBW AIRCRAFT

The takeoff rotation law helps the flight crew to perform the optimum takeoff

rotation. The takeoff rotation law consists of both the rotation law and tail strike

prevention functions.

There are different types of takeoff rotation law depending on the aircraft model.

Rotation assistance on A320ceo, A330ceo, and

A340-200/300 aircraft

Rotation law: Direct law

There is a direct relationship between the sidestick deflection and the elevator

deflection on these aircraft models. The rotation rate obtained by a fixed sidestick

deflection value may vary noticeably with different operating conditions such as

aircraft weight, center of gravity position, slats/flaps configuration, engine thrust,

and takeoff speeds.

Tail strike prevention: Pitch rate limitation function (A320ceo, A330ceo,

A340-200)

A limitation function reduces the pitch-up command sent to the elevators to reduce

the risk of tail strike in case of excessive pitch rate. This pitch rate limitation

function does not provide tail strike protection: If a nose-up input is

maintained on the sidestick, a tail strike can still occur.

Safety first - January 2021 Page 5/11

Tail strike protection function (A340-300 only) (fig.6) Rotation law on

A320ceo, A330 and

A tail strike protection function estimates the rear fuselage clearance margin A340-200 aircraft

based on radio-altimeter height and pitch attitude. This function modulates the

nose-up input order sent to the elevator whenever the clearance of the tail to the

ground becomes too small. The function protects the aircraft against tail strike

for average sidestick deflection values until the sidestick deflection reaches

approximately ¾ of nose-up order. The PF can override this protection by (fig.7) Rotation law on

pulling back on the sidestick beyond ¾ of nose-up. A340-300 aircraft

Rotation assistance on A320neo, A330neo,

A340-500/600, A350, and A380 aircraft

Rotation law: Pitch rate target

On these aircraft, the rotation law ensures that an equivalent and repeatable

rotation rate is achieved for a given sidestick deflection, and independent of the

variable operating conditions such as aircraft weight, center of gravity position,

slats/flaps configuration, engine thrust, and takeoff speeds.

Tail strike protection function (fig.8) Rotation law on

A320neo, A330neo,

A tail strike protection function similar to the one available on A340-300 is also A340-500/600, A350

available on these aircraft. and A380 aircraft

Safety first - January 2021 Page 6/11

Tail strike pitch limit indication at takeoff (A330/A340

family and A380 aircraft) (fig.9) Example of a

tail strike pitch limit

The tail strike pitch limit indication is currently displayed at takeoff and landing on indication on an A330

all A340 and A380 aircraft. The tail strike pitch limit was an option on the earlier aircraft

models of the A330ceo, but was later installed as standard for all A330ceo

produced after mid-2013.

A320, A321, A330neo, and A350 aircraft also have a tail strike pitch limit, but it is

only displayed on landing, because it is not necessary at takeoff. There is no tail

strike pitch limit indication on A318 and A319 aircraft, because these aircraft have

shorter length fuselage and less risk of tail strike.

Removing the tail strike pitch limit for takeoff

In-service experience showed that when the tail strike pitch limit indicator appears

on the display, it may cause the PF to unnecessarily reduce the rotation rate of

the aircraft during takeoff and prevent the aircraft from reaching the requested 3°/s

rotation rate. As a result, Airbus decided to deactivate the tail strike pitch limit

indicator at takeoff and to keep it activated only on landing for all aircraft models.

The tail strike protection function proved to provide A340-300, A340-500/600, and

A380 aircraft with sufficient tail strike protection.

The pitch rate limitation function on A330ceo aircraft, combined with its tail strike

margin is sufficient protection against the risk of tail strike.

Deactivation of the tail strike pitch limit indication for takeoff will be performed at

the opportunity of a next A330/A340 Flight Management Guidance and Enveloppe

Computer (FMGEC) or A380 Flight Control and Guidance Computer (FCGC)

update.

Rotation assistance on A220 aircraft

Rotation law: Direct law

There is a direct relationship between the sidestick deflection and elevator

deflection with a compensation for forward or aft center of gravity conditions on (fig.10) Pitch Target

A220 aircraft. Marker (PTM) on the

PFD of an A220

Pitch Target Marker (PTM) aircraft

The Pitch Target Marker (PTM) on the PFD provides the initial pitch for the flight

crew to target during the takeoff rotation until FD guidance is available.

Tail strike prevention: Pitch rate reduction

A limitation function will reduce the pitch-up command sent to the elevators in

case of excessive pitch rate, and will reduce the risk of tail strike. The flight crew

should be aware that this pitch rate limitation is not protection against tail

strike: A tail strike event can still occur if a nose-up input is maintained on the

sidestick.

A tail strike symbol is displayed on the Head-Up Display (HUD) during rotation

when the PTM is not displayed and the aircraft pitch angle approaches the tail

strike angle by less than 3 degrees or when the pitch rate is excessive.

Safety first - January 2021 Page 7/11

THE TAKEOFF ROTATION TECHNIQUE

A technique common to all FBW and non-FBW aircraft

A similar technique is used on all Airbus aircraft. It can be found in the FCOM “A similar

SOPs, and additional information is provided in the Flight Crew Techniques

Manual (FCTM). technique is

Step 1: Initiate Rotation used on all

When the aircraft reaches VR, the PF should apply a ① positive backward Airbus

sidestick (or control column) input to initiate the rotation. aircraft”

Step 2: Use outside visual references to achieve & maintain rotation rate

After the PF initiates the rotation, they should ② use outside visual references

to achieve and maintain the rotation rate.

Adjustments may be necessary to achieve and maintain the required rotation rate.

On aircraft with direct rotation law or non-FBW aircraft, the flight crew should

adapt to the takeoff conditions on the day. On aircraft that have the pitch rate

rotation law, the law assists the flight crew to achieve an equivalent rotation in all

conditions.

With a suitable rotation rate, the aircraft typically lifts off approximately 4 to 5 s

after the PF initiates the rotation and when the pitch reaches approximately 10°.

Step 3: Target initial pitch attitude after liftoff then follow FD guidance

When the aircraft is airborne, the PF should ③ adjust the pitch toward the initial

pitch target provided in the FCOM (e.g. 15° or 12.5° if one engine failed on A320

aircraft). On A220 aircraft, the Pitch Target Marker (PTM) provides a visual

indication of the initial target pitch. The PF should then ④ follow the FD

(fig.11) Recommended

guidance.

rotation technique

Safety first - January 2021 Page 8/11

The “What about rotation technique?” video is available on the

Worldwide Instructor News (WIN) website and provides a

step-by-step review of a full takeoff sequence performed in an

A380 simulator.

Training Areas of Special Emphasis (TASE) for A340

family aircraft

An EASA Safety Information Bulletin (SIB 2017/20) was published in 2017

following the incident described in this article. In 2018, a Training Areas of

Special Emphasis (TASE) was included in the A340 Operational Suitability Data

(OSD) for flight crew in response to the SIB. The TASE emphasizes the need to

ensure flight crews know how to perform the correct takeoff rotation technique

during initial and recurrent training. This includes:

● How to initiate the rotation

● How to achieve and maintain the rotation rate

● How to achieve the pitch attitude after liftoff.

Safety first - January 2021 Page 9/11

Contributors: Flight data monitoring shows that the takeoff rotation rates recorded

in service vary and that a lower rotation rate is observed in some

Sebastien BALZER

cases, with the associated degradation of takeoff performance.

Aircraft Performance

Engineer

Design Office

Achieving an appropriate rotation rate is essential to ensure takeoff

performance, while maintaining a sufficient margin with tail strike, stall

Philippe CASTAIGNS speed, and minimum control speeds.

Experimental Test pilot

Flight Tests Airbus aircraft are designed, tested, and certified to achieve the

necessary rotation rate, while having sufficient margins against the

Stéphane DELANNOY tail strike. Flight control laws include features that reduce the risk of

Aircraft Stability &

Control Engineer

tail strike.

Design Office

The flight crew should apply the FCOM procedures and FCTM

Thomas LEPAGNOT techniques to achieve the requested rotation rate:

Accident/Incident

investigator After the rotation is initiated with a positive nose-up input, the flight

Product Safety crew should use outside visual references to achieve and maintain

the rotation. The flight crew should fly the rotation, and make any

Xavier LESCEU

necessary adjustments to achieve and maintain the required rotation

A220 Chief Pilot

Test Pilot - TRI/TRE rate. When the aircraft is airborne, the PF adjusts the pitch toward the

Customer Services initial FCOM pitch target and then follows the FD guidance.

Daniel

LOPEZ-FERNANDEZ

Director Product Safety

Enhancement

Product Safety

Patrick SALLIER

Aircraft Performance

Senior Expert

Design Office

Gilbert SAVARY

Head of Operational &

Training Policy

Flight Operations &

Training Support

Safety first - January 2021 Page 10/11

Safety first, 2021. Safety first is

published by Airbus S.A.S. 1, rond

point Maurice Bellonte - 31707

Blagnac Cedex/France.

Editor: Yannick Malinge, Chief

Product Safety Officer.

The Airbus magazine contributing to the enhancement of the safety of

Editorial team: Guillaume aircraft operations by increasing knowledge and communication on

Estragnat, Vanessa Sadi, safety related topics.

Gwyneth Duggan, Tim Roach.

20192534. Reference: Safety first is published by the Product Safety department. It is a source

X00D16031905. of specialist safety information for the use of airlines who y and maintain

Airbus aircraft. It is also distributed to other selected organizations and is

Photos by Airbus.

available on digital devices.

© Airbus S.A.S. 2021 – All rights

reserved. Proprietary Material for publication is obtained from multiple sources and includes

documents. selected information from the Airbus Flight Safety Confidential Reporting

By taking delivery of this Brochure System, incident and accident investigation reports, system tests and

(hereafter “Brochure”), you accept fight tests. Material is also obtained from sources within the airline

on behalf of your company to industry, studies and reports from government agencies and other

comply with the following

aviation sources.

guidelines:

● No other intellectual All articles in Safety first are presented for information only and are not

property rights are granted by the intended to replace ICAO guidelines, standards or recommended

delivery of this Brochure than the practices, operator-mandated requirements or technical orders. The

right to read it, for the sole

purpose of information. contents do not supersede any requirements mandated by the State of

Registry of the Operator’s aircraft or supersede or amend any Airbus

● This Brochure and its type-specific AFM, AMM, FCOM, MMEL documentation or any other

content shall not be modified and

its illustrations and photos shall

approved documentation.

not be reproduced without prior

written consent of Airbus. Articles may be reprinted without permission, except where copyright

source is indicated, but with acknowledgement to Airbus. Where Airbus

● This Brochure and the

is not the author, the contents of the article do not necessarily reflect the

materials it contains shall not, in

whole or in part, be sold, rented, or views of Airbus, nor do they indicate Company policy.

licensed to any third party subject

to payment. Contributions, comments and feedback are welcome. Enquiries related

to this publication should be addressed to:

This Brochure contains sensitive

information that is correct at the

time of going to press. Airbus - Product Safety department

This information involves a 1, rond point Maurice Bellonte

number of factors that could

change over time, effecting the 31707 Blagnac Cedex - France

true public representation. Airbus

assumes no obligation to update safetycommunication@airbus.com

any information contained in this

document or with respect to the Visit us at safetyfirst.airbus.com or install the Safety first app:

information described herein.

Airbus S.A.S. shall assume no

liability for any damage in

connection with the use of this

Brochure and of the materials it

contains, even if Airbus S.A.S. has

been advised of the likelihood of

such damage.

Safety first - January 2021 Page 11/11

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- Case Study Pack - May 2024 - Before One PLC 2Document61 pagesCase Study Pack - May 2024 - Before One PLC 2Mark ChangNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- JMB VL3 915 PohDocument51 pagesJMB VL3 915 PohnaindejardinNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- ATR Aircraft Performance 2Document160 pagesATR Aircraft Performance 2Nicky Holden100% (9)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Weight & Balance Pa - 28 - 181 Archer Ii PDFDocument1 pageWeight & Balance Pa - 28 - 181 Archer Ii PDFAndres Santiago OrtizNo ratings yet

- C550 Bravo AFM Sec.4&7Document478 pagesC550 Bravo AFM Sec.4&7German RebollarNo ratings yet

- Normal Checklist: Model 525CDocument5 pagesNormal Checklist: Model 525CJose Otero De SantiagoNo ratings yet

- Airport Runway DesignDocument20 pagesAirport Runway DesignAryan AroraNo ratings yet

- Cls Boeing 747 Operations ManualDocument50 pagesCls Boeing 747 Operations ManualMatias Carranza100% (2)

- Falcon 20 Study GuideDocument13 pagesFalcon 20 Study GuidemacvsogchingaNo ratings yet

- Mastering Physics CH 02 HW College Physics I LCCCDocument33 pagesMastering Physics CH 02 HW College Physics I LCCCSamuel80% (15)

- Klaxksfo PDF 1652788062Document32 pagesKlaxksfo PDF 1652788062Mark ChangNo ratings yet

- Omaalfbo PDF 1654875755Document133 pagesOmaalfbo PDF 1654875755Mark ChangNo ratings yet

- Lgavlszh PDF 1653730453Document85 pagesLgavlszh PDF 1653730453Mark ChangNo ratings yet

- Lgav03r LSZH14Document7 pagesLgav03r LSZH14Mark ChangNo ratings yet

- Rjaarjbb PDF 1652968671Document106 pagesRjaarjbb PDF 1652968671Mark ChangNo ratings yet

- Klax25r Ksfo28lDocument5 pagesKlax25r Ksfo28lMark ChangNo ratings yet

- Klaxksfo PDF 1653719538Document31 pagesKlaxksfo PDF 1653719538Mark ChangNo ratings yet

- Eddmengm PDF 1652599893Document36 pagesEddmengm PDF 1652599893Mark ChangNo ratings yet

- Ltfmepwa PDF 1653309716Document108 pagesLtfmepwa PDF 1653309716Mark ChangNo ratings yet

- Eddm08r Engm01lDocument8 pagesEddm08r Engm01lMark ChangNo ratings yet

- Lfboyssy PDF 1655909324Document253 pagesLfboyssy PDF 1655909324Mark ChangNo ratings yet

- LTFM35R Epwa33Document11 pagesLTFM35R Epwa33Mark ChangNo ratings yet

- Safely Flying Non Precision Instrument ApproachesDocument9 pagesSafely Flying Non Precision Instrument ApproachesMark ChangNo ratings yet

- 01 - General Question 1 of 109: Question: Which of The Following Statements Is Correct ?Document118 pages01 - General Question 1 of 109: Question: Which of The Following Statements Is Correct ?Yahya Yıldırım100% (4)

- High Lift DevicesDocument33 pagesHigh Lift DevicesNitsugaNo ratings yet

- Avionics Training Systems by Len Buckwalter2 PDFDocument150 pagesAvionics Training Systems by Len Buckwalter2 PDFDeepak ShuklaNo ratings yet

- Free Fall Sample Problem With SolutionDocument8 pagesFree Fall Sample Problem With Solutionmark jason perezNo ratings yet

- 15 WindshearDocument5 pages15 WindshearearlNo ratings yet

- Argumentation Final Essay - Alfredo JaimeDocument7 pagesArgumentation Final Essay - Alfredo JaimeAlfredo R JaimeNo ratings yet

- MEmory Items For The LEarjet 35ADocument3 pagesMEmory Items For The LEarjet 35ABrendanRatchfordNo ratings yet

- Uav 1Document130 pagesUav 1Tufel NooraniNo ratings yet

- JDK Procedures - SummaryDocument8 pagesJDK Procedures - SummaryEthan PoonNo ratings yet

- Pilots HandbookDocument43 pagesPilots HandbookPaul TurnetNo ratings yet

- Normal Procedures Checklist RTS Seneca V 2016 13062016 PDFDocument14 pagesNormal Procedures Checklist RTS Seneca V 2016 13062016 PDFboero115No ratings yet

- Chapter I: B777: Aircraft Handling ManualDocument12 pagesChapter I: B777: Aircraft Handling Manualapi-3705891100% (3)

- Section 5 - PerformanceDocument124 pagesSection 5 - PerformanceflorentNo ratings yet

- Typhoon H User Manual T1Document29 pagesTyphoon H User Manual T1matra08No ratings yet

- Force Plates Vertical JumpsDocument10 pagesForce Plates Vertical JumpsPatricio Fernandez EtchemendiNo ratings yet

- Partenavia P.68Document4 pagesPartenavia P.68Shibin JohneyNo ratings yet

- AirplanesDocument2 pagesAirplanesJuliet BarbonNo ratings yet

- The Importance of Proper Rotation TechniqueDocument2 pagesThe Importance of Proper Rotation Techniqueaske7sp8055No ratings yet

- Cessna Stationair U206G POH - 1981Document452 pagesCessna Stationair U206G POH - 1981jwzumwalt100% (14)

- AE19402 - Aircraft Performance - Question BankDocument6 pagesAE19402 - Aircraft Performance - Question BankThejeshwarrNo ratings yet