Professional Documents

Culture Documents

1.HF-525Plus VET (32kW, 400ma, 230Vor110V, XR5)

1.HF-525Plus VET (32kW, 400ma, 230Vor110V, XR5)

Uploaded by

fortroniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1.HF-525Plus VET (32kW, 400ma, 230Vor110V, XR5)

1.HF-525Plus VET (32kW, 400ma, 230Vor110V, XR5)

Uploaded by

fortroniCopyright:

Available Formats

Technical Publication

SMS-M-001 (Rev. 2.1)

Operation & Service Manual

Model: HF-525 PLUS VET

(For Veterinary use. 32kW. Single phase, 220V AC or 110V AC)

Important!

Please read this manual thoroughly and use the system correctly before using the

system. This manual desires to keep in promised place to use always again after

reading.

EcoRay Co., Ltd.

60-10, Nanosandan 5-ro, Nam-myeon, Jangseong-gun, Jellanam-do, Korea

Tel: +82-61-392-3251 / Fax: +82-61-392-5266

#714~716, ForHu B/D, 58, Wangsimni-ro, Seongdong-gu, Seoul, KOREA, 04778

Tel) +82 70 7510 3401 ~ 6 Fax) +82 70 8630 3420 E-mail: sales@ecoray.kr

EcoRay HF-525 PLUS VET

IMPORTANT! X-RAY PROTECTIONS!

X-RAY EQUIPMENT IS DANGEROUS TO BOTH PATIENT AND OPERATOR UNLESS SAFETY

INSTRUCTIONS ARE STRICTLY OBSERVED IN USE!

Accordingly, when use this product should be thoroughly read the "Radiation Safety Control Regulation"

and then compliance with it in use. This product is serious injury's danger if do not keep use guideline

or regulation therefore, read and understood this manual before in use.

This product was designed by safety level (SL) presenting in Radiation Safety Control Regulation.

However, if do not keep using method and Radiation Safety Control Regulation, will not be able to

avoid serious injury's danger from radiation. Therefore, to prevent accident from radiation, everyone who

work connected with radioactive emission must understand radiation safety control regulation and

understand product manual fulfill thorough education and formality.

Our company recognizes enough about danger of excessive exposure to operator, installation people,

and maintenance people. Therefore, our company strongly advises that operator, installation people,

maintenance people must be educated about radiation safety control regulation and should be used this

product when understand fluently about all knowledge of operation this product.

Also, our company informs that operator, installation people, and maintenance people have a

responsibility to be educated fluently about radiation safety control regulation and understood about

product use method.

Also, our company has no responsibility about injury or calamity that occurs does not keep use method

of this product and radiation safety control regulation.

Therefore, our company strongly advises that to be used this product after that person in charge of

installation, maintenance and operator should understood radiation safety control regulation of domestic

or foreign.

Thanks for purchasing product of EcoRay.

Before using the system, please read this manual thoroughly and use the system correctly. The

precautions and prohibitions are seen though the manual is classified as follows.

(Rev. 2.1) 1 Operation & Service Manual

EcoRay HF-525 PLUS VET

NOTICE AND CONTRAINDICATION!

States a direct danger that may cause death or serious injury if it is not avoided.

States an indirect or potential danger that may cause death or serious injury if it is not avoided.

State a danger that may cause slight or medium injury or may cause damage in equipment or fire

if it is not avoided.

NOTE ☞

States the information, which helps to use the system correctly.

CONTRAINDICATION!

This x-ray system is not suitable for therapeutic applications.

(Rev. 2.1) 2 Operation & Service Manual

EcoRay HF-525 PLUS VET

Precautions in the use of X-ray system

(For the Safety and Prevention of Danger)

1. Only one experienced technician should operate the equipment.

2. When installing the equipment, pay attention to the following items.

2.1 Do not install it near water faucet or similar equipment.

2.2 Install it away from potential sources of problems such as abnormal pressure, temperature or

humidity, drafts, direct sunlight, dust, chlorine or sulphur gas.

2.3 During transportation and operation of the equipment, avoid tilting, vibration and sharp impact

against it.

2.4 Keep the equipment away from the areas where chemicals or gases are stored.

2.5 Use only the correct electrical power source with matching frequency, voltage and current (or

wattage).

2.6 Check the condition of the battery power source (Power Supply Unit – Optional item). (Power and

polarity before operating the equipment.)

3. Before operating the equipment, pay attention to the following items:

3.1 Check the conditions of switch contacts, polarity, and make sure the equipment performs correctly.

3.2 Confirm that the ground is connected properly.

3.3 Check all wiring for proper and correct connections.

3.4 Check the condition of the external electric circuit breaker.

3.5 Circuit breaker will be directly connected to the system and do not connect with another system.

3.6 When the equipment has been leaved for a long time (more than 10days), You must warm-up

equipment and X-ray tube sufficiently before use.

4. While operating the equipment, pay attention to the following items:

4.1 Do not ever-exceed time or the amount of equipment use needed for diagnosis.

4.2 Observe the equipment and the patient continuously for detection of problems.

4.3 When a problem is detected with the equipment or the patient, take proper action to stop the

equipment without harming the patient.

4.4 Do not let the equipment touched by the patient.

5. After operating the equipment, pay attention to the following items:

5.1 Turn of the switch and then, turn off the main power switch.

5.2 Clean the part that contacted with body.

6. When the equipment is out of order, call a certificated engineer. (Do not try to repair it.)

7. Do not modify any part of the equipment.

8. The equipment must be checked periodically for good operation condition without troubles.

9. Do not use x-ray system connecting with other system.

(Rev. 2.1) 3 Operation & Service Manual

EcoRay HF-525 PLUS VET

1. The owner/user have a responsibility for management and maintenance of this equipment.

2. This equipment must be operated by only authorized personnel.

3. Contact authorized service engineer when repair or inspection of the inside of the equipment.

4. In general, modifications are strictly prohibited by the Regulations. Please contact our agency if it is

needed to modify the device.

5. Do not use this system in conjunction with the other machines because seriously danger could be

happened unexpectedly.

Periodic Inspection

1. Maintenance is required to maintain safety and performance of this system for a long time.

2. Maintenance must be done periodically with maintenance plan.

3. This system must be inspected from the inspection office per every 3 years.

Warranty

1. This warranty shall apply only to defects that arise within 12months of purchase.

2. This product could have a free of charge service if troubles are occurred during the warranty

period.

3. The warranty does not cover defects caused by abuse, mishandling, accidents or improper

installation.

4. The following will not be covered under the warranty.

4-1. Modifications to the product, or repairs made by unauthorized person but manufacturer or

authorized person by manufacturer.

4-2. Acts of God. Including fire, flood, storm, power or voltage surges.

4-3. Improper use or installation.

4-4. Defects that arise in conjunction with the use of other machines.

4-5. Use of improper parts or modification the circuit.

4-6. Improper use

5. In case of repaired during the warranted period, User shall advise the result of test to manufacture.

(Rev. 2.1) 4 Operation & Service Manual

EcoRay HF-525 PLUS VET

Precautions in Use

When using this equipment, please observe the following precautions for the safety of the operator

and the patient.

1. Improper use of the X-ray equipment might cause the operator or the patient to be accidentally

exposed to X-ray radiation.

2. During X-ray radiation, any person other than the subject the patient should not stay in the room.

3. X-ray room must have radiation protection facility by "Radiation Safety Control Regulation"

1. Only qualified personnel should handle the equipment

2. Electric shock or leakage of electricity can happen unless ground is not installed necessarily.

3. Keep the equipment dry

4. Otherwise it may cause an electric shock to the operator of the patient and if any liquid or water

flew into electric device turn off the power and contact company or service agency.

1. This system is made radiation and must shield completely X-ray room with lead shield. After that,

must be inspected by authorized inspection office and then have to use system.

2. In the radiation exposure, operator have to adjust exposure area with suitable exposure point and

try to expose it with not over exposure.

3. The most effective method to secure from first and second radiation defilades perfectly and

should be established x-ray room by lead etc... And, to minimize radiation exposure from

radiation exposure to operator, lead partition, lead gloves, apron, cover, Gonad Shields, Thyroid

collar, Ovary Shields must be used.

NOTE ☞

For the safety of operator and patient, opening the X-ray generator cover, X-ray tube,

Collimator and other equipment cover are strictly prohibited. Only qualified engineer

could open the cover.

(Rev. 2.1) 5 Operation & Service Manual

EcoRay HF-525 PLUS VET

Scope

1. This manual contains information of system operation, components, control keys, switches and

hazards and technical reference information.

2. This manual may not be reproduced in whole or in part without the written permission of ECORAY

CO., LTD.

3. The text of this manual is a translation based on the Korean alphabet (Hangŭl) original.

© January, 2007

EcoRay Co., Ltd.

60-10, Nanosandan 5-ro, Nam-myeon, Jangseong-gun, Jellanam-do, Korea

Revision History

Revision No. Revision Date Change Description

Rev. 1.0 2007-01-10 Release version

Rev. 2.0 2008-03-30 Added Ceiling Tube Support (Chapter 2)

Rev. 2.1 2008-05-09 Company Name was changed to

“EcoRay Co., Ltd.”

(Rev. 2.1) 6 Operation & Service Manual

EcoRay HF-525 PLUS VET

Abbreviation

kV Kilo-voltage

mA milliampere

mAs milli-ampere Second mA*Sec

mS milli-second 1/1000 second

APR Automatic Programming Radiography

AEC Automatic Exposure Control Optional

Summary of Functions

Symbol Function Description

Switching OFF

Switching ON

When yellow lamp ON, generator is

standby condition for operation

X-ray Exposure Switch

When x-ray exposure, lamp ON

Error display

Reset switch

Filament Focal indication lamp

(Rev. 2.1) 7 Operation & Service Manual

EcoRay HF-525 PLUS VET

Table of Contents

Chapter 1. Introduction and Safety ..................................................................................... 11

1.1 An Overview ............................................................................................................................................. 12

1.2 Safety Information ............................................................................................................................... 12

1.3 Electrical Safety ...................................................................................................................................... 13

1.4 Protection from Radiation ................................................................................................................. 14

1.5 Maintenance ......................................................................................................................................... 15

1.6 Responsibilities ...................................................................................................................................... 15

1.7 System Error ............................................................................................................................................ 16

1.8 Non-Approved Modifications ......................................................................................................... 16

1.9 External Devices ................................................................................................................................... 17

1.10 Use According to Regulations .................................................................................................... 17

1.11 Contraindication ................................................................................................................................ 17

1.12 User profile .......................................................................................................................................... 17

1.13 Training .................................................................................................................................................. 17

1.14 Directive for User ....................................................................................................................... 18

1.15 Specification ....................................................................................................................... 18

1.16 Option ......................................................................................................................................... 18

1.17 Labels ......................................................................................................................................... 19

1.18 Certifications ....................................................................................................................... 20

1.19 Using environment condition ....................................................................................................... 20

1.20 Construction and Function ....................................................................................................... 20

1.21 General details ........................................................................................................................ 21

1.22 Service Numbers ....................................................................................................................... 21

1.23 Disuse of Product ....................................................................................................................... 22

1.24 Powering OFF the System ............................................................................................................... 22

1.25 Potential Hazards ........................................................................................................................ 23

Chapter 2. Introduction and Using Method ...................................................................... 28

2.1 Introduction ....................................................................................................................... 29

2.2 How to use Operator’s Console ...................................................................................... 30

2.3 How to use Touch Monitor …………………………………………………………………………………. 38

2.4 How to use Tube Stand .......................................................................................................... 39

2.5 How to use Collimator ......................................................................................................... 40

2.6 How to use Table Bucky ......................................................................................................... 42

Chapter 3. X-ray room Requirements .................................................................................. 45

(Rev. 2.1) 8 Operation & Service Manual

EcoRay HF-525 PLUS VET

3.1 Environmental Requirements ............................................................................................ 46

3.2 Electrical requirements ........................................................................................................... 46

Chapter 4. Maintenance ..................................................................................................... 48

4.1 An Overview ....................................................................................................................... 49

4.2 Periodic Maintenance Procedures ........................................................................................... 49

4.3 Cable check ........................................................................................................................ 50

4.4 Console check ...................................................................................................................... 50

4.5 High voltage transformer check ...................................................................................... 50

4.6 X-Ray Tube check ....................................................................................................................... 50

4.7 Periodic Maintenance check point ................................................................................. 51

Chapter 5. Easy Installation ..................................................................................................... 52

5.1 An Overview ...................................................................................................................... 53

5.2 Pre-installation checks points and Tools and Testers .................................................. 53

5.3 Pre-installation Check .............................................................................................................. 53

5.4 Easy Installation ........................................................................................................... 55

5.5 Detector installation (optional item) ……………………………………………………............ 89

5.6 Installing Touch screen monitor (optional item) …………………………………………. 100

5.7 How to set Touch screen monitor with PC …………………………………………… 103

5.8 How to install PSU battery pack (optional item) …………………………………………… 121

Chapter 6. Technical Information ......................................................................................... 125

6.1 An Overview .................................................................................................................... 126

6.2 Installation information ........................................................................................................ 126

6.3. Exposure condition data ........................................................................................................... 126

6.4 Maintenance History ................................................................................................................. 127

Chapter 7. Calibration ..................................................................................................... 128

7.1 An Overview ..................................................................................................................... 129

7.2 Introduction ...................................................................................................................... 129

7.3 Needed tool and testers when Calibration .............................................................. 129

7.4 Check point before calibration ........................................................................................ 129

7.5 Time of Calibration .................................................................................................................... 130

7.6 Must calibrated when Main Parts are repaired or replaced ............................... 130

7.7 How to Calibrate ...................................................................................................................... 130

Chapter 8. Trouble Shooting .......................................................................................... 164

(Rev. 2.1) 9 Operation & Service Manual

EcoRay HF-525 PLUS VET

8.1 An Overview ...................................................................................................................... 165

8.2 Error type ....................................................................................................................................... 165

8.3 Trouble Shooting ....................................................................................................................... 170

8.3.1 Charge & Discharge circuit error ..................................................................... 171

8.3.2 Tube Stator Circuit error ................................................................................... 173

8.3.3 Tube Filament Circuit error .................................................................................... 175

8.3.4 IGBT Device signal and Protection circuit trouble ............................................. 177

8.3.5 HV-DRV-OLP trouble or Error Pro O- - - error ............................................. 179

8.3.6 IGBT_OCP trouble or Error Pro - I- - error .................................................. 180

8.3.7 IGBT_OCP trouble or Error Pro - I- - error .................................................. 181

8.3.8 DRV _ PWR _ UVP trouble or Error Pro - - P – error ................................. 182

8.3.9 DRV _ PWR _ UVP trouble or Error Pro --P- error ............................... 183

8.3.10 FIL _ OCP trouble or Error Pro - - F - error ..................................... 185

8.3.11 Communication error between generator and console or Err 232 error ..... 186

8.3.12 Error AEC error ..................................................................................................... 187

Chapter 9. Circuit Diagram ..................................................................................................... 192

9.1 Block Diagram .......................................................................................................................... 193

9.2 Console Board .............................................................................................................................. 194

9.3 Mio Board ............................................................................................................................... 195

9.4 FnD Board .............................................................................................................................. 198

9.5 CnD Board ............................................................................................................................. 200

9.6 GC Board …………………………………………………………………………………………………. 202

9.7 High Voltage Transformer …………………………………………………………………………….. 203

9.8 PSU Circuit (Optional item) …………………………………………………………………………….. 204

9.9 Table Board ………………………………………………………………………………………………… 205

9.10 Collimator …………………………………………………………………………………………………. 206

(Rev. 2.1) 10 Operation & Service Manual

EcoRay HF-525 PLUS VET

Chapter 1

Introduction and Safety

Model: HF-525 PLUS VET

(For Veterinary use)

(Rev. 2.1) 11 Operation & Service Manual

EcoRay HF-525 PLUS VET

1. Introduction and Safety

1.1 An Overview

This manual contains operation instructions for HF-525 PLUS VET and also product description,

safety and operation method.

This X-ray system was designed for diagnosis’s human beings and could get good regulations by

controlled digital value by microprocessor.

This X-ray system has a self-diagnosing function and then could improve service quality, save time

and decrease customers complain.

1.2 Safety Information

1.2.1 General Safety Information

1. This manual provides guideline to operate and use the system safely.

2. The owner of this x-ray system has to get a using permission of authorized government office.

3. The owner of this x-ray system has a responsible to get a using permission from government office.

4. The owner of this x-ray system is responsible for verifying continued compliance with all applicable

regulations and standards and has to keep specific requirements or regulations that each country

made rules

5. All users of this x-ray system must know about potential hazards may occur when using.

6. All users of this x-ray system are responsible and understanding about continued compliance with

all applicable regulations and standards and safety, emergency instructions.

7. All users must know how potential hazards can be avoided and must also know how they can

protect.

8. EcoRay confirms that HF-525 PLUS VET is manufactured in accordance with the appropriate legal

regulations.

9. EcoRay assumes no responsibility or liability for after-sale operating and safety practices. (Nor can

it be responsible for personal injury or damage resulting from misuse of its systems)

1.2.2 Safety Information about X-ray exposure

1. It is very danger when x-ray over exposed to body.

2. Patient and user must observe the related radiation regulation and especially it will be more

dangerous when radiation is exposed around genitals.

3. This x-ray system must be operated by only authorized operator.

4. Radiation shields is must necessary for protection of patient and user when x-ray exposed and

radiation shields must be equipped by related regulations.

5. If X-ray was exposed to body, could be seriously injured and be careful do not exposed first,

second X-ray radiation.

(Rev. 2.1) 12 Operation & Service Manual

EcoRay HF-525 PLUS VET

6. Specially, radiant ray can be accumulated in body and can be continued from several months to

several years. Therefore, safest method for operator avoids for the first, second beam.

7. Also, because the second radiate beam can be stronger than reach to film, must take safeguard by

this.

8. The most effective method to secure from first and second radiation defilades perfectly and should

be established x-ray room by lead etc... And, to minimize radiation exposure from radiation

exposure to operator, lead partition, lead gloves, apron, cover, Gonad Shields, Thyroid collar, Ovary

Shields must be used.

1.3 Electrical Safety

Electrical circuits inside the equipment may use voltages which are capable of causing

serious injury or death from electric shock. To avoid this hazard, never remove any of

the cabinet covers.

Observe the following safety procedures to avoid electric shock or serious injury to operators and

patients and to avoid system malfunction.

1. Do not remove any of the assembly covers.

2. Do not touch all electric circuit and components to be connected this x-ray system.

3. Do not bypass, jumper or otherwise disable the safety interlocks.

4. Do not place food or beverage containers on any part of the equipment. If spilled they can cause

short circuits and power off immediately.

5. Always remove power to the equipment before cleaning.

6. When cleaning the cover, use a slightly damp cloth or sponge for cleaning.

7. When cleaning the inside of system, remove the cover then remove the dust with duster. Only

qualified service engineer could clean the inside of system. (It is danger when touched electric

parts)

8. Only qualified service engineers are allowed to service or repair a system.

This X-ray system is not rated for water-tight operation. Water, soap or other

liquids which get inside the may cause short-circuits, electrical shocks or fire. If

liquid should enter the system, do not connect the unit to the power supply. If

liquids drip into the equipment, disconnect the power cord and do not operate the

system until it can be cleaned and inspected by a qualified service engineer (EcoRay

engineer or Representative’s engineer).

(Rev. 2.1) 13 Operation & Service Manual

EcoRay HF-525 PLUS VET

1.3.1 Electric danger in product fire

1. In case of fire caused by electricity

→ The owner/operator should prepare a plan for the area in which the unit is used, containing

the following safety measures:

→ If fire is occurred by electric, must do it as follows.

● Switching off the unit and removing the main power supply cable

● Evacuation of all persons in the vicinity

● Call for assistance

● In an emergency, use only a fire extinguisher which is suitable for putting out electrical fires.

1.4 Protection from Radiation

1.4.1 Radiation Exposures Safety

1. The owner/operator must read and understood relative regulation before use.

2. After turn on the power, if push console switch or hand switch, X-ray will be exposed and

especially, must handle with care to prevent unintended X-ray exposure.

3. Use X-ray protection cloth, X-ray protection plate before X-ray exposure.

4. The owner/operator must install the lead shield facility at the X-ray room and have to check and

it is necessary for patient and operator’s safety.

5. The owner/operator has a responsibility for radiation monitoring.

6. The owner must have the periodic inspection about X-ray system by qualified expert or company.

7. X-ray radiation protection report must be made before using X-ray system and this report must

confirm the technical requirements and relative regulations are correct matched.

(Also, must complied with each state or local regulations)

8. If X-ray is exposed to body, it cause of serious injury and then especially take care do not

exposed to first, second X-ray beam.

9. Especially, X-ray will be accumulated to the body and accumulated X-ray maintain during few

months or few years. It is the best safety and certain way to avoid the X-ray exposures is avoid

first, second X-ray beam.

10. Also, second X-ray beam is stronger than first X-ray beam to be reached the film and especially

take of this beam. And the owner or operator must be prepared this safety action.

11. Best protection way from the X-ray first beam and second X-ray beam is to cover the X-ray

room with lead shield after that have to use X-ray system.

1.4.2 Maximum permissible Dose (MPD)

1. For occupational exposure, the ICRP (International commission on radiological protection)

recommends that the MPD accumulated.

Shall not exceed of the following limits:

(Rev. 2.1) 14 Operation & Service Manual

EcoRay HF-525 PLUS VET

(1) Annual effective does: 50 mSv

(2) Annual dose for the lens of the eye: 150 mSv

(3) Annual does for all other areas: 500 mSv

(e.g. red bone marrow. breast. lung. gonads and extremities)

1.4.3 Monitoring of personnel

1. The operator must do not use it with over exposure condition and must monitored continuously of

operator’s exposed.

2. The most effective method is the using the radiation leakage meter determine whether or not

existence the MPD.

3. These measurements shall be taken at all locations where the operator or any portion of his body

may be exposed. Exposure must never exceed the accepted tolerable dose of ICRP.

The operator / patient will be seriously body injured or death by potential radiation

hazards used x-ray system without maintenance plan, using procedure, operation

method.

1.5 Maintenance

1.5.1 Maintenance must be done by qualified engineer by manufacturer.

1.5.2 This X-ray system must be maintained periodically by local or state regulations.

1.6 Responsibilities

1.6.1 Ensure that all authorized person to use the equipment are aware of the danger of excessive

exposure to X-Ray radiation.

1.6.2 The responsibility herein described that is well acquainted with sufficient training of the

radiation safety control regulation and instruction of the equipment by definitely and accurately.

1.6.3 The manufacturer is not liable for injury and damage which may result from violation of the

radiation safety control regulation and instruction of the equipment.

1.6.4 The owner/operator must confirm that X-ray room must comply with relative regulations.

1.6.5 The owner/operator must ask relative regulations to be used correctly complied with regulations

to government office or independent institute. And the owner/operator has a responsibility

about this.

1.6.6 This X-ray system must be used in the suitable X-ray room to be complied with relative

regulations and technical requirements. It is the responsibility of owner/operator to keep this

rule

(Rev. 2.1) 15 Operation & Service Manual

EcoRay HF-525 PLUS VET

1.6.7. The owner of this system has a responsibility to control strictly exposed radiation of operator

and must order to operator to be used “Pocket Dose meter”.

The owner/operator must know that it is very dangerous if radiation over exposed to patient.

The manufacturers don’t have a responsibility that if seriously bodily injured or accident

occurred by over X-ray exposed.

It is a responsibility of operator/owner when accident occurred during operates X-ray system.

The manufacturer doesn’t have a responsibility about that case. Also, if X-ray system is troubled

by unauthorized amendment or adjustment, the manufacturer doesn’t have a responsibility.

1.7 System Error

1.7.1 This X-ray system has a self-diagnosing function and could be checked automatically and if

system has an error, call service or push the reset button and then initialize the main CPU data.

1.7.2 After Reset, when displayed error continuously, it is meaning of system error.

1.7.3 In this case, do not uses X-ray system before service engineer check the X-ray system.

1. Power off the console power switch.

2. Powering off the main circuit breaker.

3. Contact authorized service engineer immediately.

4. Do not use X-ray system before service engineer checked the X-ray system completely.

5. Refer to Generator service manual for more error information.

1.8 Non-Approved Modifications

1.8.1 Unauthorized changes or modifications to any parts of the system can have dangerous

consequences and changes or modifications should be done after permission of EcoRay Co., Ltd.

1.8.2 Do not use with changes or modifications without permission of manufacturer.

(Rev. 2.1) 16 Operation & Service Manual

EcoRay HF-525 PLUS VET

1.9 External Devices

1.9.1 Do not connect non-authorized devices to this system.

1.9.2 Additional equipment or external devices should only be connected by an authorized service

engineer of manufacturer and all additional equipment connected to external interfaces of

this system.

1.9.3 External interfaces of the unit must fulfill the requirements of Standard IEC 60601-1-1.

If the system is operated together with other electrical devices from a multiple socket outlet,

current leakage can increase; the operator/user in this case is responsible for ensuring that the

requirements of IEC 60601-1-1/IEC 60601-1 are still met.

1.10 Use According to Regulations

1.10.1 This X-ray system must be used by regulations after reading and understanding relative

radiation regulations.

1.10.2 EcoRay’s HF-525 PLUS VET system is intended for use on human beings.

1.10.3 Regulations on its use cover the area of only diagnostic radiography applications.

1.10.4 It is suitable for daily use in a clinical or hospital environment by various users.

1.11 Contraindication

This x-ray system is not suitable for therapeutic applications.

1.12 User profile

This x-ray system was designed suitable for diagnosis’s human beings and must be used by

qualified personnel for using this system.

1.13 Training

After installation, EcoRay engineer or EcoRay’s agent will carry our training of its use and if you

have any further questions on the system, please contact address as shown in this manual.

Obey the instructions of operation manual for both patient and operator’s continuously safety

and read and understood the operation manual and keep the manual in accessible place.

(Rev. 2.1) 17 Operation & Service Manual

EcoRay HF-525 PLUS VET

Radiation Safety plan must be established and advice strongly understand and observe the

radiation protection regulations

1.14 Directive for User

1.14.1 The user, physician must not touch the patient and the interface connectors simultaneously.

1.14.2 Communication must be easily with patient in X-ray exposure.

1.15 Specification

Item Functions HF-525 PLUS VET

Generator Type High Frequency Inverter

Maximum kVp 40~125kV ±5%

Maximum mA 10~400mA ±5%

1mSec ~ 6Sec

Exposure Time

(Below: 100mSec: ±1mSec Over 100mSec: ±10%)

Generator APR 96 (Standard)

AEC Optional item

Output Frequency 40kHz

Maximum Power 32kW

Line Voltage Single phase, 220V. 50/60Hz (or 110V)

Rating 80kV / 400mA, 125kV / 250mA

High Voltage

Maximum kVp 125kVp

Transformer

Maximum mA 400mA

1.16 Option

1.16.1 General ionization could be used at AEC function.

(Rev. 2.1) 18 Operation & Service Manual

EcoRay HF-525 PLUS VET

1.17 Labels

1.17.1 Main parts of generator has a labels contains information as follows.

1.17.2 Labeling: Product Name, Model, Main power, manufactured date, Manufacturer & Address,

Serial No. are printed and attached at the generator.

(Rev. 2.1) 19 Operation & Service Manual

EcoRay HF-525 PLUS VET

1.18 Certifications

1.18.1 EcoRay have certificate as below about production for this product.

1. ISO 9001

2. ISO 13485

1.19 Using environment condition

1.19.1 Transportation and Installation, storage condition:

1. An ambient temperature: +10°C ~ +60°C

2. Humidity: 10% ~ 90% (Must be without condensation)

3. Pressure gauge: 700hPa ~ 1,060hPa

1.19.2 Working condition:

1. An ambient temperature: +10°C ~ +35°C

2. Humidity: 30% ~ 65% (Must be without condensation)

3. Pressure gauge: 700hPa ~ 1,060hPa

4. This system must be used in the without corrosion and explosion gas.

Troubles are could be occurred in the use or storage under unsuitable environment condition.

1.20 Construction and Function

1.20.1 Construction

X-ray tube

Tube Stand

Collimator

Table

Console

X-ray

Generator

(Rev. 2.1) 20 Operation & Service Manual

EcoRay HF-525 PLUS VET

1.20.2 Function

1. This X-ray system is consisting of Tube Stand which supports X-ray tube, Console, X-ray gen

erator, table, and X-ray tube unit.

2. Tube Stand: Assembled with table, x-ray tube, collimator and operator’s console.

3. Console: Consist of each switch and could adjust exposure values and display it.

4. X-ray generator: Consists of control unit and high voltage transformer unit and PSU. And co

ntrol x-ray exposure values and make high voltages by console.

5. Table: Consists of tabletop and bucky devices and animal will lie down on the table.

6. X-ray tube unit: Consist of X-ray tube, Collimator.

7. X-ray radiation will be made by pushing of X-ray switch of console or pushing of hand switc

h or foot switch.

8. X-ray radiation will permeate animal from x-ray tube to bucky device and after permeation, c

ould archive x-ray images by x-ray film or digital detector.

1.21 General details

1.21.1 Manufacturer

EcoRay Co., Ltd.

1.21.2 Place of Manufacture of the HF-525 PLUS VET

EcoRay Co., Ltd.

621-14, Docheon-dong, Gwangsan-gu, 506-301, Korea

1.21.3 Representative in Europe Union

1.21.4 Information

Please contact if have any query about product or safety.

EcoRay Co., Ltd.

Seoul Office: 3F, Urbanlight B/D, 630, Eonju-ro, Gangnam-gu, Seoul, Korea 135-832

Tel) +82 70 7510 3402 Fax) +82 70 8630 3420 E-mail: sales@ecoray.kr

1.22 Service Numbers

1.22.1 If the system does not work reliably, or if errors occur in terms of control functions which are

described in the manual, the owner should contact the nearest EcoRay Service Center.

1.22.2 The EcoRay Service Center can be reached at the following Phone and Fax numbers:

1.22.3 Service for Europe

1.22.4 Service for Outside of Europe, Worldwide

Tel) +82 70 7510 3402 Fax) +82 70 8630 3420 E-mail: sales@ecoray.kr

(Rev. 2.1) 21 Operation & Service Manual

EcoRay HF-525 PLUS VET

1.23 Disuse of Product

1.23.1 Please observed the each national waste treatment regulations when disuse system or parts

and must be observed the.

1.23.2 It cause of environmental pollution if discard it without permission.

1.24 Powering OFF the System

1.24.1 Powering OFF Normally

1. Normally the unit should be powered off after use with power off switch of console.

1.24.2 Complete separation from the power supply

1. If the unit has been powered off, but there are still indications that parts of the system are still

powered on, off the circuit breaker switch if want to completely powered off.

2. In spite of the power off with circuit breaker, power supplied to system, call EcoRay Service

engineer and do not use the system until it has been inspected by service engineer.

If the unit has been powered off, but there are still indications that parts of the

system are still powered on, off the circuit breaker switch if want to completely

powered off.

(Rev. 2.1) 22 Operation & Service Manual

EcoRay HF-525 PLUS VET

1.24.3 Procedure when Powering OFF

1. Powering OFF Normally (Power On / Off of Console)

● Check Standby lamp condition of Console: Yellow lamp lighting

● Push the Power ON of Console: Standby lamp on and off with yellow and green

during 20 seconds, power supplied when green lamp lights up.

● Push the Power OFF of Console: When push the Power OFF switch, green lamp light

up on the Power OFF, at the same time Standby lamp light up with yellow.

2. Complete Separation from the Power Supply (Circuit breaker)

● Switch OFF the circuit breaker on the wall.

● Standby lamp condition of Console: OFF condition

● Power OFF condition of Console: OFF condition

OFF

● In spite of the power off with circuit breaker, power supplied to system, call

EcoRay Service engineer and do not use the system until it has been

inspected by service engineer.

1.25 Potential Hazards

1.25.1 Medical electrical units and X-ray systems represent potential sources of danger.

1.25.2 User must know how they can detect the conditions for possible hazards, and how they can

appropriately protect themselves and others from injury.

1.25.3 The operator must take account of possible dangers and make plans to prevent them from

occurring.

1.25.4 The emergency procedure and also the operational safety procedure for the system, as well

as the safety, emergency and operational procedures of the institution must be observed.

1.25.5 HF-525 PLUS VET system has no source of danger unusual for this kind, and meets all the

safety regulations for this type of medical electrical equipment.

(Rev. 2.1) 23 Operation & Service Manual

EcoRay HF-525 PLUS VET

1. Overheating, Explosion and Crash Hazard

Hazards Cause Precaution

Excessive use of X-ray tube causing it The temperature of the X-ray tube is

to overheat, can result in a rupture of continuously monitored and if certain

the pressure compensating bladder in temperature levels are reached, the anode

X-ray tube

the housing. This can cause hot oil to current is limited or radiation is totally

escape, potentially resulting in scalds disabled.

or burns.

Draping the X-ray generator may 1. Never install x-ray generator near the

inhibit airflow, resulting in cooling patient.

inefficiencies and may result in 2. Never place the x-ray generator against

X-ray Generator

reaching electric parts heat sooner and the patient’s skin.

if electric parts are heated over, it 3. Never put anything on the x-ray

could be exploded. generator.

Flammable and explosive anesthetics, 1. If any of these products are near the

liquids, vapors and gases can cause an system, DO NOT SWITCHES IT ON.

explosion when used around electrical 2. If any of these products are discovered

equipment. near the system while it is on, DO NOT

TOUCH ANY CONTROL OR SWITCH THE

Explosion hazard SYSTEM OFF.

3. Evacuate the facility immediately.

4. Have the facility specialists remove the

substances and ventilate the area before

having patients and personnel return to

the facility.

1. If improperly moved or use it 1. When moving Tube stand or patient

improperly, it could collide with table, watch around to prevent Crash.

other system. 2. Do not install the system not level with

floor.

3. Operator asks patient doesn’t move

Crash Hazard 2. If electronic magnetic lock system is while using electronic magnetic lock

trouble during use, Tube stand may fall system.

down and cause injury to the patient 4. After fixing exposure position, ensure

or medical personnel. the electronic magnetic lock system to be

locked.

(Rev. 2.1) 24 Operation & Service Manual

EcoRay HF-525 PLUS VET

2. Mechanical Movement Hazard

Hazards Cause Precaution

Tube stand and Patient table are used When move Tube stand and Patient table,

electronic magnetic lock system and it have to look around continuously to

Mechanical cause of patient of operator’s injury if prevent Crash with patient or things.

Movement Hazard use it with misuse or malfunction.

If used with another equipments, its 1. Do not use equipments not mentioned

cause of injury by unexpected danger in this manual or not mentioned in the

situation. EcoRay’s printed matters.

Equipment Safety 2. This system must be installed by

authorized personnel by EcoRay.

3. Radiation Safety

Hazards Cause Precaution

1. If this X-ray system is used without 1. It is the responsibility of the owner to

observe the relative regulations, it ensure that all personnel wear protective

cause of death or seriously injury. X-ray clothing and use radiation safety

2. Observe the relative regulations, precautions when operating the system.

make maintenance plan, operating 2. Operators should avoid placing their

instructions are observed. If not, it has hands or any part of their bodies in the

a possible danger to patient and path of the X-ray beam.

operator. 3. It is the responsibility of the owner to

ensure that owner or operator must

Radiation Safety understand with relative regulations.

4. This X-ray system makes an audio

warning or audio signal to operator when

radiation exposed.

Audio warning 1: Sounds when push

switch.

Audio warning 2: Sounds when radiation is

activated. (During radiation time)

Audio warning 3: Sounds when error

occurred.

(Rev. 2.1) 25 Operation & Service Manual

EcoRay HF-525 PLUS VET

4. Electrical Safety

Hazards Cause Precaution

Electrical circuits inside the system can Safety covers have been designed for this

cause serious injury or death. system to mitigate the hazards caused by

If repaired with unauthorized parts, it electrical circuits and high voltages. Never

cause of operator or patient’s serious remove the covers or operate the system

injury or death. while the covers are off. If any cover is off,

This system operates on high voltages. request service technician before using the

High voltages are present throughout systems.

the system. When repairing, must be repaired by

High voltage transformer and X-ray authorized engineer and never modify

Electrical Safety tube: Max. 150,000V circuit.

X-ray Generator: Max. 350 V DC Don’t touch the electric parts thoughtlessly.

WARNING: Removing the power cable

from the wall outlet is the only way to

eliminate the power supply voltage from

the entire system.

WARNING: Never any adjust the X-ray This x-ray tube is produced suitable for

generator and the X-ray tube. If adjust regulations. Never make any changes inside

against this warning, it makes cause of of circuit or parts. If needed change,

Unauthorized X-ray

serious injury of death. contact the EcoRay Service center before

tube change

change or modify it.

Fire from near or other equipments, it 1. Install X-ray system in good air flow

makes a same damage as like this condition.

product is fired. 2. If there is a fire in the area or system in

on fire, to do as follows.

Electrical Fire Switch the circuit breaker off, stop supply

electric power.

Escape all people near the system.

Ask assistance.

Put the fire out with fire extinguisher.

(Rev. 2.1) 26 Operation & Service Manual

EcoRay HF-525 PLUS VET

5. Handle with Care

Hazards Cause Precaution

X-ray switch is located on the console. 1. Be aware of X-ray switches of console

All of console switches are membrane are broken by using and operator has to

switch. And do not push switches with pay attention when using X-ray switches.

sharp things or wetted things. These

using is cause of trouble or 2. Hand switch works as like X-ray switch,

malfunction. take of using hand switch.

3. To install holder to prevent falling of

If hand switch is fallen or stepped, it hand switch.

X-ray Switch Safety cause of damaged or malfunction. 4. After using hand switch, return it to the

holder.

5. Be careful lest hand switch cable not

press or cut. It cause of system trouble.

Almost any liquid spilled into electronic 1. This system is not water proof, it is very

equipment automatically becomes a dander if liquid is spilled on it.

conductor of electricity. This can cause 2. Do not put liquid on system.

short circuit or fire by this short circuit. 3. It must be switched off immediately if

liquid is spilled on it.

4. Do not switch the system on until the

liquid has dried completely.

5. Do not splash or spray cleaning

solution on the system.

Cleaning Safety

6. Clean the system by unplugging the

power cord from the wall outlet and using

a damp cloth or sponge to wipe the

system clean.

7. When cleaning the inside of system,

using duster after remove the cover. This

cleaning must be done by an authorized

service engineer. (Because, it is very

danger when mishandle.)

(Rev. 2.1) 27 Operation & Service Manual

EcoRay HF-525 PLUS VET

Chapter 2

Introduction and Using Method

Model: HF-525 PLUS VET

(For Veterinary use)

(Rev. 2.1) 28 Operation & Service Manual

EcoRay HF-525 PLUS VET

2. Introduction and Using Method

2.1 Introduction

2.1.1 An Overview

1. This HF-525 PLUS VET manual contains of operation, safety and specification of this X-ray system.

2. This X-ray system was developed by high frequency inverter circuit base.

3. This X-ray system was designed for suitable for diagnosing human being with radiation.

4. This X-ray system was designed to control radiation with digital method and calibrated radiation

before delivery could checkable by radiation meter.

5. This X-ray system was designed to do self diagnostic by electric circuit and program and

therefore, it’s easy to check the system’s condition and it indicates the type of trouble on the

display.

2.1.2 Special Features

1. This X-ray system use high frequency inverter type system.

2. This X-ray system have APR (Anatomical Programming Radiographic) and AEC (Automatic

Exposure control – Optional item).

3. Maximum voltage is 125kVp.

4. Maximum power consumption is 40kw.

5. Maximum output frequency is 40kHz.

6. This X-ray system has an APR function in basic and it could save exposure condition in advance

and could use it easily when exposure.

7. APR function is changeable by operator’s need.

8. This X-ray system has a self diagnosing function by electric circuit and program and could check

system condition when trouble occurred.

9. This X-ray system has a protection function that limit operation when abnormal voltage supplied

to system.

10. This X-ray system has an X-ray tube stator’s protection function that it checks tube stator

condition by electrical sensing and if tube stator condition is abnormal, limits x-ray exposure.

11. This X-ray system has an X-ray tube Filament’s protection function that it checks tube filament

current condition by electrical sensing and it tube filament condition is abnormal, limits x-ray

exposure.

12. This X-ray system has a High voltage Feed Back circuit to check high voltage condition and

could archive good exposure dose reproducibility.

13. This X-ray system has a circuit to control inrush current when radiation exposed and it makes

system stabilized.

(Rev. 2.1) 29 Operation & Service Manual

EcoRay HF-525 PLUS VET

14. This X-ray system has quick rise time as 1mSec and could have good radiation efficiency.

15 This X-ray system could use low electric condition with PSU (Power Storage Unit – Battery type

– Optional item).

2.2 How to use Operator’s Console

2.2.1 Function of Console (FND display)

9. Ready / X-Ray lamp 1.Tube Focal lamp

10. Generator Standby 2. Reset switch

11. Over load lamp

lamp 3. Power Switch

4. kV / mA / Time

Display window

12. Anatomical

5. Bucky switch

mode

6. Ready / X-Ray switch

13. AEC mode

7. Chamber density switch

14. Chamber 8. Chamber density

Display

Detector

2.2.2 Explanation of Console Function

1. Tube Focal lamp / Reset switch

(1) Tube Focal is divided with small and large focal and lamp will be lighted when selected.

(2) Reset switch is used in system error condition and if pushed this switch, it makes microprocessor

initialization.

Reset switch

Small Focal

Large Focal

2. Power Switch

(1) This switch controls electric power and if push ON switch, power supplied to system and if OFF

switch, disconnect power. Green lamp lighted when

power off

Power ON

Power OFF

(Rev. 2.1) 30 Operation & Service Manual

EcoRay HF-525 PLUS VET

3. kV / mA / Time display window

(1) Display set exposure value with numeral.

kV, mA, mAs/Time display

kV adjustment mAs / Time selection switch

switch

mA adjustment mAs / Time adjustment switch

switch

4. Bucky selection switch – Table bucky is standard

(1) If push bucky icon and then will be selected and lamp will be lighted.

Table Bucky

5. Ready / X-Ray switch

(1) This switched are used in X-ray exposure. Ready switch is preparing radiation and X-ray switch is

radiation exposure.

(This model could be used foot switch (right side) for Ready / X-ray switch)

X-Ray exposure switch

Ready switch

6. AEC selection switch – Optional item

(1) AEC is abbreviation of Automatic Exposure Control and it controls exposure time automatically.

AEC ON/OFF switch Select Bucky

Chamber density display

Chamber Detector switch

Chamber Display switch

(Rev. 2.1) 31 Operation & Service Manual

EcoRay HF-525 PLUS VET

7. Selection of APR

(1) APR is abbreviation of Anatomical Programming Radiographic and it could memory exposure

value to the microprocessor of PCB and could use it with easily.

(2) Memorized exposure value of microprocessor could change by operator’s need.

(3) APR function will be activated automatically by Powering ON of Console.

Select body size

Select body point

Select exposure method

Memory switch

8. Generator status display lamp

(1) Display Overload, Standby, Ready and X-ray working condition and could check system condition

by lighted lamp status.

Ready status display lamp

Power status

display X-Ray exposure display lamp

Overload display lamp

2.2.3 Supply electric power

1. Supply electric power to the system

(1) Must check the input voltage by tester before Powering ON of Circuit breaker

(2) Single phase 220VAC must supply to the system and could check voltage by tester.

(But, if use PSU by option, 110VAC could be used by customer’s request)

Circuit breaker

External terminal

Voltage meter

220VAC

Back side of generator

2. Supply electric power to the generator

(1) If push power ON switch of Console, electric power will be supplied to the generator and

disconnect electric power if push OFF switch of Console.

(In OFF condition: green lamp lighting above OFF switch)

(Rev. 2.1) 32 Operation & Service Manual

EcoRay HF-525 PLUS VET

(2) Could check generator electric condition by Standby lamp lighting condition. (Standby: Yellow,

Supplied power: Green)

(3) External devices will be activated by Console power ON.

Power ON switch

Electric power status lamp Power OFF switch

Normal: Yellow

2.2.4 Turn on the Power ON

1. Introduction of Power ON

(1) To operator the system, push the power ON switch of Console.

(2) After power on, system will diagnosing automatically during 15 seconds.

● Push the power ON switch

● After power ON, Standby lamp lighting with yellow and green.

In normal condition, green lamp lighting after 15 seconds later.

● After power on, system will diagnosing automatically during 15 seconds.

● Display progress at the mA window by 0 to 100.

● In the normal condition, 100 will be displayed at the mA window and could

use X-ray system.

● In abnormal condition, error will be displayed at the mA window before 100 and

then could not use X-ray system.

2. Procedure of Power ON

(1) Push power ON switch of Console

(2) Standby lamp lighting with yellow and green if system is normal green lamp will be lighting.

(3) ”Set 0 r 1.00” will be displayed at the Console window and if system is normal condition,

“Set 100 r 1.00” display after 15 seconds later.

(4) “Set 100 r 1.00” displayed at the window, could use X-ray system.

(5) If abnormal condition, Error code will be displayed at the Console window and then could not

use X-ray system.

(Rev. 2.1) 33 Operation & Service Manual

EcoRay HF-525 PLUS VET

2.2.5 Check System Condition

1. In normal condition

(1) After power ON, check system condition automatically.

(2) After power ON, will be changed to the Radiography mode after

15 seconds later.

2. In abnormal condition

(1) After power ON, check system condition automatically.

(2) During system check condition, error code will be displayed

(3)when system

If error troubled.

displayed, turn ON/OFF repeatedly, but error code not

되며 제품을

appeared, 사용할

system must수 be

없음checked by authorized engineer.

2.2.6 How to Use APR

1. APR (Anatomical Programming Radiographic) function

(1) APR function will be activated automatically after power ON of console.

(2) Memorized APR data is saved by manufacturer’s experience but operator could change APR data

by need

(3) APR could use without specific procedure.

(4) APR is consists of 4 function switches.

1. Select Body size

3. Select Body point

2. Select Exposure method

4. Memory switch

(Rev. 2.1) 34 Operation & Service Manual

EcoRay HF-525 PLUS VET

(5) Select Body size

(6) Select Exposure method

A-P exposure method APR data memory switch

Lateral exposure method Oblique exposure

method

(7) Select Body point

● Body point is consists of 21 anatomical mode and 3 types of exposure method.

● If push switch and then selected and lamp lighting.

2. Adjust exposure condition

(1) If change exposure data and memory it, old exposure data will be deleted and could not use it

again.

APR Function Adjust kV, mA, Time Memory

Select APR point

Memorized new data

(Body size, Exposure method,

Body point)

(2) Adjust Exposure value and display

● kV adjustment: Increase →No. 1, Decrease → No. 2

Fast adjustment → No. 1 + No. 2 or No. 3 + No. 2

1 2 3

● mA adjustment: Increase → No. 1, Decrease → No. 2

1 2

● mAs / Time select: If push No. 3 switch and then selected and selected

switch will be lighting.

● mAs / Time adjustment: Increase → No. 1, Decrease → No. 2

1 2 3

(3) Display Exposure values

● Adjusted exposure values are displayed at the FND window by number.

Display window

Adjustment switches

(Rev. 2.1) 35 Operation & Service Manual

EcoRay HF-525 PLUS VET

3. Select Bucky

(1) Bucky will be activated automatically after Console power ON.

(2) Bucky signal was designed to operate only EcoRay’s bucky devices. If want to use another

company’s bucky devices, please contact authorized distributor or manufacturer and ask services.

(3) Select Bucky position

(4) How to use Bucky

● Select Bucky

● If selected, lamp lighting above the selected Bucky switch.

● Bucky device will be operated automatically by program when push Ready and X-Ray switch

4. AEC Functions - Optional

2. Select Chamber

1. AEC ON/OFF

position

4. Density lamp

switch

3. Chamber Detector switch

5. Density display

6. Density switch

(1) How to use AEC

● Ionization chamber for AEC will be installed by Bucky position and if select Bucky, chamber will

be selected automatically by program.

→ If push AEC ON/OFF switch, AEC mode will activate.

→ If turn ON AEC mode, lamp lighting above the AEC switch.

→ At the same time, density display and selected indicating lamp will be lighting.

→ Select wanted function and then adjust density with density switch.

→ Adjusted density value will be displayed by number (Density: -8 ~ +8. 16 levels))

→ If beep sound or error code occurred from Console in the using AEC function, push the

“Reset” switch of Console to initialize the system or push the OFF switch of Console and

push the ON switch. Even though, could not use AEC function, ask services by authorized

engineer. (Refer to Maintenance)

(Rev. 2.1) 36 Operation & Service Manual

EcoRay HF-525 PLUS VET

5. X-ray Exposure

(1) Beep sound and lamp is will be activated during X-ray exposure to announce X-ray radiation to

operator.

(2) X-ray switch is located at the bottom of console and indicating lamp is located at the upper of

console.

(3) X-ray switch is designed to be assembled it at the external and use it. (Hand Switch)

(4) 1 second later after pushing the “Ready” switch, in normal condition, Ready lamp lighting and

then could use X-ray exposure.

(5) If push the "Ready" switch, "Ready" lamp will be lighting with green.

(6) If push the "X-Ray" switch, beep sound will be made and “X-ray” lamp will be lighting with yellow

during X-ray exposure.

(7) X-ray exposure values are different by body point and could adjust it by operator’s need.

(8) Radiation will be exposed by only setting exposure value and could not over expose by circuit

about the X-ray tube capacity.

Ready / X-Ray

Indicating lamp

X-Ray switch

Ready switch

(Rev. 2.1) 37 Operation & Service Manual

EcoRay HF-525 PLUS VET

2.3 How to use Touch Monitor (Optional item: If selected DR touch monitor)

⑩ ⑪ ⑧

①

⑨

③

(Touch Monitor image)

① KVp adjustment area

② mA adjustment area

③ mAs adjustment area

④ ms adjustment area

⑤ mAs / ms selection icon: if selected, ③ or ④ will be activate.

⑥ AEC selection icon and adjustment area

⑦ Body size selection

⑧ Patient information

⑨ Study history

⑩ Decrease icon

⑪ Increase icon

(Rev. 2.1) 38 Operation & Service Manual

EcoRay HF-525 PLUS VET

2.4 How to use Tube Stand

2.4.1 Consist of Tube Stand

Tube Arm

X-ray Tube

Tube Stand Body

Collimator

Combined part

with table

2.4.2 Function of Tube Stand

1. Function of Main Parts.

(1) Body: Column for X-tube and collimator

(2) Combined part: Must assemble with table.

(3) X-ray Tube: Electron Tube for x-ray generation.

(Rev. 2.1) 39 Operation & Service Manual

EcoRay HF-525 PLUS VET

2.5 How to use Collimator

2.5.1 Operation of Collimator

1. Function of Collimator

- X-ray irradiation angle is adjusted by manual.

- Function and description of Collimator is as below.

No Description

① X-Ray filed adjustable knobs

② Momentaly push switch of lamp

③ Dial for film size

④ Back panel

⑤ Lock Knobe

⑥ Mounting flange for X-Ray tube

⑧ Center Cross marked plate

(Rev. 2.1) 40 Operation & Service Manual

EcoRay HF-525 PLUS VET

2. Incident rays of Collimator

1) X-ray radiation incident with vertically with table top. (Refer to below image)

3. How to use Collimator

- Move Tube Stand to the patient exposure point.

① Minimum distance should be 45cm patient with X-ray tube.

② X-ray tube should be set with long as possible in normal condition.

- Push the Collimator lamp switch.

(After turn ON lamp, 30 seconds later collimator lamp will be turn off automatically.)

- After turn ON lamp, adjust exposure area with adjusting of iris knobs.

- If collimator lamp turns off during adjusting exposure area, turn ON the collimator lamp again.

- If setting is finished, push the X-ray switch.

- There is no problem when X-ray exposed in the lighting condition.

X-ray radiation is dangerous for both patient and operator and try to be exposed in

minimum exposure area as soon as possible.

(Rev. 2.1) 41 Operation & Service Manual

EcoRay HF-525 PLUS VET

2. 6 How to use Table Bucky

2.6.1 Function of Table Bucky

Bucky Device Table Top

Foot Switch X-ray Exposure switch

Cover

Grid, Bucky device

Ion Chamber - Option

Ion Chamber holder - Option

Cassette Tray

Cassette Tray hand grip

2.6.2 Explanation of Table Bucky function

1. Explanation of Main parts

(1) Bucky Device: Reduce and control X-ray scattering.

(2) Foot Switch: Used to move Table top and locked by electromagnetic.

(3) X-ray exposure switch: If push one time and then it makes “Ready” condition and push one

more time, x-ray will be exposed.

(4) Table Top: Patient laying on the surface and it made by good condition of permeable material.

(5) Bucky Device

- Cassette Tray: Unit for set the cassette.

- Cassette Fixing Unit: Fixing unit after cassette setting.

- Grid: Plate for decreasing X-ray scattering.

- Oscillation Unit: Unit for moving Grid with left/right.

- Ionization Chamber: Automatic radiation time control sensor. - Option

2.6.3 Turn on the Power ON

1. Power will be supplied automatically by Power ON of console.

2. Turn ON the Console Power.

(1) To operator the system, push the power ON switch of Console.

(2) After power on, system will diagnosing automatically during 15 seconds.

(Rev. 2.1) 42 Operation & Service Manual

EcoRay HF-525 PLUS VET

2.6.4 How to Use table bucky

1 Positing of Table Top

Lock Switch

Ready / Exposure

switch

(1) This product uses electromagnetic lock method.

(2) Turn ON Lock switch before use lock switch. Electromagnetic lock operated by left foot switch.

When push this pedal, electromagnetic lock will be released and then could make table top

position.

(3) Bucky device will be locked when push back cassette tray to the inside table with hand grip

and when pull it, it will be released.

(4) Do not move Table top in locked condition

(5) In the case of stop moving Table top, turn back foot from the bottom of the table top.

Do not move the Table Top in locked condition, it cause of system troubles.

(Rev. 2.1) 43 Operation & Service Manual

EcoRay HF-525 PLUS VET

2. How to use cassette tray

1. Insert cassette to the cassette tray as below image.

2. Take cassette out from cassette tray as reverse procedure.

1. Insert Cassette to the cassette tray

(Refer to the image)

Lock lever Locked

2. Push the arrow direction 2. Released condition of Lock lever 3. Lock condition of Lock lever

(Rev. 2.1) 44 Operation & Service Manual

EcoRay HF-525 PLUS VET

Chapter 3

X-ray room Requirements

Model: HF-525 PLUS VET

(For Veterinary use)

(Rev. 2.1) 45 Operation & Service Manual

EcoRay HF-525 PLUS VET

3. X-ray room Requirements

3.1 Environmental Requirements

3.1.1 An ambient temperature: +10°C ~ +40°C

3.1.2 A relative humidity: 30% ~ 75% (Without dew condensation)

3.1.3 An atmospheric pressure: 700hPa ~ 1,060hPa

3.1.4 This system must be used in the without corrosion and explosion gas.

3.2 Electrical requirements

3.2.1 This generator contains advanced circuitry which will maintain the selected X-ray values during

irregular input voltage condition. If input voltage condition is over or less, then could not get a

good X-ray radiation and have a good electric facility to be supplied with good regulation

condition.

3.2.2 Supply specific electric power to the system.

1. Do not under size distribution transformer.

2. Insure the suitable electric facility for the system.

3.2.3 Generator Power line requirements.

1. Power line voltage variation must not exceed ± 10%.

2. Maximum line regulation for the maximum kVA demand is 5%.

Model HF 525 Plus (Vet)

Input Power Max. 60 kVA

Input Voltage Single phase, 220V (Or 110V by Optional)

3.2.5 Recommended wire size

1. Correct sizing of the feeder wire is critical to proper generator operation.

2. Wire size is depend on the kW rating of the generator, line voltage and the distance from the

generator and electric circuit breaker.

3. Minimum wire size from generator and electric circuit breaker.

Wire size

Generator Line Voltage

7.5 m 15 m 30 m

40 kVA 208-240 VAC 35 mm2 70 mm2 120 mm2

3.2.6 Interconnection and grounding requirements.

1. Main line of the generator must be connecting with main electric circuit breaker.

(1) Must use 415VAC 100A circuit breaker.

2. Connected external device with generator must have electric circuit breaker or fuse.

3. Ground terminal of the generator must be grounded with ground line of the main power line.

(Rev. 2.1) 46 Operation & Service Manual

EcoRay HF-525 PLUS VET

4. Use recommended ground wire size by local regulation.

5. Wiring connection of main devices.

3.2.7 Fuse capacity of main parts.

No Fuse Name Position Capacity Quantity

1 F1,F2 Main Fuse 500V, 63A 2

2 F3,F4 Trans Fuse 250V, 15A 2

3 F701 ECO-XR5-MiO 250V, 10A 1

4 F901 ECO-XR5-MiO 250V, 3.15A 1

5 F801 ECO-XR5-CnD 250V, 10A 1

6 F501 ECO-XR5-FnD 250V, 3.15A 1

7 F701 ECO-XR5-GC 250V, 20A 1

8 F700,F704,F705,F708 ECO-XR5-GC 250V, 5A 4

9 F702,F703,F706 ECO-XR5-GC 250V, 3.15A 3

10 F707 ECO-XR5-GC 250V, 10A 1

(Rev. 2.1) 47 Operation & Service Manual

EcoRay HF-525 PLUS VET

Chapter 4

Maintenance

Model: HF-525 PLUS VET

(For Veterinary use)

(Rev. 2.1) 48 Operation & Service Manual

EcoRay HF-525 PLUS VET

4. Maintenance

4.1 An Overview

4.1.1. The purpose of this Periodic Maintenance is to assure continued safe performance of the X-

Ray generator, to increase serviceability, to reduce the cost (save time, repairs, etc.) and to

assure the safety (personal risk).

4.1.2 The following checks and maintenance procedures, together with the suggested intervals, are

the manufacturer’s recommendation for the most effective periodic maintenance schedule for

this generator.

4.1.3 Service task here described must be performed exclusively by service personnel specifically

trained on medical X-Ray generator.

4.2 Periodic Maintenance Procedures

4.2.1 To use X-ray system without troubles, periodic maintenance is the most effective method.

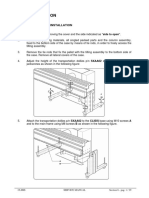

4.2.2 If X-ray system is out of order, contact local distributor or manufacturer ask service.

4.2.1 General cleaning

Never attempt to clean or handle any part of the X-Ray generator when it is turn on.

Switch off the generator main disconnect before cleaning or inspecting.

1. External surfaces cleaning

→ Clean external covers and surface frequently (without cloth).

→ If chemical is present on the surface, clean it quickly to protect rust.

→ Use dry clothe when cleaning the surface.

→ Do not use cleaners or solvents of any kind.

→ If external surface is scratched, touch up if need.

2. Internal generator cleaning

Keep the external protection cover in place all the time, only remove them to perform service

operations by qualified engineer.

(Rev. 2.1) 49 Operation & Service Manual

EcoRay HF-525 PLUS VET

4.3 Cable check

4.3.1 Check that all electrical connections are firm and secure and that all cable clamps and strain

relief are in place.

4.3.2 Also check that connectors do not have exposed wires and check cable Sheaths for wear and

fraying.

4.4 Console check

4.4.1 Check hand switch wiring condition.

4.4.2 Check correct operation of console switches, displays and indicators by performing the

following test:

1. Check console standby lamp lighting with yellow.

2. Push the “Power On” button of console and supply electric power to generator.

3. After system checking, changed normal mode to use or not.

4. Check all switches working condition.

5. Set over X-ray exposure value and check “Over Load” message display or not.

6. Check “Ready” and “X-Ray” switches working condition.

4.5 High voltage transformer check

4.5.1 Check oil leakage or not.

4.5.2 If oil leakage was found, have to check oil level with oil fill plug.

(Normal: within 15mm of the top surface of the transformer)

4.5.3 Put silicon oil to high voltage cable plug after cleaning with dry cloth.

4.5.4 Check arc evidence of high voltage cable plug and Receptacle Socket or not.

4.5.5 Check high voltage cable fixed tightly or not.

4.6 X-Ray Tube check

4.6.1 Check oil leakage or not from the X-ray tube.

4.6.2 If oil leakage was found, have to refill or exchange X-ray tube.

4.6.3 Put silicon oil to high voltage cable plug after cleaning with dry cloth.

4.6.4 Check arc evidence of high voltage cable plug and Receptacle Socket or not.

4.6.5 Check high voltage cable fixed tightly or not.

(Rev. 2.1) 50 Operation & Service Manual

EcoRay HF-525 PLUS VET

4.7 Periodic Maintenance check point

4.7.1 Make a periodic maintenance plan to use X-ray system safety and operator has a responsibility

about this.

4.7.2 Periodic maintenance must be done by qualified service engineer by manufacturer.

4.7.3 Periodic maintenance must be done after installation and must be inspected by authorized

inspection office per every 3 years.

1. Periodic Maintenance check point

Item Check Point Daily Monthly Annually

1. Check external surface condition (Damaged or Broken) ○

2. Check segment or LED display condition is normally or not. ○

3. Check cable condition. (Pressed or Twisted or Disconnected) ○

Appearance

4. Check hand switch working condition. ○