Professional Documents

Culture Documents

Tieu Chuan HACCP-HaLan Ver 1

Tieu Chuan HACCP-HaLan Ver 1

Uploaded by

thong ngovanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tieu Chuan HACCP-HaLan Ver 1

Tieu Chuan HACCP-HaLan Ver 1

Uploaded by

thong ngovanCopyright:

Available Formats

Caùc yeâu caàu cô baûn cuûa Heä thoáng HACCP

NHÖÕNG YEÂU CAÀU

CHO MOÄT

HEÄ THOÁNG AN TOAØN THÖÏC PHAÅM

DÖÏA VAØO HACCP

Bieân soaïn bôûi

National Board of Experts – HACCP

The Netherlands.

The Hague, the Netherlands: 3rd Version, September 2002

REQUIREMENTS

FOR A

HACCP BASED

FOOD SAFETY SYSTEM

Compiled by the

National Board of Experts – HACCP

The Netherlands.

The Hague, the Netherlands: 3rd Version, September 2002

D:/HACCP/dich – Tieu chuan HACCP Trang 1

Caùc yeâu caàu cô baûn cuûa Heä thoáng HACCP

Ñaây laø baûn dòch tieáng Anh ñöôc cho pheùp veà nhöõng yeâu caàu cuï theå “ Nhöõng yeâu caàu cho heä

thoáng an toaøn thöïc phaåm döïa vaøo HACCP” (phieân baûn thöù 3, 9/2002), moät trong ba taøi lieäu cho

pheùp caáp chöùng chæ cho hoaït ñoäng cuûa heä thoáng HACCP.

Hai loaïi taøi lieäu khaùc; “Nhöõng quy ñònh cuûa giaáy chöùng nhaän” vaø “ Nhöõng quy ñònh cuûa chuyeân

gia hoäi ñoàng quoác gia – HACCP” cuõng ñöôïc phaùt haønh bôûi Hoäi ñoàng quoác gia nhöõng chuyeân gia

– HACCP.

Chöùng chæ cho Heä thoáng an toaøn thöïc phaåm döïa vaøo HACCP ñöôïc duy trì bôûi Hoäi ñoàng quoác gia

nhöõng chuyeân gia – HACCP.

Chöùng chæ/ ñaêng kyù cuûa Heä thoáng an toaøn thöïc phaåm döïa vaøo HACCP caên cöù treân nhöõng

phieân baûn coù tröôùc cuûa yeâu caàu naøy ñöôïc chöùng nhaän bôûi Hoäi ñoàng chöùng nhaän Haø Lan

( RvA) töø naêm 1997.

This is the authorised English translation of the specification “Requirements for a HACCP based Food Safety

System” (3rd version, September 2002), being one of three documents which regulate the Certification Scheme

for Operational HACCP Systems.

The two other documents; the “Certification Regulations” and the “Regulations for the National Board of

Experts – HACCP” are also published by the National Board of Experts – HACCP.

The Certification Scheme for HACCP based Food Safety Systems is maintained by the National Board of

Experts - HACCP.

Certification/Registration of HACCP based Food Safety Systems on the basis of the preceding versions of this

specification has been accredited by the Dutch Accreditation Council (RvA) since 1997.

Copyright 2002 National Board of Experts - HACCP

Price: € 23,00 (excluding VAT).

All rights reserved. No part of this publication may be reproduced and/or published in any form, by means of

printed matters, photocopy, microfilm, recording or any other method or technology, without preceding written

approval by the National Board of Experts - HACCP.

National Board of Experts - HACCP,

Secretariat: P.O. Box 93202, 2509 AE, The Hague, the Netherlands.

Web site: foodsafetymanagement.info

e mail: info@foodsafetymanagement.info

CONTENTS

1 GIÔÙI THIEÄU 4

2 PHAÏM VI AÙP DUÏNG 7

D:/HACCP/dich – Tieu chuan HACCP Trang 2

Caùc yeâu caàu cô baûn cuûa Heä thoáng HACCP

3 NHÖÕNG TAØI LIEÄU THAM KHAÛO 8

4 THUAÄT NGÖÕ VAØ ÑÒNH NGHÓA 9

5 NHÖÕNG YEÂU CAÀU CUÛA HEÄ THOÁNG HACCP 12

5.1 Traùch nhieäm cuûa laõnh ñaïo 12

5.1.1 Chính saùch

5.1.2 Phaïm vi cuûa heä thoáng HACCP

5.1.3 Nhieäm vuï, Traùch nhieäm, Quyeàn haïn

5.1.4 Ñoäi HACCP

5.1.5 Nguoàn löïc

5.1.6 Xem xeùt cuûa laõnh ñaïo

5.2 Thoâng tin saûn phaåm 14

5.2.1 Nhöõng ñaëc tính saûn phaåm

5.2.2 Muïc ñích söû duïng

5.3 Thoâng tin quaù trình 15

5.3.1 Sô ñoà daây chuyeàn saûn phaåm

5.3.2 Maët baèng thieát bò

5.3.3 Kieåm soaùt vaø xaùc nhaän thoâng tin quaù trình

5.4 Chöông trình tieân quyeát 16

5.5 Phaân tích moái nguy 17

5.5.1 Xaùc ñònh moái nguy

5.5.2 Phaân tích HACCP (ruûi ro )

5.6 Phöông phaùp kieåm soaùt 19

5.6.1 Phöông phaùp kieåm soaùt ñaëc bieät

5.6.2 Phöông phaùp kieåm saùot chung

5.7 Thoâng soá vaø giôùi haïn tôùi haïn 20

5.7.1 Quaù trình tôùi haïn vaø thoâng soá saûn phaåm

5.7.2 Giaù trò chæ tieâu, giaù trò hoaït ñoäng tôùi haïn vaø giôùi haïn tôùi haïn

5.8 Giaùm saùt vaø ño löôøng 21

5.9 Haønh ñoäng söõa chöõa 22

5.10 Xaùc nhaän giaù trò söû duïng 23

5.11 Thaåm tra xaùc nhaän 24

5.12 Taøi lieäu vaø hoà sô 26

5.12.1 Taøi lieäu vaø kieåm soaùt taøi lieäu

5.12.2 Hoà sô

6 Phuï luïc 1: Chöông trình tieân quyeát (PRP) 28

7 Phuï luïc II: Moái quan heä giöõa “nhöõng yeâu caàu” 36

vaø nhöõng höôùng daãn cuûa CODEX cho aùp duïng HACCP

D:/HACCP/dich – Tieu chuan HACCP Trang 3

Caùc yeâu caàu cô baûn cuûa Heä thoáng HACCP

CONTENTS

1 INTRODUCTION 4

2 SCOPE of APPLICATION 7

3 REFERENCE DOCUMENTS 8

4 TERMS and DEFINITIONS 9

5 HACCP SYSTEM REQUIREMENTS 12

5.1 Management responsibility 12

5.1.1 Policy

5.1.2 Scope of the HACCP system

5.1.3 Task, Responsibilities, Authorities

5.1.4 HACCP team(s)

5.1.5 Resources

5.1.6 Management review

5.2 Product Information 14

5.2.1 Product characteristics

5.2.2 Intended use

5.3 Process Information 15

5.3.1 Flow Diagrams

5.3.2 Layout

5.3.3 Control and Verification of Process Information

5.4 Pre-Requisite Program (PRP) 16

5.5 Hazard Analysis 17

5.5.1 Hazard identification

5.5.2 HACCP analysis (risk)

5.6 Control Measures 19

5.6.1 Specific Control Measures

5.6.2 General Control Measures

5.7 Parameters and Critical Limits 20

5.7.1 Critical process and product parameters

5.7.2 Target values, action-limit values and critical limits

5.8 Monitoring and Measuring 21

5.9 Corrective actions 22

5.10 Validation 23

5.11 Verification 24

5.12 Documentation and records 26

5.12.1 Documents and document control

5.12.2 Records

6 ANNEX I: PRE-REQUISITE PROGRAM (PRP) 28

7 ANNEX II: RELATIONSHIP BETWEEN THE “REQUIREMENTS” 36

AND CODEX GUIDELINES FOR THE APPLICATION OF HACCP

1 GIÔÙI THIEÄU

Nhöõng taøi lieäu tham khaûo ; luaät ñònh ; thoâng tin neàn taûng

An toaøn thöïc phaåm laø moái quan taâm cuûa toaøn caàu. Khoâng chæ bôûi vì quan troïng cho söùc khoeû

coäng ñoàng, maø coøn bôûi vì aûnh höôûng cuûa noù ñeán thöông maïi quoác teá. Hieäu quaû cuûa Heä

D:/HACCP/dich – Tieu chuan HACCP Trang 4

Caùc yeâu caàu cô baûn cuûa Heä thoáng HACCP

thoáng an toaøn thöïc phaåm tröôùc heát phaûi quaûn lyù vaø ñaûm baûo söï an toaøn vaø phuø hôïp cuûa thöïc

phaåm.

ÔÛ nhieàu quoác gia treân theá giôùi, luaät ñònh veà an toaøn vaø phuø hôïp cuûa thöïc phaåm yeâu caàu

“HACCP” phaûi coù duø cho doanh nghieäp hay toå chöùc thöïc phaåm, duø cho coù lôïi nhuaän hay khoâng

vaø laø xaû hoäi hay caù nhaân, tieán haønh baát kyø hay taát caû caùc haønh ñoäng sau : sô cheà, cheá bieán,

saûn xuaát, ñoùng goùi, toàn tröõ, vaän chuyeån, phaân phoái, xöû lyù hay baùn hoaëc cung caáp thöïc phaåm.

Theo chæ thò EU 93/43/EEC veà Veä sinh thöïc phaåm cuûa hoaït ñoäng kinh doanh thöïc phaåm trong Lieân

ñoaøn Chaâu Aâu phaûi thöïc hieän HACCP1. Hoï phaûi baûo ñaûm raèng ñaày ñuû caùc qui trình an toaøn

ñöôïc xaùc ñònh, vaên baûn hoaù, duy trì vaø xem xeùt laïi nhöõng vaán ñeà chính cô baûn thöôøng söû duïng

ñeå phaùt trieån heä thoáng HACCP (“Phaân tích moái nguy vaø ñieåm kieåm soaùt tôùi haïn “)

Hoäi ñoàng Joint FAO/WHO Codex Alimentarius moâ taû moät loaït caùc böôùc, bao goàm 7 böôùc chính cho

höôùng daãn aùp duïng heä thoáng HACCP 2.

Codex cuõng khuyeân raèng ño löôøng veä sinh toái thieåu cuõng ñöôïc ñaët ra tröôùc khi HACCP ñöôïc thöïc

hieän : ”Tröôùc khi aùp duïng HACCP cho baát cöù phaàn naøo trong daây chuyeàn thöïc phaåm, phaàn ñoù

phaûi ñöôïc hoaït ñoäng döïa vaøo Codex General Principles of Food Hygiene, neáu thích hôïp Codex Codes

of Practice, and thích hôïp luaät ñònh an toaøn thöïc phaåm.”

Nhöõng chöông trình tieân quyeát phaûi ñöôïc cuï theå vaø vaên baûn hoaù, hoaït ñoäng ñaày ñuû vaø thaåm tra

xaùc nhaän ñeå deã daøng aùp duïng thaønh coâng vaø thöïc hieän HACCP. General Principles of Food

Hygiene 3, ñöôïc ñeà nghò bôûi Codex, hình thaønh moät phaàn beân trong cuûa taøi lieäu naøy “Nhöõng yeâu

caàu cho heä thoáng an toaøn thöïc phaåm döïa vaøo HACCP”.

Nhöõng yeâu caàu an toaøn thöïc phaåm ñaëc bieät ñöôïc neâu chi tieát trong luaät ñònh, caùc quy taéc veä

sinh, yeâu caàu cuûa khaùch haøng hay ngöôøi tieâu thuï. ÔÛ ñaâu maø nhöõng yeâu caàu ñaëc bieät khoâng

toàn taïi, General Principles on Food Hygiene seõ ñöôïc aùp duïng (xem Phuï luïc I). Theâm nöõa, 7 nguyeân

taéc vaø höôùng daãn aùp duïng cuûa HACCP keát hôïp vôùi nhöõng yeáu toá cô baûn trong heä thoáng quaûn

lyù chaát löôïng (ISO 9000) ñeå thieá laäp Nhöõng yeâu caàu cho Heä thoáng an toaøn thöïc phaåm döïa vaøo

HACCP.

Nhöõng taøi lieäu tham khaûo ñöôïc trình baøy trong “Nhöõng yeâu caàu” ñöôïc chæ roõ trong chöông 3.

“Nhöõng yeâu caàu” ñöôïc taäp trung chính vaøo haønh ñoäng vaø hoaït ñoäng ñeå ñaûm baûo an toaøn thöïc

phaåm. Söï ñaûm baûo thuïc phaåm thích hôïp ñöôïc quan taâm nhö laø moät phaàn baét buoäc cuûa heä thoáng

quaûn lyù chaát löôïng, tröø khi söï leäch höôùng coù theå daãn ñeán thuïc phaåm khoâng an toaøn.

Söï caàn thieát cho tieâu chuaån hay yeâu caàu

“Nhöõng yeâu caàu cho Heä thoáng an toaøn thöïc phaåm döïa vaøo HACCP” phaùt trieån bôûi vaø thay theá

döôùi traùch nhieäm cuûa Hoäi ñoàng quoác gia chuyeân gia – HACCP ñeå laøm taøi lieäu/ tieâu chuaån

chuaån. Taát caûboä phaän lieân quan ñeá daây chuyeàn caùc boä phaän ñöôïc ñaïi dieän Hoäi ñoàng quoác gia

chuyeân gia- HACCP.

Nhöõng yeâu caàu ñöôïc söû duïng bôûi boä phaän chöùng nhaän ñeå ñaùnh giaù söï phuø hôïp lieân tuïc cuûa

HACCP- heä thoáng an toaøn thöïc phaåm ñöôïc phaùt trieån vaø thöïc hieän bôûi toå chöùc kinh doanh thöïc

phaåm.

Dó nhieân laø caùc toå chöùc hoaït ñoäng kinh doanh coù theå söû duïng “Nhöõng yeâu caàu” ñeå phaùt trieån

HACCP cuûa hoï – Heä thoáng an toaøn thöïc phaåm.

Chöùng chæ/ Ñaêng kyù HACCP – Heä thoáng an toaøn thöïc phaåm ñöôïc xaùc nhaän laø phöông tieän xaùc

nhaän hình thöùc (moät chöùng chæ) vaø/hoaëc baèng chöùng, thoâng baùo ñöôïc cung caáp vôùi xaùc nhaän

1

EU Directive 93/43/EEC on the Hygiene of Foodstuffs, dated 14 June 1993 (PbEC L175).

2

Codex Alimentarius Commission, “Hazard Analysis and Critical Control Point (HACCP) System and

Guidelines for its Application”, Annex to CAC/RCP 1-1969, Rev. 3 (1997).

3

Codex Alimentarius Commission, “General Principles of Food Hygiene, CAC/RCP 1-1969, Rev. 3

(1997), amended 1999.

D:/HACCP/dich – Tieu chuan HACCP Trang 5

Caùc yeâu caàu cô baûn cuûa Heä thoáng HACCP

raèng moät saûn phaåm hay dòch vuï phuø hôïp vôùi tieâu chuaån hay yeâu caàu kyõ thuaät ñaõ ñöôïc ñònh

tröôùc. Ñieàu naøy bao goàm khaû naêng cuûa coâng ty ñeå duy trì söï phuø hôïp vôùi tieâu chuaån hoaëc yeâu

caàu.

Ñeå phaùt haønh moät baèng chöùng nhaän HACCP – Heä thoáng an toaøn thöïc phaåm cuûa moät toå chöùc

kinh doanh thöïc phaåm caàn thieát phaûi ñaùnh giaù. Vieäc ñaùnh giaù chöùng nhaän vaø giaùm saùt laïi ñeå

ñaùnh giaù hieäu quaû thöïc hieän bôûi Boä phaän chöùng nhaän laø moät cô quan ñoäc laäp (coù theå laø cuûa

chính phuû hoaëc khoâng) coù traùch nhieäm cuõng nhö laø söï tin töôûng ñeå toå chöùc heä thoáng chöùng

nhaän vôùi taàm quan troïng cuûa taát caû boä phaän lieân quan ñöôïc laø ñaïi dieän.

Ñoái vôùi söï tin töôûng cuûa Boä phaän chöùng nhaän phaûi söû duïng “Nhöõng yeâu caàu” vaø “Quy ñònh

chöùng nhaän” trong chuaån möïc thoáng nhaát. “Nhöõng yeâu caàu” ñöôïc vaên baûn hoaù baèng caùch cho

pheùp caùc ñaùnh giaù hieäu quaû veà tình traïng vaø thöïc hieän HACCP - Heä thoáng an toaøn thöïc phaåm,

cuõng nhö ñöôïc thöïc hieän bôûi toå chöùc kinh doanh thöïc phaåm. Trong “Quy ñònh chöùng nhaän”, tieâu

chuaån ñaëc bieät ñöôïc phaùt bieåu phaûi ñöôïc ñaùp öùng bôûi Boä phaän chöùng nhaän khi löïa choïn moät

ñoäi coù thaåm quyeàn ñaùnh giaù HACCP, vaø nhöõng luaät leä cuûa chính phuû trong quaù trình ñaùnh giaù

chöùng nhaän ñöôïc thieát keá vaø ñeà nghò (VD: thôøi gian ñaùnh giaù toái thieåu) phaûi ñöôïc thöïc hieän

theo.

Quyeàn haïn ñaït ñöôïc khi Boä phaän chöùng nhaän laø ñaïi dieän chính thöùc ñöôïc thöøa nhaän bôûi Boä

phaän coâng nhaän toå chöùc heä thoáng chöùng nhaän cho HACCP - Heä thoáng an toaøn thöïc phaåm vaø

ñöôïc ñaùnh giaù thöôøng xuyeân bôûi Boä phaän ñöôïc coâng nhaän naøy. Söï coâng nhaän quan taâm veà söï

tin caäy vaø thaåm quyeàn cuûa Boä phaän caáp chöùng nhaän.

Noù phaûi ñöôïc hieåu raèng chöùng chæ HACCP – Heä thoáng an toaøn thöïc phaåm thì khoâng phaûi laø

baûo ñaûm cho suï thöïc hieän an toaøn thöïc phaåm lieân tuïc cuûa toå chöùc kinh doanh thöïc phaåm. Giaù trò

gia taêng cho toå chöùc kinh doanh thöïc phaåm vôùi chöùng chæ HACCP - Heä thoáng an toaøn thöïc phaåm

naèm trong nhöõng noã löïc taïo ra bôûi hoaït ñoäng cuûa coâng ty ñeå duy trì heâ thoáng HACCP vaø nhöõng

can keát cuûa hoï ñeå caûi tieán lieân tuïc vieäc thöïc hieän an toaøn thöïc phaåm.

Nhöõng yeâu caàu cho Heä thoáng an toaøn thöïc phaåm döïa vaøo HACCP

Nhöõng yeâu caàu trong tieâu chuaån naøy cung caáp moät caùch cô baûn veà söï phuø hôïp cuûa HACCP -

Heä thoáng an toaøn thöïc phaåm vôùi nhöõng luaät ñònh quoác teá vaø caùc quy taéc thöïc haønh. Chuùng

bao goàm nhöõng yeâu caàu caàn thieát cuûa heä thoáng quaûn lyù. Caáu truùc, söï phoái hôïp vaø moái töông

giao cuûa quaù trình ñaùnh giaù ñöôc moâ taû chi tieát trong hình 1.

Trong moâ taû cuûa moãi ñieàu khoaûn, phaïm vi cuûa nhöõng yeâu caàu ñöôïc neâu chi tieát. Söû duïng

nhöõng ñieàu khoaûn, ñoäi ñaùnh giaù chöùng nhaän xem xeùt caùc taøi lieäu HACCP - Heä thoáng an toaøn

thöïc phaåm cuõng nhö laø caùc haønh ñoäng thöïc hieän hay caùc hoaït ñoäng cuûa heä thoáng treân sô ñoà

maët baèng.

“Nhöõng yeâu caàu” baét ñaàu xaây döïng moät loaït caùc yeâu caàu chung. Moät hoaït ñoäng cuûa HACCP -

Heä thoáng an toaøn thöïc phaåm phaûi laø, möùc toái thieåu, trong söï phuø hôïp vôùi nhöõng yeâu caàu naøy.

Trong phuï luïc II cuûa nhöõng taøi lieäu naøy moãi moät tieâu ñeà hay ñoaïn vaên baûn cuûa “nhöõng yeâu

caàu” daãn tôùi ñoaïn vaên tieáp theo trong taøi lieäu höôùng daãn HACCP cuûa Codex Alimentarius 4.

Figure 1. Caáu truùc cuûa HACCP – Heä thoáng an toaøn thöïc phaåm

4

Codex Alimentarius Commission, “Hazard Analysis and Critical Control Point (HACCP) System and

Guidelines for its Application”, Annex to CAC/RCP 1-1969, Rev. 3 (1997).

D:/HACCP/dich – Tieu chuan HACCP Trang 6

Caùc yeâu caàu cô baûn cuûa Heä thoáng HACCP

5.11 Thaåm tra xaùc nhaän

5.1 Traùch nhieäm 5.2 5.6.1 Phöông phaùp kieåm soaùt ñaëc bieät lieân quan ñeán

cuûa laõnh ñaïo Saûn phaåm caùc CCP

5.7 5.8 5.9

5.5 Phaân tích moái Giôùi haïn tôùi Giaùm saùt Haønh ñoäng 5.10

5.3 nguy haïn söõa chöõa Xaùc nhaän giaù

Quaù trình trò söû duïng

5.4 5.6.2 Phöông phaùp kieåm soaùt chung

PRP

Phuï luïc 1

5.12 Taøi lieäu vaø Hoà sô

Ñeå laøm cho heä thoáng roõ raøng vaø coù theå ñaùnh giaù, toå chöùc kinh doanh thöïc phaåm phaûi cung

caáp thoâng tin nhö chæ daãn trong “Nhöõng yeâu caàu”. Cho moãi ñieàu kieän ñaëc bieät (saûn phaåm/ nhoùm

saûn phaåm/ quaù trình/ boä phaän), nhöõng yeâu caàu ñaëc bieät phaûi neâu chi tieát bôûi toå chöùc kinh

doanh thöïc phaåm. Ñoäi ñaùnh giaù chöùng nhaän phaûi ñaùnh giaù hoaøn toaøn heä thoáng chung vaø

nhöõng yeâu caàu ñaëc bieät cuûa coâng ty.

Baûn dòch thöù nhaát cuûa “Nhöõng yeâu caàu” (coøn goïi laø “Tieâu chuaån”) ñöôïc phaùt trieån trong hoaït

ñoäng phuï vôùi moät vaøi Boä phaän chöùng nhaän ôû Haø Lan trong lónh vöïc nguyeân lieäu thöïc phaåm vaø

cheá bieán, döôùi traùch nhieäm vaø quyeàn haïn cuûa Hoäi ñoàng quoác gia caùc chuyeân gia – HACCP. Baûn

dòch thöù nhaát ñöôïc xuaát baûn vaøo 15/5/1996.

Döïa vaøo nhöõng boå sung cuûa Codex Alimentarius (Alinorm 97/13A, Appendix II) trong 1997, moät baûn

söûa laïi Nhöõng yeâu caàu trôû neân caàn thieát. Hoäi ñoàng quoác gia caùc chuyeân gia – HACCP cuõng coù

theå döïa vaøo nhöõng kinh nghieäm cuûa hoï ñeå caûi tieán chaát löôïng cuûa “Nhöõng yeâu caàu”.Phieân

baûn thöù hai cuûa “Nhöõng yeâu caàu” ñöôïc xuaát baûn vaøo 9/1998 vaø dòch sang tieáng Anh vaøo 2/1999.

Nhöõng söï phaùt trieån gaàn ñaây vôùi chi tieát cuï theå cho HACCP – Heä thoáng an toaøn thöïc phaåm vaø

phaùt trieån vôùi Codex, cuõng nhö laø nhöõng ñeà xuaát cho Quy ñònh veä sinh thöïc phaåm (coù lieân quan

tôùi huyû boû tham khaûo hieän taïi cuûa Quy ñònh vaø Chæ thò cuûa EU), caàn phaûi coù baûn söûa theâm :

baûn dòch thöù ba.

1 INTRODUCTION

Reference documents; legislation; background information

Food safety is a global concern. Not only because of the continuing importance for public health, but also

because of its impact on international trade. Effective Food Safety Systems shall therefore manage and ensure

the safety and suitability of foodstuffs.

D:/HACCP/dich – Tieu chuan HACCP Trang 7

Caùc yeâu caàu cô baûn cuûa Heä thoáng HACCP

In many countries world-wide, legislation on the safety and suitability of foodstuffs requires “HACCP” to be

put in place by any food business or organisation, whether profit-making or not and whether public or private,

carrying out any or all of the following activities: preparation, processing, manufacturing, packaging, storage,

transportation, distribution, handling or offering for sale or supply of foodstuffs. According to EU Directive

93/43/EEC on Food Hygiene all food business operators in the European Union shall implement HACCP 5.

They shall ensure that adequate safety procedures are identified, documented, maintained and reviewed on the

basis of the principles used to develop the system of HACCP (“Hazard Analysis and Critical Control Point”).

The Joint FAO/WHO Codex Alimentarius Commission describes a series of steps, including the 7 HACCP

6

principles giving guidance for the application of the HACCP system .

Also, Codex advises that minimum hygiene measures should be in place before HACCP is implemented: ”Prior

to application of HACCP to any sector of the food chain, that sector should be operating according to the

Codex General Principles of Food Hygiene, the appropriate Codex Codes of Practice, and appropriate food

safety legislation.”

These prerequisite programs should be well specified and documented, fully operational and verified in order to

facilitate the successful application and implementation of HACCP. The General Principles of Food Hygiene 7,

as recommended by Codex, form an intrinsic part of this document “Requirements for a HACCP based Food

Safety System”.

Specific food safety requirements are detailed in legislation, hygiene codes, customer or consumer

specifications. Where specific requirements do not exist, the General Principles on Food Hygiene will be

applied (see Annex I). Furthermore, the 7 principles and the guidelines for the application of HACCP have been

combined with basic elements of quality management systems (ISO 9000) to establish the Requirements for a

HACCP based Food Safety System.

The reference documents used to formulate the “Requirements” have been specified in Chapter 3.

The “Requirements” are primarily focused on actions and activities to ensure food safety. The assurance of

food suitability is considered to be an obligatory part of a quality management system, unless deviations may

lead to unsafe foodstuffs.

The need for a Standard or Specification

The specification “Requirements for a HACCP based Food Safety System” has been developed by and placed

under the authority of the National Board of Experts – HACCP in order to make a normative

document/standard available. All parties involved in the food chain are represented on the National Board of

Expert - HACCP.

The specification can be used by Certification Bodies to assess the continuous compliance of HACCP-based

Food Safety Systems as developed and implemented by food business operators.

Of course, a food business operator may also use the “Requirements” to develop its HACCP-based Food Safety

System.

Certification/Registration of HACCP-based Food Safety Systems signifies that by means of a

formal statement (a certificate) and/or mark, notice is given with justified confidence that a

product or a service is in conformance with a pre-defined standard or (technical)

specification. This includes the ability of the company to maintain conformance with the

standards or specifications.

5

EU Directive 93/43/EEC on the Hygiene of Foodstuffs, dated 14 June 1993 (PbEC L175).

6

Codex Alimentarius Commission, “Hazard Analysis and Critical Control Point (HACCP) System and

Guidelines for its Application”, Annex to CAC/RCP 1-1969, Rev. 3 (1997).

7

Codex Alimentarius Commission, “General Principles of Food Hygiene, CAC/RCP 1-1969, Rev. 3

(1997), amended 1999.

D:/HACCP/dich – Tieu chuan HACCP Trang 8

Caùc yeâu caàu cô baûn cuûa Heä thoáng HACCP

In order to issue such a formal statement, the HACCP-based Food Safety System of a food

business operator needs to be assessed. Certification and repetitive surveillance audits are to

be effectively performed by a Certifying Body which is an independent institution (whether or

not governmental) that has both the authority as well as the confidence to operate a

certification system within which the interests of all involved parties are represented.

For confidence the Certifying Body must use the published “Requirements” and the “Certification Regulations”

in an agreed manner. The “Requirements” are documented in such a way to allow an effective assessment of

the status and performance of the HACCP-based Food Safety System, as implemented by the food business

operator. In the “Certification Regulations”, specific criteria are stated which have to be met by the Certifying

Body when selecting a competent HACCP audit team, and rules which govern the way the certification process

is designed and offered (e.g. the minimum auditor time) have to be followed.

Authority is obtained when the Certifying Body is formally accredited by a recognised Body to operate the

certification system for HACCP based Food Safety Systems 8 and is audited regularly by this Accreditation

Body. Accreditation concerns the reliability and competence of the Certifying Body.

It must be understood that certification of a HACCP-based Food Safety System is not a guarantee of a food

business operator’s continuous food safety performance. The value added to a food business operator with a

certified HACCP-based Food Safety System lies in the efforts made by the operating company to maintain that

HACCP system and its commitment to continuously improve its food safety performance.

Requirements for a HACCP based Food Safety System

The requirements in this Specification provide a basis for compliance of a HACCP-based Food Safety System

with (inter)national legislation and codes of practice. They include the necessary management system

requirements. The structure, the sequence and interaction of the assessment process is detailed in Figure 1.

In the description of every clause, the scope of the requirements are detailed. Using these clauses, the audit

team assesses the documented HACCP-based Food Safety System as well as the implementation and operation

of the system on the 'shop floor'.

The “Requirements” lay down a generic set of requirements. An operational HACCP-based Food Safety System

shall be, as a minimum, in compliance with these Requirements. In Annex II of this document each heading or

paragraph of the “Requirements” refers to the corresponding text in the HACCP guidance document of Codex

Alimentarius 9.

Figure 1. The structure of a HACCP-based Food Safety System

5.11 Verification

5.1 Management 5.2 5.6.1 Specific Control Measures

responsibility Products related to CCP’s

8

The certification bodies must meet “General requirements for bodies operating assessment and

certification / registration of quality systems”, ISO/IEC Guide 62:1996 (ISO 45012) and

the Standards for auditing (ISO 10011, Part 1 and 2).

9

Codex Alimentarius Commission, “Hazard Analysis and Critical Control Point (HACCP) System and

Guidelines for its Application”, Annex to CAC/RCP 1-1969, Rev. 3 (1997).

D:/HACCP/dich – Tieu chuan HACCP Trang 9

Caùc yeâu caàu cô baûn cuûa Heä thoáng HACCP

5.7 5.8 Monitoring 5.9 Corrective

5.5 Hazard Critical limits actions 5.10

5.4 Analysis Validation

Processes

5.4 5.6.2 General Control Measures

PRP

Annex 1

5.12 Documentation and Registration

In order to make the system transparent and enable assessment, the food business operator shall provide

information as indicated in these “Requirements”. For each specific condition (product / product group /

process / sector), specific requirements shall be detailed by the food business operator. The audit team shall

assess this complete system of generic and company specific requirements.

The first version of these “Requirements” (then called “Criteria”) has been developed in co-operation with

several Certification Bodies in the Netherlands in the area of food materials and processing, under the authority

and responsibility of the National Board of Experts - HACCP. The 1st version was published on May 15, 1996.

Due to the modification of the Codex Alimentarius (Alinorm 97/13A, Appendix II) in 1997, a revision of the

Requirements became necessary. The National Board of Experts - HACCP was also able to draw on their

experience in order to improve the quality of the “Requirements”. The 2 nd version of the “Requirements” was

published in September 1998 and translated into English in February 1999.

Recent developments with respect to HACCP-based Food Safety System and developments within Codex, as

well as new proposals for Food Hygiene Regulations (thereby repealing the current referenced EU Directives

and Regulations), have necessitated a further revision: this 3rd version!

D:/HACCP/dich – Tieu chuan HACCP Trang 10

Caùc yeâu caàu cô baûn cuûa Heä thoáng HACCP

2 Phaïm vi aùp duïng

Trong taøi lieäu naøy, nhöõng yeâu caàu phaûi cuï theå ñöôïc söû duïng trong suoát quaù trình ñaùnh giaù cuûa

hoaït ñoäng heä thoáng HACCP ñeå baûo ñaûm an toaøn cuûa thöïc phaåm trong suoát quaù trình sô cheá, cheá

bieán, saûn xuaát, ñoùng goùi, toàn tröõ, vaän chuyeån, phaân phoái, xöû lyù hoaëc baùn hay cung caáp trong

baát cöù boä phaän naøo cuûa daây chuyeàn thöïc phaåm.

“Nhöõng yeâu caàu” ñöôïc aùp duïng cô baûn ñoái vôùi taát caû doanh nghieäp hay toå chöùc thöïc phaåm, keå

caû taïo ra lôïi nhuaän hay khoâng, keå caû nhaø nöôùc hay caù nhaân.

Thaät söï, toå chöùc kinh doanh thöïc phaåm phaûi xaùc ñònh baát kyø böôùc naøo trong hoaït ñoäng cuûa hoï

laø tôùi haïn ñeå baûo ñaûm an toaøn thöïc phaåm vaø phaûi phaùt trieån, thöïc hieän, duy trì vaø xem xeùt laïi

ñaày ñuû thuû tuïc an toaøn, aùp duïng caùc nguyeân taéc cuûa HACCP, bao goàm nhöõng nguyeân taéc chung

cuûa veä sinh thöïc phaåm, vaø neáu thích hôïp nhöõng quy taéc thöïc haønh vaø luaät ñònh an toaøn thöïc

phaåm coù lieân quan.

“ Nhöõng yeâu caàu” thì khoâng döï ñònh aùp duïng cho nhaø cung caáp vaø/ hoaëc coâng ty dòch vuï kinh

doanh thöïc phaåm, gioáng nhö nhaø cung caáp bao bì, thieát bò phuïc vuï thöïc phaåm, dòch vuï laøm saïch

coâng nghieäp…

2 SCOPE of APPLICATION

In this document, requirements have been specified to be used during the assessment of operational HACCP

systems (HACCP-based Food Safety Systems) which ensure the safety of foodstuffs during preparation,

processing, manufacturing, packaging, storage, transportation, distribution, handling or offering for sale or

supply in any sector of the food chain.

The “Requirements” are basically applicable to all food businesses or organisations, whether profit-making or

not, and whether public or private.

Obviously, the food business operators shall have identified any step in their activities which is critical to

ensure food safety and shall have developed, implemented, maintained and reviewed adequate safety

procedures, applying the principles of HACCP, including the general principles of food hygiene, and where

appropriate the relevant codes of practice and the food safety legislation.

These “Requirements” are not intended for application by suppliers and / or service companies to food

businesses, like suppliers of packaging, food equipment, industrial cleaning services, etc..

D:/HACCP/dich – Tieu chuan HACCP Trang 11

Caùc yeâu caàu cô baûn cuûa Heä thoáng HACCP

3 Nhöõng taøi lieäu tham khaûo

“ Nhöõng yeâu caàu cho heä thoáng an toaøn thöïc phaåm döïa vaøo HACCP” döïa vaøo nhöõng taøi lieäu tham

khaûo döôùi ñaây :

1

Theá giôùi :

Joint FAO/WHO Codex Alimentarius Commission,

- General Principles of Food Hygiene, CAC/RCP 1-1969, Rev. 3 (1997), amended 1999.

- Hazard Analysis and Critical Control Point (HACCP) System and Guidelines for its Application,

Annex to CAC/RCP 1-1969, Rev. 3 (1997).

2

Caáp quoác teá :

European Union

2a. General Food law

Regulation (EC) no 178/2002, laying down the general principles and requirements of food

law, establishing the European Food Safety Authority and laying down procedures in matters

of food safety, dated 28 January 2002.

2b

Council Directive 93/43/EEC on the Hygiene of Foodstuffs, dated 14 June 1993 (PbEC L175);

Specific legislation and regulations concerning food safety and hygiene have been laid down in Council

Directives such as 64/433/EEC for fresh meat, 71/118/EEC for poultry meat, 89/437/EEC for egg products,

92/46/EEC for dairy products, 92/5/EEC for meat products, 91/493/EEC for fishery products, 94/65/EEC for

minced meat, etc..

2c

Documents under 2b will be repealed by:

Proposal for a Regulation of the European Parliament and of the Council on the hygiene of foodstuffs,

COM/2000/0438 final, 14 July 2000 (COD 2000/0178), and others.

3

Caáp quoác gia :

Netherlands, Food and Commodity Act:

Warenwetregeling Hygiëne van Levensmiddelen, 12 december 1994 (DGVgz/VVP/L 942587).

4

Neáu thích hôïp :

Numerous (International, a/o. Codex) Codes of Practice, Food Commodity Standards and (national) Hygiene

Codes (generic HACCP / hygiene plans).

3 REFERENCE DOCUMENTS

The “Requirements for a HACCP-based Food Safety System” are based on the following reference documents:

1

World-wide:

Joint FAO/WHO Codex Alimentarius Commission,

- General Principles of Food Hygiene, CAC/RCP 1-1969, Rev. 3 (1997), amended 1999.

- Hazard Analysis and Critical Control Point (HACCP) System and Guidelines for its Application,

Annex to CAC/RCP 1-1969, Rev. 3 (1997).

D:/HACCP/dich – Tieu chuan HACCP Trang 12

Caùc yeâu caàu cô baûn cuûa Heä thoáng HACCP

2

International level:

European Union

2a. General Food law

Regulation (EC) no 178/2002, laying down the general principles and requirements of food

law, establishing the European Food Safety Authority and laying down procedures in matters

of food safety, dated 28 January 2002.

2b

Council Directive 93/43/EEC on the Hygiene of Foodstuffs, dated 14 June 1993 (PbEC L175);

Specific legislation and regulations concerning food safety and hygiene have been laid down in Council

Directives such as 64/433/EEC for fresh meat, 71/118/EEC for poultry meat, 89/437/EEC for egg products,

92/46/EEC for dairy products, 92/5/EEC for meat products, 91/493/EEC for fishery products, 94/65/EEC for

minced meat, etc..

2c

Documents under 2b will be repealed by:

Proposal for a Regulation of the European Parliament and of the Council on the hygiene of foodstuffs,

COM/2000/0438 final, 14 July 2000 (COD 2000/0178), and others.

3

National level:

Netherlands, Food and Commodity Act:

Warenwetregeling Hygiëne van Levensmiddelen, 12 december 1994 (DGVgz/VVP/L 942587).

4

Where appropriate:

Numerous (International, a/o. Codex) Codes of Practice, Food Commodity Standards and (national) Hygiene

Codes (generic HACCP / hygiene plans).

D:/HACCP/dich – Tieu chuan HACCP Trang 13

Caùc yeâu caàu cô baûn cuûa Heä thoáng HACCP

4 Thuaät ngöõ vaø ñònh nghóa

Chæ soá hoaït ñoäng tôùi haïn : Moät giaù trò cho saûn phaåm hay thoâng soá quaù trình quan taâm, ngoaïi

tröø giaù trò giôùi haïn tôùi haïn, chæ ra raèng söï can thieäp trong quaù trình yeâu caàu.

Khía caïnh: Moät yeáu toá cho hoaït ñoäng kinh doanh thöïc phaåm (saûn phaåm, quaù trình, PRP, dòch vuï)

maø coù lieân quan tôùi an toaøn thöïc phaåm.

Chöùng nhaän: Haønh ñoäng cuûa beân thöù ba tuyeân boá raèng coù ñuû ñieàu kieän ñeå xaùc ñònh ñuùng

saûn phaåm, quaù trình hay dòch vuï phuø hôïp vôùi moät tieâu chuaån cuï theå hay taøi lieäu chuaån naøo

khaùc.

Kieåm soaùt (ñoäng töø) : Tieán haønh taát caû nhöõng hoaït ñoäng ñeå ñaûm baûo vaø duy trì söï tuaân thuû

caùc chæ tieâu ñeà ra trong keá hoaïch HACCP.

Söï kieåm soaùt (danh töø) : Traïng thaùi khi caùc thuû tuïc tieán haønh ñuùng ñöôïc tuaân thuû vaø caùc tieâu

chí caàn ñaït ñöôïc.

Bieän phaùp kieåm soaùt : Baát cöù haønh vi vaø hoaït ñoäng naøo ñöôïc duøng ñeå ngaên ngöøa hay loaïi

tröø moät moái nguy ñoái vôùi an toaøn thöïc phaåm, hoaëc giaûm noù xuoáng moät nöùc chaáp nhaän ñöôïc.

Bieän phaùp kieåm soaùt, chung: Moät bieän phaùp kieåm soaùt cuï theå moät phaàn cuûa PRP.

Bieän phaùp kieåm soaùt, cuï theå: Moät bieän phaùp kieåm soaùt taïi CCP.

Haønh ñoäng khaéc phuïc : Baát cöù hoaït ñoäng naøo caàn laøm khi caùc keát quaû giaùm saùt ôû ñieåm

kieåm soaùt tôùi haïn (CCP) cho thaáy ñaõ bò maát kieåm soaùt.

Ñieåm kieåm soaùt tôùi haïn (CCP) : ñieåm taïi ñoù coù theå aùp duïng kieåm soaùt, vaø coù yù nghóa quan

troïng ñeå ngaên ngöøa hay loaïi tröø moät moái nguy cho an toaøn thöïc phaåm hoaëc giaûm noù xuoáng moät

möùc chaáp nhaän ñöôïc.

Giaù tri tôùi haïn : Moät tieâu chí phaân giôùi haïn giöõa phaïm vi chaáp nhaän ñöôïc vaø khoâng chaáp nhaän

ñöôïc.

Chuù yù: Tieâu chuaån naøy ñònh nghóa ngöôõng tôùi haïn cho saûn phaåm hay thoâng soá quaù trình maø

caàn quan taâm cho vieäc giaùm saùt (xem giaù trò hoaït ñoäng tôùi haïn vaø giaù trò muïc tieâu).

Sô ñoà quy trình saûn xuaát : Caùch trình baøy coù heä thoáng trình töï caùc böôùc hay caùc hoaït ñoäng,

thao taùc ñöôïc duøng trong chuaån bò, cheá bieán, saûn xuaát, ñoùng goùi, toàn tröõ, vaän chuyeån, phaân

phoái, xöû lyù hay yeâu caàu ñaët haøng cho moät maët haøng thöïc phaåm cuï theå.

Ngöôøi kinh doanh thöïc phaåm: ngöôøi hay nhoùm ngöôøi chòu traùch nhieäm baûo ñaûm caùc yeâu caàu

veà luaät ñònh cuûa thöïc phaåm ñöôïc ñaùp öùng trong kinh doanh thöïc phaåm döôùi söï kieåm soaùt.

Ngöôøi xöû lyù thöïc phaåm: Baát kyø ngöôøi naøo tieáp xuùc tröïc tieáp vôùi thöïc phaåm ñoùng hay khoâng

ñoùng goùi, duïng cuï thöïc phaåm vaø ñoà duøng naáu aên, hay tieáp xuùc beà maët thöïc phaåm vaø tröôùc

ñoù ñöôïc mong ñôïi tuaân theo yeâu caàu veä sinh thöïc phaåm.

Veä sinh thöïc phaåm: Taát caû ñieàu kieän vaø bieän phaùp caàn thieát ñaûm baûo an toaøn vaø thích hôïp

cuûa thöïc phaåm taïi taát caû coâng ñoaïn cuûa daây chuyeån thöïc phaåm.

An toaøn thöïc phaåm: Ñaûm baûo raèng thöïc phaåm seõ khoâng gaây haïi cho ngöôøi tieâu thuï khi noù

ñöôïc chuaån bò vaø/hoaëc aên theo muïc ñích söû duïng cuûa noù.

Thöïc phaåm thích hôïp: Ñaûm baûo raèng thöïc phaåm chaáp nhaän ñöôïc cho ngöôøi tieâu duøng theo muïc

ñích söû duïng.

Bieän phaùp kieåm soaùt chung: xem bieän phaùp kieåm soaùt, chung

HACCP : Moät heä thoáng xaùc ñònh, ñaùnh giaù vaø kieåm soaùt caùc moái nguy ñaùng keå ñoái vôùi an

toaøn thöïc phaåm.

D:/HACCP/dich – Tieu chuan HACCP Trang 14

Caùc yeâu caàu cô baûn cuûa Heä thoáng HACCP

Ñaùnh giaù HACCP: Moät kieåm tra ñoäc laäp hay heä thoáng quyeát ñònh heä thoáng HACCP, bao goàm

keá hoaïch HACCP vaø keát quaû lieân quan, phuø hôïp vôùi saép xeáp theo keá hoaïch, thöïc hieän coù hieäu

quaû vaø thích hôïp vôùi vieäc ñaït ñöôïc muïc tieâu ñeà ra.

Ghi chuù: Kieåm tra vieäc phaân tích moái nguy laø yeáu toá caàn thieát cho hoaït ñoäng ñaùnh giaù HACCP.

Keá hoaïch HACCP : Moät taøi lieäu ñöôïc xaây döïng phuø hôïp theo caùc nguyeân taéc cuûa HACCP ñeå

ñaûm baûo kieåm soaùt caùc moái nguy ñaùng keå ñoái vôùi an toaøn thöïc phaåm trong coâng ñoaïn ñöôïc

xem xeùt cuûa daây chuyeàn thöïc phaåm.

HACCP döïa vaøo heä thoáng an toaøn thöïc phaåm: (moät heä thoáng HACCP): Caáu truùc toå chöùc, qui

trình, quaù trình, nguoàn löïc caàn thieát cho vieäc thöïc hieän keá hoaïch HACCP vaø ñaùp öùng caùc muïc

tieâu.

Ñoäi HACCP: Nhoùm caù nhaân (nhieàu lónh vöïc) phaùt trieån, thöïc hieän vaø duy trì heä thoáng moät

HACCP.

Moái nguy : Moät taùc nhaân sinh hoïc, hoaù hoïc hay vaät lyù hoïc cuûa thöïc phaåm, hoaëc tình traïng cuûa

thöïc phaåm coù khaû naêng taùc ñoäng gaây haïi cho söùc khoeû con ngöôøi.

Phaân tích moái nguy : Quaù trình thu thaäp vaø ñaùnh giaù thoâng tin veà caùc moái nguy cuøng caùc ñieàu

kieän daãn ñeán söï xuaát hieän caùc moái nguy ñoù, ñeå quyeát ñònh moái nguy naøo laø ñaùng keå ñoái vôùi

an toaøn thöïc phaåm vaø do ñoù caàn ñöôïc ñeà caäp tôùi trong keá hoaïch HACCP.

Giaùm saùt : Vieäc tieán haønh theo keá hoaïch moät chuoãi caùc quan saùt hay ño ñaïc caùc thoâng soá caàn

kieåm soaùt ñeå ñaùnh giaù xem moät ñieåm kieåm soaùt tôùi haïn coù ñöôïc kieåm soaùt khoâng.

Chöông trình tieân quyeát (PRP): Baát cöù haønh ñoäng cuï theå hay baèng vaên baûn hoaëc ñieàu kieän

thöïc hieän phuø hôïp vôùi Codex General Principles of food hygiene, thöïc haønh saûn xuaát toát vaø luaät

ñònh veà thöïc phaåm, ñeå thieát laäp ñieàu kieän cô baûn phuø hôïp cho saûn xuaát vaø xöû lyù thöïc phaåm

an toaøn taïi taát caû coâng ñoaïn cuûa daây chuyeàn thöïc phaåm.

Haønh ñoäng phoøng ngöøa: Baát cöù bieän phaùp hay haønh ñoäng ñöôïc söû duïng ñeå ngaên ngöøa, ñaùnh

giaù hay giaûm söï taùi dieãn nguyeân nhaân sai leäch toàn taïi, khueáyt taät hay baát kyø tình huoáng khoâng

mong ñôïi khaùc lieân quan tôùi an toaøn thöïc phaåm.

Khaâu ban ñaàu : goàm nhöõng coâng ñoaïn trong chu trình thöïc phaåm coù lieân quan, ví duï: thu hoaïch,

moå thòt, vaét söõa, ñaùnh baét caù vaø taát caû coâng ñoaïn lieân quan saûn xuaát trong loø moå.

Saûn phaåm khoâng cheá bieán: Thöïc phaåm khoâng qua cheá bieán, bao goàm saûn phaåm ñöôïc, ví duï ,

chia, taùch, severed, gôõ xöông, baêm, loät da, nghieàn, caét, laøm saïch, tæa, boùc voû hay xay, laøm laïnh,

ñoùng baênng hay laøm laïnh saâu.

Saûn phaåm cheá bieán: Thöïc phaåm keát quaû töø aùp duïng saûn phaåm khoâng cheá bieán qua xöû lyù

nhö laø ñun noùng, hun khoùi, xöû lyù ñeå laâu, laøm chín, ngaâm, saáy, öôùp, trích, eùp, … hay söï keát hôïp

cuûa caù quaù trình naøy vaø/hoaëc saûn phaåm; thay theá caàn thieát saûn xuaát hay mang laïi theâm nhöõng

ñaëc tính ñaëc bieät cho saûn phaåm.

Ruûi ro: Khaû naêng nguyeân nhaân coù haïi cho söùc khoeû gaây neân bôûi söï coá vaø khaéc nghieät cuûa

moái nguy thoâng thöôøng trong thöïc phaåm khi chuaån bò hay tieâu thuï theo muïc ñích söû duïng.

Giaù trò muïc tieâu: Giaù trò cuûa saûn phaåm hay thoâng soá quaù trình ñöôïc giaùm saùt, muïc tieâu vôùi

giaù trò hoaït ñoäng tôùi haïn (khoaûng thay ñoåi chaáp nhaän) vaø dó nhieân vôùi giaù trò tôùi haïn, nhö vaäy

baûo ñaûm thöïc phaåm an toaøn.

Böôùc : Moät ñieåm, theå thöùc, hoaït ñoäng, thao taùc hay moät giai ñoaïn trong daây chuyeàn thöïc phaåm

keå caû nguyeân lieäu, töø khaâu xöû lyù ban ñaàu tôùi khaâu tieâu thuï saûn phaåm cuoái cuøng.

Söï chöùng thöïc : Baèng chöùng thöïc teá thu ñöôïc chöùng toû caùc nguyeân lyù cô baûn cuûa keá hoaïch

HACCP coù hieäu quaû.

D:/HACCP/dich – Tieu chuan HACCP Trang 15

Caùc yeâu caàu cô baûn cuûa Heä thoáng HACCP

Söï xaùc minh : Vieäc aùp duïng caùc phöông phaùp, qui trình, thöû nghieäm vaø caùc ñaùnh giaù khaùc

cuøng vôùi vieäc giaùm saùt, ñeå xaùc ñònh xem coù tuaân thuû theo keá hoaïch HACCP khoâng vaø hieäu

quaû cuûa HACCP döïa vaøo heä thoáng an toaøn thöïc phaåm.

4 TERMS and DEFINITIONS

Action-limit value: A value for the product or process parameter under consideration, deduced from the critical

limit value, which indicates that an intervention in the process is required.

Aspect: An element of the food business operation (products, processes, PRP, services) that can interact with

the food safety.

Certification: Action by a third party demonstrating that adequate confidence is given that a duly identified

product, process or service conforms with a specific standard or other normative document.

Control (verb): To take all necessary actions to ensure and maintain compliance with criteria established in the

HACCP plan.

Control (noun): The state wherein correct procedures are being followed and criteria are being met.

Control measure: Any action and activity that can be used to prevent or eliminate a food safety hazard or

reduce it to an acceptable level.

Control measure, general: A measure to control a specific part of the PRP.

Control measure, specific: A measure to control a CCP.

Corrective action: Any action to be taken when the results of monitoring at the CCP indicate a loss of control.

Critical Control Point (CCP): A step at which it is essential that a specific control measure is applied to

prevent or eliminate a food safety hazard or reduce the risk to an acceptable level.(see also Control measure,

specific .

Critical limit: A criterion which separates acceptability from non-acceptability.

Note: This criterion defines the limiting values for the product or process parameter(s) under consideration for

monitoring (see action-limit values and target values).

Flow diagram: A systematic representation of the sequence of steps or operations used in the preparation,

processing, manufacturing, packaging, storage, transportation, distribution, handling or offering for sale of a

particular food item.

Food business operator: the person or persons responsible for ensuring that the requirements of the

food legislation are met within the food business under his/their control.

Food handler: Any person who directly handles packaged or unpacked food, food equipment and utensils, or

food contact surfaces and is therefore expected to comply with food hygiene requirements.

Food hygiene: All conditions and measures necessary to ensure the safety and suitability of food at all stages of

the food chain.

Food safety: Assurance that food will not cause harm to the consumer when it is prepared and/or eaten

according to its intended use.

Food suitability: Assurance that food is acceptable for human consumption according to its intended use.

D:/HACCP/dich – Tieu chuan HACCP Trang 16

Caùc yeâu caàu cô baûn cuûa Heä thoáng HACCP

General Control Measure: see: Control measure, general

HACCP (Hazard Analysis and Critical Control Point): a system which identifies, evaluates and controls

hazards which are significant for food safety.

HACCP audit: A systematic and independent examination to determine whether the HACCP

system, including the HACCP plan and related results, comply with planned arrangements,

are implemented effectively and are suitable for the achievement of its objectives.

Note: Examination of the Hazard Analysis is an essential element of the HACCP audit.

HACCP plan: A document prepared in accordance with the principles of HACCP to ensure control of hazards

which are significant for food safety in the segment of the food chain under consideration.

HACCP based Food Safety System: (a HACCP system): The organisational structure, procedures, processes

and resources needed to execute the HACCP plan(s) and meet its objectives.

HACCP team: Group of individuals (multi-disciplinary) who develop, implement and maintain

a HACCP system.

Hazard: A biological, chemical or physical agent in, or condition of, food with the potential to cause an adverse

health effect.

Hazard analysis: The process of collecting and evaluating information on hazards and conditions leading to

their presence, to decide which are significant for food safety and should therefore be addressed in the HACCP

plan.

Monitoring: The act of conducting a planned sequence of observations or measurement of control parameters

to assess whether a CCP is under control.

Pre-Requisite Programme (PRP): Any specified and documented activity or facility

implemented in accordance with the Codex General Principles of food hygiene, good

manufacturing practice and appropriate food legislation, in order to establish basic conditions

that are suitable for the production and handling of safe food at all stages of the food chain.

Preventive action: Any measure or activity that will be used to prevent, to eliminate or to reduce the recurrence

of causes for existing deviations, defects or any other undesired situation with respect to food safety.

Primary production: Those steps in the food chain up to and including harvesting, hunting, fishing, milking and

all stages of animal production prior to slaughter.

Products, unprocessed: Foodstuffs which have not undergone a treatment, including products which have been,

for example, divided, parted, severed, boned, minced, skinned, ground, cut, cleaned, trimmed, husked or milled,

chilled, frozen or deep-frozen.

Products, processed: Foodstuffs resulting from the application to unprocessed products of a treatment such as

heating, smoking, curing, maturing, pickling, drying, marinating, extraction, extrusion, etc. or a combination of

these processes and/or products; substances necessary for their manufacture or for giving specific

characteristics to the products may be added.

Risk: The probability of causing an adverse health effect caused by the occurrence and the severity of a

particular hazard in food when prepared and consumed according to its intended use.

Target value: The value of the product or process parameter(s) to be monitored, targeted within action-limit

values (the range of acceptable variations) and certainly within critical limit values, thus securing a safe

product.

D:/HACCP/dich – Tieu chuan HACCP Trang 17

Caùc yeâu caàu cô baûn cuûa Heä thoáng HACCP

Step: A point, procedure, operation or stage in the food chain, including raw materials, from primary

production to final consumption.

Validation: Obtaining evidence (in advance) that the specific and general control measures of the HACCP plan

are effective.

Verification: The application of methods, procedures, tests and other evaluations, in addition to monitoring, to

determine compliance with the specifications laid down in the HACCP plan and the effectiveness of the

HACCP-based Food Safety System.

D:/HACCP/dich – Tieu chuan HACCP Trang 18

Caùc yeâu caàu cô baûn cuûa Heä thoáng HACCP

5. Yeâu caàu cuûa heä thoáng HACCP

5.1 Traùch nhieäm quaûn lyù

Ban giám đốc có trách nhiệm bảo đảm an toàn thực phẩm. Trách nhiệm của Ban giám đốc thể hiện qua chính

sách của tổ chức. Ban giám đốc chịu trách nhiệm hoàn toàn với chính sách đã công bố, chính sách này phải

được thể hiện bằng văn bản, được hỗ trợ thực hiện và thông tin cho mọi người trong tổ chức.

Định kỳ, Trưởng ban HACCP cần xem xét lại việc thực hiện chính sách và những thay đổi bên ngoài.

Hệ thống HACCP thể hiện sự cam kết và trách nhiệm đảm bảo cung cấp những thực phẩm an toàn của Ban

Giám đốc. Do đó, hệ thống HACCP đảm bảo tất cả mọi hoạt động yêu cầu đều được xác định, thực hiện và duy

trì có hiệu lực.

5. HACCP SYSTEM REQUIREMENTS

5.1 Management responsibility

The food business operator is responsible for the safety (and suitability) of the produced food.

Therefor, the food business operator shall include the policy with respect to food safety in the policy of the

organisation. The food business operator has ultimate responsibility for the policy of the organisation and shall

document, support and communicate this policy.

Periodically, the Food business operator shall verify the implementation of the policy and review the outcome.

The HACCP system enables the food business operator to demonstrate his commitment and his responsibility

with respect to the supply of safe products. For, the HACCP system ensures that all required activities are

effectively defined, implemented and maintained.

5.1.1 Chính saùch

Ban giaùm ñoác phaûi xaùc laäp vaø vaên baûn hoùa chính saùch an toaøn thöïc phaåm cuûa toå chöùc. Chính

saùch theå hieän söï cam keát cuûa toå chöùc veà an toaøn thöïc phaåm. Chính saùch theå hieän toå chöùc ñaõ

xaùc ñònh töøng vò trí trong daây chuyeàn thöïc phaåm. Chính saùch phaûn aùnh roõ phöông phaùp “ töø

noâng traïi ñeán baøn aên”, baét ñaàu töø vieäc mua nguyeân lieäu. Chính saùch phaûi taäp trung vaøo vaán ñeà

an toaøn thöïc phaåm vaø phaûi ñaùp öùng nhu caàu, mong ñôïi cuûa khaùch haøng.

Chính saùch phaûi bao goàm caùc muïc tieâu cuï theå (hoaït ñoäng döï kieán) ñaûm baûo caûi tieán vaán ñeà an

toaøn thöïc phaåm theo nhöõng ñieàu kieän xem xeùt khaùc nhau.

Ban giaùm ñoác phaûi ñaûm baûo chính saùch ñaõ ñöôïc thaáu hieåu, thöïc hieän vaø duy trì taïi moïi caáp

trong toå chöùc.

5.1. 1.Policy

The food business operator shall define and document (in writing) the policy of the organisation with regard to

food safety. It will demonstrate the commitment of the organisation to safe food.

The policy shall demonstrate that the organisation is fully aware of its position in the food chain. It will reflect

the “farm-to-fork” approach, starting with the purchase and acceptance of raw materials.

The policy shall be focused on the safety of foodstuffs and shall respond to the expectations and needs of its

customers and consumers.

The policy shall include concrete objectives 10 (proposed actions) to ensure and improve food safety for the

period under consideration.

The food business operator shall ensure that the policy is understood, implemented and maintained at all levels

in the organisation.

5.1.2 Phaïm vi cuûa heä thoáng HACCP

10

SMART objectives are Specific, Measurable, Acceptable, Realistic objectives, defined in Time.

D:/HACCP/dich – Tieu chuan HACCP Trang 19

Caùc yeâu caàu cô baûn cuûa Heä thoáng HACCP

Tröôûng ban HACCP phaûi xaùc ñònh phaïm vi cuûa heä thoáng HACCP.

Phaïm vi phaûi bao goàm daây chuyeàn thöïc phaåm vaø caùc hoat ñoäng kinh doanh thöïc phaåm maø

Tröôûng ban HACCP coù traùch nhieäm:

Daây chuyeàn thöïc phaåm coù theå goàm, baét ñaàu töø vieäc cung caáp nguyeân lieäu vaø keát thuùc

laø traùch nhieäm cuûa Tröôûng ban HACCP khi maø chuyeån sang hoaït ñoäng kinh doanh thöïc phaåm

khaùc. Vì vaäy, phaïm vi phaûi phuø hôïp vôùi hôïp ñoàng mua vaø baùn

Taát caû moïi vò trí vaø quaù trình lieân quan ñeán vieäc saûn xuaát vaø löu tröõ thöïc phaåm phaûi

ñöôïc xaùc ñònh ñuùng vaø coù saün khi caàn ñaùnh giaù.

Taát caû caùc saûn phaåm cung caáp cho thò tröôøng ñaõ qua cheá bieán hoaëc xöû lyù sô boä ñeàu

phaûi ñöôïc chæ roõ.

Caùc hoaït ñoäng hoã trôï (dòch vuï thueâ ngoaøi nhö ñoùng goùi, löu tröõ, vaän chuyeån) phaûi ñöôïc

ñeà caäp ñuùng caùch.

Thöïc teá, vieäc phaân loaïi saûn phaåm neân chia thaønh nhoùm saûn phaåm. Tuy nhieân coù nhöõng ñieåm

quan troïng caàn löu yù :

Söï khaùc bieät ñaëc tröng giöõa caùc saûn phaåm rieâng leû phaûi ñöôïc ñaùnh giaù ñuùng tieâu

chuaån.

So saùnh ñieàu kieän cheá bieán vaø löu tröõ.

Caùc khía caïnh quan troïng ñoái vôùi an toaøn thöïc phaåm khoâng ñöôïc boû soùt.

Quy luaät chính laø khoâng coù phaàn naøo cuûa hoaït ñoäng kinh doanh thöïc phaåm coù theå bò loaïi tröø

khoûi phaïm vi cuûa heä thoáng HACCP, taát caû moïi hoaït ñoäng ñeàu ñöôïc xaùc ñònh, coù saün ñeå ñaùnh

giaù.

5.1.2 Scope of the HACCP system

The food business operator shall define the extent (the scope) of the HACCP system.

The scope shall comprise that part of the food chain and those activities of the food business for which the food

operator is responsible and can be held liable:

The part of the food chain for which the food business operator is responsible begins where the

responsibility of the suppliers of raw materials and ingredients ends; the responsibility of the food business

operator ends where another food business in the food chain takes over the responsibility. The scope shall

therefore conform with purchase and sales contracts;

All locations and process lines where food is manufactured and/or stored by the food business shall be

properly indicated and be available for assessment;

All products which are supplied to the market by the food business, whether processed or handled, shall

be properly specified;

All subcontracted activities (outsourced services, like packaging, storage, transport) shall be

properly dealt with.

For practical reasons the total product assortment may be clustered into product groups. However it is

important that:

Specific differences between individual end products have been critically evaluated;

Manufacturing and storage conditions are comparable;

Important aspects for food safety are not overlooked.

A key principle is that no part of the operation of the food business can be excluded from the scope of

the HACCP system; all activities must be available for assessment.

5.1.3 Nhieäm vuï, traùch nhieäm vaø quyeàn haïn

Tröôûng ban HACCP phaûi cung caáp caùc taøi lieäu thích hôïp neâu roõ nhieäm vuï, traùch nhieäm vaø

quyeàn haïn cuûa nhaân vieân trong caùc vò trí lieân quan ñeán vieäc cheá bieán vaø /hoaëc kieåm soaùt vaø

ñaûm baûo tính an toaøn vaø söï phuø hôïp cuûa thöïc phaåm

Sô ñoà toå chöùc vaø caáu truùc baùo caùo cuûa toå chöùc phaûi ñöôïc laäp thaønh vaên baûn.

D:/HACCP/dich – Tieu chuan HACCP Trang 20

Caùc yeâu caàu cô baûn cuûa Heä thoáng HACCP

5.1.3 Tasks, responsibilities and authorities

The food business operator shall provide appropriate documentation with respect to the tasks, responsibilities

and authorities of food business operator’s employees who are in positions which involve handling food and / or

controlling and ensuring the safety and suitability of the food.

An organisation chart and the organisation’s reporting structure shall be documented.

5.1.4 Nhoùm HACCP

Ban Giaùm ñoác phaûi thieát laäp moät Ban HACCP (hoaëc caùc nhoùm HACCP khaùc neáu caànt thieát).

Nhoùm HACCP phaûi thieát laäp, thöïc hieän vaø duy trì heä thoáng HACCP.

Thaønh vieân cuûa nhoùm HACCP coù kieán thöùc, chuyeân moân vaø ñöôïc reøn luyeän khaùc caàn thieát

ñeå trieån khai, thöïc hieän vaø duy trì heä thoáng HACCP treân toaøn boä phaïm vi cuûa heä thoáng HACCP.

Tieâu chuaån, khaû naêng toái thieåu cuûa thaønh vieân ban HACCP bao goàm caû khaû naêng chuyeân moân.

Caùc khaû naêng naøy phaûi ñöôïc xaùc ñònh vaø cuï theå hoaù thaønh vaên baûn ñoái vôùi taát caû caùc

thaønh vieân trong nhoùm. Ngoaøi ra, nhieäm vuï - traùch nhieäm vaø quyeàn haïn phaûi cuï theå hoaù thaønh

vaên baûn.

Neáu coù hôn moät nhoùm HACCP thì phaûi chæ ñònh ngöôøi keát noái ñeå hôïp taùc trieån khai, thöïc hieän

vaø duy trì heä thoáng HACCP.

5.1.4 HACCP team(s)

The food business operator shall assemble a HACCP team (or various HACCP teams if so required).

The HACCP team shall develop, implement and maintain the HACCP system.

The organisation shall demonstrate that the members of the HACCP team have the knowledge, expertise and

different disciplines available which are required to develop, implement and maintain a HACCP system

covering the total scope of the HACCP system.

Minimum qualification criteria, including required expertise, shall be defined and documented for all members

of the HACCP team. In addition, the assignment (including tasks, responsibilities and authorities) shall be

documented for the team members.

Whenever more than one HACCP team has been assembled, a co-ordinator shall be appointed to co-ordinate

the development, implementation and maintenance of the HACCP system.

5.1.5 Nguoàn löïc

Ban Giaùm ñoác phaûi kieåm tra caùc yeàu caàu vaø cung caáp ñuùng luùc taát caû caùc nguoàn löïc maø

nhoùm HACCP caàn ñeå trieån khai, thöïc hieän vaø duy trì heä thoáng HACCP. Khi thöïc hieän haønh ñoäng

khaéc phuïc do khaùch haøng hay thuû tuïc thaåm tra xaùc nhaän yeâu caàu caàn phaûi caûi tieán hoaït ñoäng

thì Ban giaùm ñoác phaûi xem xeùt vaán ñeà vaø cung caáp caùc nguoàn löïc thích hôïp ñaûm baûo an toaøn

thöïc phaåm.

5.1.5 Resources

The food business operator shall examine the requests and provide, in a timely manner, all the resources

needed by the HACCP team(s) to develop, implement and maintain the HACCP system.

When corrective actions, verification procedures or customers indicate that operational improvements are

necessary, the food business operator shall examine the issues and provide appropriate resources to ensure

food safety.

5.1.6 Xem xeùt laõnh ñaïo.

Ban Giaùm ñoác phaûi xem xeùt heä thoáng HACCP ñònh kyø theo keá hoaïch, khoâng ñöôïc quaù 12

thaùng ñeå ñaûm baûo tính lieân tuïïc, söï phuø hôïp töông thích vaø hieäu quaû. Vieäc xem xeùt naøy phaûi

ñaùnh giaù nhu caàu thay ñoåi heä thoáng HACCP bao goàm vaán ñeà an toaøn thöïc phaåm, chính saùch

D:/HACCP/dich – Tieu chuan HACCP Trang 21

Caùc yeâu caàu cô baûn cuûa Heä thoáng HACCP

vaø muïc tieâu. Vieäc xem xeùt naøy phaûi cung caáp baèng chöùng caûi tieán heä thoáng HACCP vaø keát

quaû thöïc hieän.

5.1.6 Management Review

The food business operator shall review the HACCP system at planned intervals, of no more than 12 months,

to ensure continuing suitability, adequacy and effectiveness. The review shall evaluate the need for changes

to the HACCP system, including product safety, policy and objectives.

The review shall provide evidence of the commitment to improve the HACCP system and its performance.

D:/HACCP/dich – Tieu chuan HACCP Trang 22

Caùc yeâu caàu cô baûn cuûa Heä thoáng HACCP

5.2 Thoâng tin saûn phaåm

5.2.1 Ñaëc tính cuûa saûn phaåm

Moãi loaïi saûn phaåm hoaëc nhoùm saûn phaåm phaûi ñöôïc moâ taû ñaày ñuû thaønh vaên baûn bao goàm

caû tính nhaïy caûm vaø khaû naêng ruûi ro tieàm aån aûnh höôùng ñeán an toaøn thöïc phaåm.

Khi moâ taû ñoä an toaøn cuûa saûn phaåm phaûi lieät keâ ñaày ñuû daây chuyeàn thöïc phaåm , töø khaâu

mua nguyeân vaät lieäu ñeán khaâu phaân phoái saûn phaåm.

Vieäc truy tìm ngöôïc laïi nguyeân vaät lieäu ban ñaàu vaø nhaø cung caáp cuoái cuøng ñeàu phaûi ñöôïc

moâ taû.

Moâ taû ñaëc tính saûn phaåm theo phaïm vi roäng ñeå ñaûm baûo vieäc ñaùnh giaù caùc thuû tuïc an toaøn

thöïc phaåm toaøn dieän hôn. Moâ taû roõ caùc ñaëc tính sau cuûa saûn phaåm:

Moâ taû chung veà saûn phaåm

Nguyeân vaät lieäu vaø thaønh phaàn söû duïng

Moâ taû chung cuûa saûn phaåm nhö ngoaïi quan, troïng löôïng v.v…

Caùc ñaëc tính cuûa saûn phaåm nhö tính chaát hoùa hoïc, vi sinh vaät, tính chaát vaät lyù

Caùc yeâu caàu ñaëc tröng nhö ñaùp öùng yeâu caàu luaät phaùp, yeâu caàu cuûa khaùch

haøng

Phöông phaùp kieåm soaùt chung veà an toaøn (hoùa hoïc, vi sinh vaø vaät lyù)

Ñoùng goùi, ñieàu kieän löu tröõ, daùn nhaõn (thôøi haïn söû duïng, nhaän daïng saûn phaåm)

Nhaän daïng caùc saûn phaåm coù nguy cô tieàm aån xöû lyù hoûng

5.2Product Information

5.2.1 Product Characteristics

Each product (or a group of similar products: see 5.1.2) shall be fully specified and documented, including

its sensitivity to and potential for safety risks.

This description of the safety of the product shall encompass the food chain, ranging from raw materials

used to the distribution of the finished products.

The traceability of the raw materials up to and including final supply shall be described.

An extensive specification of the end products is required to ensure a comprehensive assessment of the food

safety procedures. This specification shall clearly define the following product characteristics:

a general product description;

raw materials and ingredients used (composition);

general product specifications such as appearance, weight, etc.;

specific product specifications such as chemical, microbiological and physical characteristics;

specific requirements such as appropriate legislation, customer requirements;

general control of (chemical, microbiological and physical) safety;

packaging, storage conditions, labelling (shelf life, product identification);

identification of potential mishandling of the product.

5.2.2 Muïc ñích söû duïng:

Muïc ñích söû duïng saûn phaåm (hoaëc nhoùm saûn phaåm) phaûi ñöôïc xaùc nhaän vaø phaûi ñöôïc vaên

baûn hoaù bôûi vì noù aûnh höôûng tröùc tieáp ñeán caùc ñaëc tính yeâu caàu cuûa saûn phaåm, ví duï:

Caùc bieän phaùp chuaån bò tröôùc khi söû duïng (gia nhieät hay haâm noùng)

Laøm maùt vaø löu tröõ ôû nhieät ñoä thích hôïp

Chæ roõ haïn söû duïng cuoái cuøng vaø ñaëc bieät sau khi môû bao bì

D:/HACCP/dich – Tieu chuan HACCP Trang 23

Caùc yeâu caàu cô baûn cuûa Heä thoáng HACCP

Caùc saûn phaåm söû duïng cho tröôøng hôïp ñaëc bieät, nhoùm khaùch haøng, ngöôøi tieâu

duøng deã bò toån thöông nhö treû sô sinh vaø treû em, phuï nöõ mang thai, ngöôøi giaø, ngöôøi bò dò öùng

hoaëc bò beänh.

Muïc ñích söû duïng cuûa saûn phaåm phaûi ñöôïc xem xeùt caûi tieán lieân tuïc, phaùp luaät lieân quan vaø

caùc qui ñònh phaûi ñöôïc vaên baûn hoaù. Khi caàn thieát, caùc ñaëc tính saûn phaåm vaø quaù trình cheá

bieán caàn phaûi thích öùng phuø hôïp vôùi caùc yeâu caàu phaùp luaät ñaëc bieät. Thoâng tin ghi treân

nhaõn saûn phaåm bao goàm höôùng daãn söû duïng cuõng caàn phaûi phuø hôïp. Nhöõng thay ñoåi naøy

phaûi ñöôïc löu hoà sô.

Neáu saûn phaåm cheá bieán khoâng ñaït hay söû duïng nhaàm saûn phaåm khoâng ñaït coù theå gaây ra

maát an toaøn thöïc phaåm, do ñoù nhöõng saûn phaåm naøy phaûi coù nhöõng thoâng tin thích hôïp ñaûm

baûo luoân saün coù ñeå ngöôøi keá tieáp trong chuoãi daây chuyeàn coù theå truy caäp deã daøng khi cheá

bieán, löu chöõ, chuaån bò hoaëc trình baøy saûn phaåm ñuùng caùch vaø an toaøn. Phaûi deã daøng xaùc

ñònh loâ hoaëc ñôït khi caàn laáy laïi.

Tröôûng ban HACCP phaûi chöùng minh ñöôïc caùc saûn phaåm hoûng söû duïng nhaàm ñeàu ñöôïc ñaùnh

giaù, bao goàm caùc ñieåm kieåm soaùt tôùi haïn nhö ñieàu kieän löu tröõ vaø giai ñoaïn chuaån bò tröôùc

khi duøng.

5.2.2 Intended use

The intended use of the product (or product group) shall be identified and documented since it has a direct

influence on the required product characteristics. For instance, the product may require:

additional preparation methods (e.g. heating) before consumption, and/or

cooling and storage at specific temperatures, and/or

an indication of the ultimate day of use, especially after breaking the packaging, and/or

the product may be intended for use by specific (vulnerable) groups of the population, such as babies

and children, pregnant women, elderly people, allergenic or sick people.

The intended use of the product shall be continually reviewed; relevant legislation and regulations shall be

documented. When necessary, the product characteristics and manufacturing processes may need to be

adapted to conform with special legislation. Information on the label, including directions for use, may also

need to be adapted. These changes shall be recorded.

If mishandling or misuse of the product can result in unsafe products the products shall bear appropriate

information to ensure that adequate and accessible information is available to the next persons in the food

chain to enable them to handle, store, process, prepare and display the product safely and correctly. It shall

be easy to identify the lot or batch when recall is required.

The food business operator shall demonstrate that it has evaluated whether the intended use or misuse

should include Critical Control Points such as storage conditions and preparation before consumption.

5.3 Thoâng tin quaù trình

5.3.1 Sô ñoà daây chuyeàn saûn xuaát

Tröôûng ban HACCP phaûi coù saün sô ñoà daây chuyeàn saûn xuaát (caùc böôùc quaù trình vaø thieát bò

saûn xuaát) moâ taû ñaày ñuû vaø ñuùng thöïc teá. Khi aùp duïng HACCP cho moät hoaït ñoäng naøo ñaáy

caàn phaûi xem xeùt caùc böôùc tröôùc vaø sau cuûa hoaït ñoäng. Nhoùm HACCP seõ veõ moâ taû vaø

xaùc nhaän.

Sô ñoà daây chuyeàn saûn xuaát cung caáp moät caùi nhìn coù heä thoáng cuûa hoaït ñoäng ñoù, moâ taû

chi tieát taát caû caùc böôùc vaø cung caáp cho nhoùm HACCP caùc thoâng tin thích hôïp ñeå xaây döïng

heä thoáng HACCP.

Sô ñoà daây chuyeàn saûn xuaát phaûi lieät keâ ñöôïc caùc böôùc lieân quan nhö saûn xuaát saûn phaåm bao

goàm caùc ñieåm tôùi haïn nhö :

Nôi löu tröõ döï bò vaø chuyeån tieáp

D:/HACCP/dich – Tieu chuan HACCP Trang 24

Caùc yeâu caàu cô baûn cuûa Heä thoáng HACCP

OÁng vaän chuyeån, van phaân phoái.v.OÂ(

Voøng taùi sinh

Phöông tieän ñeå laøm veä sinh vaø voâ truøng caùc thieát bò vaø duïng cuï bao goàm nôi ñeå

laøm veä sinh.

Döï phoøng caùc tröôøng hôïp khôûi ñoäng, ngöng maùy hoaëc tröôøng hôïp khaån caáp v.v…

5.3Process information

5.3.1 Flow Diagrams

The food business operator shall make available a complete and actual description of the operation in the

form of flow diagrams (process steps) and layouts (production facilities). When applying HACCP to a given

operation, consideration shall be given to steps preceding and following the specified operation. These

descriptions shall be drawn up and verified by the HACCP team.

The flow diagrams provide a schematic overview of the operation and will describe all the steps in sufficient

detail to provide the HACCP team with adequate information for the HACCP.

The flow diagrams shall take into account all relevant process steps, such as the

manufacturing of the product, including critical points like:

buffer and interim storage;

transport pipes, distribution valves, etc.;

loops for reworking and recycling;

facilities for cleaning and disinfection of equipment and tools, including cleaning-in-place;

provision for start up / shut down / emergency stops, etc..

5.3.2 Maët baèng boá trí

Taát caû caùc phöông tieän thuoäc cô sôû haï taàng cuûa phaân xöôûng nhö daây chuyeàn saûn xuaát, khu

vöïc löu tröõ vaø phöông tieän caù nhaân phaûi ñöôïc moâ taû trong keá hoaïch boá trí vò trí laép ñaêït maët

baèng phaân xöôûng.

Trong maët baèng boá trí phaûi chæ roõ caùc haïng muïc sau:

Voøng saûn phaåm, nhaân söï vaø doøng khoâng khí (tröôøng hôïp caùc phoøng yeâu caàu kyõ

thuaät cao)

Khu vöïc coù khaû naêng nhieãm cheùo do tieáp xuùc trong quaù trình vaø caùc saûn phaåm do

vaät lieäu töôi, soáng, chaát phuï gia, daàu nhôøn, taùc nhaân laøm maùt, nhaân söï, ñoùng goùi vaø

container khoâng theå loaïi tröø.

5.3.2 Layout

All facilities which are part of the infrastructure of the food business, such as the production lines, storage

areas and personnel facilities, shall be depicted in a layout plan.

In the layout the following items shall be indicated:

The routing of products, personnel and air flows (in the case of 'high care' rooms);

The areas where cross contamination of and incidental contact with in-process and finished products

by raw materials, additives, lubricants, cooling agents, personnel, packaging, pallets and containers, cannot

be excluded;

The areas and facilities for personnel use.

5.3.3 Kieåm tra vaø xaùc nhaän thoâng tin quaù trình

Khi thay ñoåi quaù trình saûn xuaát vaø maët baèng boá trí coù theå gaây taùc ñoäng ngöôïc laïi vôùi an

toaøn thöïc phaåm, nhöõng thay ñoåi naøy caàn phaûi ñöôïc baùo caùo vôùi nhoùm HACCP ñeå ñaùnh giaù

moái nguy tieàm aån ñeán an toaøn thöïc phaåm vaø ñöa ra haønh ñoäng phoøng ngöøa töông öùng.

D:/HACCP/dich – Tieu chuan HACCP Trang 25

Caùc yeâu caàu cô baûn cuûa Heä thoáng HACCP

Trong baát cöù tröôøng hôïp naøo, tính chính xaùc vaø ñieàu kieän thöïc teá cuûa sô ñoà daây chuyeàn saûn

xuaát ñeàu phaûi ñöôïc nhoùm HACCP xaùc nhaän laø phuø hôïp vôùi traïng thaùi ñöôïc neâu trong taøi

lieäu. Vieäc thaåm tra xaùc nhaän naøy phaûi ñöôïc laäp laïi ñònh kyø (ít nhaát 1 naêm 1 laàn) ñeå xaùc

ñònh vaø boå xung taøi lieäu veà boá trí maët baèng vaø laép ñaët quaù trình. Nhöõng thaåm tra ñònh kyø

naøy phaûi naèm trong thuû tuïc thaåm tra.

5.3.3 Control and Verification of Process Information

Prior to the execution of changes in the production process and layout that could adversely affect food

safety, these changes shall be reported to the HACCP team in order to evaluate potential hazards to food

safety and take preventive actions accordingly.

In any case the accuracy and actuality of the flow diagrams and layout shall be verified by the HACCP team

for compliance with the documented situation. This verification shall be repeated periodically (at least

annually) in order to identify and document modifications to the process installation and layout.

These periodic verifications shall be part of the verification procedure.

5.4 Chöông trình veä sinh tieân quyeát

Tröôûng ban HACCP phaûi coù saün taøi lieäu mieâu taû chöông trình veä sinh tieân quyeát cuûa toå chöùc

ñaày ñuû vaø ñuùng thöïc teá. Thuû tuïc lieân quan ñeán Chöông trình veä sinh tieân quyeát (PRR) phaûi

ñöôïc thieát laäp (ñaëc tröng vaø vaên baûn hoùa) ñaày ñuû caùc hoaït ñoäng vaø thoáng nhaát vôùi heä

thoáng HACCP vaø phaûi ñöôïc xaùc nhaän.

Caùc qui ñònh chung veà veä sinh caù nhaân taïo neàn moùng ñaûm baûo vaán ñeà an toaøn thöïc phaåm.

Tröôûng ban HACCP phaûi quyeát ñònh qui ñònh veä sinh naøo, phöông phaùp thöïc haønh saûn xuaát toát

naøo hoaëc luaät phaùp naøo lieân quan ñeán thöïc phaåm phaûi ñöôïc keå ñeán trong Chöông trình veä sinh

tieân quyeát cuûa toå chöùc. Caùc yeâu caàu cô baûn lieân quan ñeán chöông trình veä sinh tieân quyeát ñaõ

ñöôïc xem xeùt trong phuï luïc I vaø ñöôïc toùm taét trong Baûng 2

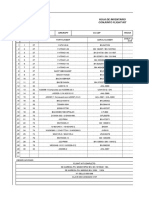

Baûng 2: Toùm taét caùc quy ñònh chung veà veä sinh trong an toaøn thöïc phaåm (CAC/RCP 1 – 1969,

Rev. 3 (1997), Amended 1999).

1. Saûn xuaát ban ñaàu 5. Thieát laäp :Veä sinh caù nhaân

1.1 Veä sinh moâi tröôøng 5.1 Tình traïng söùc khoeû

1.2 Saûn xuaát coù veä sinh caùc nguoàn thöïc5.2 Beänh vaø thöông taät

phaåm 5.3 Möùc ñoä saïch seõ caù nhaân

1.3 Cheá bieán, löu tröõ vaø vaän chuyeån 5.4 Cö xöû caù nhaân

1.4 Veä sinh, baûo trì vaø veä sinh caù nhaân

2. Thieát laäp: thieát keá vaø phöông tieän 6. Vaän chuyeån

2.1 Boá trí thieát bò, duïng cuï 6.1 Toång quan

2.2 Nhaø xöôûng vaø phoøng oác 6.2 Caùc yeâu caàu

2.3 Thieát bò duïng cuï 6.3 Söû duïng vaø baûo trì

2.4 Phöông tieän

3. Kieåm soaùt ñieàu haønh 7. Thoâng tin saûn phaåm vaø nhaän thöùc cuûa

3.1 Kieåm soaùt moái nguy thöïc phaåm ngöôøi tieâu duøng

3.2 Caùc khía caïnh chính cuûa heä thoáng kieåm7.1 Xaùc ñònh soá loâ

soaùt veä sinh 7.2 Thoâng tin saûn phaåm

3.3 Caùc yeâu caàu ñaàu vaøo cuûa nguyeân vaät7.3 Daùn nhaõn

lieäu 7.4 Kieán thöùc ngöôøi tieâu duøng

3.4 Ñoùng goùi

3.5 Nöôùc

3.6 Quaûn lyù vaø giaùm saùt

3.7 Taøi lieäu vaø hoà sô.

3.8 Thuû tuïc thu hoài

4. Thieát laäp: baûo trì vaø veä sinh 8 Ñaøo taïo

D:/HACCP/dich – Tieu chuan HACCP Trang 26

Caùc yeâu caàu cô baûn cuûa Heä thoáng HACCP

4.1 Baûo trì vaø veä sinh 8.1 Nhaän thöùc vaø traùch nhieäm

4.2 Chöông trình veä sinh 8.2 Chöông trình ñaøo taïo

4.3 Kieåm soaùt raéc roái 8.3 Höôùng daãn vaø giaùm saùt

4.4 Quaûn lyù chaát thaûi 8.4 Ñaøo taïo veà nöôùc giaûi khaùt (refresher)

4.5 Heä thoáng veä sinh

Gioáng nhö saûn phaåm vaø quaù trình, Chöông trình veä sinh tieân quyeát ñöôïc ñöa ra ñeå phaân tích moái

nguy (xem phaàn 5.5) ñeå xaùc ñònh caùc moái nguy tieàm aån vaø quyeát ñònh bieän phaùp caàn thieát ñeå

kieåm soaùt nhöõng moái nguy ñoù.

5.4Pre-requisite program

The food business operator shall make available a complete and actual description of the pre-requisite

program (PRP) of the organisation. The procedures belonging to the PRP shall be well established

(appropriately specified and documented), fully operational and integrated in the HACCP system, and be

verified.

The Codex General Principles of Food Hygiene lay a firm foundation for ensuring food safety and

suitability. The food business operator shall decide which food hygiene principles, good manufacturing

practices and food legislation must be included in the PRP of the organisation 11. The basic requirements

related to the prerequisite program have been reviewed in annex I and are summarised in Figure 2.

Figure 2: Summary of the Codex General Principles of Food Hygiene (CAC/RCP 1-1969,

Rev. 3 (1997), Amended 1999)

1 Primary production 5 Establishment: personal hygiene

1.1 Environmental hygiene 5.1 Health status

1.2 Hygienic production of food sources 5.2 Illness and injuries

1.3 Handling, storage and transport 5.3 Personal cleanliness

1.4 Cleaning, maintenance and personal hygiene 5.4 Personal behaviour

5.5 Visitors

2 Establishment: design and facilities 6 Transportation

2.1 Location 6.1 General

2.2 Premises and rooms 6.2 Requirements

2.3 Equipment 6.3 Use and maintenance

2.4 Facilities

3 Control of operation 7 Product information and consumer

3.1 Control of food hazards awareness

3.2 Key aspects of hygiene control systems 7.1 Batch identification

3.3 Incoming materials requirements 7.2 Product information

3.4 Packaging 7.3 Labelling

3.5 Water 7.4 Consumer education

3.6 Management and supervision

3.7 Documentation and records

3.8 Recall procedures

4 Establishment: maintenance and sanitation 8 Training

4.1 Maintenance and cleaning 8.1 Awareness and responsibilities

4.2 Cleaning programmes 8.2 Training programs

4.3 Pest control 8.3 Instruction and supervision

4.4 Waste management 8.4 Refresher training

4.5 Sanitation systems

11

Codex, General Food Principles state in this respect:

... there will be inevitably situations where some of the food hygiene requirements are not

applicable. The fundamental question in every case is “what is necessary and appropriate on the

grounds of the safety and suitability of food for consumption?

... in deciding whether a requirement is necessary or appropriate, an assessment of the risk should be

made, preferably within the framework of the HACCP approach!”

D:/HACCP/dich – Tieu chuan HACCP Trang 27

Caùc yeâu caàu cô baûn cuûa Heä thoáng HACCP

Like the products and the processes, (the procedures belonging to) the PRP will be subjected to the hazard

analysis (see section 5.5) in order to identify potential hazards and to decide in which way the hazards (risk)

need to be controlled (see section 5.6).

D:/HACCP/dich – Tieu chuan HACCP Trang 28

Caùc yeâu caàu cô baûn cuûa Heä thoáng HACCP

5.5 Phaân tích moái nguy

Tröôûng ban HACCP (nhoùm HACCP) phaûi xaùc ñònh, phaân tích vaø ñaùnh giaù caùc moái nguy (sinh

hoïc, hoùa hoïc vaø vaät lyù) tieàm aån coù theå coù taùc ñoäng ngöôïc laïi vôùi an toaøn thöïc phaåm.

Baát cöù khi naøo hoaït ñoäng kinh doanh thay ñoåi coù taùc ñoäng ngöôïc laïi an toaøn thöïc phaåm thì

taát caû caùc böôùc lieân quan trong quaù trình phaân tích ñeàu phaûi ñöôïc caäp nhaät.

5.5Hazard Analysis 12

The food business operator (HACCP team) shall identify, analyse and evaluate all potential (biological,

chemical and physical) hazards that can have an adverse effect on the safety of the products.