Professional Documents

Culture Documents

Ore Description

Ore Description

Uploaded by

Alejandro Bartolo YañezCopyright:

Available Formats

You might also like

- One Day On The RoadDocument3 pagesOne Day On The RoadRichard Adam Sison74% (77)

- IT6468 0911gbDocument24 pagesIT6468 0911gbmarcos lemosNo ratings yet

- Direct Drive Servomotor Turrets: SeriesDocument18 pagesDirect Drive Servomotor Turrets: SeriesSHG AUTMEC MANUTENÇÃO E AUTOMAÇÃO MÁQ. INDUSTRIAISNo ratings yet

- 05 Process Datasheet Annexure-PDocument1 page05 Process Datasheet Annexure-PpdilgnfcNo ratings yet

- Pm-Clinic Data Sheet Wd900-3 Base Information: Customer Name LocationDocument3 pagesPm-Clinic Data Sheet Wd900-3 Base Information: Customer Name LocationJuan Pablo Muñante Palacin100% (1)

- Calculation Notes (Acceleration Loss)Document17 pagesCalculation Notes (Acceleration Loss)Dennis Koay GMNo ratings yet

- Centrifugal and Axial Compressor DATA SHEET (API 617-7TH Chapter 2) SI UNITS (1-1.6.5)Document4 pagesCentrifugal and Axial Compressor DATA SHEET (API 617-7TH Chapter 2) SI UNITS (1-1.6.5)Carlos Felipe Reyes MartínezNo ratings yet

- 26148-220-V1a-Mfm0-00223 - Hoja de Datos Molino Sag 0320-ML-5001 PDFDocument10 pages26148-220-V1a-Mfm0-00223 - Hoja de Datos Molino Sag 0320-ML-5001 PDFLeonel Gamero CardenasNo ratings yet

- ChallengeDocument29 pagesChallengeMarconiVianaNo ratings yet

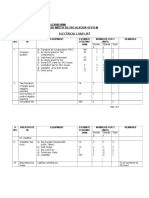

- Epc Package Gaderwara STPP Stage-Ii (2X800 MW) Ash Handling System & Ash Water Recirculation System Electrical Load ListDocument2 pagesEpc Package Gaderwara STPP Stage-Ii (2X800 MW) Ash Handling System & Ash Water Recirculation System Electrical Load ListvenkateshbitraNo ratings yet

- Annex 6Document2 pagesAnnex 6venkateshbitraNo ratings yet

- Manual Servicio CBC Tipo VDocument31 pagesManual Servicio CBC Tipo VfgdfgdfNo ratings yet

- OM MILL (Coal Pulveriser)Document7 pagesOM MILL (Coal Pulveriser)Nhật TuấnNo ratings yet

- Turbine O&M ManualDocument83 pagesTurbine O&M ManualMohammed MuzzamilNo ratings yet

- Storage Tank Gas Breathing For Purge Gas SizingDocument3 pagesStorage Tank Gas Breathing For Purge Gas SizingguhadebasisNo ratings yet

- Physical Testing of Clinker & CementDocument61 pagesPhysical Testing of Clinker & CementDineshNo ratings yet

- PM Clinic WA500-3LEDocument3 pagesPM Clinic WA500-3LEJheison ValenciaNo ratings yet

- NTPC SpecsDocument2 pagesNTPC SpecsxiaomiNo ratings yet

- Raup Iom 0705 PDFDocument35 pagesRaup Iom 0705 PDFritoNo ratings yet

- A320Document8 pagesA320Estevam Gomes de Azevedo50% (2)

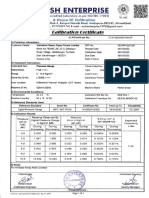

- 54-Pressure Gauge OIT Calibration CartificateDocument1 page54-Pressure Gauge OIT Calibration CartificateCustomer Support100% (1)

- 2011 Cost Models SectionDocument56 pages2011 Cost Models Sectionoduk odbayarNo ratings yet

- 'RAUP IOM-Aug06Document35 pages'RAUP IOM-Aug06Ngô Khắc ToảnNo ratings yet

- Brochure Dresser Series B3 MetersDocument4 pagesBrochure Dresser Series B3 Metersrahman ariwibowoNo ratings yet

- LM104949P TaperedRollerBearings SingleCones ImperialDocument4 pagesLM104949P TaperedRollerBearings SingleCones ImperialFernandes CoporaçõesNo ratings yet

- On-Load Tap-Changer OILTAP® G: Technical Data TD 48Document34 pagesOn-Load Tap-Changer OILTAP® G: Technical Data TD 48Ravindra AngalNo ratings yet

- MEDIDOR DRESSER 8c-11c-15c - Ngs-Mi-0006-1Document4 pagesMEDIDOR DRESSER 8c-11c-15c - Ngs-Mi-0006-1Jonathan S. R.No ratings yet

- CM600DX 24T/CM600DXP 24TDocument14 pagesCM600DX 24T/CM600DXP 24TSherif SabryNo ratings yet

- Technical Specification COP 2238 - 9851 2656 01 Low ResDocument2 pagesTechnical Specification COP 2238 - 9851 2656 01 Low Resdmb1692100% (1)

- Glued JointsDocument5 pagesGlued Jointsanildondapati1No ratings yet

- 9452 SamsungDocument13 pages9452 SamsungEdward José Chacín R.No ratings yet

- Injection Pump Test Specifications: Manu-Facturer Engine Type Vehicle ModelDocument2 pagesInjection Pump Test Specifications: Manu-Facturer Engine Type Vehicle ModelJunior IungNo ratings yet

- 33kV Cable Sizing CalcDocument9 pages33kV Cable Sizing Calcsrigirisetty208No ratings yet

- Pm-Clinic Data Sheet Wa180-3L Base Information: Customer Name LocationDocument3 pagesPm-Clinic Data Sheet Wa180-3L Base Information: Customer Name LocationjulianoNo ratings yet

- 18-Acoples Elastomericos LovejoyDocument70 pages18-Acoples Elastomericos LovejoyERIKSON EGUSQUIZANo ratings yet

- HYDRANT System Demand: Full Unit: Annexure - 1 Fire Water Demand Calculation For SUG Facilities Fire Fighting SystemDocument11 pagesHYDRANT System Demand: Full Unit: Annexure - 1 Fire Water Demand Calculation For SUG Facilities Fire Fighting SystemJMVNo ratings yet

- B70 Rock Breaker Care Operation Manual For TH86Document21 pagesB70 Rock Breaker Care Operation Manual For TH86Latifa EngineeringNo ratings yet

- 5.modification of Starter Operated 10 MT EOT - ConceptDocument18 pages5.modification of Starter Operated 10 MT EOT - ConceptIndranil DasguptaNo ratings yet

- Dust Extract SystemDocument17 pagesDust Extract Systemmathan_aeNo ratings yet

- Datasheet H2930uabc MetricoDocument1 pageDatasheet H2930uabc MetricoRodrigo J. MarqueziniNo ratings yet

- Orifice Size Calc For Gas PressureDocument2 pagesOrifice Size Calc For Gas PressureHyejune ParkNo ratings yet

- Weight CalculationDocument13 pagesWeight CalculationPankaj BijweNo ratings yet

- Wind Girder Calculations: Appendix 'M' Is Applicable?Document8 pagesWind Girder Calculations: Appendix 'M' Is Applicable?Anonymous LKi1w1uNo ratings yet

- 8103 M-42 6u2816013 Plate Type CoolersDocument60 pages8103 M-42 6u2816013 Plate Type CoolersABDULLAHNo ratings yet

- Design (Metric) 5 (1) .37Document7 pagesDesign (Metric) 5 (1) .37Huy NguyenmbvNo ratings yet

- Curved Jaw TypeDocument18 pagesCurved Jaw Typeadjime3No ratings yet

- 8474L-000-CN-0008-003-0 - Design GuidelinesDocument25 pages8474L-000-CN-0008-003-0 - Design Guidelinesdanhlakisu1No ratings yet

- Boq - 100 KLD STP Plant DJ Group ModinagarDocument1 pageBoq - 100 KLD STP Plant DJ Group ModinagarVishal shuklaNo ratings yet

- On-Load Tap-Changer OILTAP® R: Technical Data TD 115Document60 pagesOn-Load Tap-Changer OILTAP® R: Technical Data TD 115Jack DuffNo ratings yet

- Injection Pump Test Specifications: Manu-Facturer Engine Type Vehicle ModelDocument2 pagesInjection Pump Test Specifications: Manu-Facturer Engine Type Vehicle ModelKevin TtitoNo ratings yet

- SWT PreSolidsSeparation H011840 A4Document2 pagesSWT PreSolidsSeparation H011840 A4slbclqrkNo ratings yet

- 72-31-00-290-002-A - Inspection of The High Pressure Compressor Rotor AssemblyDocument30 pages72-31-00-290-002-A - Inspection of The High Pressure Compressor Rotor Assembly尹兴旺No ratings yet

- HPF Fan - AnshanDocument28 pagesHPF Fan - AnshanDangolNo ratings yet

- M-01-DS-0003 Specification Sheet: Date REV Prepared by Checked by Approved by DescriptionDocument2 pagesM-01-DS-0003 Specification Sheet: Date REV Prepared by Checked by Approved by DescriptionAJAY1381No ratings yet

- WKFI LeafletDocument16 pagesWKFI Leafletrishi pandeyNo ratings yet

- Technical OfferDocument10 pagesTechnical OfferNishantNo ratings yet

- LOVEJOY - Curved Jaw CouplingsDocument22 pagesLOVEJOY - Curved Jaw CouplingspedroNo ratings yet

- 1.0 General Plant Information: Existing Cement Mill Process Data SheetDocument6 pages1.0 General Plant Information: Existing Cement Mill Process Data SheetBùi Hắc HảiNo ratings yet

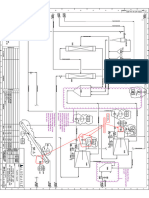

- ALB-41-PR-DP-0204-Rv-D - PID - Potash Wet - OffSites - Futuro Rev - ABDocument1 pageALB-41-PR-DP-0204-Rv-D - PID - Potash Wet - OffSites - Futuro Rev - ABAlejandro Bartolo YañezNo ratings yet

- ALB-41-PR-DP-0203-Rv-D - PID - Potash Wet - Centrifugas - Futuro Rev - ABDocument1 pageALB-41-PR-DP-0203-Rv-D - PID - Potash Wet - Centrifugas - Futuro Rev - ABAlejandro Bartolo YañezNo ratings yet

- EQUIPMENT LIST - 2021-01-15 - Rev-EDocument9 pagesEQUIPMENT LIST - 2021-01-15 - Rev-EAlejandro Bartolo YañezNo ratings yet

- Rotary Ball Feeder - Catalogación Spare Parts 1er Año OperacionesDocument48 pagesRotary Ball Feeder - Catalogación Spare Parts 1er Año OperacionesAlejandro Bartolo YañezNo ratings yet

- Spile Bar System - Catalogación Spare Parts 1er Año OperacionesDocument74 pagesSpile Bar System - Catalogación Spare Parts 1er Año OperacionesAlejandro Bartolo YañezNo ratings yet

- Recirculation Pumps Filter Plant - Catalogación Spare Parts 1er Año OperacionesDocument48 pagesRecirculation Pumps Filter Plant - Catalogación Spare Parts 1er Año OperacionesAlejandro Bartolo YañezNo ratings yet

- TEP-M-011 in Plant Conveyor - TEP - 1st Operation Year and Capital SparesDocument70 pagesTEP-M-011 in Plant Conveyor - TEP - 1st Operation Year and Capital SparesAlejandro Bartolo YañezNo ratings yet

- 01 Lista de Repuestos - 60577Document5 pages01 Lista de Repuestos - 60577Alejandro Bartolo YañezNo ratings yet

- Repuestos Mecanicos Celda TC-160 MELDocument1 pageRepuestos Mecanicos Celda TC-160 MELAlejandro Bartolo YañezNo ratings yet

- PO TEP-E-008 Distribution Transformers - WEGDocument6 pagesPO TEP-E-008 Distribution Transformers - WEGAlejandro Bartolo YañezNo ratings yet

- Hidrociclones 1.2 Recommended Spare Parts Tep-M-078spDocument1 pageHidrociclones 1.2 Recommended Spare Parts Tep-M-078spAlejandro Bartolo YañezNo ratings yet

- BAP1273-100 - Listado Recomendado de RepuestosDocument17 pagesBAP1273-100 - Listado Recomendado de RepuestosAlejandro Bartolo YañezNo ratings yet

- Listado de Equipos (Criticos Con Fecha Comisionamiento) PrincipalesDocument12 pagesListado de Equipos (Criticos Con Fecha Comisionamiento) PrincipalesAlejandro Bartolo YañezNo ratings yet

- 58-Reliability Centered MaintenanceDocument32 pages58-Reliability Centered MaintenanceAlejandro Bartolo Yañez100% (1)

- Detalle Información PO - Repuestos Comisionado ArranqueDocument5 pagesDetalle Información PO - Repuestos Comisionado ArranqueAlejandro Bartolo YañezNo ratings yet

- Planes Building&UtilitiesDocument132 pagesPlanes Building&UtilitiesAlejandro Bartolo YañezNo ratings yet

- Plan Mtto ApilamientoDocument356 pagesPlan Mtto ApilamientoAlejandro Bartolo YañezNo ratings yet

- Filosofia de Los ModelosDocument25 pagesFilosofia de Los ModelosAlejandro Bartolo YañezNo ratings yet

- Asset Strategy Development Procedure A2D SAP - 1496221Document11 pagesAsset Strategy Development Procedure A2D SAP - 1496221Alejandro Bartolo Yañez100% (1)

- SIGMADocument2 pagesSIGMAAlejandro Bartolo YañezNo ratings yet

- Tong Hop Bai Tap So Sanh Hon Va So Sanh Nhat Co Dap AnDocument14 pagesTong Hop Bai Tap So Sanh Hon Va So Sanh Nhat Co Dap AnGia HuyNo ratings yet

- Measuring Strain in RocksDocument2 pagesMeasuring Strain in Rocksdarebusi1No ratings yet

- 207 Money Saving FixesDocument149 pages207 Money Saving FixesCarmen Elena Nastasă100% (3)

- BS 2782-10 Method 1005 1977Document13 pagesBS 2782-10 Method 1005 1977Yaser ShabasyNo ratings yet

- 2016 CV - Curriculum Vitae Duy Anh 1Document11 pages2016 CV - Curriculum Vitae Duy Anh 1Cao Quang HưngNo ratings yet

- Aegis - Designer and AnalyzerDocument26 pagesAegis - Designer and Analyzeropenid_S1hHcZODNo ratings yet

- Accomplishment Report Pinagtigasan KinderDocument12 pagesAccomplishment Report Pinagtigasan KinderMay Anne AlmarioNo ratings yet

- Dreams LuDocument325 pagesDreams Luscrib3030100% (1)

- Esthetic Excellence PDFDocument32 pagesEsthetic Excellence PDFZomba ZombariraNo ratings yet

- ARX - 04 Evangelidis LibreDocument21 pagesARX - 04 Evangelidis LibreVasilis KostovassilisNo ratings yet

- Analytical ExpositionDocument9 pagesAnalytical Expositionkeira raishaNo ratings yet

- Jury Trial Moot Problem, Bar The Lex Fiesta 2016Document22 pagesJury Trial Moot Problem, Bar The Lex Fiesta 2016ShradhaNo ratings yet

- NIOS Class 12 Psychology Chapter 10 EmotionsDocument4 pagesNIOS Class 12 Psychology Chapter 10 Emotionsmanahil dollNo ratings yet

- Feasibility Study Project Proposal RequirementsDocument2 pagesFeasibility Study Project Proposal RequirementsErick NgosiaNo ratings yet

- Liebherr Brochure Boom Pumps enDocument20 pagesLiebherr Brochure Boom Pumps enVikash PanditNo ratings yet

- Perception On CatcallingDocument19 pagesPerception On CatcallingJasmin Delos ReyesNo ratings yet

- Eclipse ManualDocument10 pagesEclipse ManualgiancarlohoneyNo ratings yet

- 7.3-7.4 Electric Field and Potential Difference TemplateDocument11 pages7.3-7.4 Electric Field and Potential Difference TemplateAyman HalimeNo ratings yet

- Khidmat - The ServiceDocument6 pagesKhidmat - The ServiceAjay Prakash VermaNo ratings yet

- Catalogue 2019Document450 pagesCatalogue 2019AntonNo ratings yet

- Hand Tools and Measuring DeviceDocument86 pagesHand Tools and Measuring Devicehabtsh100% (3)

- Cabbash Vms BrochureDocument22 pagesCabbash Vms BrochureOghosa OsahenrhumwenNo ratings yet

- New Record TDocument2 pagesNew Record Tapi-309280225No ratings yet

- Transmission Structures and Foundations:: CourseDocument8 pagesTransmission Structures and Foundations:: CoursejulianobiancoNo ratings yet

- Module 4 Lesson 3Document5 pagesModule 4 Lesson 3Ludivina Lajot75% (4)

- GCC - Lesson Plan 2020Document35 pagesGCC - Lesson Plan 2020henaNo ratings yet

- Grade 6 - Specific Outcomes: Can Affect Human Development From Conception Through BirthDocument49 pagesGrade 6 - Specific Outcomes: Can Affect Human Development From Conception Through Birthapi-253059746No ratings yet

- Teaching As A ProfessionDocument5 pagesTeaching As A Professionipinloju temitopeNo ratings yet

- Module 2: Most Essential Learning Competencies (Melcs)Document5 pagesModule 2: Most Essential Learning Competencies (Melcs)Teresita EspinosaNo ratings yet

Ore Description

Ore Description

Uploaded by

Alejandro Bartolo YañezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ore Description

Ore Description

Uploaded by

Alejandro Bartolo YañezCopyright:

Available Formats

MANUFACTURER KREBS BIDDER KREBS ENGINEERS CHILE S.A.

(B)* OPERATING CONDITIONS

EQUIPMENT NO. 320-CS-006 thru 008

CYCLONE DUTY:

Service REGRIND CYCLONE

Operating Time, hrs/d 24

d/y ###

Location INDOOR

No. of Lines (clusters) Three (3)

Sp. gravity; Solid / Liquid 3.1 / 1.0

Ambient Temp. As per section 4 item 4.0

Type of Circuit Closed

% Circulating Load ###

Ore Description:

Copper Concentrate from flotation circuit

Bend of rougher Concentrate plus cleaner scavenger concentrate; 10 to 15 ( Copper sulfides + pyrite )

The phase IV Concentrator for Minera Escondida Ltda. will be designed to process a nominal throughput of 110,000 t/d

of copper ore. However, the concentrator will be started initially with a capacity of 90,000 t/d. Operating conditions for

both cases are as follows:

90 000 t/d 110 000 t/d

(For reference)

1

Increment all throughput, t/d. 0 20000

Number of Regrind Mills - HP 4- 1500 HP 4- 1500 HP

Number of Cyclone Clusters (1)

Operating 2 2

Stand by 1 1

Total 3 3

Cyclone size, inch (mm) 20 (508 mm) 20 (508 mm)

Number of Cyclones per cluster based on design flow

Operating 6 7

Stand by 3 2

Total 9 9

Vendor can quote on clusters with different number of cyclones, as alternatives, if different than the number of cyclones

specified above.

* 1. (B) INDICATES BUYER. (S) INDICATES SELLER

2. ALL (B) ITEMS SHALL BE COMPLETED BY BUYER. ALL (S) ITEMS SHALL BE COMPLETED BY SELLER

3. NOT APPLICABLE (NA) SHALL BE ENTERED WHERE INFORMATION IS NOT RELEVANT

1 23-Mar-00 Revised and reissued for Purchase HA GR RKB CL

0 29-Jul-99 Issued for Purchase HA GR RKB CL

REV. DATE DESCRIPTION ENG CHECKEGS PE

EQUIPMENT NO. REGRIND JOB NO. 24017 REV

320-CS-006 thru 008 CYCLONE CLUSTERS FORM: M-010-DS-02 1

DATA SHEET SHEET 1 OF 5

MANUFACTURER BIDDER

(B)* OPERATING CONDITIONS

Service REGRIND MILL

Regrind Cyclone Process Streams

90 000 t/d 110 000 t/d

( For reference) 1

Balance Condition Design Condit Balance Condition Design Condition

1 New Feed to Regrind Mill, Cyclone

Circuit (solids), t/h ### 992 939 1110

% solids 22 22 22 23

Pulp, m3/h 2979 3836 3645 4031 1

Pulp temperature, °C 30 30 30 30

pH 9-11 9-11 9-11 9-11

Circulating load, % ### 150 150 ###

New Feed size F80, um 120 to 140 120 to 140 120 to 140 120 to 140

2 Cyclone Feed Conditions (2)

(estimated)

Total Flow, m3/h 3802 4881 4653 5465

Flow/Operating Cluster, m3/h 1901 2441 2326 2733

1

% solids (approx) 38 38 38 38

3 Cyclone Underflow Cond.

% Solids 73 73 73 73

4 Overflow Conditions

Solids, t/h 768 992 939 1110

% Solids 22 22 22 22

1

Product size P80, um 80 to 100 80 to 100 80 to 100 80 to 100

5 Typical Screen Analysis (estimated)

New Feed to Regrind Mill/Cyclone Circuit

Size, mm 212 ### 106 75 53 45

Cum %Passing 100-95 95-90 85-80 75-70 65-60 60-55

F80 =110-90

Regrind Cyclone Overflow

Size, mm 212 ### 106 75 67 45

Cum %Passing 100 99-95 97-95 95-90 85-80 80-75

* 1. (B) INDICATES BUYER. (S) INDICATES SELLER

2. ALL (B) ITEMS SHALL BE COMPLETED BY BUYER. ALL (S) ITEMS SHALL BE COMPLETED BY SELLER

3. NOT APPLICABLE (NA) SHALL BE ENTERED WHERE INFORMATION IS NOT RELEVANT

EQUIPMENT NO. REGRIND JOB NO. 24017 REV

320-CS-006 thru 008 CYCLONE CLUSTERS FORM: M-010-DS-02 1

DATA SHEET SHEET 2 OF 5

MANUFACTURER BIDDER

(S)* CYCLONE DATA

Service REGRIND MILL

90 000 t/d 110 000 t/d

(Initial Operation)

1

Cyclone Feed O'flow Cond. U'flow Cond. Cyclone Feed O'flow Cond. U'flow Con.

TPH Solids (Total) 1919 766.8 1153 2348 937.8 1410

TPH Liquid 3148 2722 426.3 3850 3329 521.4

TPH Pulp 5067 3488 1579 6198 4267 1931

% Solid (by Wt.) 37.9 22 73 37.9 22 73

Cum/hr Pulp 3774 2974 800 4616 3638 978

Screen Analysis: (90 000 t/d at balance )

Feed Overflow Underflow Recovery

Micron %+ cum %+ ind tph %+ cum %+ ind tph %+ cum %+ ind tph

### 25.7 25.7 492.3 0.2 0.2 1.2 42.6 42.6 491.1 99.8

### 41.5 15.9 304.8 1.6 1.4 11.1 68.1 25.5 293.7 96.4

75 50.2 8.7 166.7 6.0 4.4 33.7 79.6 11.5 133.0 79.8

53 57.4 7.2 137.4 14.5 8.6 65.6 85.9 6.2 71.8 52.3

45 61.0 3.7 70.4 19.9 5.4 41.1 88.4 2.5 29.3 41.6

-45 100.0 39.0 747.7 100.0 80.1 614.1 100.0 11.6 133.6 17.9

Total 1919.3 766.8 1152.5 60

Screen Analysis: (110 000 t/d at balance ) 1

Feed Overflow Underflow Recovery

Mesh %+ cum %+ ind tph %+ cum %+ ind tph %+ cum %+ ind tph

150.0 25.7 25.7 602.2 0.2 0.2 1.5 42.6 42.6 600.7 99.8

106.0 41.5 15.9 372.8 1.6 1.4 13.6 68.1 25.5 359.2 96.4

75.0 50.2 8.7 203.9 6.0 4.4 41.2 79.6 11.5 162.7 79.8

53.0 57.4 7.2 168.1 14.5 8.6 80.2 85.9 6.2 87.8 52.3

45.0 61.0 3.7 86.1 19.9 5.4 50.3 88.4 2.5 35.8 41.6

-45.0 100.0 39.0 914.5 100.0 80.1 751.1 100.0 11.6 163.4 17.9

Total 2347.5 937.8 1409.7 60

REMARKS (B) :

The climatic and seismic conditions at the plant are described

in Section 4, Project Information of the Material Requisition

* 1. (B) INDICATES BUYER. (S) INDICATES SELLER

2. ALL (B) ITEMS SHALL BE COMPLETED BY BUYER. ALL (S) ITEMS SHALL BE COMPLETED BY SELLER

3. NOT APPLICABLE (NA) SHALL BE ENTERED WHERE INFORMATION IS NOT RELEVANT

EQUIPMENT NO. REGRIND JOB NO. 24017 REV

320-CS-006 thru 008 CYCLONE CLUSTERS FORM: M-010-DS-02 1

DATA SHEET SHEET 3 OF 5

MANUFACTURER BIDDER

(S)* CYCLONE DATA

Service Regrind Cyclone

90 000 t/d 110 000 t/d

1

Cyclone Size, mm ( 20") 508 (B) ( 20") 508 (B)

Model No. DS20LB DS20LB

Oper. Cyclones Req. 9 / 12 12 / 14

Recommended Spares

No. Cyclones/Cluster 9 (B) (*) 9 (B) (*)

No. Clusters 3 3

Feed Pressure, kPa 20 - 21 psi 20 - 21 psi

Feed Conn.Dia.,mm 152.4 (6") 152.4 (6")

Feed Inlet Dimen., mm 152.4 (6") 152.4 (6")

Feed Inlet Area, sq.mm2 17,424 (27 sq.in.) 17,424 (27 sq.in.)

Vortex Finder Dia., mm 7.5" 7.5"

Vortex Finder Material Rubber lined steel Rubber lined steel

Vortex Finder Thk., mm 19 (3 / 4") 19 (3 / 4")

O'flow Conn. Dia., mm 254 (10") 254 (10")

Apex Orifice Dia., mm 88.9 (3.5") 88.9 (3.5")

Adj. Apex Valve X N/A X N/A

Type Control X N/A X N/A

Apex Material Rubber Rubber

Apex Conn. Dia., mm

Cylindrical Section Steel Steel

ID Dia.x Lgth, mm 508 x 584 (20" x 23") 508 x 584 (20" x 23")

Conical Section Steel Steel

Angle x Lgth, mm 20° x 584 20° x 584

Casing Material Steel Steel

Casing Thickness, mm 3 3

Liner Thk.(mm)/Matl. 25 / Rubber 25 / Rubber

List Liners

Pressure Gages None

For Each Cyclone

Feed Manifold Only X (B) X (B)

Quantity 1 (B) 1 (B)

Manufacturer Aschcroft Aschcroft

Type APPCOR Diaphragm (B) APPCOR Diaphragm(B)

(*)Number of Cyclones to be confirmed by Seller

N/A = Not applicable (required)

* 1. (B) INDICATES BUYER. (S) INDICATES SELLER

2. ALL (B) ITEMS SHALL BE COMPLETED BY BUYER. ALL (S) ITEMS SHALL BE COMPLETED BY SELLER

3. NOT APPLICABLE (NA) SHALL BE ENTERED WHERE INFORMATION IS NOT RELEVANT

EQUIPMENT NO. REGRIND JOB NO. 24017 REV

320-CS-006 thru 008 CYCLONE CLUSTERS FORM: M-010-DS-02 1

DATA SHEET SHEET 4 OF 5

MANUFACTURER BIDDER

(S)* MANIFOLD AND SUPPORT SYSTEM

90 000 t/d 110 000 t/d

Service 1

Manifold/Support

required

Feed Manifold

Material Steel Steel

Liners, Matl/Thick Rubber / 25 mm Rubber / 25 mm

Diameter, mm 965 (38") 965 (38")

Height, m 1194 (47") 1194 (47")

Shut-off valves

Material Steel Steel

Type KGD6 AC KGD6 AC

Manufacturer Clarkson Clarkson

Size, mm 152 (6") 152 (6")

O'flow Launder

Material Steel Steel

Dimensions, mm 2540 (100") 2540 (100")

Liners, Matl/Thick Rubber / 12 mm Rubber / 12 mm

Conn. Size, mm 762 (30") 762 (30")

1

U'flow Launder

Material Steel Steel

Dimensions, mm 3785 (149") 3785 (149")

Liners, Matl/Thick Rubber / 25 mm Rubber / 25 mm

Conn. Size, mm 711 (28") 711 (28")

1

(S)* WEIGHTS

Cyclone, Each ### kg

Manifold, Each 8649 kg

Heaviest Piece for Erection 2000 kg

Total Shipping Weight 27,000 kg

Number of Packages 60

* 1. (B) INDICATES BUYER. (S) INDICATES SELLER

2. ALL (B) ITEMS SHALL BE COMPLETED BY BUYER. ALL (S) ITEMS SHALL BE COMPLETED BY SELLER

3. NOT APPLICABLE (NA) SHALL BE ENTERED WHERE INFORMATION IS NOT RELEVANT

EQUIPMENT NO. REGRIND JOB NO. 24017 REV

320-CS-006 thru 008 CYCLONE CLUSTERS FORM: M-010-DS-02 1

DATA SHEET SHEET 5 OF 5

You might also like

- One Day On The RoadDocument3 pagesOne Day On The RoadRichard Adam Sison74% (77)

- IT6468 0911gbDocument24 pagesIT6468 0911gbmarcos lemosNo ratings yet

- Direct Drive Servomotor Turrets: SeriesDocument18 pagesDirect Drive Servomotor Turrets: SeriesSHG AUTMEC MANUTENÇÃO E AUTOMAÇÃO MÁQ. INDUSTRIAISNo ratings yet

- 05 Process Datasheet Annexure-PDocument1 page05 Process Datasheet Annexure-PpdilgnfcNo ratings yet

- Pm-Clinic Data Sheet Wd900-3 Base Information: Customer Name LocationDocument3 pagesPm-Clinic Data Sheet Wd900-3 Base Information: Customer Name LocationJuan Pablo Muñante Palacin100% (1)

- Calculation Notes (Acceleration Loss)Document17 pagesCalculation Notes (Acceleration Loss)Dennis Koay GMNo ratings yet

- Centrifugal and Axial Compressor DATA SHEET (API 617-7TH Chapter 2) SI UNITS (1-1.6.5)Document4 pagesCentrifugal and Axial Compressor DATA SHEET (API 617-7TH Chapter 2) SI UNITS (1-1.6.5)Carlos Felipe Reyes MartínezNo ratings yet

- 26148-220-V1a-Mfm0-00223 - Hoja de Datos Molino Sag 0320-ML-5001 PDFDocument10 pages26148-220-V1a-Mfm0-00223 - Hoja de Datos Molino Sag 0320-ML-5001 PDFLeonel Gamero CardenasNo ratings yet

- ChallengeDocument29 pagesChallengeMarconiVianaNo ratings yet

- Epc Package Gaderwara STPP Stage-Ii (2X800 MW) Ash Handling System & Ash Water Recirculation System Electrical Load ListDocument2 pagesEpc Package Gaderwara STPP Stage-Ii (2X800 MW) Ash Handling System & Ash Water Recirculation System Electrical Load ListvenkateshbitraNo ratings yet

- Annex 6Document2 pagesAnnex 6venkateshbitraNo ratings yet

- Manual Servicio CBC Tipo VDocument31 pagesManual Servicio CBC Tipo VfgdfgdfNo ratings yet

- OM MILL (Coal Pulveriser)Document7 pagesOM MILL (Coal Pulveriser)Nhật TuấnNo ratings yet

- Turbine O&M ManualDocument83 pagesTurbine O&M ManualMohammed MuzzamilNo ratings yet

- Storage Tank Gas Breathing For Purge Gas SizingDocument3 pagesStorage Tank Gas Breathing For Purge Gas SizingguhadebasisNo ratings yet

- Physical Testing of Clinker & CementDocument61 pagesPhysical Testing of Clinker & CementDineshNo ratings yet

- PM Clinic WA500-3LEDocument3 pagesPM Clinic WA500-3LEJheison ValenciaNo ratings yet

- NTPC SpecsDocument2 pagesNTPC SpecsxiaomiNo ratings yet

- Raup Iom 0705 PDFDocument35 pagesRaup Iom 0705 PDFritoNo ratings yet

- A320Document8 pagesA320Estevam Gomes de Azevedo50% (2)

- 54-Pressure Gauge OIT Calibration CartificateDocument1 page54-Pressure Gauge OIT Calibration CartificateCustomer Support100% (1)

- 2011 Cost Models SectionDocument56 pages2011 Cost Models Sectionoduk odbayarNo ratings yet

- 'RAUP IOM-Aug06Document35 pages'RAUP IOM-Aug06Ngô Khắc ToảnNo ratings yet

- Brochure Dresser Series B3 MetersDocument4 pagesBrochure Dresser Series B3 Metersrahman ariwibowoNo ratings yet

- LM104949P TaperedRollerBearings SingleCones ImperialDocument4 pagesLM104949P TaperedRollerBearings SingleCones ImperialFernandes CoporaçõesNo ratings yet

- On-Load Tap-Changer OILTAP® G: Technical Data TD 48Document34 pagesOn-Load Tap-Changer OILTAP® G: Technical Data TD 48Ravindra AngalNo ratings yet

- MEDIDOR DRESSER 8c-11c-15c - Ngs-Mi-0006-1Document4 pagesMEDIDOR DRESSER 8c-11c-15c - Ngs-Mi-0006-1Jonathan S. R.No ratings yet

- CM600DX 24T/CM600DXP 24TDocument14 pagesCM600DX 24T/CM600DXP 24TSherif SabryNo ratings yet

- Technical Specification COP 2238 - 9851 2656 01 Low ResDocument2 pagesTechnical Specification COP 2238 - 9851 2656 01 Low Resdmb1692100% (1)

- Glued JointsDocument5 pagesGlued Jointsanildondapati1No ratings yet

- 9452 SamsungDocument13 pages9452 SamsungEdward José Chacín R.No ratings yet

- Injection Pump Test Specifications: Manu-Facturer Engine Type Vehicle ModelDocument2 pagesInjection Pump Test Specifications: Manu-Facturer Engine Type Vehicle ModelJunior IungNo ratings yet

- 33kV Cable Sizing CalcDocument9 pages33kV Cable Sizing Calcsrigirisetty208No ratings yet

- Pm-Clinic Data Sheet Wa180-3L Base Information: Customer Name LocationDocument3 pagesPm-Clinic Data Sheet Wa180-3L Base Information: Customer Name LocationjulianoNo ratings yet

- 18-Acoples Elastomericos LovejoyDocument70 pages18-Acoples Elastomericos LovejoyERIKSON EGUSQUIZANo ratings yet

- HYDRANT System Demand: Full Unit: Annexure - 1 Fire Water Demand Calculation For SUG Facilities Fire Fighting SystemDocument11 pagesHYDRANT System Demand: Full Unit: Annexure - 1 Fire Water Demand Calculation For SUG Facilities Fire Fighting SystemJMVNo ratings yet

- B70 Rock Breaker Care Operation Manual For TH86Document21 pagesB70 Rock Breaker Care Operation Manual For TH86Latifa EngineeringNo ratings yet

- 5.modification of Starter Operated 10 MT EOT - ConceptDocument18 pages5.modification of Starter Operated 10 MT EOT - ConceptIndranil DasguptaNo ratings yet

- Dust Extract SystemDocument17 pagesDust Extract Systemmathan_aeNo ratings yet

- Datasheet H2930uabc MetricoDocument1 pageDatasheet H2930uabc MetricoRodrigo J. MarqueziniNo ratings yet

- Orifice Size Calc For Gas PressureDocument2 pagesOrifice Size Calc For Gas PressureHyejune ParkNo ratings yet

- Weight CalculationDocument13 pagesWeight CalculationPankaj BijweNo ratings yet

- Wind Girder Calculations: Appendix 'M' Is Applicable?Document8 pagesWind Girder Calculations: Appendix 'M' Is Applicable?Anonymous LKi1w1uNo ratings yet

- 8103 M-42 6u2816013 Plate Type CoolersDocument60 pages8103 M-42 6u2816013 Plate Type CoolersABDULLAHNo ratings yet

- Design (Metric) 5 (1) .37Document7 pagesDesign (Metric) 5 (1) .37Huy NguyenmbvNo ratings yet

- Curved Jaw TypeDocument18 pagesCurved Jaw Typeadjime3No ratings yet

- 8474L-000-CN-0008-003-0 - Design GuidelinesDocument25 pages8474L-000-CN-0008-003-0 - Design Guidelinesdanhlakisu1No ratings yet

- Boq - 100 KLD STP Plant DJ Group ModinagarDocument1 pageBoq - 100 KLD STP Plant DJ Group ModinagarVishal shuklaNo ratings yet

- On-Load Tap-Changer OILTAP® R: Technical Data TD 115Document60 pagesOn-Load Tap-Changer OILTAP® R: Technical Data TD 115Jack DuffNo ratings yet

- Injection Pump Test Specifications: Manu-Facturer Engine Type Vehicle ModelDocument2 pagesInjection Pump Test Specifications: Manu-Facturer Engine Type Vehicle ModelKevin TtitoNo ratings yet

- SWT PreSolidsSeparation H011840 A4Document2 pagesSWT PreSolidsSeparation H011840 A4slbclqrkNo ratings yet

- 72-31-00-290-002-A - Inspection of The High Pressure Compressor Rotor AssemblyDocument30 pages72-31-00-290-002-A - Inspection of The High Pressure Compressor Rotor Assembly尹兴旺No ratings yet

- HPF Fan - AnshanDocument28 pagesHPF Fan - AnshanDangolNo ratings yet

- M-01-DS-0003 Specification Sheet: Date REV Prepared by Checked by Approved by DescriptionDocument2 pagesM-01-DS-0003 Specification Sheet: Date REV Prepared by Checked by Approved by DescriptionAJAY1381No ratings yet

- WKFI LeafletDocument16 pagesWKFI Leafletrishi pandeyNo ratings yet

- Technical OfferDocument10 pagesTechnical OfferNishantNo ratings yet

- LOVEJOY - Curved Jaw CouplingsDocument22 pagesLOVEJOY - Curved Jaw CouplingspedroNo ratings yet

- 1.0 General Plant Information: Existing Cement Mill Process Data SheetDocument6 pages1.0 General Plant Information: Existing Cement Mill Process Data SheetBùi Hắc HảiNo ratings yet

- ALB-41-PR-DP-0204-Rv-D - PID - Potash Wet - OffSites - Futuro Rev - ABDocument1 pageALB-41-PR-DP-0204-Rv-D - PID - Potash Wet - OffSites - Futuro Rev - ABAlejandro Bartolo YañezNo ratings yet

- ALB-41-PR-DP-0203-Rv-D - PID - Potash Wet - Centrifugas - Futuro Rev - ABDocument1 pageALB-41-PR-DP-0203-Rv-D - PID - Potash Wet - Centrifugas - Futuro Rev - ABAlejandro Bartolo YañezNo ratings yet

- EQUIPMENT LIST - 2021-01-15 - Rev-EDocument9 pagesEQUIPMENT LIST - 2021-01-15 - Rev-EAlejandro Bartolo YañezNo ratings yet

- Rotary Ball Feeder - Catalogación Spare Parts 1er Año OperacionesDocument48 pagesRotary Ball Feeder - Catalogación Spare Parts 1er Año OperacionesAlejandro Bartolo YañezNo ratings yet

- Spile Bar System - Catalogación Spare Parts 1er Año OperacionesDocument74 pagesSpile Bar System - Catalogación Spare Parts 1er Año OperacionesAlejandro Bartolo YañezNo ratings yet

- Recirculation Pumps Filter Plant - Catalogación Spare Parts 1er Año OperacionesDocument48 pagesRecirculation Pumps Filter Plant - Catalogación Spare Parts 1er Año OperacionesAlejandro Bartolo YañezNo ratings yet

- TEP-M-011 in Plant Conveyor - TEP - 1st Operation Year and Capital SparesDocument70 pagesTEP-M-011 in Plant Conveyor - TEP - 1st Operation Year and Capital SparesAlejandro Bartolo YañezNo ratings yet

- 01 Lista de Repuestos - 60577Document5 pages01 Lista de Repuestos - 60577Alejandro Bartolo YañezNo ratings yet

- Repuestos Mecanicos Celda TC-160 MELDocument1 pageRepuestos Mecanicos Celda TC-160 MELAlejandro Bartolo YañezNo ratings yet

- PO TEP-E-008 Distribution Transformers - WEGDocument6 pagesPO TEP-E-008 Distribution Transformers - WEGAlejandro Bartolo YañezNo ratings yet

- Hidrociclones 1.2 Recommended Spare Parts Tep-M-078spDocument1 pageHidrociclones 1.2 Recommended Spare Parts Tep-M-078spAlejandro Bartolo YañezNo ratings yet

- BAP1273-100 - Listado Recomendado de RepuestosDocument17 pagesBAP1273-100 - Listado Recomendado de RepuestosAlejandro Bartolo YañezNo ratings yet

- Listado de Equipos (Criticos Con Fecha Comisionamiento) PrincipalesDocument12 pagesListado de Equipos (Criticos Con Fecha Comisionamiento) PrincipalesAlejandro Bartolo YañezNo ratings yet

- 58-Reliability Centered MaintenanceDocument32 pages58-Reliability Centered MaintenanceAlejandro Bartolo Yañez100% (1)

- Detalle Información PO - Repuestos Comisionado ArranqueDocument5 pagesDetalle Información PO - Repuestos Comisionado ArranqueAlejandro Bartolo YañezNo ratings yet

- Planes Building&UtilitiesDocument132 pagesPlanes Building&UtilitiesAlejandro Bartolo YañezNo ratings yet

- Plan Mtto ApilamientoDocument356 pagesPlan Mtto ApilamientoAlejandro Bartolo YañezNo ratings yet

- Filosofia de Los ModelosDocument25 pagesFilosofia de Los ModelosAlejandro Bartolo YañezNo ratings yet

- Asset Strategy Development Procedure A2D SAP - 1496221Document11 pagesAsset Strategy Development Procedure A2D SAP - 1496221Alejandro Bartolo Yañez100% (1)

- SIGMADocument2 pagesSIGMAAlejandro Bartolo YañezNo ratings yet

- Tong Hop Bai Tap So Sanh Hon Va So Sanh Nhat Co Dap AnDocument14 pagesTong Hop Bai Tap So Sanh Hon Va So Sanh Nhat Co Dap AnGia HuyNo ratings yet

- Measuring Strain in RocksDocument2 pagesMeasuring Strain in Rocksdarebusi1No ratings yet

- 207 Money Saving FixesDocument149 pages207 Money Saving FixesCarmen Elena Nastasă100% (3)

- BS 2782-10 Method 1005 1977Document13 pagesBS 2782-10 Method 1005 1977Yaser ShabasyNo ratings yet

- 2016 CV - Curriculum Vitae Duy Anh 1Document11 pages2016 CV - Curriculum Vitae Duy Anh 1Cao Quang HưngNo ratings yet

- Aegis - Designer and AnalyzerDocument26 pagesAegis - Designer and Analyzeropenid_S1hHcZODNo ratings yet

- Accomplishment Report Pinagtigasan KinderDocument12 pagesAccomplishment Report Pinagtigasan KinderMay Anne AlmarioNo ratings yet

- Dreams LuDocument325 pagesDreams Luscrib3030100% (1)

- Esthetic Excellence PDFDocument32 pagesEsthetic Excellence PDFZomba ZombariraNo ratings yet

- ARX - 04 Evangelidis LibreDocument21 pagesARX - 04 Evangelidis LibreVasilis KostovassilisNo ratings yet

- Analytical ExpositionDocument9 pagesAnalytical Expositionkeira raishaNo ratings yet

- Jury Trial Moot Problem, Bar The Lex Fiesta 2016Document22 pagesJury Trial Moot Problem, Bar The Lex Fiesta 2016ShradhaNo ratings yet

- NIOS Class 12 Psychology Chapter 10 EmotionsDocument4 pagesNIOS Class 12 Psychology Chapter 10 Emotionsmanahil dollNo ratings yet

- Feasibility Study Project Proposal RequirementsDocument2 pagesFeasibility Study Project Proposal RequirementsErick NgosiaNo ratings yet

- Liebherr Brochure Boom Pumps enDocument20 pagesLiebherr Brochure Boom Pumps enVikash PanditNo ratings yet

- Perception On CatcallingDocument19 pagesPerception On CatcallingJasmin Delos ReyesNo ratings yet

- Eclipse ManualDocument10 pagesEclipse ManualgiancarlohoneyNo ratings yet

- 7.3-7.4 Electric Field and Potential Difference TemplateDocument11 pages7.3-7.4 Electric Field and Potential Difference TemplateAyman HalimeNo ratings yet

- Khidmat - The ServiceDocument6 pagesKhidmat - The ServiceAjay Prakash VermaNo ratings yet

- Catalogue 2019Document450 pagesCatalogue 2019AntonNo ratings yet

- Hand Tools and Measuring DeviceDocument86 pagesHand Tools and Measuring Devicehabtsh100% (3)

- Cabbash Vms BrochureDocument22 pagesCabbash Vms BrochureOghosa OsahenrhumwenNo ratings yet

- New Record TDocument2 pagesNew Record Tapi-309280225No ratings yet

- Transmission Structures and Foundations:: CourseDocument8 pagesTransmission Structures and Foundations:: CoursejulianobiancoNo ratings yet

- Module 4 Lesson 3Document5 pagesModule 4 Lesson 3Ludivina Lajot75% (4)

- GCC - Lesson Plan 2020Document35 pagesGCC - Lesson Plan 2020henaNo ratings yet

- Grade 6 - Specific Outcomes: Can Affect Human Development From Conception Through BirthDocument49 pagesGrade 6 - Specific Outcomes: Can Affect Human Development From Conception Through Birthapi-253059746No ratings yet

- Teaching As A ProfessionDocument5 pagesTeaching As A Professionipinloju temitopeNo ratings yet

- Module 2: Most Essential Learning Competencies (Melcs)Document5 pagesModule 2: Most Essential Learning Competencies (Melcs)Teresita EspinosaNo ratings yet