Professional Documents

Culture Documents

MCC - General Notes

MCC - General Notes

Uploaded by

imthyas.npcCopyright:

Available Formats

You might also like

- Elemental Bill of Quantities For 3 Bedroom Apartment BlockDocument29 pagesElemental Bill of Quantities For 3 Bedroom Apartment BlockAliyu Shehu83% (72)

- CNH Spec DWGB001 - Drawing Tolerance & InterpretationDocument11 pagesCNH Spec DWGB001 - Drawing Tolerance & InterpretationJoe ScopeliteNo ratings yet

- E18189 Full Set - BATCHED PDFDocument13 pagesE18189 Full Set - BATCHED PDFchristineNo ratings yet

- Sample BQ For TNBDocument60 pagesSample BQ For TNBWei Li Neoh100% (1)

- CIGRHandbook Vol 2Document378 pagesCIGRHandbook Vol 2cristian_iacomi3416No ratings yet

- 2335-Summit RD OWNER REVISIONS V4 ENTRY PORCHDocument5 pages2335-Summit RD OWNER REVISIONS V4 ENTRY PORCHArnoldo VanegasNo ratings yet

- Basement Framing Plan 5-1: S C A L E: N T SDocument1 pageBasement Framing Plan 5-1: S C A L E: N T SRenmaster ConstructionNo ratings yet

- Design Drawing: Baladna Farm 2 Tse Polishing PlantDocument12 pagesDesign Drawing: Baladna Farm 2 Tse Polishing PlantWasim OfficialNo ratings yet

- A B C 4850 4850 9700 A1: Revision No. byDocument1 pageA B C 4850 4850 9700 A1: Revision No. byPaschal MazikuNo ratings yet

- Single Line Diagram 2Document1 pageSingle Line Diagram 2Ronel Jasen BiriNo ratings yet

- Single Line Diagram 1Document1 pageSingle Line Diagram 1Ronel Jasen BiriNo ratings yet

- Roof Level: QiblaDocument1 pageRoof Level: QiblaMostafaHeshmatNo ratings yet

- CW - 03 General Notes (Sheet 01 of 02)Document1 pageCW - 03 General Notes (Sheet 01 of 02)Hurriyat AliNo ratings yet

- Sensi Office: Construction Drawing Architectural Denah Alt.02Document1 pageSensi Office: Construction Drawing Architectural Denah Alt.02Winanjar 401No ratings yet

- Service Apartment 1 Bedroom Type 01 Drawings PackageDocument34 pagesService Apartment 1 Bedroom Type 01 Drawings PackageRaja SekharNo ratings yet

- DrainDocument1 pageDrainKhaled AshrafNo ratings yet

- Mml4-Ca09-Chctpl-Civ-Dwg-D-Stn-Cmn-60232 - (Rev-A) (For Single Column) - Sh. 2 of 4Document1 pageMml4-Ca09-Chctpl-Civ-Dwg-D-Stn-Cmn-60232 - (Rev-A) (For Single Column) - Sh. 2 of 4AJAY SHINDENo ratings yet

- DRAWING 2-A1 SheetDocument1 pageDRAWING 2-A1 SheetFervid Prim01No ratings yet

- Steel Structure Drawing XAT10 20X10Document9 pagesSteel Structure Drawing XAT10 20X10Casio AutomaNo ratings yet

- Update The Levels As Per Architecture: 200 MM RC WallDocument1 pageUpdate The Levels As Per Architecture: 200 MM RC WallOmer HayatNo ratings yet

- 2.content SheetDocument1 page2.content SheetbappyNo ratings yet

- 01laboratory Design 101023Document14 pages01laboratory Design 101023Mushe MwanzaNo ratings yet

- السقفDocument1 pageالسقفafk.oxfordNo ratings yet

- Symbols List of Drawing: A Column Grid Graphic Scale North Direction SDocument1 pageSymbols List of Drawing: A Column Grid Graphic Scale North Direction SZaw Hlaing AungNo ratings yet

- Vdocument - in - General Notes Plumbing Abbreviations Notes Symbols List and Details Are ApplicableDocument31 pagesVdocument - in - General Notes Plumbing Abbreviations Notes Symbols List and Details Are ApplicableReden H. ArgawanonNo ratings yet

- Mounting For Slope On Uphill Side Mounting For Slope On Downhill SideDocument1 pageMounting For Slope On Uphill Side Mounting For Slope On Downhill SideTsui DanielNo ratings yet

- Bali Vasaka Housing: Pot-ADocument1 pageBali Vasaka Housing: Pot-AalexNo ratings yet

- Weight by Drawing Sheet: RevisionDocument1 pageWeight by Drawing Sheet: RevisionOseni MomoduNo ratings yet

- NCGM-DU-XX-D-AEC-DR-930-1153 C7: Stage E Vinci Construction Uk LTDDocument1 pageNCGM-DU-XX-D-AEC-DR-930-1153 C7: Stage E Vinci Construction Uk LTDyusufuNo ratings yet

- Indicative FQP-for Structural SteelDocument14 pagesIndicative FQP-for Structural SteelghansaNo ratings yet

- Ground FloorDocument1 pageGround FloorrbelduaNo ratings yet

- Rear ElevationDocument1 pageRear ElevationJEREMIAH Nepomuceno BAÑARESNo ratings yet

- General Notes Concrete Works and Reinforcing Bars: Project TitleDocument5 pagesGeneral Notes Concrete Works and Reinforcing Bars: Project TitleCamille Ariel100% (1)

- Abs Tamm Ald Ab It 03Document1 pageAbs Tamm Ald Ab It 03fairoos aliNo ratings yet

- Off 1 B3 6Document1 pageOff 1 B3 6Don Roseller DumayaNo ratings yet

- DPWH Building PlansDocument5 pagesDPWH Building PlansHelp DACNo ratings yet

- Ar 04Document1 pageAr 04JOSHUA ALZAGANo ratings yet

- Punch List For Qurainat DGSDocument8 pagesPunch List For Qurainat DGSAhmed JawadNo ratings yet

- s102 - Steel Strcutre - 3d ViewDocument1 pages102 - Steel Strcutre - 3d ViewOsama FouadNo ratings yet

- Mml4-Ca09-Chctpl-Civ-Dwg-D-Stn-Cmn-60231. (Rev-A) 08.02.2023 (Typical DWG For Twin Column) (1) - Sh. 2 of 4Document1 pageMml4-Ca09-Chctpl-Civ-Dwg-D-Stn-Cmn-60231. (Rev-A) 08.02.2023 (Typical DWG For Twin Column) (1) - Sh. 2 of 4AJAY SHINDENo ratings yet

- Design of 33 SQM HousingDocument1 pageDesign of 33 SQM HousingDJNo ratings yet

- Actual Size: Condenser UnitDocument1 pageActual Size: Condenser UnitIsmaelNo ratings yet

- GIGLM-1004-SV4016-CS-DOC-CAL-R-7516 DESIGN CALCULATION FOR BOUNDARY WALL FOR SV-4016 - UnlockedDocument172 pagesGIGLM-1004-SV4016-CS-DOC-CAL-R-7516 DESIGN CALCULATION FOR BOUNDARY WALL FOR SV-4016 - UnlockedReza SalimiNo ratings yet

- Assignment Project 01Document34 pagesAssignment Project 01DanielNo ratings yet

- CL CL: Standard DrawingDocument6 pagesCL CL: Standard DrawingTyo ReynaldyNo ratings yet

- First Floor 1: DN 40Ft Containerized Offices 20Ft Attached ContainerDocument1 pageFirst Floor 1: DN 40Ft Containerized Offices 20Ft Attached Containeruche ekeNo ratings yet

- 39 Renown - BP Set Submission - 2020-05-28Document18 pages39 Renown - BP Set Submission - 2020-05-28Owen Francis Arles MaongatNo ratings yet

- Cruz Residence Plans & ScheduleDocument36 pagesCruz Residence Plans & ScheduleFrancis BautistaNo ratings yet

- Bedroom Design SampleDocument1 pageBedroom Design SampleWilliam Lewis BaquianoNo ratings yet

- Tle-02 Dossier.Document40 pagesTle-02 Dossier.suria qaqcNo ratings yet

- Strutcural Steel General Notes BSDocument1 pageStrutcural Steel General Notes BSSumeshNo ratings yet

- QIP For EPCL Structure Rev-0002Document3 pagesQIP For EPCL Structure Rev-0002suria qaqcNo ratings yet

- Larsen & Toubro Limited - Ecc Division: Engineering Design and Research CentreDocument2 pagesLarsen & Toubro Limited - Ecc Division: Engineering Design and Research CentreOuseppachan AmbookenNo ratings yet

- Mml4-Ca11-Chctpl-Civ-Dwg-D-Stn-Cmn-60231. (Rev-A) 08.02.2023 (Typical DWG For Twin Column) - Sh. 2 of 4Document1 pageMml4-Ca11-Chctpl-Civ-Dwg-D-Stn-Cmn-60231. (Rev-A) 08.02.2023 (Typical DWG For Twin Column) - Sh. 2 of 4AJAY SHINDENo ratings yet

- 7villa-Om-Me-02 DX Hi Wall Split Ac UnitsDocument60 pages7villa-Om-Me-02 DX Hi Wall Split Ac UnitsAravindhan ANo ratings yet

- D92-1001 Tarea 2 ArranqueDocument4 pagesD92-1001 Tarea 2 ArranquemarioNo ratings yet

- Revision History Date Description ECN REV: Apr-29-20 A2 ME357 Reference DocumentsDocument1 pageRevision History Date Description ECN REV: Apr-29-20 A2 ME357 Reference Documentsapi-510259807No ratings yet

- Sr. No. Description Quantity Unit Rate (PKR) Amount (PKR) : KW&SB New 100Mgd Pump House at DhabejiDocument2 pagesSr. No. Description Quantity Unit Rate (PKR) Amount (PKR) : KW&SB New 100Mgd Pump House at DhabejigreatwellwisherNo ratings yet

- ST 009Document1 pageST 009MahMoudAbdEl-KaderNo ratings yet

- NCGM-DU-XX-D-AEC-DR-930-1154 C9: Stage E Vinci Construction Uk LTDDocument1 pageNCGM-DU-XX-D-AEC-DR-930-1154 C9: Stage E Vinci Construction Uk LTDyusufuNo ratings yet

- Data Entry: Larsen & Toubro Limited, Construction, Buildings & FactoriesDocument17 pagesData Entry: Larsen & Toubro Limited, Construction, Buildings & FactoriesOuseppachan AmbookenNo ratings yet

- S-101 Shoring Layout & DetailsDocument1 pageS-101 Shoring Layout & Detailsjibeesh cmNo ratings yet

- STRUCT1Document689 pagesSTRUCT1kokueiNo ratings yet

- BMT-S4-RCC Structures Class - 02june2021Document56 pagesBMT-S4-RCC Structures Class - 02june2021aishNo ratings yet

- Study of Mechanical Properties of The Available Brands of Steel Reinforcement in Kurdistan IraqDocument10 pagesStudy of Mechanical Properties of The Available Brands of Steel Reinforcement in Kurdistan IraqIAEME PublicationNo ratings yet

- Pds Leap Bridge Concrete LTR en LRDocument4 pagesPds Leap Bridge Concrete LTR en LRDen BagusNo ratings yet

- Steel Fiber ConcreteDocument16 pagesSteel Fiber ConcreteMagdy MakramNo ratings yet

- Concrete Repair - Estopatch MP - Data Sheet - 160704Document2 pagesConcrete Repair - Estopatch MP - Data Sheet - 160704Edy SumaryantoNo ratings yet

- IP 2 LatestDocument39 pagesIP 2 LatestIbrahim DawudNo ratings yet

- Pile Cap Design ExamplesDocument70 pagesPile Cap Design Examplest_solanki200160% (5)

- Section 10 Piling Works PDFDocument31 pagesSection 10 Piling Works PDFLeanna Abdul Wahab75% (4)

- Qap-15-23 - rg1700 01 Rev-5 Design Criteria For Concrete Foundations and StructuresDocument23 pagesQap-15-23 - rg1700 01 Rev-5 Design Criteria For Concrete Foundations and StructuresAnonymous uLAATWpfNo ratings yet

- Overview of Ufc 3-340-02, Structures To Resist The Effects of Accidental ExplosionsDocument16 pagesOverview of Ufc 3-340-02, Structures To Resist The Effects of Accidental ExplosionsEhsanNasrollahzadehNo ratings yet

- Manual For Design Using Etabs PDFDocument46 pagesManual For Design Using Etabs PDFPankaj Sardana100% (1)

- 2-CE 305 MOD 2 Singly RCFDocument10 pages2-CE 305 MOD 2 Singly RCFLester Khiets RoaNo ratings yet

- Vietnam Oil and Gas Corporation (Petrovietnam) Dung Quat Refinery (DQR) ProjectDocument8 pagesVietnam Oil and Gas Corporation (Petrovietnam) Dung Quat Refinery (DQR) ProjectSudip ShresthaNo ratings yet

- Spread Footing Design ExampleDocument8 pagesSpread Footing Design Examplemorphie_blackNo ratings yet

- Example. A Reinforced Concrete Spandrel Beam Has Overall Dimensions of 250 X 460 and Is JoinedDocument4 pagesExample. A Reinforced Concrete Spandrel Beam Has Overall Dimensions of 250 X 460 and Is JoinedJames NeoNo ratings yet

- SpecificationsDocument6 pagesSpecificationsRomeo Atienza100% (1)

- Notes PDFDocument1 pageNotes PDFVemajala GaneshNo ratings yet

- Notation 8.0 Aashto Specification References 8.1 Principles and Advantages of PrestressingDocument14 pagesNotation 8.0 Aashto Specification References 8.1 Principles and Advantages of PrestressingRammiris ManNo ratings yet

- FanellaDocument4 pagesFanellamendoncajam100% (1)

- Report On Design Methods With BS-En-SABS For Water Retaining StructuresDocument93 pagesReport On Design Methods With BS-En-SABS For Water Retaining StructuresSanjeev BundhunNo ratings yet

- Using Design Results From Analysis For Reinforcement Design in RevitDocument22 pagesUsing Design Results From Analysis For Reinforcement Design in RevitАндрей Николаевич ГоревNo ratings yet

- EQTip 22Document2 pagesEQTip 22raj_ferrariNo ratings yet

- BOX Culvert Bridge Reinforced With FRPDocument8 pagesBOX Culvert Bridge Reinforced With FRPAlsayed DiabNo ratings yet

- Harakeke Reinforcement of Soil-Cement Building MaterialsDocument14 pagesHarakeke Reinforcement of Soil-Cement Building MaterialsAndor-Csongor NagyNo ratings yet

- Guide To Tremie Concrete For Deep FoundationsDocument83 pagesGuide To Tremie Concrete For Deep FoundationsMax Gabriel Timo BarbosaNo ratings yet

- Bridge Column Design Based On AASHTO 17th & ACI 318-14: Input Data & Design SummaryDocument3 pagesBridge Column Design Based On AASHTO 17th & ACI 318-14: Input Data & Design SummaryRhobbie NolloraNo ratings yet

MCC - General Notes

MCC - General Notes

Uploaded by

imthyas.npcOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MCC - General Notes

MCC - General Notes

Uploaded by

imthyas.npcCopyright:

Available Formats

lOMoARcPSD|36487264

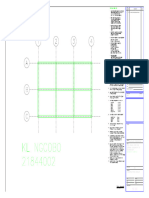

Typical Drawing Ref.

Rev. Drawing No. Date

Z1 AB-TYP-S-201 11-Nov-17

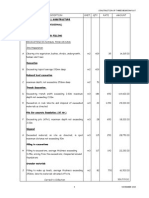

A GENERAL CONCRETE MATERIAL SCHEDULE

A1 STRUCTURAL DRAWINGS READ IN CONJUNCTION WITH ALL OTHER DISCIPLINE DRAWINGS, DOCUMENTS, 28-DAY CUBE

ELEMENT GRADE COMPRESSIVE CEMENT TYPE REMARKS

SPECIFICATIONS ETC. AS MAY BE ISSUED DURING THE COURSE OF THE CONTRACT. ALL DISCREPANCIES TO ASTM C150

STRENGTH (Mpa)

REFERRED TO THE DESIGN CONSULTANT FOR DECISION BEFORE PROCEEDING.

SUBSTRUCTURE

A2 ALL DIMENSIONS ARE IN MILLIMETERS UNLESS NOTED OTHERWISE. DIMENSIONS NOT BE OBTAINED BY PILES K415 40.71 TYPE II

SCALING DRAWINGS. RAFT/ PILE CAPS K415 40.71 TYPE II

RETAINING WALLS K415 40.71 TYPE II DURABLE MIX

A3 ALL LEVELS SHOWN ARE IN METERS WITH REFERENCE TO ABU DHABI MUNICIPALITY DATUM UNLESS NOTED

OTHERWISE. GRADE BEAMS K415 40.71 TYPE II

GRADE SLAB K415 40.71 TYPE II

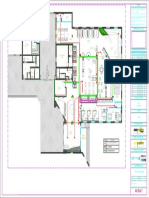

A4 FOR MAIN SETTING OUT LINES AND LEVELS REFER TO CIVIL DRAWINGS

BLINDING K140 13.73 TYPE I

A5 THE CONTRACTOR RESPONSIBLE FOR ENSURING THE SAFETY OF CONSTRUCTION AT ALL TIMES AND

D3 THE CONTRACTOR PERFORM AND SUBMIT FOR REVIEW INSTRUMENT SURVEYS OF FINISHED CONCRETE

ENSURE THAT NO PARTLY COMPLETED CONSTRUCTION IS HAZARDOUS.

SLAB SURFACES, BOTH BEFORE AND AFTER REMOVAL OF FORMWORK AND/OR SHORING SYSTEM TO

A6 THE CONTRACTOR PROVIDE TEMPORARY BRACING AND SHORING AGAINST LATERAL FORCES AND ALL

VERIFY AS-BUILT TOLERANCES.

CONSTRUCTION LOADS THROUGHOUT THE CONSTRUCTION PROCESS.

A7 D4 REFER TO SPECIFICATIONS FOR REQUIREMENTS OF CONCRETE SURFACE FINISH AND CASTING

ALL ELEMENTS OF THE STRUCTURE DESIGNED BY THE CONTRACTOR SUBMITTED TO DESIGN CONSULTANT

TOLERANCE.

FOR REVIEW. D5 PROVIDE UPWARD CAMBER TO SLABS AND BEAMS AS NOTED ON STRUCTURAL DRAWINGS AND/OR

THE DESIGN CONSULTANT'S REVIEW PROCESS FOR ALL SUBMITTALS, DRAWINGS, METHOD STATEMENTS SPECIFICATIONS. CAMBER BOTH UNDERSIDE AND TOP OF CONCRETE TO MAINTAIN THE SLAB AND BEAM

A8

AND DOCUMENTS IS ONLY COMPLETE ONCE A STATUS OF 'NO OBJECTION' IS REACHED. THE SUBMITTAL DEPTH SHOWN ON THE DRAWINGS UNLESS NOTED OTHERWISE.

REVIEWED BY THE DESIGN CONSULTANT FOR COMPLIANCE WITH THE DESIGN INTENT. THIS DOES NOT D6 AGGREGATE FOR CONCRETE FROM APPROVED SOURCE AND COMPLY WITH THE SPECIFICATION

RELIEVE THE CONTRACTOR FROM HIS CONTRACTUAL RESPONSIBILITIES. REQUIREMENTS.

A9 ALL DESIGN, WORKMANSHIP AND MATERIAL IN ACCORDANCE WITH THE CURRENT ACI, UBC, IBC, AISC AND D7 ALL CONCRETE CURED IN ACCORDANCE WITH THE SPECIFICATIONS.

LOCAL AUTHORITY STANDARDS AND PROJECT DESIGN CRITERIA UNLESS NOTED OTHERWISE. EQUIVALENT

D8 ALL REINFORCING BARS CONFORM TO BS 4449 GRADE 460 TYPE 2 DEFORMED HIGH YIELD BARS. DENOTED

BRITISH STANDARDS MAY BE ACCEPTABLE SUBJECT TO APPROVAL OF THE DESIGN CONSULTANT.

BY `T' ON STRUCTURAL DRAWINGS.

D9 REINFORCING BARS SHOULD BE EPOXY COATED

B FOUNDATIONS

D10 ALL REINFORCING BARS DETAILED, FABRICATED, LABELED, SUPPORTED, SPACED IN FORMS AND SECURED

B1 THE NET ALLOWABLE GROUND BEARING CAPACITY IS ASSUMED AS2 50kN/m AT 1.50m DEPTH FOR IN PLACE IN ACCORDANCE WITH THE PROCEDURES AND REQUIREMENTS OUTLINED IN THE CURRENT ACI

FOUNDATION TYPE 6 (PAD FOOTING FOUNDATIONS). 318 AND ACI 315 UNLESS NOTED OTHERWISE ON THE STRUCTURAL DRAWINGS.

D11 WELDING AND/OR SITE CUTTING OF THE REINFORCING BARS NOT BE PERMITTED UNLESS REVIEWED AND

B2 CONTRACTOR CARRY OUT GEOTECHNICAL INVESTIGATION AS NECESSARY TO SUPPORT HIS DESIGN OF

ACCEPTED BY THE DESIGN CONSULTANT.

CAST IN SITU DRILLED PIER FOUNDATION.

D12 ALL PROPRIETARY FIXING INSTALLED IN ACCORDANCE WITH THE MANUFACTURER'S INSTRUCTIONS.

C EXCAVATION AND DE-WATERING

D13 MECHANICAL SPLICING OF LARGE DIAMETER BARS MAY BE ACCEPTABLE SUBJECT TO REVIEW BY THE

C1 THE CONTRACTOR PROVIDE SURFACE DRAINAGE CHANNELS, SUMPS AND SUMP PUMPS TO PROTECT ALL DESIGN CONSULTANT.

EXCAVATIONS FROM FLOODING. FLOODING OF ANY EXCAVATION AFTER APPROVAL OF SUBGRADE CAUSE

D14 ALL CONCRETE CONTAIN AN APPROVED WATER REDUCING, PLASTICIZING ADMIXTURE. APPROVED

FOR COMPLETE RE-PREPARATION AND APPROVAL OF THE SUBGRADE.

HIGH-RANGE WATER REDUCING ADMIXTURE MAY BE UTILIZED AT THE CONTRACTOR'S OPTION. ALL

C2 THE CONTRACTOR PROVIDE POSITIVE PROTECTION (MAT/SHEET COVERING) FOR ALL EXCAVATED SLOPES

CONCRETE PERMANENTLY EXPOSED TO WEATHER ALSO CONTAIN AN APPROVED AIR-ENTRAINING

TO PROTECT SLOPES FROM INSTABILITY AND DETERIORATION DUE TO ENVIRONMENTAL CONDITIONS.

ADMIXTURE TO PROVIDE PERCENTAGE OF AIR REQUIRED FOR SEVERE EXPOSURE AS PER ACI 318.

C3 THE EXCAVATION RETENTION SYSTEM DESIGNED AND INSTALLED BY THE CONTRACTOR, UNLESS NOTED D15 NO CALCIUM CHLORIDE USED IN ANY CONCRETE.

OTHERWISE, IN ACCORDANCE WITH THE GEOTECHNICAL DESIGN PARAMETERS AND SOIL PRESSURES AS

D16 THE FOLLOWING CONCRETE CLEAR COVER TO PRIMARY REINFORCEMENT PROVIDED, UNLESS LARGER

INDICATED IN THE GEOTECHNICAL INVESTIGATION REPORT.

COVER IS NOTED ON THE STRUCTURAL DRAWINGS.

C4 THE CONTRACTOR INSTALL AND CONTINUOUSLY SURVEY VERTICAL AND HORIZONTAL MOVEMENTS OF

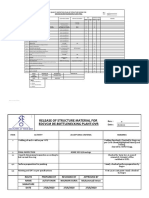

THE TOP OF THE SOIL RETENTION SYSTEM, IF INSTALLED, BENCH MARKS ADJACENT TO AND AWAY FROM CONCRETE CLEAR COVER SCHEDULE

THE SITE PERIMETER FOR VERTICAL AND HORIZONTAL MOVEMENTS AND OBSERVATION WELLS FOR CLEAR COVER TO PRIMARY REINFORCEMENT (mm)

MONITORING WATER LEVELS BELOW GROUND SURFACE. ELEMENT ABOVE GROUND ABOVE GROUND

SURFACE IN CONTACT REMARKS

WITH GROUND INTERIOR EXTERIOR

C5 AFTER COMPLETION OF THE PERIMETER SOIL RETENTION SYSTEM, THE SITE DE-WATERED, AS ENVIRONMENT ENVIRONMENT

PILES 75 - -

NECESSARY, BEFORE (OR AS) THE EXCAVATION PROCEEDS. THE CONTRACTOR PROVIDE ALL COLUMNS/PEDESTAL 75 40 50

FOOTING 75 - -

CONSTRUCTION AND EQUIPMENT FOR THE DE-WATERING SYSTEM INCLUDING, BUT NOT LIMITED TO,

EQUIPMENT PADS 40 40

TRENCHES, SUMPS, DE-WATERING WELLS, WELL POINTS, OBSERVATION WELLS, PUMPING SYSTEM,

DISPOSAL LOCATION, SETTLING BASINS, MAINTENANCE AND EMERGENCY BACK-UP EQUIPMENT, ETC. . D17 SPLICES IN REINFORCEMENT CONFORM TO THE REQUIREMENTS OF THE RELEVANT BRITISH STANDARD

AND MADE ONLY IN THE POSITIONS SHOWN OR AS OTHERWISE APPROVED BY THE KEO. THE FOLLOWING

C6 THE DE-WATERING SYSTEM MAINTAIN THE WATER LEVEL AT MINIMUM OF 0.50 METER BELOW THE

MINIMUM SPLICE LENGTH USED UNLESS OTHERWISE NOTED

DEEPEST FOUNDATION SUBGRADE AT ALL TIMES.

BAR SIZE (mm) LAP LENGTH (mm)

10 500

D REINFORCED CONCRETE 12 600 NOTES:

D1 THE CONTRACTOR SUBMIT DETAILED RC DRAWINGS AND BAR BENDING SCHEDULES SHOWING BAR SIZES,

16 800 SPLICE LENGTHS PROVIDED FOR

SPACING, PLACEMENT AND SUPPORT DETAILS OF DOWELS AT EXPANSION JOINTS AND LAPS ETC. FOR

20 1000 THE SMALLER OF THE TWO BARS BEING

REVIEW AND ACCEPTANCE OF THE DESIGN CONSULTANT. WORK NOT COMMENCE UNTIL THE SHOP SPLICED

25 1250

DRAWINGS ARE REVIEWED AND ACCEPTED. REVIEW OF SHOP DRAWINGS DOES NOT ALLEVIATE THE 32 1600

CONTRACTOR'S RESPONSIBILITY TO COORDINATE THE INPUT OF ALL TRADES ON THE SHOP DRAWINGS. E PROTECTIVE COATINGS FOR CONCRETE

E1 UNLESS SHOWN OTHERWISE, ALL EXTERNAL CONCRETE SURFACE EXPOSED TO SOIL PROTECTED AS

D2 ALL CAST-IN-SITU CONCRETE HAVE MINIMUM 28-DAY CUBE COMPRESSIVE STRENGTH FOR VARIOUS

FOLLOWS: HORIZONTAL AND VERTICAL SURFACES: PROTECTION OF EXTERNAL CONCRETE SURFACE IN

ELEMENTS AS GIVEN IN THE CONCRETE MATERIAL SCHEDULE. ALL CONCRETE NORMAL WEIGHT

CONTACT WITH WATER & SOIL BELOW GROUND. ONE COAT PRIMER+ONE LAYER 5MM THICK TORCH

CONCRETE MINIMUM DENSITY OF 2400Kg/m³. AND MAXIMUM SIZE OF COURSE AGGREGATES OF 20mm

APPLIED SBS MODIFIED WATER PROOFING MEMBRANE+ONE LAYER OF 3MM THICK PROTECTION BOARD.

UNLESS NOTED OTHERWISE.

STRUCTURAL DRAWING NOTES (13 / 24)

You might also like

- Elemental Bill of Quantities For 3 Bedroom Apartment BlockDocument29 pagesElemental Bill of Quantities For 3 Bedroom Apartment BlockAliyu Shehu83% (72)

- CNH Spec DWGB001 - Drawing Tolerance & InterpretationDocument11 pagesCNH Spec DWGB001 - Drawing Tolerance & InterpretationJoe ScopeliteNo ratings yet

- E18189 Full Set - BATCHED PDFDocument13 pagesE18189 Full Set - BATCHED PDFchristineNo ratings yet

- Sample BQ For TNBDocument60 pagesSample BQ For TNBWei Li Neoh100% (1)

- CIGRHandbook Vol 2Document378 pagesCIGRHandbook Vol 2cristian_iacomi3416No ratings yet

- 2335-Summit RD OWNER REVISIONS V4 ENTRY PORCHDocument5 pages2335-Summit RD OWNER REVISIONS V4 ENTRY PORCHArnoldo VanegasNo ratings yet

- Basement Framing Plan 5-1: S C A L E: N T SDocument1 pageBasement Framing Plan 5-1: S C A L E: N T SRenmaster ConstructionNo ratings yet

- Design Drawing: Baladna Farm 2 Tse Polishing PlantDocument12 pagesDesign Drawing: Baladna Farm 2 Tse Polishing PlantWasim OfficialNo ratings yet

- A B C 4850 4850 9700 A1: Revision No. byDocument1 pageA B C 4850 4850 9700 A1: Revision No. byPaschal MazikuNo ratings yet

- Single Line Diagram 2Document1 pageSingle Line Diagram 2Ronel Jasen BiriNo ratings yet

- Single Line Diagram 1Document1 pageSingle Line Diagram 1Ronel Jasen BiriNo ratings yet

- Roof Level: QiblaDocument1 pageRoof Level: QiblaMostafaHeshmatNo ratings yet

- CW - 03 General Notes (Sheet 01 of 02)Document1 pageCW - 03 General Notes (Sheet 01 of 02)Hurriyat AliNo ratings yet

- Sensi Office: Construction Drawing Architectural Denah Alt.02Document1 pageSensi Office: Construction Drawing Architectural Denah Alt.02Winanjar 401No ratings yet

- Service Apartment 1 Bedroom Type 01 Drawings PackageDocument34 pagesService Apartment 1 Bedroom Type 01 Drawings PackageRaja SekharNo ratings yet

- DrainDocument1 pageDrainKhaled AshrafNo ratings yet

- Mml4-Ca09-Chctpl-Civ-Dwg-D-Stn-Cmn-60232 - (Rev-A) (For Single Column) - Sh. 2 of 4Document1 pageMml4-Ca09-Chctpl-Civ-Dwg-D-Stn-Cmn-60232 - (Rev-A) (For Single Column) - Sh. 2 of 4AJAY SHINDENo ratings yet

- DRAWING 2-A1 SheetDocument1 pageDRAWING 2-A1 SheetFervid Prim01No ratings yet

- Steel Structure Drawing XAT10 20X10Document9 pagesSteel Structure Drawing XAT10 20X10Casio AutomaNo ratings yet

- Update The Levels As Per Architecture: 200 MM RC WallDocument1 pageUpdate The Levels As Per Architecture: 200 MM RC WallOmer HayatNo ratings yet

- 2.content SheetDocument1 page2.content SheetbappyNo ratings yet

- 01laboratory Design 101023Document14 pages01laboratory Design 101023Mushe MwanzaNo ratings yet

- السقفDocument1 pageالسقفafk.oxfordNo ratings yet

- Symbols List of Drawing: A Column Grid Graphic Scale North Direction SDocument1 pageSymbols List of Drawing: A Column Grid Graphic Scale North Direction SZaw Hlaing AungNo ratings yet

- Vdocument - in - General Notes Plumbing Abbreviations Notes Symbols List and Details Are ApplicableDocument31 pagesVdocument - in - General Notes Plumbing Abbreviations Notes Symbols List and Details Are ApplicableReden H. ArgawanonNo ratings yet

- Mounting For Slope On Uphill Side Mounting For Slope On Downhill SideDocument1 pageMounting For Slope On Uphill Side Mounting For Slope On Downhill SideTsui DanielNo ratings yet

- Bali Vasaka Housing: Pot-ADocument1 pageBali Vasaka Housing: Pot-AalexNo ratings yet

- Weight by Drawing Sheet: RevisionDocument1 pageWeight by Drawing Sheet: RevisionOseni MomoduNo ratings yet

- NCGM-DU-XX-D-AEC-DR-930-1153 C7: Stage E Vinci Construction Uk LTDDocument1 pageNCGM-DU-XX-D-AEC-DR-930-1153 C7: Stage E Vinci Construction Uk LTDyusufuNo ratings yet

- Indicative FQP-for Structural SteelDocument14 pagesIndicative FQP-for Structural SteelghansaNo ratings yet

- Ground FloorDocument1 pageGround FloorrbelduaNo ratings yet

- Rear ElevationDocument1 pageRear ElevationJEREMIAH Nepomuceno BAÑARESNo ratings yet

- General Notes Concrete Works and Reinforcing Bars: Project TitleDocument5 pagesGeneral Notes Concrete Works and Reinforcing Bars: Project TitleCamille Ariel100% (1)

- Abs Tamm Ald Ab It 03Document1 pageAbs Tamm Ald Ab It 03fairoos aliNo ratings yet

- Off 1 B3 6Document1 pageOff 1 B3 6Don Roseller DumayaNo ratings yet

- DPWH Building PlansDocument5 pagesDPWH Building PlansHelp DACNo ratings yet

- Ar 04Document1 pageAr 04JOSHUA ALZAGANo ratings yet

- Punch List For Qurainat DGSDocument8 pagesPunch List For Qurainat DGSAhmed JawadNo ratings yet

- s102 - Steel Strcutre - 3d ViewDocument1 pages102 - Steel Strcutre - 3d ViewOsama FouadNo ratings yet

- Mml4-Ca09-Chctpl-Civ-Dwg-D-Stn-Cmn-60231. (Rev-A) 08.02.2023 (Typical DWG For Twin Column) (1) - Sh. 2 of 4Document1 pageMml4-Ca09-Chctpl-Civ-Dwg-D-Stn-Cmn-60231. (Rev-A) 08.02.2023 (Typical DWG For Twin Column) (1) - Sh. 2 of 4AJAY SHINDENo ratings yet

- Design of 33 SQM HousingDocument1 pageDesign of 33 SQM HousingDJNo ratings yet

- Actual Size: Condenser UnitDocument1 pageActual Size: Condenser UnitIsmaelNo ratings yet

- GIGLM-1004-SV4016-CS-DOC-CAL-R-7516 DESIGN CALCULATION FOR BOUNDARY WALL FOR SV-4016 - UnlockedDocument172 pagesGIGLM-1004-SV4016-CS-DOC-CAL-R-7516 DESIGN CALCULATION FOR BOUNDARY WALL FOR SV-4016 - UnlockedReza SalimiNo ratings yet

- Assignment Project 01Document34 pagesAssignment Project 01DanielNo ratings yet

- CL CL: Standard DrawingDocument6 pagesCL CL: Standard DrawingTyo ReynaldyNo ratings yet

- First Floor 1: DN 40Ft Containerized Offices 20Ft Attached ContainerDocument1 pageFirst Floor 1: DN 40Ft Containerized Offices 20Ft Attached Containeruche ekeNo ratings yet

- 39 Renown - BP Set Submission - 2020-05-28Document18 pages39 Renown - BP Set Submission - 2020-05-28Owen Francis Arles MaongatNo ratings yet

- Cruz Residence Plans & ScheduleDocument36 pagesCruz Residence Plans & ScheduleFrancis BautistaNo ratings yet

- Bedroom Design SampleDocument1 pageBedroom Design SampleWilliam Lewis BaquianoNo ratings yet

- Tle-02 Dossier.Document40 pagesTle-02 Dossier.suria qaqcNo ratings yet

- Strutcural Steel General Notes BSDocument1 pageStrutcural Steel General Notes BSSumeshNo ratings yet

- QIP For EPCL Structure Rev-0002Document3 pagesQIP For EPCL Structure Rev-0002suria qaqcNo ratings yet

- Larsen & Toubro Limited - Ecc Division: Engineering Design and Research CentreDocument2 pagesLarsen & Toubro Limited - Ecc Division: Engineering Design and Research CentreOuseppachan AmbookenNo ratings yet

- Mml4-Ca11-Chctpl-Civ-Dwg-D-Stn-Cmn-60231. (Rev-A) 08.02.2023 (Typical DWG For Twin Column) - Sh. 2 of 4Document1 pageMml4-Ca11-Chctpl-Civ-Dwg-D-Stn-Cmn-60231. (Rev-A) 08.02.2023 (Typical DWG For Twin Column) - Sh. 2 of 4AJAY SHINDENo ratings yet

- 7villa-Om-Me-02 DX Hi Wall Split Ac UnitsDocument60 pages7villa-Om-Me-02 DX Hi Wall Split Ac UnitsAravindhan ANo ratings yet

- D92-1001 Tarea 2 ArranqueDocument4 pagesD92-1001 Tarea 2 ArranquemarioNo ratings yet

- Revision History Date Description ECN REV: Apr-29-20 A2 ME357 Reference DocumentsDocument1 pageRevision History Date Description ECN REV: Apr-29-20 A2 ME357 Reference Documentsapi-510259807No ratings yet

- Sr. No. Description Quantity Unit Rate (PKR) Amount (PKR) : KW&SB New 100Mgd Pump House at DhabejiDocument2 pagesSr. No. Description Quantity Unit Rate (PKR) Amount (PKR) : KW&SB New 100Mgd Pump House at DhabejigreatwellwisherNo ratings yet

- ST 009Document1 pageST 009MahMoudAbdEl-KaderNo ratings yet

- NCGM-DU-XX-D-AEC-DR-930-1154 C9: Stage E Vinci Construction Uk LTDDocument1 pageNCGM-DU-XX-D-AEC-DR-930-1154 C9: Stage E Vinci Construction Uk LTDyusufuNo ratings yet

- Data Entry: Larsen & Toubro Limited, Construction, Buildings & FactoriesDocument17 pagesData Entry: Larsen & Toubro Limited, Construction, Buildings & FactoriesOuseppachan AmbookenNo ratings yet

- S-101 Shoring Layout & DetailsDocument1 pageS-101 Shoring Layout & Detailsjibeesh cmNo ratings yet

- STRUCT1Document689 pagesSTRUCT1kokueiNo ratings yet

- BMT-S4-RCC Structures Class - 02june2021Document56 pagesBMT-S4-RCC Structures Class - 02june2021aishNo ratings yet

- Study of Mechanical Properties of The Available Brands of Steel Reinforcement in Kurdistan IraqDocument10 pagesStudy of Mechanical Properties of The Available Brands of Steel Reinforcement in Kurdistan IraqIAEME PublicationNo ratings yet

- Pds Leap Bridge Concrete LTR en LRDocument4 pagesPds Leap Bridge Concrete LTR en LRDen BagusNo ratings yet

- Steel Fiber ConcreteDocument16 pagesSteel Fiber ConcreteMagdy MakramNo ratings yet

- Concrete Repair - Estopatch MP - Data Sheet - 160704Document2 pagesConcrete Repair - Estopatch MP - Data Sheet - 160704Edy SumaryantoNo ratings yet

- IP 2 LatestDocument39 pagesIP 2 LatestIbrahim DawudNo ratings yet

- Pile Cap Design ExamplesDocument70 pagesPile Cap Design Examplest_solanki200160% (5)

- Section 10 Piling Works PDFDocument31 pagesSection 10 Piling Works PDFLeanna Abdul Wahab75% (4)

- Qap-15-23 - rg1700 01 Rev-5 Design Criteria For Concrete Foundations and StructuresDocument23 pagesQap-15-23 - rg1700 01 Rev-5 Design Criteria For Concrete Foundations and StructuresAnonymous uLAATWpfNo ratings yet

- Overview of Ufc 3-340-02, Structures To Resist The Effects of Accidental ExplosionsDocument16 pagesOverview of Ufc 3-340-02, Structures To Resist The Effects of Accidental ExplosionsEhsanNasrollahzadehNo ratings yet

- Manual For Design Using Etabs PDFDocument46 pagesManual For Design Using Etabs PDFPankaj Sardana100% (1)

- 2-CE 305 MOD 2 Singly RCFDocument10 pages2-CE 305 MOD 2 Singly RCFLester Khiets RoaNo ratings yet

- Vietnam Oil and Gas Corporation (Petrovietnam) Dung Quat Refinery (DQR) ProjectDocument8 pagesVietnam Oil and Gas Corporation (Petrovietnam) Dung Quat Refinery (DQR) ProjectSudip ShresthaNo ratings yet

- Spread Footing Design ExampleDocument8 pagesSpread Footing Design Examplemorphie_blackNo ratings yet

- Example. A Reinforced Concrete Spandrel Beam Has Overall Dimensions of 250 X 460 and Is JoinedDocument4 pagesExample. A Reinforced Concrete Spandrel Beam Has Overall Dimensions of 250 X 460 and Is JoinedJames NeoNo ratings yet

- SpecificationsDocument6 pagesSpecificationsRomeo Atienza100% (1)

- Notes PDFDocument1 pageNotes PDFVemajala GaneshNo ratings yet

- Notation 8.0 Aashto Specification References 8.1 Principles and Advantages of PrestressingDocument14 pagesNotation 8.0 Aashto Specification References 8.1 Principles and Advantages of PrestressingRammiris ManNo ratings yet

- FanellaDocument4 pagesFanellamendoncajam100% (1)

- Report On Design Methods With BS-En-SABS For Water Retaining StructuresDocument93 pagesReport On Design Methods With BS-En-SABS For Water Retaining StructuresSanjeev BundhunNo ratings yet

- Using Design Results From Analysis For Reinforcement Design in RevitDocument22 pagesUsing Design Results From Analysis For Reinforcement Design in RevitАндрей Николаевич ГоревNo ratings yet

- EQTip 22Document2 pagesEQTip 22raj_ferrariNo ratings yet

- BOX Culvert Bridge Reinforced With FRPDocument8 pagesBOX Culvert Bridge Reinforced With FRPAlsayed DiabNo ratings yet

- Harakeke Reinforcement of Soil-Cement Building MaterialsDocument14 pagesHarakeke Reinforcement of Soil-Cement Building MaterialsAndor-Csongor NagyNo ratings yet

- Guide To Tremie Concrete For Deep FoundationsDocument83 pagesGuide To Tremie Concrete For Deep FoundationsMax Gabriel Timo BarbosaNo ratings yet

- Bridge Column Design Based On AASHTO 17th & ACI 318-14: Input Data & Design SummaryDocument3 pagesBridge Column Design Based On AASHTO 17th & ACI 318-14: Input Data & Design SummaryRhobbie NolloraNo ratings yet