Professional Documents

Culture Documents

What Is Difference Between PCB Slip Ring and Split Ring

What Is Difference Between PCB Slip Ring and Split Ring

Uploaded by

jackCopyright:

Available Formats

You might also like

- Report On Transformer ManufacturingDocument36 pagesReport On Transformer ManufacturingRaj Moyal89% (57)

- Amorphous Metal TransformersDocument17 pagesAmorphous Metal TransformersAnjeri PhelestusNo ratings yet

- Equipment Specification BRIDGEMASTER 2017 02Document12 pagesEquipment Specification BRIDGEMASTER 2017 02suronocaturatmojoNo ratings yet

- Project Report On Wire RodDocument9 pagesProject Report On Wire RodEIRI Board of Consultants and Publishers100% (1)

- Materials Selection in Design of An Automobile DifferentialDocument17 pagesMaterials Selection in Design of An Automobile DifferentialVinayak RaoNo ratings yet

- 9853 1287 01d Overhaul Instructions DHR6 H Ver. B PDFDocument68 pages9853 1287 01d Overhaul Instructions DHR6 H Ver. B PDFMiguel CastroNo ratings yet

- What Is Difference Between PCB Slip Ring and Split RingDocument13 pagesWhat Is Difference Between PCB Slip Ring and Split RingjackNo ratings yet

- What Is A PCB Screw TerminalFunctions, Types and Install MethodsDocument16 pagesWhat Is A PCB Screw TerminalFunctions, Types and Install MethodsjackNo ratings yet

- What Is PCB Edge PlatingDocument23 pagesWhat Is PCB Edge PlatingjackNo ratings yet

- Submerged Arc WeldingDocument5 pagesSubmerged Arc Weldingmanikandan.vNo ratings yet

- Submerged Arc WeldingDocument21 pagesSubmerged Arc WeldingSACHIN A. MORENo ratings yet

- GMAW Welding ParametersDocument32 pagesGMAW Welding Parametersnarutothunderjet216No ratings yet

- Functions and Benefits of The PCB Stator MotorDocument10 pagesFunctions and Benefits of The PCB Stator MotorjackNo ratings yet

- Aeroflex Airflyte: Basic Slip Ring Design GuideDocument6 pagesAeroflex Airflyte: Basic Slip Ring Design GuideSaran CoolNo ratings yet

- Manufacturing and Assembling of Stator and Rotor Inturbo GeneratorsDocument4 pagesManufacturing and Assembling of Stator and Rotor Inturbo GeneratorsAshfiya YazdaniNo ratings yet

- Lecture Note For Ece 210Document23 pagesLecture Note For Ece 210ozimedetimilehinNo ratings yet

- Semiconductor DevicesDocument19 pagesSemiconductor DevicesKobby BrineNo ratings yet

- What Is PCB Busbar or PCB Stiffener Busbar in ElectronicsDocument13 pagesWhat Is PCB Busbar or PCB Stiffener Busbar in ElectronicsjackNo ratings yet

- Experiment 1Document16 pagesExperiment 1samayNo ratings yet

- Welding Electrodes Types and Application Procedures Welding DefectsDocument77 pagesWelding Electrodes Types and Application Procedures Welding DefectsmkpqNo ratings yet

- Slip Ring and Split RingDocument5 pagesSlip Ring and Split RingboltuNo ratings yet

- How To Create A Planar Transformer PCB DesignDocument20 pagesHow To Create A Planar Transformer PCB DesignjackNo ratings yet

- ECG 1st LectureDocument20 pagesECG 1st LectureKAMALJEET SINGHNo ratings yet

- Solid State Relay Vs MOSFET - What Are Their Similarities and DifferencesDocument11 pagesSolid State Relay Vs MOSFET - What Are Their Similarities and DifferencesjackNo ratings yet

- Types of PCB and Wave SolderingDocument4 pagesTypes of PCB and Wave Solderingpuranamravinder100% (2)

- Dragon ToothDocument15 pagesDragon ToothOmar Reinoso TigreNo ratings yet

- Wire Edm, Edg, EddgDocument23 pagesWire Edm, Edg, EddgKrishna GopalNo ratings yet

- Electrode: Flux Lime Silica Calcium FluorideDocument2 pagesElectrode: Flux Lime Silica Calcium FluoridemihirthakkarNo ratings yet

- Parte1-Description Material and ConclusionsDocument3 pagesParte1-Description Material and ConclusionsLisaNo ratings yet

- Active Magnetic BearingDocument7 pagesActive Magnetic BearingsomendratrivediNo ratings yet

- Key Words: Rogowski Coil, Relay Protection, Electric Arc Furnace TransformerDocument16 pagesKey Words: Rogowski Coil, Relay Protection, Electric Arc Furnace TransformerKartik SamantaNo ratings yet

- 1 - MMAW Process - PPT (Compatibility Mode)Document44 pages1 - MMAW Process - PPT (Compatibility Mode)Kumawat Prakash100% (1)

- Features: Submerged Arc Welding (SAW) Is A CommonDocument3 pagesFeatures: Submerged Arc Welding (SAW) Is A CommonPradeep LakumNo ratings yet

- Annular Ring Via A Comprehensive OverviewDocument10 pagesAnnular Ring Via A Comprehensive OverviewjackNo ratings yet

- Types of InductorsDocument14 pagesTypes of InductorsSan G. AbirinNo ratings yet

- 3 Phase Motor ConstructionDocument21 pages3 Phase Motor ConstructionAurelio Jr TambigaNo ratings yet

- Welding WorkDocument3 pagesWelding Workcamsarm550No ratings yet

- Functions of The PCB Loop Antenna in A Printed Circuit BoardDocument13 pagesFunctions of The PCB Loop Antenna in A Printed Circuit BoardjackNo ratings yet

- JJ104 Workshop Technology CHAPTER9 Arc WeldingDocument14 pagesJJ104 Workshop Technology CHAPTER9 Arc WeldingAh Tiang50% (4)

- What Is Wire BondingDocument27 pagesWhat Is Wire BondingjackNo ratings yet

- C !" # $%&C'C (') C) ') C) + 'CDocument8 pagesC !" # $%&C'C (') C) ') C) + 'COmar QasmiNo ratings yet

- Substation Interview Questions AnswersDocument4 pagesSubstation Interview Questions AnswersShashi ShekharNo ratings yet

- TDSWE 7018 Electrode TSDocument2 pagesTDSWE 7018 Electrode TSKhaled A MarashliNo ratings yet

- ATI Allegheny Ludlum's Grain-Oriented Electrical Steels AreDocument4 pagesATI Allegheny Ludlum's Grain-Oriented Electrical Steels Arelaith76No ratings yet

- Hard Gold Plating For Edge ConnectorsDocument12 pagesHard Gold Plating For Edge ConnectorsjackNo ratings yet

- Lundahl Design PhilosDocument2 pagesLundahl Design PhilosM PNo ratings yet

- Types of SMD Components and How To Identify ThemDocument9 pagesTypes of SMD Components and How To Identify ThemjackNo ratings yet

- What Is A Socket PCBDocument8 pagesWhat Is A Socket PCBjackNo ratings yet

- Laser CommunicationDocument19 pagesLaser CommunicationNeel VaniyaNo ratings yet

- Parts of A DC GeneratorDocument7 pagesParts of A DC GeneratorRolen GeocadinNo ratings yet

- Job Knowledge 12Document3 pagesJob Knowledge 12Mehmet SoysalNo ratings yet

- Rexnord Metal Table Top ChainDocument36 pagesRexnord Metal Table Top ChainWhisnu AlbertusNo ratings yet

- Basic Circuitry of Metal DetectionDocument6 pagesBasic Circuitry of Metal DetectionBalbalaManiukNo ratings yet

- What Is PCB Copper FoilDocument14 pagesWhat Is PCB Copper FoiljackNo ratings yet

- TransformerDocument23 pagesTransformerRenuka KutteNo ratings yet

- Three Phase Induction Motor: Unit 4Document39 pagesThree Phase Induction Motor: Unit 4Hill HermitNo ratings yet

- Welding Types Procedures ParametersDocument156 pagesWelding Types Procedures ParametersVinodh Kumar YallaNo ratings yet

- Automated Optical Inspection: Advancements in Computer Vision TechnologyFrom EverandAutomated Optical Inspection: Advancements in Computer Vision TechnologyNo ratings yet

- Why The Arlon 49N PCB Material Is Useful in High Temperature or High Performance ApplicationsDocument4 pagesWhy The Arlon 49N PCB Material Is Useful in High Temperature or High Performance ApplicationsjackNo ratings yet

- Xilinx XAZU2EG-1SBVA484I Fpga ApplicationDocument5 pagesXilinx XAZU2EG-1SBVA484I Fpga ApplicationjackNo ratings yet

- Why You Should Choose The Shengyi S7439G PCB MaterialDocument5 pagesWhy You Should Choose The Shengyi S7439G PCB MaterialjackNo ratings yet

- Why Is The Panasonic R-F705S Useful For Mobile and Automotive ProductsDocument4 pagesWhy Is The Panasonic R-F705S Useful For Mobile and Automotive ProductsjackNo ratings yet

- Why A PCB Ground Plane Is Crucial For PCB FunctioningDocument3 pagesWhy A PCB Ground Plane Is Crucial For PCB FunctioningjackNo ratings yet

- Why Non Recurring Engineering Cost (NRE Charge) Is Important For Your PCBDocument4 pagesWhy Non Recurring Engineering Cost (NRE Charge) Is Important For Your PCBjackNo ratings yet

- Why Is The Home Energy Monitor ImportantDocument7 pagesWhy Is The Home Energy Monitor ImportantjackNo ratings yet

- Why OEM Circuit Boards Are Ideal For Use in Several ApplicationsDocument6 pagesWhy OEM Circuit Boards Are Ideal For Use in Several ApplicationsjackNo ratings yet

- Why 3D Print PCBs Matter in Today's Electronics ProductionDocument4 pagesWhy 3D Print PCBs Matter in Today's Electronics ProductionjackNo ratings yet

- Where Does The QuickLogic Eclipse FPGA Architecture Family Play A RoleDocument11 pagesWhere Does The QuickLogic Eclipse FPGA Architecture Family Play A RolejackNo ratings yet

- What Is The Significance of Home Electronics PCBDocument6 pagesWhat Is The Significance of Home Electronics PCBjackNo ratings yet

- Where To Buy Rogers RT Duroid 5880 LaminateDocument5 pagesWhere To Buy Rogers RT Duroid 5880 LaminatejackNo ratings yet

- Who Are The Leading Electrical Coil ManufacturersDocument5 pagesWho Are The Leading Electrical Coil ManufacturersjackNo ratings yet

- What Is The Significance of Azure IoTDocument6 pagesWhat Is The Significance of Azure IoTjackNo ratings yet

- What Is The Significance of ENIG Plating ThicknessDocument4 pagesWhat Is The Significance of ENIG Plating ThicknessjackNo ratings yet

- What Is Xilinx Spartan-7 Its Datasheet and Reference DesignsDocument20 pagesWhat Is Xilinx Spartan-7 Its Datasheet and Reference DesignsjackNo ratings yet

- What Is Xilinx XA6SLX75T-2FGG484I ChipDocument5 pagesWhat Is Xilinx XA6SLX75T-2FGG484I ChipjackNo ratings yet

- What Is Taconic TSM-DS3b PCBDocument7 pagesWhat Is Taconic TSM-DS3b PCBjackNo ratings yet

- What Is Xilinx Virtex-5 FPGADocument8 pagesWhat Is Xilinx Virtex-5 FPGAjackNo ratings yet

- What Is The Significance of IOT in AgricultureDocument8 pagesWhat Is The Significance of IOT in AgriculturejackNo ratings yet

- What Is Through Hole PCB AssemblyDocument12 pagesWhat Is Through Hole PCB AssemblyjackNo ratings yet

- What Is Signal Integrity A Comprehensive OverviewDocument9 pagesWhat Is Signal Integrity A Comprehensive OverviewjackNo ratings yet

- What Is The Difference Between ARM and FPGA ProcessorsDocument9 pagesWhat Is The Difference Between ARM and FPGA ProcessorsjackNo ratings yet

- What Is The Purpose and Applications of A PCB MotherboardDocument4 pagesWhat Is The Purpose and Applications of A PCB MotherboardjackNo ratings yet

- What Is The Melting Point of SolderDocument4 pagesWhat Is The Melting Point of SolderjackNo ratings yet

- What Is The Difference Between FFC Connector and FPC ConnectorDocument14 pagesWhat Is The Difference Between FFC Connector and FPC ConnectorjackNo ratings yet

- What Is Thermal Consideration in PCB DesignDocument6 pagesWhat Is Thermal Consideration in PCB DesignjackNo ratings yet

- What Is SMT Soldering Process Step by StepDocument12 pagesWhat Is SMT Soldering Process Step by StepjackNo ratings yet

- What Is Xilinx Kintex UltraScale UltraScale+Document8 pagesWhat Is Xilinx Kintex UltraScale UltraScale+jackNo ratings yet

- What Is The Difference Between Clean Flux and No Clean Flux Off PCBDocument13 pagesWhat Is The Difference Between Clean Flux and No Clean Flux Off PCBjackNo ratings yet

- Unit 3-StatisticsDocument15 pagesUnit 3-Statisticsmcoleman10No ratings yet

- Q7 - A5 Side Assist SSP - 375Document14 pagesQ7 - A5 Side Assist SSP - 375mihaicatalinnNo ratings yet

- Interreg Danube Implementation ManualDocument84 pagesInterreg Danube Implementation ManualMadalina SbarceaNo ratings yet

- ch.2 Electric Potential and Capacitor - NotesDocument10 pagesch.2 Electric Potential and Capacitor - Notesnandank44373No ratings yet

- Abstract Synopsis For Arpa River Front at Bilaspur1Document7 pagesAbstract Synopsis For Arpa River Front at Bilaspur1Aarohan InfraNo ratings yet

- EuphemismsDocument2 pagesEuphemismssifo nebbarNo ratings yet

- Biochemistry: Questions & AnswersDocument17 pagesBiochemistry: Questions & AnswersA-Naeem To'mah Al-sawaieNo ratings yet

- Final XM PeparationDocument29 pagesFinal XM PeparationMd.Atikur RahmanNo ratings yet

- Principles and Practice of Management (MGT 420) : Shuib SepahtuDocument6 pagesPrinciples and Practice of Management (MGT 420) : Shuib SepahtuMuhd FakrullahNo ratings yet

- Learn JAVASCRIPT in Arabic 2021 (41 To 80)Document57 pagesLearn JAVASCRIPT in Arabic 2021 (41 To 80)osama mohamedNo ratings yet

- ME145 IBT2022 School Report SDocument546 pagesME145 IBT2022 School Report SshamshadNo ratings yet

- Curriculum VitÆ Nom Et Prénom: Bachari Khaldoun Date EtDocument5 pagesCurriculum VitÆ Nom Et Prénom: Bachari Khaldoun Date EtThe-ScribderNo ratings yet

- Romania Approves Neptun Deep ProjectDocument2 pagesRomania Approves Neptun Deep ProjectFloyd BurgessNo ratings yet

- Quick Recap Applied Maths Formula Sheet Class 12Document12 pagesQuick Recap Applied Maths Formula Sheet Class 12yashsharma2837No ratings yet

- Franklin B. Bernales - CVDocument2 pagesFranklin B. Bernales - CVFRANKLIN BERNALESNo ratings yet

- History Masters Thesis ExamplesDocument6 pagesHistory Masters Thesis Examplessararousesyracuse100% (1)

- 2023 LO Grade 10 Term 2 MG FinalDocument10 pages2023 LO Grade 10 Term 2 MG FinalsheronmoyoshalomNo ratings yet

- DLL English SLM Based w9Document5 pagesDLL English SLM Based w9Jerwin Caba�ero (Lunduyan 2)No ratings yet

- Footstep Power Generation Using Piezoelectric SensorDocument6 pagesFootstep Power Generation Using Piezoelectric SensorJeet DattaNo ratings yet

- Bill Mosley John Bungey & Ray Hulse: Reinforced Concrete Design To EC2Document31 pagesBill Mosley John Bungey & Ray Hulse: Reinforced Concrete Design To EC2RyanWongJiaHanNo ratings yet

- DLL Q2 Week 8 Health 6Document4 pagesDLL Q2 Week 8 Health 6Claudine CornitaNo ratings yet

- 02mapeh-3RD Quarter Week 7Document8 pages02mapeh-3RD Quarter Week 7ivan abandoNo ratings yet

- Reduced Voltage Motor Starters 1: Description ITDocument32 pagesReduced Voltage Motor Starters 1: Description ITANDRE LUIZ RAMOS DE FREITASNo ratings yet

- On The Tangent Indicatrix of Special Viviani's Curve and Iits Corresponding Smarandache Curves According To Sabban FrameDocument12 pagesOn The Tangent Indicatrix of Special Viviani's Curve and Iits Corresponding Smarandache Curves According To Sabban FrameScience DirectNo ratings yet

- Ezydek 44 Profile - DimensionsDocument2 pagesEzydek 44 Profile - DimensionsAnirban BhattacharjeeNo ratings yet

- B. Sc. Environmental Science Sem 1Document4 pagesB. Sc. Environmental Science Sem 1Uzeir SelotNo ratings yet

- B.Sc. Quantitative BiologyDocument2 pagesB.Sc. Quantitative BiologyHarshit NirwalNo ratings yet

- Angliyskiy Yazyk LGT 11 Klass 2018Document5 pagesAngliyskiy Yazyk LGT 11 Klass 2018CavenlyNo ratings yet

- Principal Component Analysis (PCA) - : San José State University Math 253: Mathematical Methods For Data VisualizationDocument49 pagesPrincipal Component Analysis (PCA) - : San José State University Math 253: Mathematical Methods For Data VisualizationAndreea IsarNo ratings yet

What Is Difference Between PCB Slip Ring and Split Ring

What Is Difference Between PCB Slip Ring and Split Ring

Uploaded by

jackOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

What Is Difference Between PCB Slip Ring and Split Ring

What Is Difference Between PCB Slip Ring and Split Ring

Uploaded by

jackCopyright:

Available Formats

RAYMING PCB & ASSEMBLY

What Is Difference Between PCB Slip Ring and Split Ring?

Slip rings and split rings are two important devices used in electrical and

mechanical systems for transmitting power and signals across rotating

interfaces. Both allow transmission between stationary and rotating

components, but have some key differences in their design and

applications.

In this article, we will provide a detailed comparison between PCB slip

rings and split rings, including:

Definitions and working principles

Construction and design

Materials and manufacturing

Performance characteristics

Advantages and disadvantages

Typical applications

Main differences summarized

Understanding the differences between slip rings and split rings enables

selecting the right device for different use cases requiring rotary

transmission.

Request PCB Manufacturing & Assembly Quote

Table of Contents

PCB Manufacturing & Assembly Services https://www.raypcb.com/

RAYMING PCB & ASSEMBLY

Defining Slip Rings and Split Rings

What is a Slip Ring?

A slip ring is an electromechanical device that allows transmission of

power and electrical signals from a stationary source to a rotating

structure. It consists of a stationary part called the stator, and a rotating

part called the rotor.

The stator contains conductive rings that are electrically insulated from

each other. The rotor contains metal brushes that make sliding contact

with the rings on the stator. As the rotor turns, the brushes maintain

continuous electrical connection by sliding over the rings, allowing

transmission of power/signals across the rotating interface.

Diagram showing construction of a slip ring.

PCB Manufacturing & Assembly Services https://www.raypcb.com/

RAYMING PCB & ASSEMBLY

Common configurations of slip rings include:

Pancake slip ring – Rings are arranged in a flat stack.

Cylindrical slip ring – Rings are arranged concentrically on a

cylinder.

PCB slip ring – Rings are etched on a printed circuit board.

Slip rings are bidirectional and can transmit power/signals in both

directions across the rotating interface. They allow transmission of low

to high power, as well as a wide range of analog and digital signals.

What is a Split Ring?

A split ring, also called a brush block commutator, is a modified slip ring

designed to transmit only low power signals or currents in one direction

across a rotating interface.

It consists of a rotor assembly containing conductive segments or poles

isolated from each other by small gaps. Stationary brushes contact these

rotating poles to transmit signals.

As the rotor turns, the brushes make sliding contact with each pole in

sequence, allowing transmission in only one direction – from the rotating

poles to the fixed brushes. The small gaps between the poles prevent

reverse transmission or short circuiting between segments.

PCB Manufacturing & Assembly Services https://www.raypcb.com/

RAYMING PCB & ASSEMBLY

Diagram showing construction of a split ring.

Split rings are unidirectional and can only transmit signals in one direction

– from rotor to stator. They are suitable for low power signals, and not for

high power transfer.

Construction and Design

PCB Slip Ring Construction

PCB slip rings are constructed from rings etched on a printed circuit board,

which allows compact construction and precise control of ring placement.

Key components of a PCB slip ring include:

Printed circuit board (FR4) that forms the stator, with conductive

copper rings etched on one side.

Rotor containing metal brushes (copper, bronze, precious metals)

Insulating cover/housing enclosing the PCB and rotor assembly

Bearings allowing smooth rotation of rotor

The PCB is designed with the required number of concentric copper rings

etched at precise intervals needed for circuit contacts. The rotor fits over

the PCB and the brushes make sliding contact with the copper rings.

Cross section of a PCB slip ring showing copper rings and rotor brushes.

PCB Manufacturing & Assembly Services https://www.raypcb.com/

RAYMING PCB & ASSEMBLY

Advantages of PCB slip rings include compact size, easy manufacturing,

precise control of tracks, and fast assembly.

Split Ring Construction

Split ring construction consists of a rotor containing segmented

conductive poles separated by small air gaps. Common materials used

include copper, brass or steel.

The rotor mounts on a bearing and is enclosed in a housing. Brushes are

fixed to the stator housing and make sliding contact with the rotor poles.

As the rotor turns, the brushes consecutively connect with each rotor pole,

allowing transmission from rotor to stator. The gaps between the poles

prevent reverse transmission through the brushes.

Diagram of a split ring showing segmented rotor poles and fixed brushes.

Split rings provide unidirectional transmission and are suitable for

intermittent signal contacts. Their simple construction allows low cost

manufacturing.

Materials and Manufacturing

PCB Manufacturing & Assembly Services https://www.raypcb.com/

RAYMING PCB & ASSEMBLY

PCB Slip Ring Materials

PCB slip rings are manufactured from the following materials:

Printed Circuit Board (FR4) – Forms the stator containing the copper

ring tracks. FR4 provides electrical insulation between rings.

Copper – Used to etch the conductive rings on the PCB. Provides

excellent conductivity.

Precious metal brushes (gold, silver, palladium) – Used for

contacting the copper rings due to high durability and low contact

resistance.

Plastics like PTFE, PEEK – Used for casing and flange components.

Provide mechanical stability.

Bearings – Allow smooth rotation and consist of steel balls/rollers

with a plastic retainer.

PCB Manufacturing & Assembly Services https://www.raypcb.com/

RAYMING PCB & ASSEMBLY

The PCB fabrication process allows high precision patterning of ring tracks

in different configurations. The brushes are designed for stable

low-friction contact and minimal wear. High quality materials ensure

reliability with prolonged use.

Split Ring Materials

Split rings use the following common materials:

Copper, brass or steel for the rotor segments. Copper provides the

best conductivity.

Precious metal brushes (silver, gold) for low contact resistance and

reduced oxidation.

Plastic housings like nylon, PTFE to enclose the rotor and provide

insulation.

Bearings using steel balls/rollers to enable smooth rotor rotation.

Split rings use basic materials that provide stable performance at low cost.

The materials offer reasonable durability with low friction contacts

between the brushes and rotor segments.

Performance Characteristics

PCB Slip Ring Performance

PCB slip rings provide the following performance characteristics:

PCB Manufacturing & Assembly Services https://www.raypcb.com/

RAYMING PCB & ASSEMBLY

Number of circuits – Can support 10 to 100+ ring contacts for

multiple circuits.

Current rating – Handle currents from a few mA to over 100 A. Gold

brushes allow up to 500 A on each ring.

Voltage rating – Rated up to 1000V AC/DC for standard designs.

Speed – Standard rings allow rotational speeds up to 1000

rpm. High speed rings support above 5000 rpm.

Temperature range – Operate from -40°C to +80°C. Special designs

work upto 250°C.

Noise – Low noise of 10-50 mΩ allows transmission of sensitive

signals.

Contact resistance – Brush contact resistance of 1-10 mΩ allows

high power transfer.

Lifetime – Brush lifetime over 100 million rotations with precious

metal contacts.

Isolation – Up to 1000V isolation between adjacent rings.

PCB manufacturing provides precise ring dimensions and spacing for

reliable transmission of multiple power/data circuits.

Split Ring Performance

Split rings have the following typical performance ratings:

PCB Manufacturing & Assembly Services https://www.raypcb.com/

RAYMING PCB & ASSEMBLY

Current – Maximum current around 15-20A. Only suitable for low

power signal transmission.

Voltage – Maximum voltage rating up to 60V DC.

Speed – Standard split rings rated for speeds up to 3000 rpm.

Poles – Typical number of poles is 6 to 20. More poles allow more

brush contacts.

Temperature – Operating temperature range of -20°C to +80°C.

Noise – Prone to electrical noise due to brush arcing.

Contact resistance – Brush contact resistance around 50-100 mΩ.

Higher than slip rings.

Wear – Brush wear out faster than slip rings due to arcing and

higher contact resistance.

Lifetime – Brush lifetime around 25 million rotations. Less than slip

rings.

Split rings are designed for unidirectional transmission of intermittent, low

power signals. They offer lower performance than slip rings but at a lower

cost.

Request PCB Manufacturing & Assembly Quote

Advantages and Disadvantages

PCB Manufacturing & Assembly Services https://www.raypcb.com/

RAYMING PCB & ASSEMBLY

PCB Slip Ring Advantages

PCB slip rings provide the following benefits:

Compact size due to PCB manufacturing

Precise control and spacing of ring circuits

Low and stable brush contact resistance

Low electrical noise for reliable signal transmission

High current and voltage capacity

High rotational speeds capability

Long service life with minimal wear

Bi-directional transmission through rings

Easy integration and installation

Suitable for data and power transfer

PCB technology enables fabrication of small, high performance slip rings

with multiple circuit capacity.

PCB Manufacturing & Assembly Services https://www.raypcb.com/

RAYMING PCB & ASSEMBLY

PCB Slip Ring Disadvantages

Some disadvantages of PCB slip rings include:

More complex manufacturing process

Higher cost than basic slip rings

Larger minimum diameter required for ring spacing

Not easy to repair or replace brushes

Precious metal brushes can be expensive

Requires smooth rotor shaft and precision assembly

While PCB slip rings provide superior performance, they also have higher

costs and complexity than basic slip ring types.

Split Ring Advantages

Split rings offer the following benefits:

PCB Manufacturing & Assembly Services https://www.raypcb.com/

RAYMING PCB & ASSEMBLY

Simple and low cost construction

Compact, lightweight design

High speed operation easily achievable

Low friction provides smooth running

Only basic tools needed for manufacturing

Easy to repair and replace brushes

No need for special materials or complex production

The simple design of split rings allows them to be manufactured cheaply

and used easily in applications requiring only low power transmission.

Split Ring Disadvantages

Some limitations of split rings include:

Only allow unidirectional transmission

Prone to electrical noise and interference

Low power and voltage capacity

Limited number of brush contacts

Short service life due to brush wear

Cannot transmit high speed data or multiple signals

Contact resistance is higher than slip rings

Not suitable for continuous power transfer

PCB Manufacturing & Assembly Services https://www.raypcb.com/

RAYMING PCB & ASSEMBLY

Split rings are not capable of the bi-directional, high power and data

transmission possible with slip rings. Their design and materials impose

limits on performance.

Typical Applications

PCB Slip Ring Applications

Some common applications of PCB slip rings include:

Industrial machinery – To transmit control and telemetry data

between stationary controls and rotating machinery.

Medical equipment – MRI machines, CT scanners, etc. use slip rings

to transfer signals/power.

Avionics – Used in radar systems, control surfaces, weapon turrets

that must rotate continuously.

PCB Manufacturing & Assembly Services https://www.raypcb.com/

RAYMING PCB & ASSEMBLY

Robots – For transferring signals between robot base and rotating

joints or platform.

Amusement rides – Used on rotating food trays, lighting rings and

ride platforms.

Wind turbines – Allow power transfer from rotating turbine hub to

stationary conductors.

CCTV cameras – Enable continuous video feed transmission from

pan-tilt security cameras.

PCB slip rings are used anywhere continuous, bi-directional transmission

under rotation is needed. Their compact size and high performance allow

integration into complex systems.

Split Ring Applications

Typical applications of split rings include:

Low voltage electric motors – For periodic power transmission to

rotor coils.

Automotive systems – Used in sliding door connectors, seat and

mirror controls.

Rotating displays – For transmitting display data from stationary

controllers to rotating signboards.

PCB Manufacturing & Assembly Services https://www.raypcb.com/

RAYMING PCB & ASSEMBLY

Assembly machinery – Allow power and control signals to rotating

tool heads and positioners.

Material handling – Used on continuously rotating conveyors and

sorters for sensor signals.

Split rings are suitable for cost-sensitive, unidirectional transmission

applications that only require low power or occasional contacts.

Main Differences Between Slip Rings and Split Rings

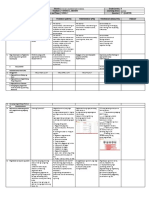

Parameter PCB Slip Rings Split Rings

Construction Copper rings etched on PCB. Precious Segmented rotor poles separated by

metal brushes. gaps. Metal graphite brushes.

Transmission Bi-directional – Signals can pass in Unidirectional – Transmission only

either direction. from rotor to stator.

PCB Manufacturing & Assembly Services https://www.raypcb.com/

RAYMING PCB & ASSEMBLY

Parameter PCB Slip Rings Split Rings

Power rating Up to 100s of Amps, 1000s of Volts. Less than 20A, under 60V.

Speed Up to 5000 rpm for standard rings. High Around 3000 rpm max speed.

speed rings even higher.

Noise Very low electrical noise. Suited for Prone to electrical noise due to arci

sensitive data.

Contacts 10 to 100+ separate isolated contacts. Typically 6 to 20 contacts.

Resistance 1-10 mΩ brush contact resistance. 50-100 mΩ typical contact resistan

Service life 100 million rotations or more. Around 25 million rotations max.

Cost Higher cost due to advanced materials Low cost because of simple

and production. construction.

Applications Industrial, Low power motors, basic machinery,

medical, military, robotics. For intermittent signals.

high speed data, video, power

transmission.

Conclusion

PCB Manufacturing & Assembly Services https://www.raypcb.com/

RAYMING PCB & ASSEMBLY

PCB slip rings and split rings both allow transmission across rotating

interfaces, but have major differences in their design, capabilities and

applications.

Key Points:

PCB slip rings use precise etched copper rings to enable

bi-directional, low noise transmission of multiple power and data

circuits simultaneously.

Split rings consist of an insulated rotor with segmented contacts,

allowing only unidirectional, intermittent signal transmission.

Slip rings handle high speeds, power, voltages and lifetimes. Split

rings are limited to low power signals and shorter lifetimes.

PCB manufacturing provides slip rings with small sizes but higher

cost. Split rings have simple construction but lower performance.

Slip rings are used where high speed rotation and reliable

transmission are needed. Split rings find use in cost-sensitive

applications requiring only simple unidirectional contacts.

In summary, PCB slip rings are the preferred choice wherever continuous,

reliable transmission of power and high-speed data in both directions is

required – such as in precision industrial machinery, robotics, medical

systems and military applications. Split rings are suitable for basic low cost

PCB Manufacturing & Assembly Services https://www.raypcb.com/

RAYMING PCB & ASSEMBLY

systems involving only simple unidirectional signal contacts, like low

voltage motors, basic automated systems and rotating displays.

Related Posts:

1. Annular Ring Via: A Comprehensive Overview

2. What’s the Difference between EMI EMS and EMC ?

3. SMD Vs SMT: What’s the Difference?

4. Raspberry Pi 4 vs 3:What’s the Difference?

https://www.raypcb.com/pcb-slip-ring-vs-split-ring/

PCB Manufacturing & Assembly Services https://www.raypcb.com/

You might also like

- Report On Transformer ManufacturingDocument36 pagesReport On Transformer ManufacturingRaj Moyal89% (57)

- Amorphous Metal TransformersDocument17 pagesAmorphous Metal TransformersAnjeri PhelestusNo ratings yet

- Equipment Specification BRIDGEMASTER 2017 02Document12 pagesEquipment Specification BRIDGEMASTER 2017 02suronocaturatmojoNo ratings yet

- Project Report On Wire RodDocument9 pagesProject Report On Wire RodEIRI Board of Consultants and Publishers100% (1)

- Materials Selection in Design of An Automobile DifferentialDocument17 pagesMaterials Selection in Design of An Automobile DifferentialVinayak RaoNo ratings yet

- 9853 1287 01d Overhaul Instructions DHR6 H Ver. B PDFDocument68 pages9853 1287 01d Overhaul Instructions DHR6 H Ver. B PDFMiguel CastroNo ratings yet

- What Is Difference Between PCB Slip Ring and Split RingDocument13 pagesWhat Is Difference Between PCB Slip Ring and Split RingjackNo ratings yet

- What Is A PCB Screw TerminalFunctions, Types and Install MethodsDocument16 pagesWhat Is A PCB Screw TerminalFunctions, Types and Install MethodsjackNo ratings yet

- What Is PCB Edge PlatingDocument23 pagesWhat Is PCB Edge PlatingjackNo ratings yet

- Submerged Arc WeldingDocument5 pagesSubmerged Arc Weldingmanikandan.vNo ratings yet

- Submerged Arc WeldingDocument21 pagesSubmerged Arc WeldingSACHIN A. MORENo ratings yet

- GMAW Welding ParametersDocument32 pagesGMAW Welding Parametersnarutothunderjet216No ratings yet

- Functions and Benefits of The PCB Stator MotorDocument10 pagesFunctions and Benefits of The PCB Stator MotorjackNo ratings yet

- Aeroflex Airflyte: Basic Slip Ring Design GuideDocument6 pagesAeroflex Airflyte: Basic Slip Ring Design GuideSaran CoolNo ratings yet

- Manufacturing and Assembling of Stator and Rotor Inturbo GeneratorsDocument4 pagesManufacturing and Assembling of Stator and Rotor Inturbo GeneratorsAshfiya YazdaniNo ratings yet

- Lecture Note For Ece 210Document23 pagesLecture Note For Ece 210ozimedetimilehinNo ratings yet

- Semiconductor DevicesDocument19 pagesSemiconductor DevicesKobby BrineNo ratings yet

- What Is PCB Busbar or PCB Stiffener Busbar in ElectronicsDocument13 pagesWhat Is PCB Busbar or PCB Stiffener Busbar in ElectronicsjackNo ratings yet

- Experiment 1Document16 pagesExperiment 1samayNo ratings yet

- Welding Electrodes Types and Application Procedures Welding DefectsDocument77 pagesWelding Electrodes Types and Application Procedures Welding DefectsmkpqNo ratings yet

- Slip Ring and Split RingDocument5 pagesSlip Ring and Split RingboltuNo ratings yet

- How To Create A Planar Transformer PCB DesignDocument20 pagesHow To Create A Planar Transformer PCB DesignjackNo ratings yet

- ECG 1st LectureDocument20 pagesECG 1st LectureKAMALJEET SINGHNo ratings yet

- Solid State Relay Vs MOSFET - What Are Their Similarities and DifferencesDocument11 pagesSolid State Relay Vs MOSFET - What Are Their Similarities and DifferencesjackNo ratings yet

- Types of PCB and Wave SolderingDocument4 pagesTypes of PCB and Wave Solderingpuranamravinder100% (2)

- Dragon ToothDocument15 pagesDragon ToothOmar Reinoso TigreNo ratings yet

- Wire Edm, Edg, EddgDocument23 pagesWire Edm, Edg, EddgKrishna GopalNo ratings yet

- Electrode: Flux Lime Silica Calcium FluorideDocument2 pagesElectrode: Flux Lime Silica Calcium FluoridemihirthakkarNo ratings yet

- Parte1-Description Material and ConclusionsDocument3 pagesParte1-Description Material and ConclusionsLisaNo ratings yet

- Active Magnetic BearingDocument7 pagesActive Magnetic BearingsomendratrivediNo ratings yet

- Key Words: Rogowski Coil, Relay Protection, Electric Arc Furnace TransformerDocument16 pagesKey Words: Rogowski Coil, Relay Protection, Electric Arc Furnace TransformerKartik SamantaNo ratings yet

- 1 - MMAW Process - PPT (Compatibility Mode)Document44 pages1 - MMAW Process - PPT (Compatibility Mode)Kumawat Prakash100% (1)

- Features: Submerged Arc Welding (SAW) Is A CommonDocument3 pagesFeatures: Submerged Arc Welding (SAW) Is A CommonPradeep LakumNo ratings yet

- Annular Ring Via A Comprehensive OverviewDocument10 pagesAnnular Ring Via A Comprehensive OverviewjackNo ratings yet

- Types of InductorsDocument14 pagesTypes of InductorsSan G. AbirinNo ratings yet

- 3 Phase Motor ConstructionDocument21 pages3 Phase Motor ConstructionAurelio Jr TambigaNo ratings yet

- Welding WorkDocument3 pagesWelding Workcamsarm550No ratings yet

- Functions of The PCB Loop Antenna in A Printed Circuit BoardDocument13 pagesFunctions of The PCB Loop Antenna in A Printed Circuit BoardjackNo ratings yet

- JJ104 Workshop Technology CHAPTER9 Arc WeldingDocument14 pagesJJ104 Workshop Technology CHAPTER9 Arc WeldingAh Tiang50% (4)

- What Is Wire BondingDocument27 pagesWhat Is Wire BondingjackNo ratings yet

- C !" # $%&C'C (') C) ') C) + 'CDocument8 pagesC !" # $%&C'C (') C) ') C) + 'COmar QasmiNo ratings yet

- Substation Interview Questions AnswersDocument4 pagesSubstation Interview Questions AnswersShashi ShekharNo ratings yet

- TDSWE 7018 Electrode TSDocument2 pagesTDSWE 7018 Electrode TSKhaled A MarashliNo ratings yet

- ATI Allegheny Ludlum's Grain-Oriented Electrical Steels AreDocument4 pagesATI Allegheny Ludlum's Grain-Oriented Electrical Steels Arelaith76No ratings yet

- Hard Gold Plating For Edge ConnectorsDocument12 pagesHard Gold Plating For Edge ConnectorsjackNo ratings yet

- Lundahl Design PhilosDocument2 pagesLundahl Design PhilosM PNo ratings yet

- Types of SMD Components and How To Identify ThemDocument9 pagesTypes of SMD Components and How To Identify ThemjackNo ratings yet

- What Is A Socket PCBDocument8 pagesWhat Is A Socket PCBjackNo ratings yet

- Laser CommunicationDocument19 pagesLaser CommunicationNeel VaniyaNo ratings yet

- Parts of A DC GeneratorDocument7 pagesParts of A DC GeneratorRolen GeocadinNo ratings yet

- Job Knowledge 12Document3 pagesJob Knowledge 12Mehmet SoysalNo ratings yet

- Rexnord Metal Table Top ChainDocument36 pagesRexnord Metal Table Top ChainWhisnu AlbertusNo ratings yet

- Basic Circuitry of Metal DetectionDocument6 pagesBasic Circuitry of Metal DetectionBalbalaManiukNo ratings yet

- What Is PCB Copper FoilDocument14 pagesWhat Is PCB Copper FoiljackNo ratings yet

- TransformerDocument23 pagesTransformerRenuka KutteNo ratings yet

- Three Phase Induction Motor: Unit 4Document39 pagesThree Phase Induction Motor: Unit 4Hill HermitNo ratings yet

- Welding Types Procedures ParametersDocument156 pagesWelding Types Procedures ParametersVinodh Kumar YallaNo ratings yet

- Automated Optical Inspection: Advancements in Computer Vision TechnologyFrom EverandAutomated Optical Inspection: Advancements in Computer Vision TechnologyNo ratings yet

- Why The Arlon 49N PCB Material Is Useful in High Temperature or High Performance ApplicationsDocument4 pagesWhy The Arlon 49N PCB Material Is Useful in High Temperature or High Performance ApplicationsjackNo ratings yet

- Xilinx XAZU2EG-1SBVA484I Fpga ApplicationDocument5 pagesXilinx XAZU2EG-1SBVA484I Fpga ApplicationjackNo ratings yet

- Why You Should Choose The Shengyi S7439G PCB MaterialDocument5 pagesWhy You Should Choose The Shengyi S7439G PCB MaterialjackNo ratings yet

- Why Is The Panasonic R-F705S Useful For Mobile and Automotive ProductsDocument4 pagesWhy Is The Panasonic R-F705S Useful For Mobile and Automotive ProductsjackNo ratings yet

- Why A PCB Ground Plane Is Crucial For PCB FunctioningDocument3 pagesWhy A PCB Ground Plane Is Crucial For PCB FunctioningjackNo ratings yet

- Why Non Recurring Engineering Cost (NRE Charge) Is Important For Your PCBDocument4 pagesWhy Non Recurring Engineering Cost (NRE Charge) Is Important For Your PCBjackNo ratings yet

- Why Is The Home Energy Monitor ImportantDocument7 pagesWhy Is The Home Energy Monitor ImportantjackNo ratings yet

- Why OEM Circuit Boards Are Ideal For Use in Several ApplicationsDocument6 pagesWhy OEM Circuit Boards Are Ideal For Use in Several ApplicationsjackNo ratings yet

- Why 3D Print PCBs Matter in Today's Electronics ProductionDocument4 pagesWhy 3D Print PCBs Matter in Today's Electronics ProductionjackNo ratings yet

- Where Does The QuickLogic Eclipse FPGA Architecture Family Play A RoleDocument11 pagesWhere Does The QuickLogic Eclipse FPGA Architecture Family Play A RolejackNo ratings yet

- What Is The Significance of Home Electronics PCBDocument6 pagesWhat Is The Significance of Home Electronics PCBjackNo ratings yet

- Where To Buy Rogers RT Duroid 5880 LaminateDocument5 pagesWhere To Buy Rogers RT Duroid 5880 LaminatejackNo ratings yet

- Who Are The Leading Electrical Coil ManufacturersDocument5 pagesWho Are The Leading Electrical Coil ManufacturersjackNo ratings yet

- What Is The Significance of Azure IoTDocument6 pagesWhat Is The Significance of Azure IoTjackNo ratings yet

- What Is The Significance of ENIG Plating ThicknessDocument4 pagesWhat Is The Significance of ENIG Plating ThicknessjackNo ratings yet

- What Is Xilinx Spartan-7 Its Datasheet and Reference DesignsDocument20 pagesWhat Is Xilinx Spartan-7 Its Datasheet and Reference DesignsjackNo ratings yet

- What Is Xilinx XA6SLX75T-2FGG484I ChipDocument5 pagesWhat Is Xilinx XA6SLX75T-2FGG484I ChipjackNo ratings yet

- What Is Taconic TSM-DS3b PCBDocument7 pagesWhat Is Taconic TSM-DS3b PCBjackNo ratings yet

- What Is Xilinx Virtex-5 FPGADocument8 pagesWhat Is Xilinx Virtex-5 FPGAjackNo ratings yet

- What Is The Significance of IOT in AgricultureDocument8 pagesWhat Is The Significance of IOT in AgriculturejackNo ratings yet

- What Is Through Hole PCB AssemblyDocument12 pagesWhat Is Through Hole PCB AssemblyjackNo ratings yet

- What Is Signal Integrity A Comprehensive OverviewDocument9 pagesWhat Is Signal Integrity A Comprehensive OverviewjackNo ratings yet

- What Is The Difference Between ARM and FPGA ProcessorsDocument9 pagesWhat Is The Difference Between ARM and FPGA ProcessorsjackNo ratings yet

- What Is The Purpose and Applications of A PCB MotherboardDocument4 pagesWhat Is The Purpose and Applications of A PCB MotherboardjackNo ratings yet

- What Is The Melting Point of SolderDocument4 pagesWhat Is The Melting Point of SolderjackNo ratings yet

- What Is The Difference Between FFC Connector and FPC ConnectorDocument14 pagesWhat Is The Difference Between FFC Connector and FPC ConnectorjackNo ratings yet

- What Is Thermal Consideration in PCB DesignDocument6 pagesWhat Is Thermal Consideration in PCB DesignjackNo ratings yet

- What Is SMT Soldering Process Step by StepDocument12 pagesWhat Is SMT Soldering Process Step by StepjackNo ratings yet

- What Is Xilinx Kintex UltraScale UltraScale+Document8 pagesWhat Is Xilinx Kintex UltraScale UltraScale+jackNo ratings yet

- What Is The Difference Between Clean Flux and No Clean Flux Off PCBDocument13 pagesWhat Is The Difference Between Clean Flux and No Clean Flux Off PCBjackNo ratings yet

- Unit 3-StatisticsDocument15 pagesUnit 3-Statisticsmcoleman10No ratings yet

- Q7 - A5 Side Assist SSP - 375Document14 pagesQ7 - A5 Side Assist SSP - 375mihaicatalinnNo ratings yet

- Interreg Danube Implementation ManualDocument84 pagesInterreg Danube Implementation ManualMadalina SbarceaNo ratings yet

- ch.2 Electric Potential and Capacitor - NotesDocument10 pagesch.2 Electric Potential and Capacitor - Notesnandank44373No ratings yet

- Abstract Synopsis For Arpa River Front at Bilaspur1Document7 pagesAbstract Synopsis For Arpa River Front at Bilaspur1Aarohan InfraNo ratings yet

- EuphemismsDocument2 pagesEuphemismssifo nebbarNo ratings yet

- Biochemistry: Questions & AnswersDocument17 pagesBiochemistry: Questions & AnswersA-Naeem To'mah Al-sawaieNo ratings yet

- Final XM PeparationDocument29 pagesFinal XM PeparationMd.Atikur RahmanNo ratings yet

- Principles and Practice of Management (MGT 420) : Shuib SepahtuDocument6 pagesPrinciples and Practice of Management (MGT 420) : Shuib SepahtuMuhd FakrullahNo ratings yet

- Learn JAVASCRIPT in Arabic 2021 (41 To 80)Document57 pagesLearn JAVASCRIPT in Arabic 2021 (41 To 80)osama mohamedNo ratings yet

- ME145 IBT2022 School Report SDocument546 pagesME145 IBT2022 School Report SshamshadNo ratings yet

- Curriculum VitÆ Nom Et Prénom: Bachari Khaldoun Date EtDocument5 pagesCurriculum VitÆ Nom Et Prénom: Bachari Khaldoun Date EtThe-ScribderNo ratings yet

- Romania Approves Neptun Deep ProjectDocument2 pagesRomania Approves Neptun Deep ProjectFloyd BurgessNo ratings yet

- Quick Recap Applied Maths Formula Sheet Class 12Document12 pagesQuick Recap Applied Maths Formula Sheet Class 12yashsharma2837No ratings yet

- Franklin B. Bernales - CVDocument2 pagesFranklin B. Bernales - CVFRANKLIN BERNALESNo ratings yet

- History Masters Thesis ExamplesDocument6 pagesHistory Masters Thesis Examplessararousesyracuse100% (1)

- 2023 LO Grade 10 Term 2 MG FinalDocument10 pages2023 LO Grade 10 Term 2 MG FinalsheronmoyoshalomNo ratings yet

- DLL English SLM Based w9Document5 pagesDLL English SLM Based w9Jerwin Caba�ero (Lunduyan 2)No ratings yet

- Footstep Power Generation Using Piezoelectric SensorDocument6 pagesFootstep Power Generation Using Piezoelectric SensorJeet DattaNo ratings yet

- Bill Mosley John Bungey & Ray Hulse: Reinforced Concrete Design To EC2Document31 pagesBill Mosley John Bungey & Ray Hulse: Reinforced Concrete Design To EC2RyanWongJiaHanNo ratings yet

- DLL Q2 Week 8 Health 6Document4 pagesDLL Q2 Week 8 Health 6Claudine CornitaNo ratings yet

- 02mapeh-3RD Quarter Week 7Document8 pages02mapeh-3RD Quarter Week 7ivan abandoNo ratings yet

- Reduced Voltage Motor Starters 1: Description ITDocument32 pagesReduced Voltage Motor Starters 1: Description ITANDRE LUIZ RAMOS DE FREITASNo ratings yet

- On The Tangent Indicatrix of Special Viviani's Curve and Iits Corresponding Smarandache Curves According To Sabban FrameDocument12 pagesOn The Tangent Indicatrix of Special Viviani's Curve and Iits Corresponding Smarandache Curves According To Sabban FrameScience DirectNo ratings yet

- Ezydek 44 Profile - DimensionsDocument2 pagesEzydek 44 Profile - DimensionsAnirban BhattacharjeeNo ratings yet

- B. Sc. Environmental Science Sem 1Document4 pagesB. Sc. Environmental Science Sem 1Uzeir SelotNo ratings yet

- B.Sc. Quantitative BiologyDocument2 pagesB.Sc. Quantitative BiologyHarshit NirwalNo ratings yet

- Angliyskiy Yazyk LGT 11 Klass 2018Document5 pagesAngliyskiy Yazyk LGT 11 Klass 2018CavenlyNo ratings yet

- Principal Component Analysis (PCA) - : San José State University Math 253: Mathematical Methods For Data VisualizationDocument49 pagesPrincipal Component Analysis (PCA) - : San José State University Math 253: Mathematical Methods For Data VisualizationAndreea IsarNo ratings yet