Professional Documents

Culture Documents

HogZilla - Grinder 2011

HogZilla - Grinder 2011

Uploaded by

André Graeff0 ratings0% found this document useful (0 votes)

13 views4 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

13 views4 pagesHogZilla - Grinder 2011

HogZilla - Grinder 2011

Uploaded by

André GraeffCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 4

HogZilla Grinders are

MONSTER Grinders

for waste reduction,

recycling, landclearing,

construction demolition,

or any other tough

grinding application.

Our number one selling mill drive

is a Torque Converter Drive System

providing multiplied engine

gi, torque, jon from torsional

@? shock & vibration, and the added

efficiency that comes with load

sensing engine RPM jement.

You owe it to yourself to learn

more about the advantages of a

1 True Torque Converter over

«> clutches and other fluid couplings.

HogZilla Tub Grinders

are built Extra-Heavy ,

Duty in sizes ranging ¢

from mid-sized to

MASSIVE and can be

configured as fifth-wheel

portable, track mounted, Mc

‘stationary, or mounted Reese ym eta

grapple units. 3 Asad

The most elite class of grinders

on the market are HogZilla TC

p series tub grinders. Engineered

with the commitment that all

possible components must be

the best, over-sized, and most

rugged available, the TC series

has earned its place at the top

of the market. The heart of a | yy

TC series grinder is the Torque

p Converter drive that always

allows the engine to perform at

peak efficiency with multiplied * v

torque. Torque Converters allow |. 360-2000HP Cat, Cummins or Detroit

J} the engine to avoid lugging and), 5 year/6000 Hour Engine Warranty

© irc cngine tron shock snd |* Torque Converter Drive w/'5yr/6000 hr. Warranty

+ Extreme Condition - Clog & Leak Resistant Radiator

+ Adjustable Swing 36", 38”, or 46"x 64" Hammermill

* Radial 60° Stacking Elevator

==, - Combustion Airand Radiator Precleaner Enclosure

* Auxiliary Service Hydraulics/30+CFM Air Compressor

+ Optional Wide Frame with 72" Conveyer

*HC-1462P ¢HC-1462L e¢HTC-1462T e¢HTC-1464T

HC series grinders have the |

ideal combination of features,

portability, and large-scale

production capabilities to meet

all of the needs of large industrial

grinding operations. While

"manufactured with heavy-duty

components for large-scale

production, they maintain a low

§ profile and sleek design. The HC

series is equipped standard with

a Hydraulic Coupling fluid drive

to eliminate the common repair

hassles of dry clutch and protect -

the engine from torsional shock. |° 650-1000HP Cat, Cummins or Detroit

‘* Hydraulic Fluid Coupling Drive

© 31"x 62" Hammermill

Optional Torque Converter Drive

* Radial 30° Stacking Elevator

« Radiator Precleaner

* Auxiliary Service Hydraulics/Air Compressor

'* Optional Northshore or 180E Prentice Loader

'* Optional Self-Propelled TRACKS

. © TC-1564P ° TAC 564P *TCII-1564P *TCIl-1664W

eer rides)

*WC-1354P *WC-1354L eWTC-1354T

CW's commitment to providing the best | Pi

industrial tub grinders carries through |

to the mid-sized WC series. Starting in ||

wood grinding completely focused on|

providing the biggest and highest [anol

production machines allowed us to adapt

proven, big grinder features intoa |

‘smaller, mid-sized model. WC series are |

‘equipped standard with a Hydraulic PTO}

drive. This hydraulic clutch is similar to}

those in high horsepower power-shift |}

transmissions. Mid-sized grinder owners |

are no longer forced to use the dry

over-center clutches. WC grinders are

often equipped with an upgrade Torque

Converter or Hydraulic Coupling drive

based on the customer's request.

| 525-860 HP Cat, Cur

/* Hydraulic Clutch Drive

|» 31" 54" Hammermill

" * Optional Fluid Coupling or Torque Converter Drive

* Auxiliary Service Hydraulics

* Air Compressor

* Optional Radial Stacking Elevator

'* Optional Northshore or 180E Prentice Loader

'* Optional Self-Propelled TRACKS

¢ HZL-6250P

For 15 years we have been watching

the horizontal grinder industry develop

from disc chippers and ram feeders

to the variety of mill and feeder |

configurations available today. During |

these years we have listened to the |

discontent of horizontal owners and |

customers who have demonstrated | —

e¢HZL-6250T

them. Our conclusion is a downturn |

plate mill offers the most production

and versatility - as we predicted.

Getting the proper angle of impact is

the key to making it work. A torque

converter with 16-belt drive provides

increased production and reliability.

Our exclusive dual feeder wheels

improve the feeding process for both

large and small material. Years ago,

we could have built a horizontal that

was similar to the others that were

‘on the market, but a design worthy

of being called HogZilla did not

exist until now.

or Detroit Diesel Engines

* Choice of Mill Drives including Wet Clutch,

Hydraulic Coupling, or Torque Converter

* Choice of Hammermill Configurations including

HogZilla’s own “‘Super-Colossal Mill”

* Auxiliary service hydraulics

+ Compressed air system with maintenance

support kit

* Radial Stacking Elevator

* Choice of feeder system including drag chain,

rubber belt, and metal-track

* Dual feed-rollers (Patent Poncing) or 44" Single Wheel

+ Hot Vulcanized Continuous Conveyor and

Elevator Belts

As the cost of diesel fuel has increased, electric powered wood grinders have become the

grinder of choice for an increasing number of grinding professionals. Spanning over four

decades, CW Mill Equipment Co., Inc. has been manufacturing electric powered grinders

in addition to its diesel powered units. CW's 800 HP Electric HogZilla TC-1564SE is what

‘experienced buyers are looking for today with increased efficiency, reduced maintenance,

massive construction, simplicity, and steady mill RPM generating amazing production from

its 46" diameter, super-colossal, 12 pin, hammermill that has an 8 %" main shaft. Although

CW offers many other sizes and configurations, the TC-1564SE model shown here is a

stationary unit mounted onto a foundation and equipped with a 15 foot tub that is constructed

from 18" thick steel. The tub floor is made of %" thick abrasion resistant steel, and the belly

conveyor is 72" wide. One of the several available thrown object restraint options was included

‘on the unit shown. Options are available including portability options for moving the grinder.

1-1564P | f

11-1564P | F

Diesel Horsepower |cat__| 1000-1650 _| 860 - 1000 525 - 860 860 - 1000

{Cummins} 1050 760 - 1050 650 - 760 760 - 1050

IDetroit_| 1005 - 1200 760 -1005 600 - 760 760 - 1005

Electric Horsepower - 400 - 1600 HP - To customer specifications with upgrade available for all HogZilla models.

[Hammer Swing 38/46" x 64" 31" x 62" 31" x 54" 46" x 64"

‘Screen Area 4610/5480 sq.in._| 3813 sq. in. 3921 sq. in. 5480 sq. in.

‘Screen Thickness We Tin. tin. 1-18

[Hammer Weight 80/110 ibs. | 50 Ibs. 50 Ibs. 75ilbs.

|Hammer Number 24-48 28 24 36-72

Rod Diameter & # in. & 6 ea. 2in. & 8 ea. Zin. &8 ea. _/3in. &i2ea

(Tub Top Width 15 ft. 14 ft. 13 ft. 62 in. inlet

Conveyor Belts 48" & 42" 42" & 36" 36" & 36" 60" & 48”

Transport Width wi" 1 1-1 wit

Transport Length 56"- 3” 48°- 6" a7" 48"

(Total Weight Sia" feciatars| 88 - 94,000 Ibs | 85 - 108,000 lbs | 65- 92,000 lbs _ 95- 116,000Ibs

‘Specifications subject to change without notice. As improvements are made, actual product otfered for sale may vary in design.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Haas - Drum Chipper HTHDocument2 pagesHaas - Drum Chipper HTHAndré GraeffNo ratings yet

- En - HR 60 - 150dpiDocument2 pagesEn - HR 60 - 150dpiAndré GraeffNo ratings yet

- En - HR 45 - 150dpiDocument2 pagesEn - HR 45 - 150dpiAndré GraeffNo ratings yet

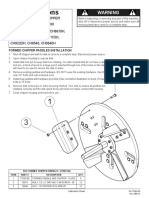

- 77583-00 Formed Chipper Paddles Kit English 080113Document2 pages77583-00 Formed Chipper Paddles Kit English 080113André GraeffNo ratings yet

- 31514-00 8 INCH 720cc SUBARU 010113Document45 pages31514-00 8 INCH 720cc SUBARU 010113André GraeffNo ratings yet

- 31508-00 8 INCH 720cc SUBARU ENGLISH 010113Document37 pages31508-00 8 INCH 720cc SUBARU ENGLISH 010113André GraeffNo ratings yet

- TAD1353VE Technical Data.22494043.08Document18 pagesTAD1353VE Technical Data.22494043.08André GraeffNo ratings yet

- 77369-00 Plus One Service Tool English 041513Document24 pages77369-00 Plus One Service Tool English 041513André GraeffNo ratings yet

- FA87 GDRN132M4 ProductData en DEDocument1 pageFA87 GDRN132M4 ProductData en DEAndré GraeffNo ratings yet

- 1986 Hartler Optimum+Chip+QualityDocument5 pages1986 Hartler Optimum+Chip+QualityAndré GraeffNo ratings yet

- 17 Erikssonetal 2013 StateoftheartDocument24 pages17 Erikssonetal 2013 StateoftheartAndré GraeffNo ratings yet

- Gerenciamento Setor Projetos - V3 - Foco Nos RecursosDocument1 pageGerenciamento Setor Projetos - V3 - Foco Nos RecursosAndré GraeffNo ratings yet

- Gerenciamento Projetos - V1 - Foco TarefasDocument3 pagesGerenciamento Projetos - V1 - Foco TarefasAndré GraeffNo ratings yet

- DESCH - PH - 19 - Hydraulically Actuated - GBDocument6 pagesDESCH - PH - 19 - Hydraulically Actuated - GBAndré GraeffNo ratings yet