Professional Documents

Culture Documents

Electrical: Section 2C - Timing, Synchronizing & Adjusting

Electrical: Section 2C - Timing, Synchronizing & Adjusting

Uploaded by

Dr. Centelha Mecânica NaúticaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electrical: Section 2C - Timing, Synchronizing & Adjusting

Electrical: Section 2C - Timing, Synchronizing & Adjusting

Uploaded by

Dr. Centelha Mecânica NaúticaCopyright:

Available Formats

TIMING, SYNCHRONIZING & ADJUSTING

ELECTRICAL

Section 2C - Timing, Synchronizing & Adjusting

Table of Contents

2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2C-2 Idle Speed Adjustment . . . . . . . . . . . . . . . . . . . . 2C-4

C

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2C-3

90-854785R2 DECEMBER 2001 Page 2C-1

TIMING, SYNCHRONIZING & ADJUSTING

Specifications

Type Capacitor Discharge Ignition

Spark Plug

Type NGK DPR6EA-9

Gap 0.035 in. (1.0 mm)

Hex Size 18 mm

Hole Size 12 mm

Torque 150 lb-in. (17 Nm)

Firing Order 1-2

Ignition Timing:

Below 800 RPM

ECM (p/n 855311--) 10° B.T.D.C

ECM (p/n 856058--/856190--) 5° B.T.D.C

IGNITION ECM (p/n 856190-–/856482-–) 5° B.T.D.C

SYSTEM ECM (p/n 856177--/856178-–) 5° B.T.D.C

Readings taken @ ECM (p/n 878433--) 5° B.T.D.C

68°F (20°C). Fully Advanced (6000 RPM) 30° B.T.D.C

Charge Coil Resistance 660 - 710 Ω (GRN/WHT - WHT/GRN)

Crank Position Sensor Resistance 300 - 350 Ω (RED - WHT)

Ignition Coil Resistance:

Primary 0.08 - 0.7 Ω

Secondary (W/o Boots) 3.5 - 4.7 kΩ

ECM Engine Speed Limiter

Soft Reduction (Retards Timing) 6200 RPM

Spark Cut-Out Reduction (Percent-

ages of ignition spark are Cut-Out) 6250 RPM

ECM Overheat/Low Oil Pressure

Speed Control Approximately 2000 RPM

Oil Pressure Switch Below 2.5 psi (17 kPa) Continuity

NOTE: The 25 four stroke ECM unit electronically controls the ignition timing, therefore

making the ignition timing non adjustable. When initially running the outboard, use a timing

light to verify that the ignition timing falls within the timing windows. If the ignition timing does

not stay within the timing windows, replace the ignition ECM unit and retest.

Page 2C-2 90-854785R2 DECEMBER 2001

TIMING, SYNCHRONIZING & ADJUSTING

Special Tools

1. DMT 2000 Digital Tachometer Multi-meter P/N 91-854009A1.

2. Timing Light P/N 91-99379.

90-854785R2 DECEMBER 2001 Page 2C-3

TIMING, SYNCHRONIZING & ADJUSTING

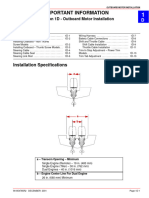

Idle Speed Adjustment

NOTE: The engine should be completely warmed up for the adjustment. Correct adjust-

ments can not be obtained in a cold condition.

1. With the outboard in the water, start engine and allow to warm up. Shift the outboard to

neutral.

2. With the outboard in neutral, turn the idle speed adjustment screw to obtain the specified

idle RPM.

a - Idle Adjustment Screw

Page 2C-4 90-854785R2 DECEMBER 2001

You might also like

- 491QEengine Service ManualDocument222 pages491QEengine Service ManualFabian Carrasco Naula100% (1)

- 09 - SsangYong-Korando - 2012 - EN - US - Manual - de - Taller - Caja - Automatica - 1f0efc15ddDocument74 pages09 - SsangYong-Korando - 2012 - EN - US - Manual - de - Taller - Caja - Automatica - 1f0efc15ddMateus FumuassucaNo ratings yet

- Y290 WML 209.PDF Rexton SsangyongDocument6 pagesY290 WML 209.PDF Rexton SsangyongVelasquez JavierNo ratings yet

- Imv3 Rev4 Master Book 29dec08Document95 pagesImv3 Rev4 Master Book 29dec08rvozgovNo ratings yet

- RIICO Building Bye LawsDocument21 pagesRIICO Building Bye LawsSohan AdvaniNo ratings yet

- CatalogoDocument10 pagesCatalogopedroNo ratings yet

- Timing, Synchronizing, & AdjustingDocument15 pagesTiming, Synchronizing, & AdjustingpeninalbertoNo ratings yet

- Electrical: Section 2A - IgnitionDocument27 pagesElectrical: Section 2A - IgnitionDr. Centelha Mecânica NaúticaNo ratings yet

- 2C - Timing-Synchronizing & AdjustingDocument13 pages2C - Timing-Synchronizing & AdjustingDenis RoscaNo ratings yet

- Electrical and Ignition: Timing/Synchronizing/AdjustingDocument9 pagesElectrical and Ignition: Timing/Synchronizing/AdjustingJim LassNo ratings yet

- Electrical: Section 2A - IgnitionDocument34 pagesElectrical: Section 2A - IgnitionpedroNo ratings yet

- Important Information: Section 1A - Master SpecificationsDocument12 pagesImportant Information: Section 1A - Master Specificationsibrahimvisham99No ratings yet

- Timing Synchronizing AdjustingDocument6 pagesTiming Synchronizing AdjustingRyan ActonNo ratings yet

- Foreword 2. Ignition Timing: Service ProcedureDocument16 pagesForeword 2. Ignition Timing: Service Procedurevadim vadimNo ratings yet

- CZ Sincro DG83Document14 pagesCZ Sincro DG83JoNo ratings yet

- 226Document2 pages226rigadacNo ratings yet

- SpecificationsDocument25 pagesSpecificationsthomas rulduNo ratings yet

- Swing Motor Leakage Test-200CLC and 230CLCDocument3 pagesSwing Motor Leakage Test-200CLC and 230CLCLupin GonzalezNo ratings yet

- Specifications: C280-16 Marine PropulsionDocument4 pagesSpecifications: C280-16 Marine PropulsionwalacrNo ratings yet

- 225Document1 page225rigadacNo ratings yet

- Verado Electrical 8m8023781 - 2aDocument60 pagesVerado Electrical 8m8023781 - 2aJon KnappNo ratings yet

- Cat C32 ACERT™ DITTA-SCAC Marine Propulsion EngineDocument3 pagesCat C32 ACERT™ DITTA-SCAC Marine Propulsion EngineSu truong vanNo ratings yet

- Altronic Iii: Ignition System For Industrial EnginesDocument4 pagesAltronic Iii: Ignition System For Industrial EnginesClever NegreteNo ratings yet

- CH3 Engine TroubleshootingDocument51 pagesCH3 Engine TroubleshootingMigue SalazarNo ratings yet

- Cat c280-8 MarinoDocument4 pagesCat c280-8 MarinoHugo GodoyNo ratings yet

- Engine Electric StstemDocument51 pagesEngine Electric StstemnahomNo ratings yet

- Chery A21 Service Manual Mechanism of 2.0nalc EngineDocument45 pagesChery A21 Service Manual Mechanism of 2.0nalc Enginehusnihameed74No ratings yet

- Digital No Flow TimerDocument4 pagesDigital No Flow Timerzhangjie100% (1)

- Specification of 1250 Kva DG Set PDFDocument7 pagesSpecification of 1250 Kva DG Set PDFraj_sh242001No ratings yet

- Lehm0028 00Document4 pagesLehm0028 00Aidel MustafaNo ratings yet

- 02 02 TRansmissionDocument51 pages02 02 TRansmissionKhaerul Ade WiyatnoNo ratings yet

- 1g Charging Starting System PDFDocument21 pages1g Charging Starting System PDFNuwan NishanthaNo ratings yet

- C280-12 3460kw Spec SheetDocument4 pagesC280-12 3460kw Spec SheetAidel MustafaNo ratings yet

- Catalyst: Catalyst Deterioration Monitor Ca 1 - . - . - . - . - . - . .Document3 pagesCatalyst: Catalyst Deterioration Monitor Ca 1 - . - . - . - . - . - . .Garvin Alberto Sandrea ParisNo ratings yet

- Skoda Workshop Manuals Fabia Mk2 Engine 1-6-77 KW MPI Engine Engine CyliDocument6 pagesSkoda Workshop Manuals Fabia Mk2 Engine 1-6-77 KW MPI Engine Engine CyliBezzaouya MustaphaNo ratings yet

- Pistola Estroboscópica SAMDocument16 pagesPistola Estroboscópica SAMaudioimagenNo ratings yet

- Accent P0011 Camshaft Position-Timing Over-AdvancedDocument6 pagesAccent P0011 Camshaft Position-Timing Over-Advancedflash_24014910No ratings yet

- Marine Installation Manual - Volume 3Document24 pagesMarine Installation Manual - Volume 3Святослав ВороновNo ratings yet

- DYNC10502 Linear Actuator Product Bulletin PDFDocument4 pagesDYNC10502 Linear Actuator Product Bulletin PDFEfrain MarceloNo ratings yet

- Important Information: Section 1A - Master SpecificationsDocument10 pagesImportant Information: Section 1A - Master SpecificationsJon KnappNo ratings yet

- Catalogue Yanmar 4TNV106T GGEDocument17 pagesCatalogue Yanmar 4TNV106T GGEMikh MIKH100% (1)

- Whitlock-A-10753 DNFTDocument4 pagesWhitlock-A-10753 DNFTmarbbanNo ratings yet

- Condura Room Air Conditioner Specifications: ModelsDocument1 pageCondura Room Air Conditioner Specifications: ModelsJayson FernandezNo ratings yet

- 210 m2 Jet ElectricalDocument47 pages210 m2 Jet ElectricalДмитрий ЗолотковNo ratings yet

- Hyundai Elantra 1.6 Engine Electrical1Document55 pagesHyundai Elantra 1.6 Engine Electrical1MANUALES2000CLNo ratings yet

- Electrical: Section 2A - IgnitionDocument76 pagesElectrical: Section 2A - Ignitionibrahimvisham99No ratings yet

- 4TNV106T-GGE: For GeneratorDocument17 pages4TNV106T-GGE: For Generatorcaleb diversity100% (1)

- Specifications: Standards and Service LimitsDocument20 pagesSpecifications: Standards and Service Limitsvadim vadimNo ratings yet

- Specifications: C280-16 Marine PropulsionDocument4 pagesSpecifications: C280-16 Marine PropulsionwalacrNo ratings yet

- IgnitionDocument26 pagesIgnitionRyan ActonNo ratings yet

- Evo X SST ManualDocument18 pagesEvo X SST ManualSheldon Gilkes100% (1)

- System Diagram: Engine Stop SwitchDocument10 pagesSystem Diagram: Engine Stop SwitchgenuineswedeNo ratings yet

- Marine CaterpillarDocument4 pagesMarine CaterpillarFelipe Emanuel Basniak SilvaNo ratings yet

- 3512B B 861bkW 1155bhp 1200rpmDocument6 pages3512B B 861bkW 1155bhp 1200rpmFernandez Gonzalo100% (1)

- Brake Switch B HighDocument2 pagesBrake Switch B HighDannyDDannyDNo ratings yet

- Catalogue Yanmar 4TNV84T GGEDocument4 pagesCatalogue Yanmar 4TNV84T GGEAhmad Fahmi IrfandaNo ratings yet

- 13 Air Conditioner and Heating Device-N900 Series JMCDocument38 pages13 Air Conditioner and Heating Device-N900 Series JMCRusonegro100% (2)

- SS15 CPGKDocument4 pagesSS15 CPGKDenzo RyugaNo ratings yet

- Clymer Suzuki GT 380 750Document172 pagesClymer Suzuki GT 380 750Leandro van der LaanNo ratings yet

- Electronic Automotive Transmission Troubleshooter Nissan-Infinity VehiclesFrom EverandElectronic Automotive Transmission Troubleshooter Nissan-Infinity VehiclesNo ratings yet

- 4a MercuryDocument58 pages4a MercuryDr. Centelha Mecânica NaúticaNo ratings yet

- 3b MercuryDocument58 pages3b MercuryDr. Centelha Mecânica NaúticaNo ratings yet

- 3d MercuryDocument8 pages3d MercuryDr. Centelha Mecânica NaúticaNo ratings yet

- Important Information: Section 1D - Outboard Motor InstallationDocument13 pagesImportant Information: Section 1D - Outboard Motor InstallationDr. Centelha Mecânica NaúticaNo ratings yet

- Important Information: Section 1B - MaintenanceDocument17 pagesImportant Information: Section 1B - MaintenanceDr. Centelha Mecânica NaúticaNo ratings yet

- Electrical: Section 2A - IgnitionDocument27 pagesElectrical: Section 2A - IgnitionDr. Centelha Mecânica NaúticaNo ratings yet

- Important Information: Section 1C - General InformationDocument21 pagesImportant Information: Section 1C - General InformationDr. Centelha Mecânica NaúticaNo ratings yet

- Outboard Maintenance ManualDocument141 pagesOutboard Maintenance ManualDr. Centelha Mecânica NaúticaNo ratings yet

- Electrical: Section 2B - Charging & Starting SystemDocument26 pagesElectrical: Section 2B - Charging & Starting SystemDr. Centelha Mecânica NaúticaNo ratings yet

- MERCURY - 2 - Stroke - Tehnicheskoe - Diagramas Eletricos - Combustivel e OutrosDocument230 pagesMERCURY - 2 - Stroke - Tehnicheskoe - Diagramas Eletricos - Combustivel e OutrosDr. Centelha Mecânica NaúticaNo ratings yet

- MEO Indian WKC DocumentDocument3 pagesMEO Indian WKC Documentprasad_satyamNo ratings yet

- Manual Rele SickDocument6 pagesManual Rele SickElian SilvaNo ratings yet

- Design Problem:: Design A Fully Differential Version of Two Stage CMOS Op-Amp With The Following SpecificationsDocument37 pagesDesign Problem:: Design A Fully Differential Version of Two Stage CMOS Op-Amp With The Following Specificationslearn simplyNo ratings yet

- Department of Education School Improvement Plan (SIP) Quality Assessment ToolDocument11 pagesDepartment of Education School Improvement Plan (SIP) Quality Assessment ToolYeah, CoolNo ratings yet

- Ritsu Mate ApplicationDocument6 pagesRitsu Mate ApplicationMher MaterianoNo ratings yet

- Teaching Learning Process 2Document2 pagesTeaching Learning Process 2BuvaneswariNo ratings yet

- Gap AnalysisDocument2 pagesGap AnalysisCarol LeeNo ratings yet

- Easi joistTechnicalManual2008Document36 pagesEasi joistTechnicalManual2008Bartlomiej KuczynskiNo ratings yet

- The Future of Nanotechnology Extended EssayDocument25 pagesThe Future of Nanotechnology Extended EssaySephye100% (1)

- Bearing FailureDocument25 pagesBearing Failureokta saputra100% (1)

- Rareplanes Model Kit ListDocument2 pagesRareplanes Model Kit Listgarbage63100% (1)

- Standardi PERFORMANSI U Građenju Engleski ISO 9836 PDFDocument12 pagesStandardi PERFORMANSI U Građenju Engleski ISO 9836 PDFsaban saulic100% (1)

- Ancientgemastrology Blogspot in 2013 11 Tantra Ke Gopaniye RDocument7 pagesAncientgemastrology Blogspot in 2013 11 Tantra Ke Gopaniye Ravtar_singh450No ratings yet

- Hang FireDocument12 pagesHang FireMiloš DavitkovićNo ratings yet

- PPG Wave 3.v ManualDocument82 pagesPPG Wave 3.v Manualsalvaes100% (2)

- Grenade Launcher 40 MM M79Document14 pagesGrenade Launcher 40 MM M79virtualbobNo ratings yet

- Problem Identification: MIT - World Peace University, Pune - 2019Document9 pagesProblem Identification: MIT - World Peace University, Pune - 2019priyadarshan chouguleNo ratings yet

- EcoDocument16 pagesEcovpsampathNo ratings yet

- Government of Manipur X-10: Employment Exchange Identity CardDocument1 pageGovernment of Manipur X-10: Employment Exchange Identity CardNongmaithem Bilash SinghNo ratings yet

- Solar Crimp ToolsDocument4 pagesSolar Crimp ToolsCase SalemiNo ratings yet

- Device Summary EnglishDocument14 pagesDevice Summary Englishكاظم محمدNo ratings yet

- Admission: National Institute of Electronics & Information TechnologyDocument3 pagesAdmission: National Institute of Electronics & Information TechnologyUtkarsh AnandNo ratings yet

- Star Rating List Submersibles 2018Document8 pagesStar Rating List Submersibles 2018RAVICHANDRAN LNo ratings yet

- 3 Phase Soft-Starter Data SheetDocument4 pages3 Phase Soft-Starter Data SheetcoronaqcNo ratings yet

- Tyco Electronics HVS 3 1582S Instruction SheetDocument12 pagesTyco Electronics HVS 3 1582S Instruction SheetAlexander KurosakiNo ratings yet

- VortexDocument16 pagesVortexMitch GagnonNo ratings yet

- CD HL NC Manual Issue 11Document44 pagesCD HL NC Manual Issue 11bernard100% (1)

- Power Quality 2 Marks and 16 MarksDocument6 pagesPower Quality 2 Marks and 16 MarksBala MuruganNo ratings yet