Professional Documents

Culture Documents

Nimco Loads of Control

Nimco Loads of Control

Uploaded by

lukasz20511Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nimco Loads of Control

Nimco Loads of Control

Uploaded by

lukasz20511Copyright:

Available Formats

fluid power

torbjörn nord

loads of control

Agricultural loaders are becoming increasingly sophisticated,

with load-sensing pumps, low spool-leakage valves and

electrical proportional valves offering more control options

T

he agricultural loader market has The special Nimco concept,

become far more sophisticated over where all ports are facing

the last 10 years. The main forward, allows for easy

developments are the use of load-sensing assembly of all hoses from

pumps on larger tractors, the introduction one side and is available in the

Right: The CV152 is of more advanced valves that offer very CV 152 and CV 452 valves,

a loader valve for low spool leakage for load-holding which are designed for

flows up to 75 l/min operations, and the integration of flows up to 75 and 120 l/

(shown here with

QDC coupling) electrical proportional valves that can min respectively.

offer a number of control options that Both models can

were not previously possible with earlier be fitted

hydraulic systems. with the

Nimco Controls has been at the company’s

forefront of this evolution. The company QDC fast-

has introduced a number of solutions and connect coupling system Depending on the manufacturer, the

has been instrumental in bringing the which allows for the quick standard leakage rate for valves in the

market to its present technical level. coupling of all the hoses to the loader from mobile industry is around 8cm3/min spool

Most tractors with engines below 80hp the tractor in a single movement. leakage at 46 cSt, which gives a traditional

are equipped with fixed displacement With a maximum flow rate of 45 l/min, cylinder with a diameter of 63/40mm at

pumps, while tractors over 80hp usually the CV 112 loader valve is an option for 100 bar pressure a drift of 1.3mm per

feature a load-sensing pump which smaller loaders mounted on tractors. It minute per lifting cylinder. While this might

requires either an open-centre valve or a has proven very popular as it can be be acceptable in many applications for

load-sensing valve. Load-sensing pumps equipped with a variety of spools many customers, it is not the case for

have traditionally had a standby pressure including float and regen, and can be most loader applications as the operator

of around 24 bar, but new models are fitted with a direct-acting joystick as well often needs to keep the load steady

Comparison of a

Nimco low-leakage being introduced with standby pressures as cable control options. As mentioned without any cylinder drift, so that he can

(2cc/min) valve as low as 5 bar. earlier, the CV 112 valve is offered in a carry out other operations simultaneously.

with competitive Nimco Controls offers a full range of load-sensing version. Nimco offers its customers a leakage

model (8cc/min)

on a parked loader,

open-centre and load-sensing valves rate which is below 2cm3/min on all of its

concerning drift covering all tractor and loader sizes with Complete control loader valves, which translates to only

of lift and bucket flows ranging from 15-120 l/min. All Nimco One of the most critical factors for any 0.4mm per minute cylinder drift. A

cylinders over 10

minutes with a 100

loader valves can be offered as open-or mobile machine operator today is absolute conventional valve would have 13mm in

bar load and a 46 closed-centre and can accommodate all control of the load at all times. This is cylinder drift over a 10-minute period,

cST viscosity levels of standby signals down to 5 bar. made easier by the use of well-designed while a Nimco valve would have only

valves that include load-holding check 4mm. Considering the geometry of the

valves and ‘tuned’ spools which not only loader, this has a big effect on where the

allow the operator to have absolute control load ends up over this period of time. This

of the load at all times for safety reasons, has proved particularly useful when the

but also give him the ability to keep the agricultural loader is being used for

load steady without cylinder drift. precise work such as pallet stacking or

The float position is a necessity for animal and goods transporting.

most loaders. As it is not feasible to use

traditional over-centre valves in Not forgetting the ergonomics

combination with the float position, it is As tractors and loaders have become more

necessary to achieve very low spool sophisticated and efficient with regard to

leakage in the directional control valve to productivity and hours used, good

obtain minimum cylinder drift. Nimco has ergonomics and operator comfort have

solved this problem by offering valves become increasingly important. This has

with exceptionally low spool leakage rates, lead to rapid development of

which is the combined result of electrohydraulic control of the directional

continuous improvement in the design of control valve, where the traditional manual

the valve itself and the finished spool bore cable control joystick has been exchanged

through highly specific spool bore for an electrical joystick (analogue or

finishing methods. CANbus), which will eliminate the need for

?? iVT International 2006

the machine The EPC-600 has the

operator to manually processor capacity to send,

shift the valve spools receive and process information,

through the which means it enables the

mechanical joystick and use of preset movements

cables. based on the information

This type of control is used received from the different

mainly on larger-flow tractors, sensors placed on the machine.

due to the cost difference over The CANbus joystick is

cable control units. However, there is connected to a driver box which operates

a clear trend towards this kind of system the proportional pressure-reducing The CV452 is a special front-loader valve in The EPC600 is a

for smaller equipment, as a new generation valves integrated in the main valve via a open- and closed-centre versions for controlling programmable

of farmers is appreciating and demanding PWM signal. flows up to 120 l/min CANbus joystick

with integrated

all the productivity-improving factors that button to shake the bucket to release any display

the programmable electrical proportional Feature rich material stuck inside; a quick-dump

systems offer. A number of different standard features function; an automatic return to dig cycle;

To develop electrical proportional have been incorporated into the EPC-600 and speed control for post hole diggers

control for the loader market is probably system for loaders, which can be used for driven by hydraulic motors.

one of the most demanding tasks due to open-centre as well as load-sensing By combining load-sensing technology,

its many application areas. This has lead to systems. The latest feature is a complete advanced valve technology and

a move from traditional analogue controls electrical self-levelling function that removes programmable electrical controls, even

to the more adaptable CANbus systems. the need for mechanical or hydraulic self- relatively simple loaders can become

Nimco offers a full range of electrical levelling as used on loaders today. sophisticated, highly productive machines

hydraulic proportional controlled valves The most basic feature of the EPC-600 compared with the small loaders of 10

(EHPs) as well as a large number of system is the electrical proportional years ago. The operating features and

different joystick controls from the control of the lift, lower, tilt, dump and float ergonomics offered in the EPC-600 system

simplest on/off control to proportional functions, which copies the mechanical have improved the working conditions for

controls where a number of productivity- control used today, albeit in a more operators, who can utilise their equipment

enhancing features can be integrated as ergonomic way. to a greater extent and make further

options into the system. Standard features are the activation of increases in productivity.

For loaders, Nimco’s EPC-600 second any third and fourth functions such as The challenge that remains is to further

generation of fully programmable electrical circuit selector valves operating grapples, improve cost efficiencies in the components

proportional CANbus control systems is soft drive accumulators and hydraulic tool so that these types of systems can be

now available. The series is built around a lock and release functions via an electrical made available for all machines. iVT

CANbus joystick unit with an integrated switch in the joystick hand grip. . Torbjörn Nord is founder and managing

display on which the user can call up any Other features include fast and slow director of the Nimco Controls Group

of the preprogrammed features available mode selection where the operator can

for any specific loader. Specific programs reduce the speed of any operation to any

for different types of operations are level in relation to the stroke of the cCONTACT

available, as well as sub-menus for specific joystick; a rattle function whereby the www.nimco-controls.com

tools or pre-programmed movements. operator can simply push the joystick saleseurope@nimco.se

EPC452 dual-spool proportional

Third and fourth circuit valve (in combination with two

selector valves circuit selector valves) CANbus

iVT International 2006 ??

You might also like

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- Intelligent Completions - CatalogDocument54 pagesIntelligent Completions - CatalogRzvnNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Subsea Bop PDFDocument48 pagesSubsea Bop PDFJorge VarelaNo ratings yet

- Skoda Specific Quality Requirement v3Document24 pagesSkoda Specific Quality Requirement v3Yo GoldNo ratings yet

- SOP 0102 Standard Operating Procedures 1Document6 pagesSOP 0102 Standard Operating Procedures 1Agil MahendraNo ratings yet

- BC435084501801en 000101Document22 pagesBC435084501801en 000101Felipe Doria RibeiroNo ratings yet

- 7.castildi WaterjetDocument4 pages7.castildi Waterjetaat syarifNo ratings yet

- OIL PLEM Control Systems Brochure 2019 3 WDocument8 pagesOIL PLEM Control Systems Brochure 2019 3 WFaisal AwanNo ratings yet

- Sky / Startup Vents: Modulating Control ValvesDocument8 pagesSky / Startup Vents: Modulating Control ValvesGaneshNo ratings yet

- RTUA RTCA Designed To Perform Built To Last PDFDocument20 pagesRTUA RTCA Designed To Perform Built To Last PDFModussar IlyasNo ratings yet

- Pala O&KRH90CDocument7 pagesPala O&KRH90Cmchan1965100% (1)

- Powerline: Rg15/Ug15Document4 pagesPowerline: Rg15/Ug15pedro perezNo ratings yet

- Flow Control August 2019 PDFDocument37 pagesFlow Control August 2019 PDFAlberto Fernández MarínNo ratings yet

- Brochure o P CPP Propeller SystemsDocument8 pagesBrochure o P CPP Propeller SystemsalmondayNo ratings yet

- Mokveld Brochure Angle Choke ValveDocument16 pagesMokveld Brochure Angle Choke ValvekglorstadNo ratings yet

- NQ Specification 01Document8 pagesNQ Specification 01Jose MonroyNo ratings yet

- 28990-Turbinebypass Prds PDFDocument12 pages28990-Turbinebypass Prds PDFbuddhivasu100% (3)

- Integrated Advanced Digital Turbine Control For Steam TurbinesDocument4 pagesIntegrated Advanced Digital Turbine Control For Steam TurbinesJames IzquierdoNo ratings yet

- Refrigeration - EN-AQUATECH TANK CILLER PDFDocument12 pagesRefrigeration - EN-AQUATECH TANK CILLER PDFVISHALNo ratings yet

- Fachaufsatz 2014 02-gbDocument6 pagesFachaufsatz 2014 02-gbGoutham KSNo ratings yet

- What's: Fluids HandlingDocument4 pagesWhat's: Fluids HandlingRaul TejedaNo ratings yet

- Cameron Subsea SystemsDocument49 pagesCameron Subsea Systemsady_fernando100% (4)

- EQ-011 Multielement WavemakerDocument4 pagesEQ-011 Multielement WavemakerFahmy ArdhiansyahNo ratings yet

- Rotork Innovation Assists Automation in The Water Industry: Also InsideDocument20 pagesRotork Innovation Assists Automation in The Water Industry: Also InsideIñaki EseberriNo ratings yet

- VACON 100 FLOW BrochureDocument12 pagesVACON 100 FLOW Brochurehunt huntNo ratings yet

- Brochure 1Document20 pagesBrochure 1련서긔No ratings yet

- Equipo Pala rh-90Document8 pagesEquipo Pala rh-90hernanNo ratings yet

- Control-Valve-Handbook-En-3661206 Pages 51-60Document10 pagesControl-Valve-Handbook-En-3661206 Pages 51-60trevNo ratings yet

- 95C-10828 - VC6800, VC6900 Series Floating Control Valves - Product Data - 001750Document6 pages95C-10828 - VC6800, VC6900 Series Floating Control Valves - Product Data - 001750Cuajinike1No ratings yet

- Clorador v10kDocument8 pagesClorador v10kMarco Antonio VelazcoNo ratings yet

- Flex-Valve CatalogDocument20 pagesFlex-Valve CatalogMina MagdyNo ratings yet

- Dewatering Solutions For Mining Applications: Flexible PipelinesDocument6 pagesDewatering Solutions For Mining Applications: Flexible PipelinesBahadır FeyzioğluNo ratings yet

- Andritz Valves en DataDocument14 pagesAndritz Valves en DataHenrique RosaNo ratings yet

- 105 0020 4100B - Nov2018 PDFDocument4 pages105 0020 4100B - Nov2018 PDFdevendra bansalNo ratings yet

- Numerical and Experiential Study of Motion Control Using Pressure FeedbackDocument7 pagesNumerical and Experiential Study of Motion Control Using Pressure Feedbackgil lerNo ratings yet

- Bulk Storage Transfer Equipment PsDocument1 pageBulk Storage Transfer Equipment Psalvaro netoNo ratings yet

- Multipurpose Crane SystemDocument12 pagesMultipurpose Crane SystemPhu DoNo ratings yet

- MANUALDocument12 pagesMANUALmimi lrNo ratings yet

- KecocatalogDocument6 pagesKecocatalogTimothy HevenerNo ratings yet

- Dynapac Pneumatic Tire Rollers: DYNAPAC CP1200 / CP1200W / CP2100 / CP2100W and CP2700Document8 pagesDynapac Pneumatic Tire Rollers: DYNAPAC CP1200 / CP1200W / CP2100 / CP2100W and CP2700danielfbarradas1370No ratings yet

- Dokumen - Tips Hiab Xs 166 CLX Capacity 17 TM 4 Hiab Xs 166 CLX Capacity 17 TM Front RunnersDocument8 pagesDokumen - Tips Hiab Xs 166 CLX Capacity 17 TM 4 Hiab Xs 166 CLX Capacity 17 TM Front Runnersbharat singhNo ratings yet

- Performance: The Strong Universal TalentDocument10 pagesPerformance: The Strong Universal TalentSirene Diaz GarciaNo ratings yet

- Palfinger PK 40002 EH GDocument8 pagesPalfinger PK 40002 EH Gjose lozadaNo ratings yet

- Link Belt Rough Terrain Cranes Spec f75124Document6 pagesLink Belt Rough Terrain Cranes Spec f75124Artur Erre Emme100% (1)

- Flow Control July 2019Document37 pagesFlow Control July 2019Alberto Fernández MarínNo ratings yet

- Linear Globe Valve: ActuatorsDocument40 pagesLinear Globe Valve: ActuatorsLuis AngelNo ratings yet

- Excavator O&KDocument8 pagesExcavator O&Keknasius iwan sugoro100% (2)

- PB-166CLX-EN-US L 111123 Original 76135Document8 pagesPB-166CLX-EN-US L 111123 Original 76135bharat singhNo ratings yet

- Drilling Chokes BrochureDocument12 pagesDrilling Chokes BrochureAshok SureshNo ratings yet

- Dynapac AplanadorasDocument16 pagesDynapac AplanadorasMarcos CarrascosaNo ratings yet

- Ficha Tecnica Polipasto Electrico Yale CPV (Vego)Document12 pagesFicha Tecnica Polipasto Electrico Yale CPV (Vego)Fabio NieraNo ratings yet

- Pala O&KRH200Document8 pagesPala O&KRH200mchan1965100% (1)

- Rotork Actuators With Profibus: Case StudyDocument5 pagesRotork Actuators With Profibus: Case StudympicaNo ratings yet

- RH 120eDocument8 pagesRH 120eSawadogo Gustave NapinguebsonNo ratings yet

- Valve Actuation at The World's Largest Flow Metering: Calibration FacilityDocument5 pagesValve Actuation at The World's Largest Flow Metering: Calibration FacilityFelipe Gamboa GálvezNo ratings yet

- PCT 259645Document4 pagesPCT 259645Liquidstate glassNo ratings yet

- Matching Antisurge Control Valve Performance With Integrated Turbomachinery Control SystemsDocument4 pagesMatching Antisurge Control Valve Performance With Integrated Turbomachinery Control SystemsPankaj TiwariNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Highly Integrated Gate Drivers for Si and GaN Power TransistorsFrom EverandHighly Integrated Gate Drivers for Si and GaN Power TransistorsNo ratings yet

- SsssssDocument2 pagesSsssssUdhaya FreaksNo ratings yet

- DOMDocument14 pagesDOMMANSI SALUNKENo ratings yet

- Dice Resume CV Sasikala AtmakuriDocument7 pagesDice Resume CV Sasikala AtmakuriHarinath AkulaNo ratings yet

- HBR Guide To Data Analytics Basics For Managers - Compress Pages 1 50 Flip PDF Download - FlipHTML5Document258 pagesHBR Guide To Data Analytics Basics For Managers - Compress Pages 1 50 Flip PDF Download - FlipHTML5Vishav SharmaNo ratings yet

- THB360Document581 pagesTHB360Favoreel PatrickNo ratings yet

- 12207Document45 pages12207Prabhat VermaNo ratings yet

- Phoenix Contact 1343381 enDocument22 pagesPhoenix Contact 1343381 enIkhtiander IkhtianderNo ratings yet

- Engineering Stem 1Document29 pagesEngineering Stem 1IlannaSharonMandelNo ratings yet

- Fr1500mk3 Series Service Manual BDocument138 pagesFr1500mk3 Series Service Manual Bmod denizenNo ratings yet

- Application of Computer in Manufacturing DPE426: Experiments OnDocument14 pagesApplication of Computer in Manufacturing DPE426: Experiments OnPrabha KaranNo ratings yet

- 0500 012 C7 3 Series Operation Manual v3Document32 pages0500 012 C7 3 Series Operation Manual v3themartensclanNo ratings yet

- Oracle Database 11g Administrator Certified Associate Exam GuideDocument2 pagesOracle Database 11g Administrator Certified Associate Exam GuideEmanuel KrulNo ratings yet

- Diodes Automotive Brochure 2014Document20 pagesDiodes Automotive Brochure 2014abibulaNo ratings yet

- India ElevatorDocument14 pagesIndia ElevatorNaren AnandNo ratings yet

- Chapter 22 Transport LayerDocument25 pagesChapter 22 Transport LayerAnonymous ey6J2bNo ratings yet

- MDC ProfilemdcDocument1 pageMDC ProfilemdcYano BekawantoNo ratings yet

- Mopups P:: Key FeaturesDocument2 pagesMopups P:: Key Featuresfukinagashi0% (1)

- Information Technology (Subject Code 402) : MARKING SCHEME For Sample Paper 2 Term - 1Document2 pagesInformation Technology (Subject Code 402) : MARKING SCHEME For Sample Paper 2 Term - 1Daksh KumarNo ratings yet

- Dukpt ExplainedDocument42 pagesDukpt Explainedsrx dev100% (1)

- Appendix-C: Patent Search and Analysis Report (PSAR)Document15 pagesAppendix-C: Patent Search and Analysis Report (PSAR)Hemal JoshiNo ratings yet

- JSEC 12.a-R LGDDocument208 pagesJSEC 12.a-R LGDTucsi2000No ratings yet

- Tech - Man ENG 541D18 2007.12Document25 pagesTech - Man ENG 541D18 2007.12korculaNo ratings yet

- BMW F20 Video Interface User ManualDocument20 pagesBMW F20 Video Interface User ManualPham Cao ThanhNo ratings yet

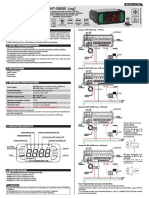

- MT-512 Log: 1. DescriptionDocument5 pagesMT-512 Log: 1. DescriptionJhonny Alberto BermudezNo ratings yet

- Gmail Recovery After Being Hacked PDFDocument2 pagesGmail Recovery After Being Hacked PDFMd Kamruzzaman KhanNo ratings yet

- VLX 70002017Document138 pagesVLX 70002017PABLO JOSE BRICEÑONo ratings yet

- Oled (Organic Light Emitting Diode) : E.Bhanu PrakashDocument17 pagesOled (Organic Light Emitting Diode) : E.Bhanu Prakashbhanu prakashNo ratings yet