Professional Documents

Culture Documents

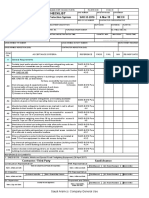

Checklist For Fire Protection Systems and Fire Safety Measures

Checklist For Fire Protection Systems and Fire Safety Measures

Uploaded by

Min Htut WinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Checklist For Fire Protection Systems and Fire Safety Measures

Checklist For Fire Protection Systems and Fire Safety Measures

Uploaded by

Min Htut WinCopyright:

Available Formats

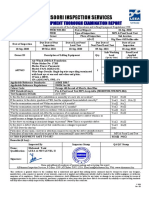

Fire Certificate

Inspection Checklist

1 SCDF/CED/FC/GC 1 July 2014

CED FC ACS

AIR-CONDITIONING SYSTEM

Name of Building:

* Status of Inspection

A AHU Yes N.A.

i Smoke cut-off system provided within return air stream of AHU

ii Activation of smoke-cut-off system shuts down AHU

iii Manual reset provision for AHU

iv No storage in AHU room

v Smoke detector provided and tested in order

* Status of Inspection

B FIRE DAMPERS Yes N.A.

i Fire Dampers are properly installed

ii Motorised Fire dampers operate upon activation of auto fire alarm detectors

iii No obstruction to dampers louver (blades) movement

iv Access door for inspection of Fire dampers provided

v Fire dampers of approved rating and with PSB label

Date of inspection and testing of system:

2 SCDF/CED/FC/GC 1 July 2014

CED FC ASCS

ATRIUM SMOKE CONTROL SYSTEM

Name of Building:

* Status of Inspection

S/No. DETAILS:- Yes N.A.

i Smoke detectors provided at the perimeter of the Atrium

ii Separate manual reset switch provided

iii Functions under Secondary supply provided

iv Auto supply mode activated by fire alarm system (where applicable) under

Secondary power supply

v Manual activation provision installed

vi System extraction air fan operate upon activation of fire alarm

vii Smoke curtains operate upon activation of fire alarm

viii Ventilation louvers operation by fire alarm and under secondary power

supply are in order

ix All fire scenarios where is / are designed under the engineered smoke

control system has / have been tested

x Air-condition cut-off upon activation of fire alarm

Date of inspection and testing of system:

3 SCDF/CED/FC/GC 1 July 2014

CED FC AFAS

AUTOMATIC FIRE ALARM SYSTEM

Name of Building:

Name of Monitoring Company: Building Code No:

* Status of Inspection

S/No. HEAT / SMOKE DETECTOR TEST Yes N.A.

i Sufficient coverage

ii Detector points not painted

iii Detector points unobstructed

iv System connected to monitoring company / 995

v Alarm signal transmission received by monitoring company

vi Zone tested is indicated correctly on main-alarm panel

vii Audible fault alarm & fault indication light provide at main-alarm panel

viii Zoning diagram provided next to the main-alarm panel

ix Zone tested is indicated correctly on sub-alarm panel

x Audible fault alarm & fault indication light provide at sub-alarm panel

xi Zoning diagram / mimic panel provided next to the sub-alarm panel

xii Alarm bells in operational condition

xiii Alarm general sounding throughout the building

Date of inspection and testing of system:

4 SCDF/CED/FC/GC 1 July 2014

CED FC AFSS

AUTOMATIC FIRE SUPPRESSION SYSTEM FOR COOKING HOOD

Name of Building:

* Status of Inspection

A GENERAL Yes N.A.

i System connected to Main / Sub Fire Alarm Panel

ii Automatic cut-off device for gas fuel supply provided

iii Emergency manual release for extinguishing agent provided

iv Sign “IN CASE OF FIRE – PULL TO RELEASE”CALL 995 is provided

* Status of Inspection

B CYLINDER FOR EXTINGUISHING AGENT Yes N.A.

i PSB Approved label provided

ii Rigidly mounted

iii Service by fire safety work contractor (competent personnel)

iv Date of service

* Status of Inspection

C NOZZLE & PIPE WORKS Yes N.A.

i Rigidly mounted

ii Free of grease (internal & external)

iii Free of obstruction

iv Double layer provided

* Status of Inspection

D HEAT ACTIVATING DEVICE Yes N.A.

i Fusible link enclosed in piping

ii Free of obstruction

iii Free of grease

iv Properly installed

v Ensure in functioning condition (conduct simulated test)

Date of inspection and testing of system:

5 SCDF/CED/FC/GC 1 July 2014

CED FC CPSES

CAR PARK SMOKE EXTRACT SYSTEM

Name of Building:

* Status of Inspection

S/No. DETAILS:- Yes N.A.

i Intake / discharge location with at least 5m separation

ii Exhaust discharge directed to external

iii Connected to secondary power supply & fire alarm system

iv Failure of the Exhaust Fan will cut off the corresponding supply fan

Date of inspection and testing of system:

6 SCDF/CED/FC/GC 1 July 2014

CED FC DRS

DRY RISER SYSTEM

Name of Building:

DRY RISER: size 2 way (100mm) No. /4 way (150mm) No.

* Status of Inspection

A BREECHING INLET Yes N.A.

i Inlet housed in glass fronted protective enclosure

ii Properly installed / secured

iii Clear of Obstruction

iv About 0.76m above finished floor level

v Labelled “DRY RISER INLET” and differentiated

vi Inlet painted in yellow colour

* Status of Inspection

B RISER Yes N.A.

i Not passing through unprotected area / Fire rated

ii Air release valve provided

iii Earthling provided

* Status of Inspection

C LANDING VALVE Yes N.A.

i 0.76m to 1m above finished floor level

ii Condition of hand wheel satisfactory

iii Blank Cap provided

iv Strapped and padlocked in closed position

v Labelled / Numbered

vi Clear of Obstruction

vii Landing valve painted in yellow colour

* Status of Inspection

D TESTING OF HYDROSTATIC PRESSURE Yes N.A.

i Pressure constant at 200 PSI for 2 hrs

ii Air release valve functioning

Date of inspection and testing of system:

7 SCDF/CED/FC/GC 1 July 2014

CED FC ESCS

ENGINEERED SMOKE CONTROL SYSTEM

Name of Building:

* Status of Inspection

S/No. DETAILS:- Yes N.A.

i Separate manual reset switch provided

ii Functions under secondary supply provided

iii Auto supply mode activated by fire alarm system under normal power

supply

iv Auto supply mode activated by fire alarm system under secondary power

supply

v Manual activation provision installed

vi Air exhaust fan operate upon operation of fire alarm

vii Air condition system cut-off upon activation of system

viii Smoke curtain operate upon activation of system

Date of inspection and testing of system:

8 SCDF/CED/FC/GC 1 July 2014

CED FC HRS

HOSE REEL SYSTEM (WITH PUMP)

Name of Building:

* Status of Inspection

A Hose Yes N.A.

i Non-kinking reinforced rubber

ii Length of hose (30m)

iii Nozzle condition satisfactory

iv Locking device provided in-order

v Condition of stop cock satisfactory

vi Clear of obstruction

vii Labelling provided for cabinet

viii Labelling provided for instruction signage

ix No locking device provided

* Status of Inspection

B Testing Yes N.A.

i No Leakage detected

ii 6m throw achievable or flow rate of 0.4 litre / sec

* Status of Inspection

C Pump Yes N.A.

i Pump can be manually tested

ii Auto changeover from normal to secondary power supply

iii Auto changeover from duty to standby pump operation in order

iv Differentiated

Date of inspection and testing of system:

9 SCDF/CED/FC/GC 1 July 2014

CED FC LIFT

LIFT

Name of Building:

(No. of Passenger Lift ______________ Cargo Lift ______________ Fire Lift ______________)

* Status of Inspection

A Passenger and Fire Lift Yes N.A.

i Lift homing under fire alarm activation in order (Clause 13.1.3)

ii Lift homing under secondary power supply (Clause 13.1.2)

iii Warning notice for fire situation provided (Clause 13.1.8)

iv PSB (SISIR) approved EBOPS provided (Clause 12.3)

v EBOPS supply to lift car bell, lighting and fan in order

vi Lift differentiated with numbers

vii Storey Numbering for lift lobbies provided

viii Lifts home at designated floor

* Status of Inspection

B Fire Lift (Size & Capacity __________________________) Yes N.A.

i Lift travel from ground to top level within 1 minute

ii Fire lift operated under fire switch in order

iii Labelled “FIRE LIFT”

iv Fire switch properly enclosed in labelled glass fronted cover

v No combustible furnishing

Date of inspection and testing of system:

10 SCDF/CED/FC/GC 1 July 2014

CED FC OSF

OTHER SYSTEMS AND FIXTURES

1) HOSE REEL (without pump)

* Status of Inspection

A Hose Yes N.A.

i Non-kinking reinforced rubber

ii Length of hose (30m)

iii Nozzle condition satisfactory

iv No locking device provided

v Condition of stop cock satisfactory

vi Clear of obstruction

vii Labelling provided for cabinet

iv Labelling provided for instruction signage

* Status of Inspection

B Testing Yes N.A.

i No Leakage detected

ii 6m throw achievable/0.4 l/sec

Date of inspection and testing:

2) PORTABLE FIRE EXTINGUISHER

* Status of Inspection

S/No Details: Yes N.A.

i Properly hung on bracket

ii Clear of obstruction

iii Service by licensed contractor

iv PSB label

v Date of service

Date of inspection:

11 SCDF/CED/FC/GC 1 July 2014

CED FC OSF

3) MANUAL ALARM SYSTEM (CALL POINT)

* Status of Inspection

S/No Details: Yes N.A.

i The colour for all fire alarm panels, bell ,conduit

and trunking are painted red

ii Clear of obstruction

iii Fire alarm zoning diagrams provided near fire

alarm panel

iv General sounding throughout the building

v Located about 1.4m from floor level

vi Alarm bell in operational condition

vii The fire alarm sounding distinguishable from any other alarm

system

viii Audible fault alarm & fault indication light

provided at sub / main panel

ix Zone tested is indicated correctly on the fire

alarm main / sub panel

x “IN CASE OF FIRE CALL 995” signage provided

Date of inspection and testing:

4) EXIT SIGN AND EMERGENCY LIGHTING

* Status of Inspection

A Exit Sign / Exit Directional Sign Yes N.A.

i Exit Sign adequately provided along :-

a) Staircase

b) Escape Routes

c) Public Area

ii Exit Sign Visible

iii Directional Exit Sign provided where necessary

iv Exit Sign operation in order

v Exit Sign connected to secondary power supply

tested in order

vi Exit sign complied with CP 19 colour code

(green and white combination)

12 SCDF/CED/FC/GC 1 July 2014

CED FC OSF

* Status of Inspection

B Emergency Lighting Yes N.A.

i Emergency Lighting provide along :-

a) Staircase

b) Escape Route

c) Public Area

d) Essential plant rooms

ii Automatic operation tested in order

iii Emergency lighting provided is sufficient

iv Identification ( Cl 7.8 CP 19 )

v Emergency Lighting connected to secondary

power supply

Date of inspection and testing:

5) fire door and exit door

* Status of Inspection

A Fire Door Yes N.A.

i Fire door installed at follow location are in order

a) Staircases

b) Escape Routes

c) Public Area

ii Fire doors provided with PSB label

iii Swing of door in direction of escape

iv No stopper detected

v Self-closer provided

vi Doors are closed fitting

vii Clear of obstruction

viii Panel above the door same rating as the wall

ix No locking device for doors passing to the fire fighting

staircase

x Viewing glass panel at fire rated door does not exceed 650

cm2

13 SCDF/CED/FC/GC 1 July 2014

CED FC OSF

* Status of inspection

B Exit Door Yes N.A.

i Doors unlocked during operating hour

ii Clear of obstruction

Date of inspection:

6) DUCT RISER

* Status of inspection

S/No Details: Yes N.A.

i Fire stopped accordingly

ii Protected by fire-resisting enclosure

iii No Storage

Date of inspection:

7) STAIRCASE (ENCLOSED OPEN )

* Status of Inspection

S/No Details: Yes N.A.

i Standard Stairway Numbering System provided

ii Clear of obstruction

iii No combustible furnishing

vi Fully compartmented

v Service pipe (gas, oil and ventilation) other that water pipe not

passing through protected

staircase, lobbies area

Date of inspection:

8) EXTERNAL FIRE FIGHTING ACCESS OPENING

* Status of Inspection

S/No Details: Yes N.A.

i Clear of obstruction internal and external

ii (Red or Orange) External marking provided

iii Signage “Fire Fighting Access – Do Not Obstruct” provided

vi Readily open from inside and outside

Date of inspection:

14 SCDF/CED/FC/GC 1 July 2014

CED FC OSF

9) THEATRE

* Status of Inspection

A AUDITORIUM Yes N.A.

i Approved occupant load

ii Seats firmly fixed

iii Exit doors provided with panic bolts

iv Hose reel tested in order

v Exit signs in good working order

vi Exit signs provide with secondary power supply

Complying with CP 19

vii Beacon light operation in order

v Emergency lighting auto changeover tested in

Order

* Status of Inspection

B STAGE Yes N.A.

i Provided with self-closing fire rated door

ii Fire extinguisher provided

iii No storage

Iv Smoke curtain provided

* Status of Inspection

C PROJECTION ROOM Yes N.A.

I Provided with self-closing fire rated door

Ii Fire extinguisher provided

Iii Emergency lighting tested in order

Iv Emergency message slide / public address system tested in

order

V Shutter operated smoothly / fire rated glass

Installed

Vi No smoking sign displayed

Date of inspection and testing:

15 SCDF/CED/FC/GC 1 July 2014

CED FC PS

PRESSURISATION SYSTEM

Name of Building:

Location of Fans

Fans supply to (staircase / lift lobby / corridor / )

* Status of Inspection

S/No. DETAILS:- Yes N.A.

i Separate manual reset switch provided

ii Fan operation at high speed under fire alarm (if single)

iii Both fans operating under fire alarm (if double)

iv Fan operating upon secondary power supply (Fire mode)

v Fan in operation can only be stopped manually

vi Average air velocity not less than 1 m/s

vii Force require to open any door is not more than 110 N

viii Independent system for smoke lobby / protected corridor connected to

secondary power supply

Date of inspection and testing of system:

16 SCDF/CED/FC/GC 1 July 2014

CED FC PHS

PRIVATE HYDRANT SYSTEM

Name of Building:

HYDRANT No.:

* Status of Inspection

A HYDRANT Yes N.A.

i Rigidly mounted on ground

ii Cover for spindle chamber visible

iii Spindle depth not more than 1 metre

iv Blank cap provided

v Spindle chamber and Hydrant clear of obstruction

vi Hydrant painted with yellow colour band

F TESTING OF STATIC PORESSURE AND FLOW RATE

i

HYDRANT NO. STATIC PRESSURE FLOW RATE IN L/SEC REMARKS

Date of inspection and testing of system:

17 SCDF/CED/FC/GC 1 July 2014

CED FC SGS

STANDBY GENERATOR SET

Name of Building:

Location of Standby generator set(s):

* Status of Inspection

A GENERATOR OPERATION Yes N.A.

i Automatically changeover within 15 sec.

ii Smoke exhaust in-order

iii No storage

B GENERATOR SET TESTED ON FULL LOAD - SUPPLY TO THE * Status of Inspection

FOLLOWING SYSTEMS SIMULTANEOUSLY Yes N.A.

i Emergency lighting - Common corridor / staircases

- Fire pump rooms

- Generator / switch rooms

- Illuminated exit / directional exit signs

ii Fire pump system - Wet riser main pump

- Wet riser transfer pump

- Sprinkler main pump

- Sprinkler transfer pump

- Hose reel pump

iii Lift system - Homing of lifts

- Operation of fire lift

iv Mechanical - Atrium fan

Ventilation system - Engineered smoke control system fan

- Pressurisation fan

- Car park smoke extract system fan

- Fire pump room fan

- Smoke stop lobby

v Public addressing system

Date of inspection and testing of system:

18 SCDF/CED/FC/GC 1 July 2014

CED FC VCS

VOICE COMMUNICATION SYSTEM

Name of Building:

* Status of Inspection

A One-way Communication Yes N.A.

i Operational test in order

ii Standby battery provided

iii Secondary power supply provided

iv Over riding switch provided at Fire Command Center (FCC)

* Status of Inspection

B Two-way communication Yes N.A.

i Operation tested in order

ii Standby battery provided

iii Secondary power supply provided

iv Provided at Strategic Location

v To label & colour in red

vi 1.5m above the floor

vii Operational test is indicated correctly at panel in FCC

Date of inspection and testing of system:

19 SCDF/CED/FC/GC 1 July 2014

CED FC WRS

WET RISER SYSTEM

Name of Building:

WET RISER: Size: Nos.

* Status of Inspection

A BREECHING INLET Yes N.A.

i Inlet housed in glass fronted protective enclosure

ii Properly installed / secured

iii Clear of Obstruction

iv About 0.76m above finished floor level

v Labelled “WET RISER INLET” and differentiated

* Status of Inspection

B RISER Yes N.A.

i Earthing provided

ii Air release valve provided

iii Not passing through unprotected area / fire rated

* Status of Inspection

C LANDING VALVES Yes N.A.

i 0.76m to 1m above finished floor level

ii Condition of hand wheel satisfactory

iii Blank Cap provided

iv Strapped and padlocked in closed position

v Labelled / Numbered

vi Clear of Obstruction

* Status of Inspection

D WATER TANK Yes N.A.

i Overflow pipe provided

ii Inflow pipe provided

iii Compartmented

* Status of Inspection

E TRANSFER PUMP Yes N.A.

i Pump can be manually tested

ii Auto changeover from normal to secondary power supply in order

iii Auto changeover from duty to standby pump operation in order

* Status of Inspection

F PUMP OPERATION CONTROL PANEL Yes N.A.

i Pump numbering tallied with actual control panel indicator

20 SCDF/CED/FC/GC 1 July 2014

ii Clear from drain off test facilities

iii Power to pump indicator light “on”

iv Sheltered / weather proof

FSSD FC (02 - 02)

* Status of Inspection

G PUMP Yes N.A.

i Auto changeover from normal to secondary power supply in order

ii Auto changeover from duty to standby pump operation in order

iii All valves to pumps kept strapped and padlocked

iv Top most landing valve fully opened (under pump gravity feed) and flow

rate in order

v Discharge for the test drain pipe provided

* Status of Inspection

H TESTING OF STATIC PRESSURE AND FLOW RATE Yes N.A.

i Running pressure in between 3.5 bar to 5.5 bar

ii Static pressure less than 8 bar

* Status of Inspection

I PUMP ROOM VENTILATION Yes N.A.

i Mechanical ventilation fan provided are in working order

FLOW RATE TEST ON WET RISER SYSTEM

STACK STOREY STATIC FLOW RATE IN PUMP(P)/ REMARKS

NO TESTED PRESSURE L/SEC GRAVITY (G) FEED

Date of inspection and testing of system:

21 SCDF/CED/FC/GC 1 July 2014

CED FC SPRS

AUTOMATIC SPRINKLER SYSTEM

Name of Building:

Storey serve:

* Status of Inspection

A LAYOUT Yes N.A.

i Sufficient Coverage

ii Sprinkler Head Obstructed

iii Cut-off sprinkler head provided (toilets, staircase landings, etc)

iv Protective guard provided for sprinkler head (if applicable)

* Status of Inspection

B BREECHING INLET Yes N.A.

i Clear of obstruction

ii Inlet housed in protective enclosure

iii Labelled “SPRINKLER BREECHING INLET”

iv 2/4 way inlet provided

v About 0.76m above surrounding road or pavement level

vi Rigidity supported

vii Inlet connected to main sprinkler Tank/Break Tank

* Status of Inspection

C SPRINKLER TANK Yes N.A.

i Access panel and ladder provided

ii Overflow pipe provided

iii Compartmented

* Status of Inspection

D TRANSFER PUMP Yes N.A.

i Pumps can be manually tested

ii Inflow pipe provided

iii Compartmented

* Status of Inspection

E TRANSFER PUMP Yes N.A.

i Pump can be manually tested

i Auto changeover from normal to emergency power supply in order

iii Auto changeover from duty to standby pump operation in order

22 SCDF/CED/FC/GC 1 July 2014

* Status of Inspection

F PUMPS Yes N.A.

i Auto change over from duty to standby pumps operation in order

ii Auto change over from normal to emergency power supply in order

iii Differentiated

iv Discharge for the test drain pipe provided

v Pressure gauge provided

vi Cut in pressure tested in orders

* Status of Inspection

G SPRINKLER CONTROL VALVE Yes N.A.

i Gong provided in order

ii Labelled to indicate storey served

iii Strapped and padlocked in open position

iv Approximately 1m high

v Clear of obstruction

vi Location plate with label provided at the access door (if enclosed)

* Status of Inspection

H SPRINKLER PIPE Yes N.A.

i Not passing through unprotected area/fire rated

ii Not encased by concrete

* Status of Inspection

I PUMP INDICATOR PANEL Yes N.A.

i Pump numbering tallied with actual operation

ii Selector switch in Auto position

iii Power to pump indicator light “ON”

* Status of Inspection

J DRAIN TEST Yes N.A.

i Drain off at control valve/pump room

ii Cut-in pressure of pumps not less than 80% of running pressure

(K) DRAIN OFF TEST RESULT

Control Valve Installed Duty Pump Standby Pump REMARKS

Location Coverage Pressure Cut-in Pre Running Pre Cut-in Pre Running Pre

Date of inspection and testing of system:

23 SCDF/CED/FC/GC 1 July 2014

CED FC PFP

PASSIVE FIRE PROTECTION TO STRUCTURAL STEEL COLUMNS AND BEAMS

Name of Building:

* Status of Inspection

A Intumescent Paint provided with signage Yes N.A.

i Name of Supplier

ii Fire resistance rating of the intumescent paint

iii Date of painting

iv Expected date of re-painting

v Caution notice: “Caution: No other paint/coating shall be applied to the

Surfaces of the structural steel members protected by the intumescent paint

system”

vi No storage of highly flammable/combustible materials within the vicinity of

Structural steel members protected by the intumescent paint

* Status of Inspection

B Dry Board Yes N.A.

i No alterations and additions work to the dry board

(unless approval is obtained)

ii Check for any damages or tempering to the dry board

* Status of Inspection

C Spray-On Material Yes N.A.

i No alterations and additions work to the spray-on material

(unless approval is obtained)

ii Check for any damages or tempering to the spray-on material

Date of inspection and testing of system: ______________________________________

24 SCDF/CED/FC/GC 1 July 2014

You might also like

- Checklist For Testing Commissioning of Sprinkler SystemDocument2 pagesChecklist For Testing Commissioning of Sprinkler SystemMuhammad Fathullah bin Suhaili100% (1)

- Frick RXFCompressor PartsDocument60 pagesFrick RXFCompressor PartsDario Manriquelme100% (3)

- Checklist For Testing & Commissioning of Sprinkler SystemDocument2 pagesChecklist For Testing & Commissioning of Sprinkler Systembeho2000100% (6)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- FSSD Fire ChecklistDocument25 pagesFSSD Fire ChecklistLim BrandonNo ratings yet

- FSSD FCCHKDocument21 pagesFSSD FCCHKLawrence LawNo ratings yet

- Compliance ReportDocument2 pagesCompliance Reportmohammad AshrafNo ratings yet

- Compliance ReportDocument2 pagesCompliance Reportmohammad AshrafNo ratings yet

- Compliance ReportDocument2 pagesCompliance Reportmohammad AshrafNo ratings yet

- Method of Statement MetsDocument5 pagesMethod of Statement MetsEmmanuel ToretaNo ratings yet

- Fire DetectionDocument63 pagesFire DetectionKrisannNo ratings yet

- 2.20 QK-SRCL-10-00001-Site Readiness Check List For HVACs Duct InstallationDocument1 page2.20 QK-SRCL-10-00001-Site Readiness Check List For HVACs Duct InstallationMoh'd SameerNo ratings yet

- Maintenance (21.09.2022)Document2 pagesMaintenance (21.09.2022)Imelisya JaulinNo ratings yet

- FF Water Sprinkler Test ProcedureDocument2 pagesFF Water Sprinkler Test ProcedureSalim Bakhsh100% (1)

- Victoria Health Centre - Panic Alarm - TestsheetsDocument6 pagesVictoria Health Centre - Panic Alarm - TestsheetsYlenia BonelloNo ratings yet

- IKDC-BINKEI-FP-SAT-RFA-069 FA, Gas Suppression, Pre-ActionDocument33 pagesIKDC-BINKEI-FP-SAT-RFA-069 FA, Gas Suppression, Pre-ActionjendrikoNo ratings yet

- Fat Report For Fedegari SterilisersDocument4 pagesFat Report For Fedegari Sterilisersrahul_inj84100% (1)

- SEI Report CoimbatoreDocument20 pagesSEI Report Coimbatoresrbh1977No ratings yet

- J1525-HW1-010 SAT Procedure - Rev ADocument16 pagesJ1525-HW1-010 SAT Procedure - Rev Aluis HernandezNo ratings yet

- J1525-HW6-010 SAT Procedure - Rev ADocument17 pagesJ1525-HW6-010 SAT Procedure - Rev Aluis HernandezNo ratings yet

- Permit To WorkDocument1 pagePermit To WorkIshtiaq AhmadNo ratings yet

- Maintenance (22.09.2022)Document2 pagesMaintenance (22.09.2022)Imelisya JaulinNo ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- J1525-NT8-010 SAT Procedure - Rev ADocument15 pagesJ1525-NT8-010 SAT Procedure - Rev Aluis HernandezNo ratings yet

- Sei Ir Ge ChennaiDocument45 pagesSei Ir Ge Chennaisrbh1977No ratings yet

- Sop-99 Camera Survilleance System Installlation & MonitoringDocument3 pagesSop-99 Camera Survilleance System Installlation & MonitoringOSAMANo ratings yet

- Enclosure Ex. Protection Type Gas Group Temp. Class IP Rating Certifying Authority Certificate NoDocument2 pagesEnclosure Ex. Protection Type Gas Group Temp. Class IP Rating Certifying Authority Certificate Nowinandra 97No ratings yet

- Cold Work PermitDocument2 pagesCold Work Permitmassmoudi58No ratings yet

- SVN-AVR-ERI-0008 Unsafe StorageDocument11 pagesSVN-AVR-ERI-0008 Unsafe Storagemohamedkhafagy099No ratings yet

- J1525-HW2-010 SAT Procedure - Rev ADocument16 pagesJ1525-HW2-010 SAT Procedure - Rev Aluis HernandezNo ratings yet

- Project: Project Name Site No.:: Check Sheet For Testing and Commissioning of Fire Alarm System Sheet NoDocument1 pageProject: Project Name Site No.:: Check Sheet For Testing and Commissioning of Fire Alarm System Sheet NovoNo ratings yet

- IQ Procedure & Report ALP AutoclaveDocument9 pagesIQ Procedure & Report ALP AutoclavePhong LeNo ratings yet

- J1525-HW3-010 SAT Procedure - Rev ADocument16 pagesJ1525-HW3-010 SAT Procedure - Rev Aluis HernandezNo ratings yet

- Pre-Commissioning Format For Reactor: I. General DetailsDocument27 pagesPre-Commissioning Format For Reactor: I. General Detailsmayur dhandeNo ratings yet

- Brand-Ventilation - Folder - Webb bs12101-2 PDFDocument5 pagesBrand-Ventilation - Folder - Webb bs12101-2 PDFdmitar stevanovicNo ratings yet

- Sn. Kim Ear 196 Chain Sling WLL 7.5 T Grade 80: Report of A Thorough Examination of Lifting EquipmentDocument1 pageSn. Kim Ear 196 Chain Sling WLL 7.5 T Grade 80: Report of A Thorough Examination of Lifting EquipmentKHALILCHABBOUHNo ratings yet

- FIR Magnesium Anode Test QCDocument1 pageFIR Magnesium Anode Test QCFafa seyzaNo ratings yet

- Foam DelugeDocument35 pagesFoam DelugeKrisannNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- OHS-PR-09-13-F02 (A) FIRE RISK ASSESSMENT SiteDocument9 pagesOHS-PR-09-13-F02 (A) FIRE RISK ASSESSMENT SiteShariq AhmedNo ratings yet

- Job Safety Analysis Sheet: FacilityDocument1 pageJob Safety Analysis Sheet: FacilityHelza RahmanniaNo ratings yet

- Model 4WG 100 - 800 HP BoilersDocument4 pagesModel 4WG 100 - 800 HP BoilerssebaversaNo ratings yet

- 3TI9iiIH64o06kQH5rp94Q0j8rD17x9Ln1uvURrFOplRfdyGJcz, GP 7UNWzn3owDocument1 page3TI9iiIH64o06kQH5rp94Q0j8rD17x9Ln1uvURrFOplRfdyGJcz, GP 7UNWzn3owmk090571No ratings yet

- Victoria Health Centre - CCTV - Test SheetsDocument5 pagesVictoria Health Centre - CCTV - Test SheetsYlenia BonelloNo ratings yet

- Saudi Aramco Test Report: SATR-B-6103 10-Jun-19 Inst Fire Alarm System - Smoke / Heat Detector - Pre-Commissioning TestDocument5 pagesSaudi Aramco Test Report: SATR-B-6103 10-Jun-19 Inst Fire Alarm System - Smoke / Heat Detector - Pre-Commissioning TestSino hydroNo ratings yet

- For Internal AuditDocument2 pagesFor Internal AuditMark LagahitNo ratings yet

- Certificate of Completion & Conformity: Name)Document3 pagesCertificate of Completion & Conformity: Name)JesusNo ratings yet

- Checklist Fire Hydrant InstallationDocument1 pageChecklist Fire Hydrant InstallationAmie GTunedNo ratings yet

- PWL20AP0001Document4 pagesPWL20AP0001ankitNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saic B 2016Document2 pagesSaic B 2016usmanNo ratings yet

- Magnesium Anode Test Quality Control and Inspection Report FormDocument1 pageMagnesium Anode Test Quality Control and Inspection Report Formsindalisindi0% (1)

- Saudi Aramco Test Report: SATR-B-6103 30-Oct-17 Inst Fire Alarm System - Smoke / Heat Detector - Pre-Commissioning TestDocument9 pagesSaudi Aramco Test Report: SATR-B-6103 30-Oct-17 Inst Fire Alarm System - Smoke / Heat Detector - Pre-Commissioning TestJagdishNo ratings yet

- Checklist For Access Control System InstallationDocument1 pageChecklist For Access Control System InstallationRommel Espinosa ParasNo ratings yet

- Method Statement For ExcavationDocument13 pagesMethod Statement For Excavationymkawai224No ratings yet

- Testing and Commissioning: Pneumatic TestDocument12 pagesTesting and Commissioning: Pneumatic TestSalim BakhshNo ratings yet

- Commissioning Checklist VRVDocument6 pagesCommissioning Checklist VRVFawaz KtNo ratings yet

- S-101004-03FIG Critical Jobs - ALL ShipsDocument2 pagesS-101004-03FIG Critical Jobs - ALL ShipsThe WreckerNo ratings yet

- Fsi Reminder App RequiredDocument8 pagesFsi Reminder App Requiredare.em1.dc202002No ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument9 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Saudi Aramco Test Report: Vaccum Box Leak Test Report 15-Dec-09 MECH-NDEDocument2 pagesSaudi Aramco Test Report: Vaccum Box Leak Test Report 15-Dec-09 MECH-NDEWaleed MedhatNo ratings yet

- Commercial Pump Motor InfoDocument10 pagesCommercial Pump Motor Infojolonoff5094100% (1)

- FN 4b Oral QsDocument8 pagesFN 4b Oral QsAnoop VijayakumarNo ratings yet

- Fiche Technique Compacteur DYNAPAC CA510D - 10000165VKC009480Document2 pagesFiche Technique Compacteur DYNAPAC CA510D - 10000165VKC009480Manuel LoureiroNo ratings yet

- SV212 & SV216 Vibratory RollersDocument4 pagesSV212 & SV216 Vibratory Rollershaiccdk6No ratings yet

- Plant RO 26 TPHDocument13 pagesPlant RO 26 TPHveroniu ricaNo ratings yet

- Liebherr Hs 8300 HD Data Sheet Englisch 11244650 Email 13877-0Document16 pagesLiebherr Hs 8300 HD Data Sheet Englisch 11244650 Email 13877-0Angel ArocaNo ratings yet

- Valvulas de Control Schroedahl Broschure Regelarmaturen Uk 012Document20 pagesValvulas de Control Schroedahl Broschure Regelarmaturen Uk 012cristobal_tl2277No ratings yet

- Tabla U1Document20 pagesTabla U1Eduardo Castillo BarbaNo ratings yet

- Topic 4 - TurbomachineryDocument77 pagesTopic 4 - TurbomachinerySati Ullah MaikashNo ratings yet

- Centrifugal Pumps: Bombas CentrifugasDocument11 pagesCentrifugal Pumps: Bombas CentrifugasMariana Correa TorresNo ratings yet

- Difference Between Reciprocating Pump and Centrifugal Pump With PDFDocument4 pagesDifference Between Reciprocating Pump and Centrifugal Pump With PDFSantiago TutilloNo ratings yet

- JD JONES-catalogue PDFDocument90 pagesJD JONES-catalogue PDFNaved HavaNo ratings yet

- Section 02760 Performance Testing of Pressure Pipelines Part 1 - GeneralDocument5 pagesSection 02760 Performance Testing of Pressure Pipelines Part 1 - Generaljungzki jungzkiNo ratings yet

- Training - Flowserve Apm Pump CW Pump Part3Document4 pagesTraining - Flowserve Apm Pump CW Pump Part3hasan099No ratings yet

- 1.1 Traced Lines: Fig 1.1 - Insulating Tracer and Product LinesDocument14 pages1.1 Traced Lines: Fig 1.1 - Insulating Tracer and Product Linesmurugn08No ratings yet

- Pu Grouting SpecsDocument10 pagesPu Grouting Specsrowaters0% (1)

- Commercial Heating Brochure 2022Document52 pagesCommercial Heating Brochure 2022reeb khanNo ratings yet

- Overhaul Manual - IO-360-N1A Engine 02-2016Document52 pagesOverhaul Manual - IO-360-N1A Engine 02-2016Gabriel vieiraNo ratings yet

- Basic Civil and Mechanical Engineering Unit III Pumps and TurbinesDocument10 pagesBasic Civil and Mechanical Engineering Unit III Pumps and TurbinesA.R. Pradeep Kumar100% (1)

- TG Lube Oil Flushing ProcedureDocument16 pagesTG Lube Oil Flushing ProcedureAnudeep ChittluriNo ratings yet

- Manual Peças Wa320-5Document543 pagesManual Peças Wa320-5Lucas Silva Ramires Torres100% (1)

- Daikin McQuay. Centrifugal Chiller Dual Compressor WDC, TDC, HDC 087. Replacement Parts List No Revision K 11 - 2016Document126 pagesDaikin McQuay. Centrifugal Chiller Dual Compressor WDC, TDC, HDC 087. Replacement Parts List No Revision K 11 - 2016SBD AtkinsNo ratings yet

- A Simple and Efficient Solution: The New Magna1Document8 pagesA Simple and Efficient Solution: The New Magna1Óh facuNo ratings yet

- 1.577 81 1.655 66 77 KW TDI CR Engine (CAYA CAYB CAYC CLNA CWXB CWXC)Document577 pages1.577 81 1.655 66 77 KW TDI CR Engine (CAYA CAYB CAYC CLNA CWXB CWXC)Kunji ManiNo ratings yet

- 8923a053 DespieceDocument26 pages8923a053 DespieceOFFICE DANACNo ratings yet

- Prssurised Flushing SystemDocument19 pagesPrssurised Flushing SystemjeiohkotaNo ratings yet

- Technical Instructions El CM Eplus ENGDocument48 pagesTechnical Instructions El CM Eplus ENGradepajic8No ratings yet

- Installation Checklist For Fire PumpsDocument1 pageInstallation Checklist For Fire PumpsAmie GTunedNo ratings yet

- Fluid Mechanics and Hydraulic MachineryDocument8 pagesFluid Mechanics and Hydraulic MachineryDhanush RagavNo ratings yet