Professional Documents

Culture Documents

Certificate 2019.08.13

Certificate 2019.08.13

Uploaded by

M. Andri Ludfi Fanani0 ratings0% found this document useful (0 votes)

14 views10 pagescertificate 2019

Original Title

certificate 2019.08.13

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentcertificate 2019

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

14 views10 pagesCertificate 2019.08.13

Certificate 2019.08.13

Uploaded by

M. Andri Ludfi Fananicertificate 2019

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 10

abdhez w

= ~ eyeuioy

ss0n0n0 ECU 1

un oY Poo -xareane

su sua. 6

, ttoena m ssansva wo100 8 |

se10890 oi , shore oLssauisvs¥o109 L

seveoanusy cor | mua | 9

>rews vnouvowna [}—~—

| senoanusy © | mom | y g

‘se-reos a nusy we | wom Xu v

Lon enone

sore05 anusy eer | sonar " €

stats xx 0 om z

= wore oI sso T

| GOHLAW S31 NOWLWOISIO3dS| LINN WAL! 1S. ‘ON

F380} peyyenbun | soy Pewrend | .Naw39anr| OF ALLLNWND 000-00-00-20zaouL ON Lud

08 “20 "610z, BLVO NOWO3SNI | airoo7wausnare-wwesL neoMvie OaNaA 39S FeATG | Led | 48S Za4F2q) ofug

oust asiva | suvaany

S06106}A88491 | waEWAN LIGTO

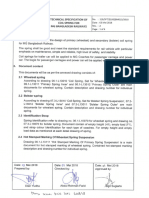

Flame Retardant Test Report

CREDIT NUMBER : LCPSBY1901995

AND DATE : DATED 190701

Report No. : SCT-B20151222-013N1

Page 1/3

Applicant Information

Company name | Jiangsu Tedrail industrial Co.,Ltd

pee =|

. No.6,Gang’ao Road, Zhangjiagang

Company Address Free Trade Zone, Jiangsu,China

Consignor Xiangquan Meng

Consigned Date 2015-12-22

Remark | /

— sh a :

Sample Information

{ |

Sample Name Driver Seat

[ Sample Type /

i. |

Sample Quantity 6 Sets

|

Sample Description Solid Body

Manufacturer /

oy

| Serial No, /

|

|

Flame Retardant Test Report

CREDIT NUMBER + LCPSBY1901995,

AND DATE : DATED 190701

Report No. : SCT-B20151222-013N1 Page 2/3

Test Information

| Test Type Application of testing

Test Period 2015-12-23. — 2016-01-28

Test Item Seat Flame Retardant test

| Test Equipment

DINS5S10-2-2009 preventive fire protect

Test Standard in railway vehicle parts 2: Fire behaviour

and fire side effects of material and parts

~ Classification, requirements and test

methods

Test Conclusion The test results see the third page.

Remark }

Flame Retardant Test Report

CREDIT NUMBER ; LCPSBY1901995

AND DATE + DATED 190701

Report No. : SCT-B20151222-013N1 Page 3/3

| ] |

No, Test Item | Test Data Remark

L | ] |

| Flame height | 99, 99, gs /

p———_} |

Continuous /

| 452, 516, 413

| burning time:

| s

Does the

Flame flame reach No. /

1 | Retardant | the side edge

test TSP (Total 30.9,

smoke 28.7, /

production): 35.4

r

!

r 1. Requirements:

(Flame height: from the seat surface, the maximum flame height does

not exceed 100cm;

@)The flame must be extinguished within 15 minutes of the start of the

test;

G)The flame front can not reach the side edge on any seat in the test;

| When the seat fire class of 2-4, the total amount of smoke can not exceed

60 mm.

2.Conclusion: Conformity

3.Test condition: temperature23°C +2'C, humidity50% ++ 6%,

L___| period >:

Remark

Approver;: = Auditor: Mg Editor: fork has

(lsat

me

Test Report

Sample anette HS «ALAR riverset

Testitems TASCA «= ARSRLBEARAR stati suength est

‘Sampling date Wi 5 : (2019-07-05

Test start time TUB FFSE RYT] 2019-07-08

Endtimeoftet RUSMATERT] «: 2019-07-00

Testrsut URE HILTR IR See nent page

Eat,

el: Ea

SHARAAARTUMABFRAGARG, RESIN, ANA RR OR, ATR RANE.

‘This tet report i issued by the company subject to is general condons of serve. This test report refer only othe

samp) tested unless otherwise stated. This test report cannct be reproduced, except in ul without prior wren of

the company.

Fut

wa: SRE

NO. : ISaT190701296

Date HM: 2019-07-09

Page m8 10f3

repr umes Leeseyigons3s

‘No DATE DATED 190701

ARAGRELARABRAA

BREE

tar

ee: SSE

KARL ‘No. #43: 1SQT190701296

- Date: A =: | 2019-07-09

ISQT Pane HL: 2013

ator Nomen + ersev90195

ANDDATE—: ATED 070

PURE Test report

SBAEWRG: svength test

Testmethod RULAIE : TANT 3264-2011

Es

Bt oe wae BER Requirement GER Result

pas | BEL | Leadake

suor | teoon | feR/uameimR so0xz0nm wa | RaAmRIORL

a ee leanne, ae semen

wowes | GE | 1800N (BRERA ASE, Ma ‘ae, Rciaerticshent

[eee ERLE

RH | FMR | 3000N BASE AL, SABER RED | KARA

met [ms pre Nee ee kee |, ARAB RAE

be ‘2. RRB RAADE, REO.

ai gagray

ac RRR

ST oo

ARARAATREOM ADSM, RERAN, ABAONAN RE, AOA MO RAKE.

‘Tis test report is saved by the company subject tis general condtions of service. This tet report refer any to the

‘sampe() tested uniess otherwise stated. This test report cannot be reproduced, excep nfl without prior wien of

the company.

oa =

at

RRL No #8: ISaT190701296

ey 1saT renee

BEL 4 Ry Totton

‘rnp sr 6 TSC TIF tcp ater cing

Sa

SHARAAREBDRSRTANES, RESAOM, AHEONRRIM, RBITTTARA MELAS,

‘This test report i issuad by the company eubjct to its general condltons of service, This test report refer only othe

amples) ested unos oervco sated, This tes repr cannot be reproduced, except inf, wihou pt Witen of

the company.

Fatigue Test Report

CREDIT NUMBER : LCPSBY1901995

AND DATE : DATED 190701

Report No. : SCT-B20151209-005N2

Applicant Information

Page 1/3

Company name Jiangsu Tedrail industrial Co.,Ltd

Company Address No.6,Gang’ao Road, Zhangjiagang

Free Trade Zone, Jiangsu,China

Consignor Xiangquan Meng 7

; Consigned Date 2015-12-08 |

Remark /

Sample Information

Sample Name Driver Seat

Sample Type /

Sample Quantity - 6 Sets

Sample Description Solid Body

Manufacturer /

i Serial No. - /

The above information is provided and confirmed by client.

Fatigue Test Report

CREDIT NUMBER : LCPSBY1901995

AND DATE : DATED 190701

Report No. : SCT-B20151209-005N2 Page 2/3

Test Information

Test Type | Application of testing

Test Period 2015-12-10 — 2016-01-28

Test Item Seat Fatigue test

Test Equipment

Test Standard | TB/T3264-2011 Railway Passenger seat

Kees

‘ennai

ns_

Test Conclusion The test results see the third page.

|

Remark |

Fatigue Test Report

CREDIT NUMBER : LCPSBY1901995

AND DATE : DATED 190701

Report No. : SCT-B20151209-005N2 Page 3/3

| No. Test Item Test Data Remark

L |

“Armrest horizontal

After the test, | installation, from the font

| armrest edge of 60mm, apply a

Fatigue permanent periodic 600N force, the force

strength of | deformation of | | diestion of45 ° outward and

armrest downward, the frequency of |

Sim: There is run wots

no damage, | + totes

defects and

abnormal sound.

Do I * 10% cycles on the seat

Endurance | Seat | After the test, cycle of the backrest at the

1 test | backrest | there is no maximum angle, elease the

| angle | damage, defects. | adiustment handle, so that the

| adjustment | and abnormal _| b*kreststep by step rebound

life test_/ sound. towematiode

backrest Adjusted tothe

‘maximum angle), the

frequency of 2 eyclesmin

i - The simulation of the

| Height installation ofthe seat o exert

| adjustment No damage. a force of 600N, the force

of the seat down the direction of vertical,

| life test frequency 20 times/min, a total

| of $x103 cycles.

The simulation ofthe

Vibration installation ofthe seat to

reduction | No damage, | PO SON fs, ef

system life * | dow the direction of vera,

fest frequency 20 times/mia, a tot

of 100 million cycles.

Remark /

Approver:

Ancient - Bitor: X. rhe be .

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 28. Effectiveness of Shot Peening 喷丸强度Document1 page28. Effectiveness of Shot Peening 喷丸强度M. Andri Ludfi FananiNo ratings yet

- RM4TR32 DATASHEET SG en-GBDocument9 pagesRM4TR32 DATASHEET SG en-GBM. Andri Ludfi FananiNo ratings yet

- Tyfon MKT 75-660Document2 pagesTyfon MKT 75-660M. Andri Ludfi FananiNo ratings yet

- 0899 - 119-SPT-E1002BM013-18 - CoilSpring - A - 20180516085320.601 - XDocument21 pages0899 - 119-SPT-E1002BM013-18 - CoilSpring - A - 20180516085320.601 - XM. Andri Ludfi FananiNo ratings yet

- Ut 0001Document10 pagesUt 0001M. Andri Ludfi FananiNo ratings yet

- 弹簧作业指导书-Testing ProcedureDocument7 pages弹簧作业指导书-Testing ProcedureM. Andri Ludfi FananiNo ratings yet

- 1 s2.0 S1474667015383245 MainDocument6 pages1 s2.0 S1474667015383245 MainM. Andri Ludfi FananiNo ratings yet

- 2018 Lfse en RevDocument2 pages2018 Lfse en RevM. Andri Ludfi FananiNo ratings yet

- Industry 4.0 Technology ImplementationDocument6 pagesIndustry 4.0 Technology ImplementationM. Andri Ludfi FananiNo ratings yet

- Lesson IvDocument9 pagesLesson IvM. Andri Ludfi FananiNo ratings yet

- APTA-PR-CS-S-016-99 - Rev2 - Standard For Passenger SeatsDocument52 pagesAPTA-PR-CS-S-016-99 - Rev2 - Standard For Passenger SeatsM. Andri Ludfi FananiNo ratings yet

- Approval Subtitusi MCCB 600A 4P REKADocument3 pagesApproval Subtitusi MCCB 600A 4P REKAM. Andri Ludfi FananiNo ratings yet

- TeSys LRD - LR3D086Document3 pagesTeSys LRD - LR3D086M. Andri Ludfi FananiNo ratings yet

- Booklet - Workshop Reading ProTEFLDocument10 pagesBooklet - Workshop Reading ProTEFLM. Andri Ludfi FananiNo ratings yet

- Skywell - The Readiness of Skywell EBus Sept 8 2020Document14 pagesSkywell - The Readiness of Skywell EBus Sept 8 2020M. Andri Ludfi FananiNo ratings yet

- TM4 CO150 - Dana TM4 1Document2 pagesTM4 CO150 - Dana TM4 1M. Andri Ludfi FananiNo ratings yet

- Data Sheet2004-1301 21.05.2021Document20 pagesData Sheet2004-1301 21.05.2021M. Andri Ludfi FananiNo ratings yet

- Nova Electric CGL SeriesDocument18 pagesNova Electric CGL SeriesM. Andri Ludfi FananiNo ratings yet

- Job Vacancy LRT JakartaDocument2 pagesJob Vacancy LRT JakartaM. Andri Ludfi FananiNo ratings yet

- Siemens MotorDocument18 pagesSiemens MotorM. Andri Ludfi FananiNo ratings yet

- Penerbit, 009Document8 pagesPenerbit, 009M. Andri Ludfi FananiNo ratings yet

- Iris Guideline 4 - Rams-Lcc 4994enDocument11 pagesIris Guideline 4 - Rams-Lcc 4994enM. Andri Ludfi Fanani100% (2)

- Selecontrol® Mas: Tcp/Ip and UdpDocument26 pagesSelecontrol® Mas: Tcp/Ip and UdpM. Andri Ludfi FananiNo ratings yet

- 5586 ZM 380c As Chime Microphone Specification PDFDocument1 page5586 ZM 380c As Chime Microphone Specification PDFM. Andri Ludfi FananiNo ratings yet

- LX4FH110: Product Data SheetDocument2 pagesLX4FH110: Product Data SheetM. Andri Ludfi FananiNo ratings yet

- 5436 ZP 2240 Power Amplifier SpecificationDocument1 page5436 ZP 2240 Power Amplifier SpecificationM. Andri Ludfi Fanani100% (1)

- Krauss & Naimer KN100GBDocument60 pagesKrauss & Naimer KN100GBM. Andri Ludfi FananiNo ratings yet

- MPT 3000R - User Manual PDFDocument91 pagesMPT 3000R - User Manual PDFM. Andri Ludfi FananiNo ratings yet

- Weidmuller PROmax Datasheet PDFDocument2 pagesWeidmuller PROmax Datasheet PDFM. Andri Ludfi FananiNo ratings yet

- AA1-230 Shunt Trip: General InformationDocument3 pagesAA1-230 Shunt Trip: General InformationM. Andri Ludfi FananiNo ratings yet