Professional Documents

Culture Documents

Tds Refgun 1500 LPX

Tds Refgun 1500 LPX

Uploaded by

Calvin CooksonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tds Refgun 1500 LPX

Tds Refgun 1500 LPX

Uploaded by

Calvin CooksonCopyright:

Available Formats

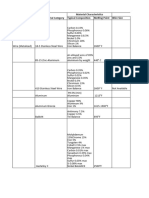

REFGUN1500 LPX

Low porosity high strength

Classification Gunning

General and Physical Properties Bulk Density Kg/m³ 2400

Maximum Service Temperature ⁰C 1500

Water required l/100Kg 8-10

Cold Crushing Strength at 110 ⁰C N/mm² (MPa) 65

Cold Crushing Strength at 1200 ⁰C N/mm² (MPa) 75

Modulus of Rupture N/mm² (MPa) 5

Permanent Linear Change After Heating at 1000⁰C % -0.19

Refractoriness PCE Orton Cone 35

Wear Resistance ASTM C 704 cm³

Packaging 25Kg

Chemical Composition Alumina (AI₂O₃) % 45.3

Silica (SiO₂) % 50.9

Magnesite (MgO) % 0.1

Lime (CaO) % 1.9

Iron Oxide (Fe₂O₃) % 0.7

Silicon Carbide (SiC) % 0.0

Zirconia (ZrO₂) % 0.0

Carbon (C) % 0.0

Chrome Oxide (Cr₂O₃) % 0.0

LOI %

Thermal Expansion 400⁰C % 0.31

800⁰C % 0.42

1000⁰C % 0.55

1200⁰C % 0.70

1400⁰C % 0.85

Thermal Conductivity 400⁰C (W/m.K) 1.30

600⁰C (W/m.K) 1.40

800⁰C (W/m.K) 1.50

1000⁰C (W/m.K) 1.60

The above

Th bov ddata are typical

yp values

v u o of the

h pproperties

op of the

o h samples

mp tested d according

o d ng too the

h internal

n n pprocedure

o du and

nd standard

nd d oof R

Refraline.

n W We reserves

v the

h right

gh too upd

update the

h above

bov ddata

and

nd change

h ng ou

our internal

n n p procedure

o du and nd standard

nd d w without

hou anyny p

prior

o no

notice.

You might also like

- 870 43 18 Technical Documentation Sika AnchorFix 3030 (06 2018) 1Document15 pages870 43 18 Technical Documentation Sika AnchorFix 3030 (06 2018) 1Lucian BogorodeaNo ratings yet

- Refractory Datasheet - KAST-O-LITE 23 LI PLUSDocument1 pageRefractory Datasheet - KAST-O-LITE 23 LI PLUSSubrata DasNo ratings yet

- Aluminium Alloy 5083 PDFDocument5 pagesAluminium Alloy 5083 PDFrajanNo ratings yet

- 2003-10 Siam MC 60 DHDocument1 page2003-10 Siam MC 60 DHSyed Kazam RazaNo ratings yet

- 2 High Alumina BricksDocument25 pages2 High Alumina BricksManekGoris0% (1)

- Andura 70: Physical Properties ClassificationDocument2 pagesAndura 70: Physical Properties ClassificationSyed Kazam RazaNo ratings yet

- Kemresis S15Document1 pageKemresis S15hamedmustafa093No ratings yet

- Insulating Brick ExampleDocument1 pageInsulating Brick ExamplepsaayoNo ratings yet

- Insulating Brick Example PDFDocument1 pageInsulating Brick Example PDFpsaayoNo ratings yet

- Insulation - Filippich 2015Document22 pagesInsulation - Filippich 2015vũ minh tâmNo ratings yet

- AISI 321 SpecificationsDocument1 pageAISI 321 SpecificationsMatija BušićNo ratings yet

- Type 1 BricksDocument20 pagesType 1 Bricksprachi410No ratings yet

- C.F Blanket, CerawoolDocument1 pageC.F Blanket, CerawoolfrankieNo ratings yet

- Amorkast 80al C - AdtechDocument2 pagesAmorkast 80al C - AdtechFaisal YaniNo ratings yet

- CumilagDocument1 pageCumilagAshwini JainNo ratings yet

- ClassificationDocument1 pageClassificationGmail For ABT WorkNo ratings yet

- IsoplatonDocument1 pageIsoplatonikahashimNo ratings yet

- CV. Dunia Isolasi RefractoryDocument3 pagesCV. Dunia Isolasi RefractoryHerberth SilitongaNo ratings yet

- Plicast 40Document1 pagePlicast 40Saint JossNo ratings yet

- Nikrothal LX: (Resistance Heating Wire and Resistance Wire)Document2 pagesNikrothal LX: (Resistance Heating Wire and Resistance Wire)yasir127No ratings yet

- Hempel Alloy254SMO14547LongflatproductsHempel PDFDocument1 pageHempel Alloy254SMO14547LongflatproductsHempel PDFqualityNo ratings yet

- Metalcor 1.4876 Alloy 800Document1 pageMetalcor 1.4876 Alloy 800tonicmiraNo ratings yet

- Special Metals UDIMET® Alloy 250 Maraging SteelDocument1 pageSpecial Metals UDIMET® Alloy 250 Maraging SteelshubhamNo ratings yet

- Reflite 1200 HS GDocument1 pageReflite 1200 HS GTEDDY KENCONONo ratings yet

- Alloy: C97300: Typical UsesDocument2 pagesAlloy: C97300: Typical UsesalextentwentyNo ratings yet

- A286 Tech DataDocument5 pagesA286 Tech Datagowtham raju buttiNo ratings yet

- Refractory Calculation Sheet For C-102 PDFDocument2 pagesRefractory Calculation Sheet For C-102 PDFAttyubNo ratings yet

- Raw MaterialDocument14 pagesRaw MaterialAbhijeet AnkushNo ratings yet

- Versaflow ® 60 PlusDocument1 pageVersaflow ® 60 PlusarnettoNo ratings yet

- Rogers - Unknown - RO4400 Series BondplyDocument4 pagesRogers - Unknown - RO4400 Series BondplyHadi SaeidiManeshNo ratings yet

- 1414059256wpdm - Stainless Steel Grade AISI 310Document2 pages1414059256wpdm - Stainless Steel Grade AISI 310Riian ApriansyahNo ratings yet

- JIS S45C Steel, Normalized: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Medium Carbon SteelDocument1 pageJIS S45C Steel, Normalized: Metal Ferrous Metal Carbon Steel AISI 1000 Series Steel Medium Carbon SteelPuji RiatnoNo ratings yet

- Alloy 276 Spec SheetDocument3 pagesAlloy 276 Spec SheetJAYA BHARATHA REDDYNo ratings yet

- Grades of Steel Used in Ship BuildingDocument1 pageGrades of Steel Used in Ship BuildingAnkit MauryaNo ratings yet

- Metalcor 1.4361 Alloy 1815Document1 pageMetalcor 1.4361 Alloy 1815Francisco SousalimaNo ratings yet

- Cumirex: - Ceramics Aluminium Copper Iron & SteelDocument2 pagesCumirex: - Ceramics Aluminium Copper Iron & SteeldebasisNo ratings yet

- Insulating 25 GRDocument2 pagesInsulating 25 GRKARIM BOUJJANo ratings yet

- Eastman Eastapure: Electronic ChemicalsDocument4 pagesEastman Eastapure: Electronic ChemicalsChemtools ChemtoolsNo ratings yet

- Metalcor 2.4375 Alloy K500Document1 pageMetalcor 2.4375 Alloy K500Gourav SharmaNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Amandeep SinghNo ratings yet

- Datasheet Kanthal A 1Document2 pagesDatasheet Kanthal A 1Claudio ZalazarNo ratings yet

- Dmls Inconel 625Document1 pageDmls Inconel 625CRISTIANONo ratings yet

- Nominal Composition Standard Inventory SpecificationsDocument3 pagesNominal Composition Standard Inventory Specificationssafat parNo ratings yet

- A286 (Ficha Tecnica)Document3 pagesA286 (Ficha Tecnica)Alex Zambrana RodríguezNo ratings yet

- C2700Document6 pagesC2700Andrew TanNo ratings yet

- Aaepl: TDC No. AAEPL/RM/lDocument2 pagesAaepl: TDC No. AAEPL/RM/lSandip PandeNo ratings yet

- Fine Ceramics PerformanceDocument1 pageFine Ceramics PerformanceArvin Jun PerezNo ratings yet

- Copper Cu-Dhp / Sf-Cu: Page 1/2Document2 pagesCopper Cu-Dhp / Sf-Cu: Page 1/2gemilanglpNo ratings yet

- 1.4401 1.4404 316 316L X2Crnimo17-12-2 S31603: en Designation Astm DesignationDocument2 pages1.4401 1.4404 316 316L X2Crnimo17-12-2 S31603: en Designation Astm Designation池边树No ratings yet

- Morflo 170Document2 pagesMorflo 170baselNo ratings yet

- Harbison WalkerDocument1 pageHarbison WalkerKevin Vargas100% (1)

- Metalcor 1.4742Document1 pageMetalcor 1.4742Pablo PerdomoNo ratings yet

- Copper-Nickel Cu-Ni 90/10 Alloy (UNS C70600) : Heanjia Super-Metals Co., LTD, Call-12068907337. WebDocument7 pagesCopper-Nickel Cu-Ni 90/10 Alloy (UNS C70600) : Heanjia Super-Metals Co., LTD, Call-12068907337. Webboydoc inspectionNo ratings yet

- The Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedDocument1 pageThe Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedRavindra ErabattiNo ratings yet

- Physical Properties Classification: The Siam Refractory Industry Co., LTDDocument23 pagesPhysical Properties Classification: The Siam Refractory Industry Co., LTDManekGorisNo ratings yet

- Hy-Tuf / AMS 6425: Additional InformationDocument2 pagesHy-Tuf / AMS 6425: Additional Informationapurv bhartiNo ratings yet

- Hy-Tuf - AMS 6425 PDFDocument2 pagesHy-Tuf - AMS 6425 PDFapurv bhartiNo ratings yet

- Hy-Tuf - AMS 6425 PDFDocument2 pagesHy-Tuf - AMS 6425 PDFapurv bhartiNo ratings yet

- Hy-Tuf - AMS 6425 PDFDocument2 pagesHy-Tuf - AMS 6425 PDFapurv bhartiNo ratings yet

- Analytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryFrom EverandAnalytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryNo ratings yet

- 4.3 Exam QuestionsDocument52 pages4.3 Exam QuestionsRegirocksNo ratings yet

- Development of Nanostructured Lipid Carriers Loaded With Corosolic Acid An Efficient Carrier For Antidiabetic Effects PDFDocument5 pagesDevelopment of Nanostructured Lipid Carriers Loaded With Corosolic Acid An Efficient Carrier For Antidiabetic Effects PDFVidyavardhini UshirNo ratings yet

- Presentation On Case StudyDocument19 pagesPresentation On Case StudyNehar ShubheschaNo ratings yet

- Q&a Meo 1Document132 pagesQ&a Meo 1shilparabNo ratings yet

- UntitledDocument64 pagesUntitledAgilan ChellaramNo ratings yet

- Petroleum Naphtha - Wikipedia PDFDocument4 pagesPetroleum Naphtha - Wikipedia PDFSauptik DattaNo ratings yet

- 10.5 Extraction of MetalsDocument19 pages10.5 Extraction of MetalsUmida ZaylobiddinovaNo ratings yet

- MIJA Datasheet Extinguisher Manometro de PresionDocument1 pageMIJA Datasheet Extinguisher Manometro de PresionMiguel PumaNo ratings yet

- Cereales, Legumbres - Determinacion de CenizasDocument6 pagesCereales, Legumbres - Determinacion de CenizasCristhian CarrizalesNo ratings yet

- FCF Intro With Technical ExpertiseDocument23 pagesFCF Intro With Technical ExpertiseLina Marcela GaravitoNo ratings yet

- EC1 - Maintenance & Safety - Quiz 2Document13 pagesEC1 - Maintenance & Safety - Quiz 2AnandababuNo ratings yet

- Thermochemistry and Reaction Mechanisms of Nitromethane IgnitionDocument15 pagesThermochemistry and Reaction Mechanisms of Nitromethane IgnitionDevis anugraNo ratings yet

- The Cell Quiz L 9Document2 pagesThe Cell Quiz L 9moutaz bedeweyNo ratings yet

- Fiber Selectionforthe Productionof NonwovensDocument33 pagesFiber Selectionforthe Productionof NonwovensTimothy PonrathnamNo ratings yet

- Chapter 9 Ism 11e FinalDocument29 pagesChapter 9 Ism 11e FinalNathan VitorNo ratings yet

- Nitrogen Gass SystemDocument29 pagesNitrogen Gass SystemshaieraNo ratings yet

- Final Period Long Quiz - ME 410 - 3101Document2 pagesFinal Period Long Quiz - ME 410 - 3101siva sachaphibulkijNo ratings yet

- Immunophysics - WikipediaDocument7 pagesImmunophysics - WikipediabNo ratings yet

- Energy Potential of Yam and Plantain Peels: Oladiran FasinaDocument6 pagesEnergy Potential of Yam and Plantain Peels: Oladiran FasinaGoummeli6 SocratesNo ratings yet

- Hydrothermal Effects of Epoxy ResinDocument8 pagesHydrothermal Effects of Epoxy ResinVansala GanesanNo ratings yet

- Delta AluminaDocument8 pagesDelta AluminaFahim Bin Abdur RahmanNo ratings yet

- Petrochemical Processes HandbookDocument305 pagesPetrochemical Processes HandbookĐạigia Kute91% (23)

- F Block ElementsDocument4 pagesF Block ElementsAfaf HucynNo ratings yet

- Chapter 8Document1 pageChapter 8dheerakalra1988No ratings yet

- Ammonium Peroxydisulfate MSDSDocument8 pagesAmmonium Peroxydisulfate MSDSFitriani TanraNo ratings yet

- Pipette - SOPDocument7 pagesPipette - SOPRakesh MariNo ratings yet

- Syllabus 7 Sem PDFDocument26 pagesSyllabus 7 Sem PDFMahika PatilNo ratings yet

- Preparation and Characterization of (Ba Ca) (ZR Ti) Tio (BCZT) /bi O Composites As Efficient Visible-Light-Responsive PhotocatalystsDocument11 pagesPreparation and Characterization of (Ba Ca) (ZR Ti) Tio (BCZT) /bi O Composites As Efficient Visible-Light-Responsive PhotocatalystsAbhinay SreeramNo ratings yet

- Somer 2001 Classical and Statistical Thermodynamics (Carter Ashley H)Document2 pagesSomer 2001 Classical and Statistical Thermodynamics (Carter Ashley H)FrizarNo ratings yet