Professional Documents

Culture Documents

Cat-Ecs M0011

Cat-Ecs M0011

Uploaded by

CHANDAN0 ratings0% found this document useful (0 votes)

15 views2 pagesEddy Current Sorter is a portable machine that uses electromagnetic induction to segregate ferrous and non-ferrous metals without damage. It generates eddy currents in metallic objects placed within its energized coil, and compares the magnitude and phase of these currents to sort objects based on metallurgical differences. The machine has adjustable settings for frequency, sensitivity, phase, gain and thresholds to sort a variety of metal forms and conditions. It is used in automotive, manufacturing and other industries to separate mixed metals during processing.

Original Description:

EDDY CURRENT SORTER

Original Title

CAT-ECS M0011

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentEddy Current Sorter is a portable machine that uses electromagnetic induction to segregate ferrous and non-ferrous metals without damage. It generates eddy currents in metallic objects placed within its energized coil, and compares the magnitude and phase of these currents to sort objects based on metallurgical differences. The machine has adjustable settings for frequency, sensitivity, phase, gain and thresholds to sort a variety of metal forms and conditions. It is used in automotive, manufacturing and other industries to separate mixed metals during processing.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

15 views2 pagesCat-Ecs M0011

Cat-Ecs M0011

Uploaded by

CHANDANEddy Current Sorter is a portable machine that uses electromagnetic induction to segregate ferrous and non-ferrous metals without damage. It generates eddy currents in metallic objects placed within its energized coil, and compares the magnitude and phase of these currents to sort objects based on metallurgical differences. The machine has adjustable settings for frequency, sensitivity, phase, gain and thresholds to sort a variety of metal forms and conditions. It is used in automotive, manufacturing and other industries to separate mixed metals during processing.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

EDDY CURRENT SORTER

MODEL : ECS-ML 011

In all industries mix-up of metals in the form of raw, semi finished or

finished products may occur in transit, storage or at different stages at

manufacturing processes and is segregated by chemical, spectro analysis or

metallurgical tests. When proper coils are selected, Eddy Current Sorter is used

for segregation of ferrous and non-ferrous metals without even a scratch on

job or when bulk materials having external similarity are mixed up. Eddy

Current Sorter can segregate metals of all forms and conditions when proper

coils are selected. This instrument is

widely used for segregation of mixed-

up of metals in the form of bars, pipes,

tubes, rods, bolts, nuts, gears, machined

components, forged parts and various

types of metal components in

a u t o m o b i l e industries, heat

treatment shop, fastener industries,

forging unit, metal processing unit, fertilizer, refinery and petrochemical

projects & also final inspection in quality control department.

Description :

Eddy Current Sorter is sturdy, light weight and portable test unit with a

adjustable handle. Powered from single phase, 220V a.c., 50 Hz source. The

unit offers both sine wave and ellipse display. A ten (10) position rotary band

switch (frequency from 10 Hz to 10000 Hz), two threshold level controls to set

upper and lower limits of acceptance, a phase control to adjust the 10Oto 170O

phase of the sine wave. Three level indicators (Red for upper rejection, Green

for acceptance and Blue for lower rejection) to indicate three different groups

according to limits of acceptance set, buzzer is provided at rejection mode to

alert the operator. An additional indicator (amber) to indicate improper setting

or internal fault of instrument by blinking. This machine is for quick fault

identification and easy maintenance and has all the components with reliability

durability and perfect functioning.

How it works?

When a metallic object is placed within or adjacent to a coil energized by

alternating current, eddy currents are generated in it due to electromagnetic

induction. If two metal objects having identical dimensions differ in

metallurgical conditions, magnitude and phase of eddy currents generated in

them will also differ. Eddy current sorter compares this difference

electronically & it is projected on monochrome LCD. Another logical circuit

also compares this difference and shows a indication on LEDs. Thus the test

objects can be sorted out.

Technical Specification :

Input Supply : Single Phase, 230V AC, 50 Hz

Power Consumption : 30 Watts (approx)

Dimension (L X W X H) : 450 mm x 340mm x 160 mm

Screen (monitor) Size : Monochrome LCD 70 mm

Mode of Operation : Sine / Elipse both mode.

Receptacle : For external remote alarm & indication

Test Frequency : 10 Hz to 10000 Hz in ten steps

Sensitivity : Increasing in five steps.

Phase Control : to adjust sine wave at 10O to 170O

Threshold I & II : to control upper limit & lower limit respectively

Bridge Volt : Increasing the bridge volt in five steps

Coil Balance : to balance the Coil impedence

Bridge Balance : to control unbalance impedence.

Gain Control : Low to High gain amplification for test

sensitivity.

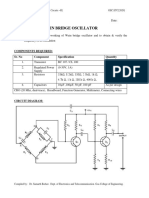

REAR VIEW OF EQUIPMENT

SAYACHAN ELECTRO SYSTEMS

NDT Equipment & other Electronics Devices Manufacturer

34/3/D-1, P. K. ROAD KOLKATA 700 061 MOB : 9432346673

Email : sesystems10@gmail.com Web : www.sayachanelectrosystems.com

You might also like

- UGRD-BAMM6204 Professional Salesmanship QuizDocument11 pagesUGRD-BAMM6204 Professional Salesmanship QuizJordan Nieva AndioNo ratings yet

- Chapter 5 SensorsDocument46 pagesChapter 5 SensorsKetul ShahNo ratings yet

- Excell NHP 250-350Document4 pagesExcell NHP 250-350JM33% (3)

- A Guide to Electronic Maintenance and RepairsFrom EverandA Guide to Electronic Maintenance and RepairsRating: 4.5 out of 5 stars4.5/5 (7)

- Taking Anthropometric MeasurementsDocument8 pagesTaking Anthropometric MeasurementsRaja Kumar100% (6)

- Eddy Current Sorter: MODEL: ECS-M 0011Document2 pagesEddy Current Sorter: MODEL: ECS-M 0011CHANDANNo ratings yet

- AI 210 InstrumentationDocument61 pagesAI 210 InstrumentationSiswoyo SuwidjiNo ratings yet

- ELS-DR-Dual Relay Tilt SwitchDocument5 pagesELS-DR-Dual Relay Tilt SwitchKrum KashavarovNo ratings yet

- Basic InstrumentationDocument55 pagesBasic InstrumentationvenkatsubbuNo ratings yet

- Titular Curs: S.L. Dr. Ing. Nicoleta-Cristina GĂITANDocument197 pagesTitular Curs: S.L. Dr. Ing. Nicoleta-Cristina GĂITANNicolae MorarNo ratings yet

- ETS Tilt Switch Single Axis1Document4 pagesETS Tilt Switch Single Axis1banavaram1No ratings yet

- S3 D000030106 - E - en - ZMD400xT Technical DataDocument8 pagesS3 D000030106 - E - en - ZMD400xT Technical DataDasuki FahmiNo ratings yet

- ST251Document18 pagesST251kingarpit24No ratings yet

- Eico 685 Operating ManualDocument29 pagesEico 685 Operating ManualkokoromialosNo ratings yet

- EE-252-Electronic Devices & Digital Electronics Laboratory Manual/ RecordDocument85 pagesEE-252-Electronic Devices & Digital Electronics Laboratory Manual/ RecordkishorebabNo ratings yet

- SC ISC TrainingDocument45 pagesSC ISC TrainingsuberorrNo ratings yet

- Centurion Eddy Current Ed520Document6 pagesCenturion Eddy Current Ed520mgmqroNo ratings yet

- Tek 575 1960Document124 pagesTek 575 1960bobvillaisthemanNo ratings yet

- Eddy Probe System On The Basis of New Technology: FT L C L I T UDocument6 pagesEddy Probe System On The Basis of New Technology: FT L C L I T UNatthaphon NaosookNo ratings yet

- Analog Dialogue, Volume 48, Number 1: Analog Dialogue, #13From EverandAnalog Dialogue, Volume 48, Number 1: Analog Dialogue, #13Rating: 4 out of 5 stars4/5 (1)

- Purity MeterDocument24 pagesPurity Meterfernandopedersoli88No ratings yet

- RISH EM 3490 SS - Digital Multifunctional Energy Meters With RS 485 CommunicationDocument6 pagesRISH EM 3490 SS - Digital Multifunctional Energy Meters With RS 485 CommunicationAarif PatelNo ratings yet

- Cathodic Disbonding TesterDocument1 pageCathodic Disbonding TesterfelavinNo ratings yet

- Switchmode Power Supply Testing FundamentalsDocument1 pageSwitchmode Power Supply Testing FundamentalsWahNo ratings yet

- Practical ElectronicsDocument107 pagesPractical ElectronicsSaeed Ali Shahani100% (2)

- ST251 30MHzDocument18 pagesST251 30MHzTushar PatilNo ratings yet

- AI 210 InstrumentationDocument61 pagesAI 210 InstrumentationBurhan KhanNo ratings yet

- CLS EngDocument1 pageCLS EngkevinNo ratings yet

- 电磁流量计安装使用说明书 最新【搜狗文档翻译 译文 中译英】Document33 pages电磁流量计安装使用说明书 最新【搜狗文档翻译 译文 中译英】pniam91No ratings yet

- Ed-Sa015 LCDDocument2 pagesEd-Sa015 LCDCHANDANNo ratings yet

- Function GeneratorDocument78 pagesFunction GeneratorVishali Chowdary100% (1)

- SC Tuning Fork Level Switch - B0-08 - ADocument18 pagesSC Tuning Fork Level Switch - B0-08 - AZeeshan ChoudharyNo ratings yet

- Ent Korea Meter Catalog (Shinhwa Ent Korea)Document36 pagesEnt Korea Meter Catalog (Shinhwa Ent Korea)Yakdhan YaseenNo ratings yet

- Harman Kardon Service Manual For AVR 430 and AVR 630 ReceiversDocument126 pagesHarman Kardon Service Manual For AVR 430 and AVR 630 ReceiversDavid Derting100% (1)

- Aoc Ct520g Series s554b Series 41as554-Aoc-E00 Version A00Document44 pagesAoc Ct520g Series s554b Series 41as554-Aoc-E00 Version A00Luis Gamalier Zurita0% (1)

- Shaft EarthningDocument11 pagesShaft Earthningsugandha772No ratings yet

- Spesifikasi Electromagnetic FlowmeterDocument12 pagesSpesifikasi Electromagnetic FlowmeterRibur AritonangNo ratings yet

- Introduction To EMC: Electronic ComponentsDocument26 pagesIntroduction To EMC: Electronic ComponentsAnonymous qqJnZqkak3No ratings yet

- TV Philips l03.1l Aa 21pt6446Document53 pagesTV Philips l03.1l Aa 21pt6446José Mamani Oyardo100% (1)

- Adi TV Philips 21pt5221 60 Chassis L01.2A ABDocument70 pagesAdi TV Philips 21pt5221 60 Chassis L01.2A ABbioteky33% (3)

- Flaw Detection Using Encircling CoilDocument3 pagesFlaw Detection Using Encircling Coilأحمد دعبسNo ratings yet

- Harman Kardon 3370Document105 pagesHarman Kardon 3370Rodrigo Cardenas MartinezNo ratings yet

- L01 2aabDocument72 pagesL01 2aab111sNo ratings yet

- Inductive Proximity Sensors: GeneralDocument4 pagesInductive Proximity Sensors: GeneralJack Agung SihombingNo ratings yet

- AI 210 InstrumentationDocument59 pagesAI 210 InstrumentationShaukat Ali ShahNo ratings yet

- Harman Kardon Avr-2600 SMDocument216 pagesHarman Kardon Avr-2600 SMCarollyne SabioniNo ratings yet

- Manual de Instalacion Detector de MetalesDocument28 pagesManual de Instalacion Detector de MetalesMirla Marisel Chavez NajeraNo ratings yet

- Harman/Kardon AVR 254 Service Manual)Document189 pagesHarman/Kardon AVR 254 Service Manual)jrubins100% (1)

- B20100GDocument4 pagesB20100GBals Gadda100% (4)

- Panasonic BT-LH1710-1760 (E-MC) PDFDocument116 pagesPanasonic BT-LH1710-1760 (E-MC) PDFboroda2410100% (1)

- Elmag 200m Instruction ManualDocument22 pagesElmag 200m Instruction ManualAnand BagadeNo ratings yet

- Expt 5 - Wein Bridge Oscillator (2020)Document3 pagesExpt 5 - Wein Bridge Oscillator (2020)samarthNo ratings yet

- 29WK500Document19 pages29WK500Claudio Teruo TanakaNo ratings yet

- Wireless RC Car With 3-AXIS Accelerometer Based ControllerDocument27 pagesWireless RC Car With 3-AXIS Accelerometer Based ControllerTanu JainNo ratings yet

- Liteon c1770nsl T CRT MonitorDocument40 pagesLiteon c1770nsl T CRT MonitorNelu FnNo ratings yet

- Rotary Position Sensors Line Guide: FeaturesDocument10 pagesRotary Position Sensors Line Guide: FeaturesGerman GodiNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Water Level Indicator Circuit Using Bipolar Junction TransistorFrom EverandWater Level Indicator Circuit Using Bipolar Junction TransistorRating: 4.5 out of 5 stars4.5/5 (7)

- Welder's Qualification Test CertificateDocument1 pageWelder's Qualification Test CertificatekannanNo ratings yet

- Role of Critical Care NursingDocument8 pagesRole of Critical Care NursingHari Mas KuncoroNo ratings yet

- "W.C. Asorio's ASC Me' Model of Care": NAME: Asorio, Wendale Claire G. Student ID#: 18-0972-39Document3 pages"W.C. Asorio's ASC Me' Model of Care": NAME: Asorio, Wendale Claire G. Student ID#: 18-0972-39Wendale Claire G. ASORIONo ratings yet

- Suitcase X-Treme 12Vs: Ce and Non-Ce ModelsDocument44 pagesSuitcase X-Treme 12Vs: Ce and Non-Ce ModelsBaskoro PMCKNo ratings yet

- Physics Category 1 9th - 10th Grades SAMPLE TESTDocument4 pagesPhysics Category 1 9th - 10th Grades SAMPLE TESTAchavee SukratNo ratings yet

- S B Mallur - C VDocument12 pagesS B Mallur - C VsbmallurNo ratings yet

- Loba Chemie Price List 2018-19 PDFDocument288 pagesLoba Chemie Price List 2018-19 PDFdelta lab sangliNo ratings yet

- Physics Project of Class 11 IscDocument1 pagePhysics Project of Class 11 Iscpratima patelNo ratings yet

- BX - Cleansweep Pro ManualDocument10 pagesBX - Cleansweep Pro ManualVICTOR CHRISTIAN VASQUEZ CHAVEZNo ratings yet

- 214.039 Operation of Sieve Shaker2012Document3 pages214.039 Operation of Sieve Shaker2012Pradeep KumarNo ratings yet

- Gravitational FieldDocument12 pagesGravitational FieldAmaliani Candra PradiptaNo ratings yet

- The Importance of Reading To Expand KnowledgeDocument8 pagesThe Importance of Reading To Expand KnowledgeAnindhita NabilahNo ratings yet

- Cl400e VDocument2 pagesCl400e VCá ThuNo ratings yet

- A Project Report Peer PressureDocument17 pagesA Project Report Peer PressureTannu GuptaNo ratings yet

- A Is For Alienation ArticleDocument4 pagesA Is For Alienation ArticleFamily Court-CorruptionNo ratings yet

- Childhood and Growing UpDocument181 pagesChildhood and Growing UpManichander100% (2)

- TLE6 Module5 Propagating Tress and Fruit-Bearing TreesDocument29 pagesTLE6 Module5 Propagating Tress and Fruit-Bearing TreesLorranne Maice D. Morano100% (1)

- Slides Chapter 3Document18 pagesSlides Chapter 3Reebeeccal LeeNo ratings yet

- Reciprocating Compressor Power Calculation Part 2Document6 pagesReciprocating Compressor Power Calculation Part 2Rifka Aisyah0% (1)

- Rhetorical AppealsDocument1 pageRhetorical AppealsSoham AherNo ratings yet

- 1st Year Exam (Re-Exam) 1. Årsprøve (Reeksamen) : August 2021Document14 pages1st Year Exam (Re-Exam) 1. Årsprøve (Reeksamen) : August 2021SafridNo ratings yet

- Rousseau: The Government of Poland - Rousseau, Jean-Jacques, 1712-1778Document151 pagesRousseau: The Government of Poland - Rousseau, Jean-Jacques, 1712-1778PécuchetNo ratings yet

- QuestionsDocument20 pagesQuestionsmaheshNo ratings yet

- Project: Pakistan International School (English Section), Riyadh Boys' Wing Afternoon ShiftDocument3 pagesProject: Pakistan International School (English Section), Riyadh Boys' Wing Afternoon ShiftMUHAMMAD YAMEEN KHANNo ratings yet

- Businessstudy Xii DDocument2 pagesBusinessstudy Xii Dvarun ChoudharyNo ratings yet

- Personality DevelopmentDocument28 pagesPersonality Developmentmaverick-riouNo ratings yet

- Erp Case StudyDocument2 pagesErp Case StudymehakNo ratings yet

- St. Andrew Academy Bacarra, Ilocos Norte First Grading-Grade 7 MathematicsDocument10 pagesSt. Andrew Academy Bacarra, Ilocos Norte First Grading-Grade 7 MathematicsJACOBAGONOYNo ratings yet