Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

11 views28day Strength

28day Strength

Uploaded by

muhammedssebatindira3This document summarizes the results of a compressive strength test of concrete cubes conducted by Mohammed Muhammed of Kabale University. Three 150mm cubes were tested at ages of 3, 7, 21, and 28 days. The average compressive strengths were 4.1 MPa at 3 days, 5.4 MPa at 7 days, 6.8 MPa at 21 days, and 7.0 MPa at 28 days. However, these values did not meet the minimum required strength of 17.7 MPa or minimum single cube strength of 11.1 MPa. This failure is attributed to poor curing where the water tank ran dry for 3 days, as well as insufficient compaction during mixing as several group

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- MK Indy Build ManualDocument40 pagesMK Indy Build ManualGabinete LessepsNo ratings yet

- Manual Roca RX 100Document5 pagesManual Roca RX 100Mile Blažević100% (3)

- Hotel Booking Application (Project) : Pega's University Academic ProgramDocument11 pagesHotel Booking Application (Project) : Pega's University Academic ProgramSucharitha RametiNo ratings yet

- CC 1Document1 pageCC 1Sagar BarotNo ratings yet

- CC 3Document1 pageCC 3Sagar BarotNo ratings yet

- BS EN 1991-1-1:2002, BS EN 1993-1-1:2005 - Chequered Plate Design 3/14/2020Document88 pagesBS EN 1991-1-1:2002, BS EN 1993-1-1:2005 - Chequered Plate Design 3/14/2020MohMohkNo ratings yet

- Concrete Compression Test Report: 150X150X150 150X150X150 150X150X150 150X150X150 150X150X150 150X150X150Document3 pagesConcrete Compression Test Report: 150X150X150 150X150X150 150X150X150 150X150X150 150X150X150 150X150X150Okello StevenNo ratings yet

- High MastDocument16 pagesHigh MastIam VinitNo ratings yet

- Wang BoDocument5 pagesWang BodimasarchitechtureNo ratings yet

- Fiberglass Rebar Data SheetDocument2 pagesFiberglass Rebar Data SheetAlex CrispimNo ratings yet

- Compressive Strength of Concrete Cubes, (BS 1881 Part 116: 1983)Document3 pagesCompressive Strength of Concrete Cubes, (BS 1881 Part 116: 1983)Kasulumbay CosmasNo ratings yet

- STRENG FC 10 LC MC MEI 05 OkDocument15 pagesSTRENG FC 10 LC MC MEI 05 OkSurtiman Adhi FanjayaNo ratings yet

- GSW (Galvanized Steel Wire) ASTM A475Document2 pagesGSW (Galvanized Steel Wire) ASTM A475Vaza Firdaus100% (1)

- Kojex 1Document1 pageKojex 1Okello StevenNo ratings yet

- A Detail Study On Autoclave Aerated Concrete: International Research Journal of Engineering and Technology (IRJET)Document3 pagesA Detail Study On Autoclave Aerated Concrete: International Research Journal of Engineering and Technology (IRJET)Velmurugan Siva KamarajNo ratings yet

- 09sakthivelAMS65 68 2015 257 PDFDocument6 pages09sakthivelAMS65 68 2015 257 PDFSakthivelNo ratings yet

- 3.1 Research Flow ChartDocument23 pages3.1 Research Flow ChartHendri HermawanNo ratings yet

- GFRP RebarsDocument16 pagesGFRP Rebarsrajbir1001No ratings yet

- Netc DBMDocument34 pagesNetc DBMMorya RonakNo ratings yet

- Flakiness IndexDocument4 pagesFlakiness Indexmarkagaba004No ratings yet

- Archstruct 3Document33 pagesArchstruct 3Kyran Joeffer EsporlasNo ratings yet

- Test Kuat Tekan 350Document3 pagesTest Kuat Tekan 350erik tiblolaNo ratings yet

- 4.2 Bolt DesignDocument14 pages4.2 Bolt DesignbernabasNo ratings yet

- Hot Dipped Galvanized Welded Steel PipesDocument2 pagesHot Dipped Galvanized Welded Steel PipesMuthuKumarNo ratings yet

- Ucs Crushed SandDocument1 pageUcs Crushed SandMohammed SalhinNo ratings yet

- Polyester Double Braid: Tech SheetDocument2 pagesPolyester Double Braid: Tech SheetMARLA ALEJANDRA TORRES PEREZNo ratings yet

- Unbound MaterialsDocument3 pagesUnbound Materialsmadhav choudharyNo ratings yet

- Cement Testing Week No 37Document1 pageCement Testing Week No 37DNYANESHWAR PATILNo ratings yet

- Use of RHA CementDocument8 pagesUse of RHA CementTokay Moe ZNo ratings yet

- Test Certificate: (, Phone: 26751763 MillDocument1 pageTest Certificate: (, Phone: 26751763 MillQc QatarNo ratings yet

- RGU ENM 201 Wells Coursework-May2017 FinalDocument7 pagesRGU ENM 201 Wells Coursework-May2017 FinalEmenike Donald EjiejiNo ratings yet

- Bean BallsDocument31 pagesBean BallsYathish143No ratings yet

- ASTM A53 Schedule 40 and Schedule 80 Pipe DimensionsDocument11 pagesASTM A53 Schedule 40 and Schedule 80 Pipe DimensionsjohnmarbautistaNo ratings yet

- DEVI, OLYVIA, EDI - Pengaruh Penambahan Serat Kawat Bendhrat Terhadap Kuat Tekan Dan Kuat Tarik BetonDocument9 pagesDEVI, OLYVIA, EDI - Pengaruh Penambahan Serat Kawat Bendhrat Terhadap Kuat Tekan Dan Kuat Tarik BetonExcellenza Nafidzun AzzamNo ratings yet

- Test Report For Gabion Wire: Parameters ResultDocument1 pageTest Report For Gabion Wire: Parameters ResultmirwaisNo ratings yet

- Roko 09.01.2023-5Document1 pageRoko 09.01.2023-5Okello StevenNo ratings yet

- Strength Test ResultsDocument7 pagesStrength Test Resultsmpairwe cliffortNo ratings yet

- Multilock Plastic Pile SpecificationsDocument2 pagesMultilock Plastic Pile SpecificationsFritz NatividadNo ratings yet

- Tension - Test (ASTM A 615M) - ReportDocument3 pagesTension - Test (ASTM A 615M) - ReportNadira PervinNo ratings yet

- SSB 449Document1 pageSSB 449yudhisindrasNo ratings yet

- 7c. Spesifik Brosur Hal 33Document1 page7c. Spesifik Brosur Hal 33jimz armyNo ratings yet

- Mcgill Channels & SupportsDocument3 pagesMcgill Channels & SupportsAlan Magat SantosNo ratings yet

- Gaon Cable Catalogue (Eng.)Document54 pagesGaon Cable Catalogue (Eng.)harry jangNo ratings yet

- Pipe CatalogueDocument6 pagesPipe CatalogueirfanNo ratings yet

- Test Rate BUETDocument5 pagesTest Rate BUETEngr Swapan82% (11)

- BVI-29434-TR-593160Document1 pageBVI-29434-TR-593160Vikas SavantNo ratings yet

- Testing For Bending of WoodDocument6 pagesTesting For Bending of WoodPatrice Suerte FelipeNo ratings yet

- Pembangunan Jalan Tol Semarang-Batang SEKSI4&5: Aashto T 27 - 82 / Astm C. 33Document40 pagesPembangunan Jalan Tol Semarang-Batang SEKSI4&5: Aashto T 27 - 82 / Astm C. 33Budhi KurniawanNo ratings yet

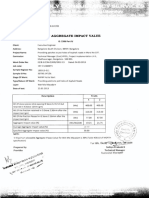

- Test Results of Aggregate Impact Value: Lab IDDocument7 pagesTest Results of Aggregate Impact Value: Lab IDyoseph dejeneNo ratings yet

- Ball Cover TensileDocument1 pageBall Cover Tensileshalinda Anup RitigahapolaNo ratings yet

- Reading 1 PDFDocument10 pagesReading 1 PDFGabriela HuertaNo ratings yet

- Lab Report U1 (Workability)Document11 pagesLab Report U1 (Workability)SYaz WAniNo ratings yet

- Optimization of Machining Parameters in EDM Process Using Cast and Sintered Copper ElectrodesDocument11 pagesOptimization of Machining Parameters in EDM Process Using Cast and Sintered Copper Electrodesaji setioNo ratings yet

- Cmir 014 CorregidoDocument1 pageCmir 014 Corregidomario uzuriagaNo ratings yet

- FRP Rebar Data SheetDocument2 pagesFRP Rebar Data Sheetkevin smith100% (1)

- AL-Yarmouk University Department of Civil Engineering AL-Hijjawi Faculty Highway Laboratory / CE 444Document15 pagesAL-Yarmouk University Department of Civil Engineering AL-Hijjawi Faculty Highway Laboratory / CE 444Mohammed MigdadyNo ratings yet

- PolyesterDocument3 pagesPolyestermesattyNo ratings yet

- Sub: Testing of Concrete Block Samples Project:: SL No Particulars Amount in RupeesDocument5 pagesSub: Testing of Concrete Block Samples Project:: SL No Particulars Amount in RupeesSandeep KumarNo ratings yet

- Carbon Fibre Reinforced Polymer: Polymer Matrix Composites: Applica-TionsDocument29 pagesCarbon Fibre Reinforced Polymer: Polymer Matrix Composites: Applica-Tionsanis suhailiNo ratings yet

- GRP Furniture PipeDocument1 pageGRP Furniture PipeNurul LailyahNo ratings yet

- Plastic Concrete TestDocument8 pagesPlastic Concrete TestSlan ClanNo ratings yet

- BCE 2203 Computing For Civil Engineering Test I-Marking GuideDocument7 pagesBCE 2203 Computing For Civil Engineering Test I-Marking Guidemuhammedssebatindira3No ratings yet

- Group D AssigDocument3 pagesGroup D Assigmuhammedssebatindira3No ratings yet

- Mechanical Properties of Soils 1Document12 pagesMechanical Properties of Soils 1muhammedssebatindira3No ratings yet

- Aspects of Water and Waste Water QualitiesDocument48 pagesAspects of Water and Waste Water Qualitiesmuhammedssebatindira3No ratings yet

- Modbus TCP ScadaDocument22 pagesModbus TCP ScadaEmerson KleemNo ratings yet

- Annex 1 CJ2 Mechanical Self-Locking Operation Manual - For Reference OnlyDocument3 pagesAnnex 1 CJ2 Mechanical Self-Locking Operation Manual - For Reference OnlyAndré MartinsNo ratings yet

- Internet of Things A Comparative StudyDocument10 pagesInternet of Things A Comparative StudyِAl TuraihiNo ratings yet

- Zamil DY - Series PDFDocument23 pagesZamil DY - Series PDFgagokapalaNo ratings yet

- Empowerment TechnologiesDocument4 pagesEmpowerment Technologieskristoffer50% (6)

- Stop Light Switch CircuitDocument3 pagesStop Light Switch Circuitcelestino tuliaoNo ratings yet

- TM Midea VRF V8 Medium Static Pressure Duct UAE 20230608 V2Document23 pagesTM Midea VRF V8 Medium Static Pressure Duct UAE 20230608 V2mohamed.irfan.mepNo ratings yet

- RV 2SD 2SDB Mitsubishi Robot Standard Manual PDFDocument150 pagesRV 2SD 2SDB Mitsubishi Robot Standard Manual PDFMatheus OliveiraNo ratings yet

- WM4 User ManualDocument44 pagesWM4 User ManualpcatruongNo ratings yet

- Interview FormDocument4 pagesInterview FormBond JamesNo ratings yet

- Eden Jahmiel LeonardoDocument3 pagesEden Jahmiel LeonardoRanz AbadNo ratings yet

- Manoj. Madduri: Qualification Board/University Name of Institution Year of Passing AggregateDocument3 pagesManoj. Madduri: Qualification Board/University Name of Institution Year of Passing AggregateSita Ram RamisettyNo ratings yet

- Accounting and Financial Close - Group Ledger IFRS (1GA - FR) : Test Script SAP S/4HANA Cloud - 06-10-20Document56 pagesAccounting and Financial Close - Group Ledger IFRS (1GA - FR) : Test Script SAP S/4HANA Cloud - 06-10-20cricriAF33830No ratings yet

- DMRC Industrial Training ReportDocument35 pagesDMRC Industrial Training ReportPRERAK MATHURNo ratings yet

- Lesson10 ICT 0417Document25 pagesLesson10 ICT 0417thamalieariyarathnaNo ratings yet

- University of Gondar: Information Storage and Retrieval SystemDocument29 pagesUniversity of Gondar: Information Storage and Retrieval SystemAisha mNo ratings yet

- Icom IC 706 MKIIG Service MenuDocument2 pagesIcom IC 706 MKIIG Service MenurustyNo ratings yet

- Dire Dawa University Institution of Technology: Year: 4thDocument5 pagesDire Dawa University Institution of Technology: Year: 4thAnonymous nZo3uhY8uRNo ratings yet

- Apparel Manufacturing ProcessDocument27 pagesApparel Manufacturing ProcessGarima AgarwalNo ratings yet

- Basic Discussion On Pcie Configuration and EnumerationDocument16 pagesBasic Discussion On Pcie Configuration and EnumerationnazimNo ratings yet

- Time Frame D8R MidlifeDocument17 pagesTime Frame D8R MidlifeMaintenance PlannerNo ratings yet

- Force Copy Queries From One Info Provider To Another With Different StructureDocument11 pagesForce Copy Queries From One Info Provider To Another With Different StructureMohammed NaveedNo ratings yet

- DS - 30xa450Document3 pagesDS - 30xa450Leonardo Martinho DobrianskyjNo ratings yet

- ShipmentsDocument2 pagesShipmentsSaul ChampacNo ratings yet

- Commutation Failure Presentation - NewDocument8 pagesCommutation Failure Presentation - NewNaresh RamNo ratings yet

- Understanding Cisco Express Forwarding: Document ID: 47321Document5 pagesUnderstanding Cisco Express Forwarding: Document ID: 47321Nishant MishraNo ratings yet

- FA18 VI-EXTC-MJ2022 GradeDocument31 pagesFA18 VI-EXTC-MJ2022 GradenicO neeNo ratings yet

28day Strength

28day Strength

Uploaded by

muhammedssebatindira30 ratings0% found this document useful (0 votes)

11 views1 pageThis document summarizes the results of a compressive strength test of concrete cubes conducted by Mohammed Muhammed of Kabale University. Three 150mm cubes were tested at ages of 3, 7, 21, and 28 days. The average compressive strengths were 4.1 MPa at 3 days, 5.4 MPa at 7 days, 6.8 MPa at 21 days, and 7.0 MPa at 28 days. However, these values did not meet the minimum required strength of 17.7 MPa or minimum single cube strength of 11.1 MPa. This failure is attributed to poor curing where the water tank ran dry for 3 days, as well as insufficient compaction during mixing as several group

Original Description:

Cube strength 1

Original Title

28day strength

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document summarizes the results of a compressive strength test of concrete cubes conducted by Mohammed Muhammed of Kabale University. Three 150mm cubes were tested at ages of 3, 7, 21, and 28 days. The average compressive strengths were 4.1 MPa at 3 days, 5.4 MPa at 7 days, 6.8 MPa at 21 days, and 7.0 MPa at 28 days. However, these values did not meet the minimum required strength of 17.7 MPa or minimum single cube strength of 11.1 MPa. This failure is attributed to poor curing where the water tank ran dry for 3 days, as well as insufficient compaction during mixing as several group

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

11 views1 page28day Strength

28day Strength

Uploaded by

muhammedssebatindira3This document summarizes the results of a compressive strength test of concrete cubes conducted by Mohammed Muhammed of Kabale University. Three 150mm cubes were tested at ages of 3, 7, 21, and 28 days. The average compressive strengths were 4.1 MPa at 3 days, 5.4 MPa at 7 days, 6.8 MPa at 21 days, and 7.0 MPa at 28 days. However, these values did not meet the minimum required strength of 17.7 MPa or minimum single cube strength of 11.1 MPa. This failure is attributed to poor curing where the water tank ran dry for 3 days, as well as insufficient compaction during mixing as several group

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 1

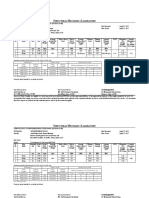

Geotechnical Civil Engineering Laboratory,

Department of Civil Engineering,

Kabale University,

P.O. BOX 317,

Kabale Uganda.

CUBE COMPRESSIVE STRENGTH TEST

YEAR OF STUDY 2 SEM 2 CASTING DATE: 31/03/2023 MAX AGG SIZE:

GROUP: GROUP D TYPE OF CEMENT: OPC 32.5N/mm2 20mm

INDIVIDUAL NAME: SSEBATINDIRA MUHAMMED

REG NO: 2021/A/KCE/1720/G/F

CLASS OF CONCRETE: 15 Mpa SLUMP:30mm

Cube Date Of Testing Specimen Age Weight Density Crushing Comp. Ave

Ref Crushing Date Size(mm) (Days) Of The (kg/m3) Load(KN) Strength Comp

No Cube(g) (Mpa) strength

(Mpa)

1 3/4/2023 150*150*150 3 8060 2388.1 110.7 4.9 4.1

2 150*150*150 8255 2445.9 75 3.3

1 8/4/2023 150*150*150 7 7590 2248.9 120.6 5.3 5.4

2 150*150*150 8115 2404.4 117.3 5.2

3 150*150*150 8015 2374.8 126.5 5.6

1 22/4/2023 150*150*150 21 8510 2521.5 139.4 6.1 6.8

2 150*150*150 8370 2480.0 170.6 7.5

1 29/4/2023 150*150*150 28 8110 2403.0 169.8 7.5 7.0

2 150*150*150 8225 2437.0 136.8 6.0

3 150*150*150 8100 2400.0 168.6 7.4

Acceptance analysis(ref.series 7000table 7205/4 acceptance factors for strength of structural concrete)

Checked by:

No.of cubes tested per lot= 3

Acceptance factor A = 2.7 (MPa) Name:

Sign:

Acceptance factor B = 3.9 (MPa) Date:

Mean value xn = 7.0 (MPa)

Min required value(X+A) = 17.7 (MPa)

Min single value(X-B) = 11.1 (MPa)

CONCLUSION:

None of the cubes attained the minimum single value (11.1Mpa) as well as the minimum required

value(17.7Mpa).

We attribute this failure to achieve the target strengths to poor curing process as after two days the water tank

ran dry for about three more days, also during the preparation of cubes the compaction was insufficient as many

of the group members were learning how things are done. During design process the choice of MSA didn’t

correspond to the actual size of aggregates we used(maybe poor sampling during gradation)

You might also like

- MK Indy Build ManualDocument40 pagesMK Indy Build ManualGabinete LessepsNo ratings yet

- Manual Roca RX 100Document5 pagesManual Roca RX 100Mile Blažević100% (3)

- Hotel Booking Application (Project) : Pega's University Academic ProgramDocument11 pagesHotel Booking Application (Project) : Pega's University Academic ProgramSucharitha RametiNo ratings yet

- CC 1Document1 pageCC 1Sagar BarotNo ratings yet

- CC 3Document1 pageCC 3Sagar BarotNo ratings yet

- BS EN 1991-1-1:2002, BS EN 1993-1-1:2005 - Chequered Plate Design 3/14/2020Document88 pagesBS EN 1991-1-1:2002, BS EN 1993-1-1:2005 - Chequered Plate Design 3/14/2020MohMohkNo ratings yet

- Concrete Compression Test Report: 150X150X150 150X150X150 150X150X150 150X150X150 150X150X150 150X150X150Document3 pagesConcrete Compression Test Report: 150X150X150 150X150X150 150X150X150 150X150X150 150X150X150 150X150X150Okello StevenNo ratings yet

- High MastDocument16 pagesHigh MastIam VinitNo ratings yet

- Wang BoDocument5 pagesWang BodimasarchitechtureNo ratings yet

- Fiberglass Rebar Data SheetDocument2 pagesFiberglass Rebar Data SheetAlex CrispimNo ratings yet

- Compressive Strength of Concrete Cubes, (BS 1881 Part 116: 1983)Document3 pagesCompressive Strength of Concrete Cubes, (BS 1881 Part 116: 1983)Kasulumbay CosmasNo ratings yet

- STRENG FC 10 LC MC MEI 05 OkDocument15 pagesSTRENG FC 10 LC MC MEI 05 OkSurtiman Adhi FanjayaNo ratings yet

- GSW (Galvanized Steel Wire) ASTM A475Document2 pagesGSW (Galvanized Steel Wire) ASTM A475Vaza Firdaus100% (1)

- Kojex 1Document1 pageKojex 1Okello StevenNo ratings yet

- A Detail Study On Autoclave Aerated Concrete: International Research Journal of Engineering and Technology (IRJET)Document3 pagesA Detail Study On Autoclave Aerated Concrete: International Research Journal of Engineering and Technology (IRJET)Velmurugan Siva KamarajNo ratings yet

- 09sakthivelAMS65 68 2015 257 PDFDocument6 pages09sakthivelAMS65 68 2015 257 PDFSakthivelNo ratings yet

- 3.1 Research Flow ChartDocument23 pages3.1 Research Flow ChartHendri HermawanNo ratings yet

- GFRP RebarsDocument16 pagesGFRP Rebarsrajbir1001No ratings yet

- Netc DBMDocument34 pagesNetc DBMMorya RonakNo ratings yet

- Flakiness IndexDocument4 pagesFlakiness Indexmarkagaba004No ratings yet

- Archstruct 3Document33 pagesArchstruct 3Kyran Joeffer EsporlasNo ratings yet

- Test Kuat Tekan 350Document3 pagesTest Kuat Tekan 350erik tiblolaNo ratings yet

- 4.2 Bolt DesignDocument14 pages4.2 Bolt DesignbernabasNo ratings yet

- Hot Dipped Galvanized Welded Steel PipesDocument2 pagesHot Dipped Galvanized Welded Steel PipesMuthuKumarNo ratings yet

- Ucs Crushed SandDocument1 pageUcs Crushed SandMohammed SalhinNo ratings yet

- Polyester Double Braid: Tech SheetDocument2 pagesPolyester Double Braid: Tech SheetMARLA ALEJANDRA TORRES PEREZNo ratings yet

- Unbound MaterialsDocument3 pagesUnbound Materialsmadhav choudharyNo ratings yet

- Cement Testing Week No 37Document1 pageCement Testing Week No 37DNYANESHWAR PATILNo ratings yet

- Use of RHA CementDocument8 pagesUse of RHA CementTokay Moe ZNo ratings yet

- Test Certificate: (, Phone: 26751763 MillDocument1 pageTest Certificate: (, Phone: 26751763 MillQc QatarNo ratings yet

- RGU ENM 201 Wells Coursework-May2017 FinalDocument7 pagesRGU ENM 201 Wells Coursework-May2017 FinalEmenike Donald EjiejiNo ratings yet

- Bean BallsDocument31 pagesBean BallsYathish143No ratings yet

- ASTM A53 Schedule 40 and Schedule 80 Pipe DimensionsDocument11 pagesASTM A53 Schedule 40 and Schedule 80 Pipe DimensionsjohnmarbautistaNo ratings yet

- DEVI, OLYVIA, EDI - Pengaruh Penambahan Serat Kawat Bendhrat Terhadap Kuat Tekan Dan Kuat Tarik BetonDocument9 pagesDEVI, OLYVIA, EDI - Pengaruh Penambahan Serat Kawat Bendhrat Terhadap Kuat Tekan Dan Kuat Tarik BetonExcellenza Nafidzun AzzamNo ratings yet

- Test Report For Gabion Wire: Parameters ResultDocument1 pageTest Report For Gabion Wire: Parameters ResultmirwaisNo ratings yet

- Roko 09.01.2023-5Document1 pageRoko 09.01.2023-5Okello StevenNo ratings yet

- Strength Test ResultsDocument7 pagesStrength Test Resultsmpairwe cliffortNo ratings yet

- Multilock Plastic Pile SpecificationsDocument2 pagesMultilock Plastic Pile SpecificationsFritz NatividadNo ratings yet

- Tension - Test (ASTM A 615M) - ReportDocument3 pagesTension - Test (ASTM A 615M) - ReportNadira PervinNo ratings yet

- SSB 449Document1 pageSSB 449yudhisindrasNo ratings yet

- 7c. Spesifik Brosur Hal 33Document1 page7c. Spesifik Brosur Hal 33jimz armyNo ratings yet

- Mcgill Channels & SupportsDocument3 pagesMcgill Channels & SupportsAlan Magat SantosNo ratings yet

- Gaon Cable Catalogue (Eng.)Document54 pagesGaon Cable Catalogue (Eng.)harry jangNo ratings yet

- Pipe CatalogueDocument6 pagesPipe CatalogueirfanNo ratings yet

- Test Rate BUETDocument5 pagesTest Rate BUETEngr Swapan82% (11)

- BVI-29434-TR-593160Document1 pageBVI-29434-TR-593160Vikas SavantNo ratings yet

- Testing For Bending of WoodDocument6 pagesTesting For Bending of WoodPatrice Suerte FelipeNo ratings yet

- Pembangunan Jalan Tol Semarang-Batang SEKSI4&5: Aashto T 27 - 82 / Astm C. 33Document40 pagesPembangunan Jalan Tol Semarang-Batang SEKSI4&5: Aashto T 27 - 82 / Astm C. 33Budhi KurniawanNo ratings yet

- Test Results of Aggregate Impact Value: Lab IDDocument7 pagesTest Results of Aggregate Impact Value: Lab IDyoseph dejeneNo ratings yet

- Ball Cover TensileDocument1 pageBall Cover Tensileshalinda Anup RitigahapolaNo ratings yet

- Reading 1 PDFDocument10 pagesReading 1 PDFGabriela HuertaNo ratings yet

- Lab Report U1 (Workability)Document11 pagesLab Report U1 (Workability)SYaz WAniNo ratings yet

- Optimization of Machining Parameters in EDM Process Using Cast and Sintered Copper ElectrodesDocument11 pagesOptimization of Machining Parameters in EDM Process Using Cast and Sintered Copper Electrodesaji setioNo ratings yet

- Cmir 014 CorregidoDocument1 pageCmir 014 Corregidomario uzuriagaNo ratings yet

- FRP Rebar Data SheetDocument2 pagesFRP Rebar Data Sheetkevin smith100% (1)

- AL-Yarmouk University Department of Civil Engineering AL-Hijjawi Faculty Highway Laboratory / CE 444Document15 pagesAL-Yarmouk University Department of Civil Engineering AL-Hijjawi Faculty Highway Laboratory / CE 444Mohammed MigdadyNo ratings yet

- PolyesterDocument3 pagesPolyestermesattyNo ratings yet

- Sub: Testing of Concrete Block Samples Project:: SL No Particulars Amount in RupeesDocument5 pagesSub: Testing of Concrete Block Samples Project:: SL No Particulars Amount in RupeesSandeep KumarNo ratings yet

- Carbon Fibre Reinforced Polymer: Polymer Matrix Composites: Applica-TionsDocument29 pagesCarbon Fibre Reinforced Polymer: Polymer Matrix Composites: Applica-Tionsanis suhailiNo ratings yet

- GRP Furniture PipeDocument1 pageGRP Furniture PipeNurul LailyahNo ratings yet

- Plastic Concrete TestDocument8 pagesPlastic Concrete TestSlan ClanNo ratings yet

- BCE 2203 Computing For Civil Engineering Test I-Marking GuideDocument7 pagesBCE 2203 Computing For Civil Engineering Test I-Marking Guidemuhammedssebatindira3No ratings yet

- Group D AssigDocument3 pagesGroup D Assigmuhammedssebatindira3No ratings yet

- Mechanical Properties of Soils 1Document12 pagesMechanical Properties of Soils 1muhammedssebatindira3No ratings yet

- Aspects of Water and Waste Water QualitiesDocument48 pagesAspects of Water and Waste Water Qualitiesmuhammedssebatindira3No ratings yet

- Modbus TCP ScadaDocument22 pagesModbus TCP ScadaEmerson KleemNo ratings yet

- Annex 1 CJ2 Mechanical Self-Locking Operation Manual - For Reference OnlyDocument3 pagesAnnex 1 CJ2 Mechanical Self-Locking Operation Manual - For Reference OnlyAndré MartinsNo ratings yet

- Internet of Things A Comparative StudyDocument10 pagesInternet of Things A Comparative StudyِAl TuraihiNo ratings yet

- Zamil DY - Series PDFDocument23 pagesZamil DY - Series PDFgagokapalaNo ratings yet

- Empowerment TechnologiesDocument4 pagesEmpowerment Technologieskristoffer50% (6)

- Stop Light Switch CircuitDocument3 pagesStop Light Switch Circuitcelestino tuliaoNo ratings yet

- TM Midea VRF V8 Medium Static Pressure Duct UAE 20230608 V2Document23 pagesTM Midea VRF V8 Medium Static Pressure Duct UAE 20230608 V2mohamed.irfan.mepNo ratings yet

- RV 2SD 2SDB Mitsubishi Robot Standard Manual PDFDocument150 pagesRV 2SD 2SDB Mitsubishi Robot Standard Manual PDFMatheus OliveiraNo ratings yet

- WM4 User ManualDocument44 pagesWM4 User ManualpcatruongNo ratings yet

- Interview FormDocument4 pagesInterview FormBond JamesNo ratings yet

- Eden Jahmiel LeonardoDocument3 pagesEden Jahmiel LeonardoRanz AbadNo ratings yet

- Manoj. Madduri: Qualification Board/University Name of Institution Year of Passing AggregateDocument3 pagesManoj. Madduri: Qualification Board/University Name of Institution Year of Passing AggregateSita Ram RamisettyNo ratings yet

- Accounting and Financial Close - Group Ledger IFRS (1GA - FR) : Test Script SAP S/4HANA Cloud - 06-10-20Document56 pagesAccounting and Financial Close - Group Ledger IFRS (1GA - FR) : Test Script SAP S/4HANA Cloud - 06-10-20cricriAF33830No ratings yet

- DMRC Industrial Training ReportDocument35 pagesDMRC Industrial Training ReportPRERAK MATHURNo ratings yet

- Lesson10 ICT 0417Document25 pagesLesson10 ICT 0417thamalieariyarathnaNo ratings yet

- University of Gondar: Information Storage and Retrieval SystemDocument29 pagesUniversity of Gondar: Information Storage and Retrieval SystemAisha mNo ratings yet

- Icom IC 706 MKIIG Service MenuDocument2 pagesIcom IC 706 MKIIG Service MenurustyNo ratings yet

- Dire Dawa University Institution of Technology: Year: 4thDocument5 pagesDire Dawa University Institution of Technology: Year: 4thAnonymous nZo3uhY8uRNo ratings yet

- Apparel Manufacturing ProcessDocument27 pagesApparel Manufacturing ProcessGarima AgarwalNo ratings yet

- Basic Discussion On Pcie Configuration and EnumerationDocument16 pagesBasic Discussion On Pcie Configuration and EnumerationnazimNo ratings yet

- Time Frame D8R MidlifeDocument17 pagesTime Frame D8R MidlifeMaintenance PlannerNo ratings yet

- Force Copy Queries From One Info Provider To Another With Different StructureDocument11 pagesForce Copy Queries From One Info Provider To Another With Different StructureMohammed NaveedNo ratings yet

- DS - 30xa450Document3 pagesDS - 30xa450Leonardo Martinho DobrianskyjNo ratings yet

- ShipmentsDocument2 pagesShipmentsSaul ChampacNo ratings yet

- Commutation Failure Presentation - NewDocument8 pagesCommutation Failure Presentation - NewNaresh RamNo ratings yet

- Understanding Cisco Express Forwarding: Document ID: 47321Document5 pagesUnderstanding Cisco Express Forwarding: Document ID: 47321Nishant MishraNo ratings yet

- FA18 VI-EXTC-MJ2022 GradeDocument31 pagesFA18 VI-EXTC-MJ2022 GradenicO neeNo ratings yet