Professional Documents

Culture Documents

Sop Hydraulic Press Brake

Sop Hydraulic Press Brake

Uploaded by

Sudhan SudhanPowerTechOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sop Hydraulic Press Brake

Sop Hydraulic Press Brake

Uploaded by

Sudhan SudhanPowerTechCopyright:

Available Formats

HYDRAULIC PRESS BRAKE

DO NOT use this machine unless a teacher has instructed you in its safe

use and operation and has given permission

Safety glasses must be worn at all times in Long and loose hair must be

work areas. contained or restrained.

Appropriate protective footwear with Coveralls, protective clothing, or a

substantial uppers must be worn. workshop apron, is recommended.

Rings and jewellery must not be DO NOT wear large leather gloves

worn. when operating this machinery

PRE-OPERATIONAL SAFETY CHECKS

1. Ensure that all guards and safety devices are in position and secured.

2. Adjust all guards to minimum practicable clearances for the material to be pressed.

3. Note: any guards and safety devices should NEVER be removed, except for maintenance

purposes, and only by an authorised staff member.

4. Working parts should be well lubricated and all jaws, fingers, ‘V’ blocks and blades be free of

rust and other foreign matter.

5. Adjust the head rams (teacher only) to suit the material thickness.

6. Adjust and check that the ‘v’ forming blocks and/or knife blades are aligned correctly.

7. Be aware of any other personnel in the immediate vicinity and ensure the area is clear before

using this equipment.

8. Familiarise yourself with all electrical, hydraulic and mechanical operations and controls,

including the roving foot pedal control.

OPERATIONAL SAFETY CHECKS

1. Strictly only one operator is to use this heavy duty press brake, and, when necessary, with a

safety observer present.

2. Never use any press or pan brake to bend or fold beyond the capacity of the machine.

3. Ensure that both hands are positioned away from any possible pinch point e.g. clamping bar.

4. Particular preparation and caution is to be observed when bending rod, strap or spring steel.

5. This heavy duty press brake is likely to be fitted with infra-red safety beams or electronic

sensors to detect hazardous circumstances. If so, this machine should NOT operate if these

safety devices are breached in any way, either by materials or by the operator.

6. Never leave the machine in operational mode while unattended.

HOUSEKEEPING

1. Isolate all switches on completion. Leave machine and floor in a safe, clean and tidy state.

POTENTIAL HAZARDS

Entanglement and entrapment Striking and shearing

n Pinch, crush and squash Manual handling

Electrical and hydraulic components Eye injury

Date of last review ______________ Signature ______________________

Reviewed July 2018 V5 Department of Education

Uncontrolled when printed. Organisational Safety and Wellbeing

You might also like

- SDS Powerweld S12Document6 pagesSDS Powerweld S12azreen96.worksNo ratings yet

- Scratch WorksheetDocument4 pagesScratch WorksheetGazal Bansal91% (11)

- Product Name Product Number Cantidad: Fiberclamp, 3Fiber-3Powercable, 10PcsDocument1 pageProduct Name Product Number Cantidad: Fiberclamp, 3Fiber-3Powercable, 10PcsSuhailer BoscanNo ratings yet

- Plywood Material Safety Data Sheet For MR Plywood PDFDocument4 pagesPlywood Material Safety Data Sheet For MR Plywood PDFNirvana NircisNo ratings yet

- Forklift TruckDocument1 pageForklift TruckShazaley AbdullahNo ratings yet

- Brahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysisDocument2 pagesBrahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysiszebmechNo ratings yet

- Portable Puller 4 Ton: Set Up and Operating InstructionsDocument12 pagesPortable Puller 4 Ton: Set Up and Operating InstructionstheimproviserNo ratings yet

- Sop Hydraulic Punch and ShearDocument1 pageSop Hydraulic Punch and ShearBorislav VulićNo ratings yet

- Milling Machine SopDocument1 pageMilling Machine SopAizrul ShahNo ratings yet

- PB - D-Type DecanterDocument24 pagesPB - D-Type DecanterShark1971100% (1)

- SP-091-C CNC Router SOPDocument1 pageSP-091-C CNC Router SOPBorislav VulićNo ratings yet

- Sop Drills Screwdrivers CordlessDocument1 pageSop Drills Screwdrivers CordlessSravan CholeteNo ratings yet

- Mitre SawDocument1 pageMitre Sawapi-534238122No ratings yet

- Milling MachineDocument1 pageMilling MachineFikri Maulana100% (1)

- SWP Metal Cutting Guillotine AS525Document2 pagesSWP Metal Cutting Guillotine AS525Riddhi SarvaiyaNo ratings yet

- Angle Grinder SOPDocument1 pageAngle Grinder SOPAek JayNo ratings yet

- Metal LatheDocument1 pageMetal LatheNibhaNo ratings yet

- Forklift Truck SopDocument1 pageForklift Truck SopGyanendra Narayan NayakNo ratings yet

- Sop Welder TigDocument2 pagesSop Welder TigShahid Raza100% (1)

- SOP For Drill PressDocument1 pageSOP For Drill Press5am. exeNo ratings yet

- Sop Drill Electric HandDocument2 pagesSop Drill Electric HandLOCAL ExplorerNo ratings yet

- Shop Safety Safe Work Procedure DRILL PRESSDocument1 pageShop Safety Safe Work Procedure DRILL PRESSTamoy CooreNo ratings yet

- Forklift RADocument5 pagesForklift RAFachri HidayatNo ratings yet

- SP-020-B Electrically Powered Hand Tools SOPDocument1 pageSP-020-B Electrically Powered Hand Tools SOPDeon Pillay100% (1)

- Surface Grinding Machine: Standard Operating ProcedureDocument1 pageSurface Grinding Machine: Standard Operating ProcedureAzreen ZainolNo ratings yet

- Earth Compactor Daily Check ListDocument2 pagesEarth Compactor Daily Check ListpjosesmNo ratings yet

- Gas Cutting SetDocument1 pageGas Cutting SetProjects DepartmentNo ratings yet

- Safe Operating Procedure: Pinch PointsDocument1 pageSafe Operating Procedure: Pinch PointsAndri IrawanNo ratings yet

- Genie Superlift SOP 003Document27 pagesGenie Superlift SOP 003Mauricio SantanaNo ratings yet

- SWP Welder Gas Metal Arc AS560Document2 pagesSWP Welder Gas Metal Arc AS560patelkamlesh092No ratings yet

- RA - SandblastingDocument2 pagesRA - Sandblasting721917114 47No ratings yet

- Confined Space PlanDocument25 pagesConfined Space PlanPokiko MikotoNo ratings yet

- SWP Grinder Bench AS520Document1 pageSWP Grinder Bench AS520Tosif AliNo ratings yet

- Safe Work Procedure in Cold SawDocument1 pageSafe Work Procedure in Cold SawCyril AngkiNo ratings yet

- 16 Tractor Inspection ChecklistDocument1 page16 Tractor Inspection ChecklistKoneti JanardhanaraoNo ratings yet

- Working at Heights Checklist-TCNDocument2 pagesWorking at Heights Checklist-TCNYuli AriyonoNo ratings yet

- Safe Operating Procedure of Motor BikeDocument4 pagesSafe Operating Procedure of Motor BikeTafadzwaNo ratings yet

- Electrical SafetyDocument27 pagesElectrical Safetyadeeb zahidNo ratings yet

- Toolbox Training Session - Harness and LanyardDocument3 pagesToolbox Training Session - Harness and LanyardSarah AjodhaNo ratings yet

- 5 - Hand Trucks & Dollies: Safety Training: Eh&S - MgaDocument2 pages5 - Hand Trucks & Dollies: Safety Training: Eh&S - MgaDaniel MihailaNo ratings yet

- My Report 2 1Document6 pagesMy Report 2 1Tariq AkhtarNo ratings yet

- Standard Operating Procedure Welding machine-MIG: PedestalDocument2 pagesStandard Operating Procedure Welding machine-MIG: PedestalKranthi Kumar ReddyNo ratings yet

- Visitor Instruction PDFDocument1 pageVisitor Instruction PDFRajib ChatterjeeNo ratings yet

- SWP Buffing Machine - AS506Document2 pagesSWP Buffing Machine - AS506NOOR DIANA KHAIRUDDINNo ratings yet

- Belt & Orbital Sander PDFDocument2 pagesBelt & Orbital Sander PDFcityofdarwingisNo ratings yet

- H&S Meeting Minutes - TemplateDocument5 pagesH&S Meeting Minutes - Templategrant100% (1)

- !drilling Machine Geared Head InstructionDocument5 pages!drilling Machine Geared Head InstructionTiago PaivaNo ratings yet

- Camp Inspection ReportDocument4 pagesCamp Inspection ReportgkNo ratings yet

- Grinding Machine Check ListDocument4 pagesGrinding Machine Check Listjignesh sutariyaNo ratings yet

- Day5 Delivery WAH Management Training.Document88 pagesDay5 Delivery WAH Management Training.MarthaNo ratings yet

- Hand and Power Tools Safety ExaminationDocument21 pagesHand and Power Tools Safety ExaminationSharon GonzalezNo ratings yet

- F-Sp-Hse06-01 Rev 03 Hira NewDocument14 pagesF-Sp-Hse06-01 Rev 03 Hira Newvishal bailurNo ratings yet

- Compulsory Ppe As Needed Ppe: Safe Operating Procedures SOP 02 - Bench GrinderDocument2 pagesCompulsory Ppe As Needed Ppe: Safe Operating Procedures SOP 02 - Bench GrinderMuhammad Oji L100% (1)

- 09-Safety Training Attendance SheetDocument1 page09-Safety Training Attendance SheetSainu Kalathingal0% (1)

- MSDS - Asada Threading Oiil Red - ENDocument7 pagesMSDS - Asada Threading Oiil Red - ENnghiaNo ratings yet

- Sand Blasting and Painting Rescue Plan: in The Event of An Emergency in TanksDocument1 pageSand Blasting and Painting Rescue Plan: in The Event of An Emergency in TanksGiorgi KOGOSHVILINo ratings yet

- DailyCranePre OpChecklist PDFDocument1 pageDailyCranePre OpChecklist PDFPablo Hidalgo ValenzuelaNo ratings yet

- Pera JackhammerDocument7 pagesPera Jackhammerjumansyahamid1988No ratings yet

- Sop Guillotine Light Sheet MetalDocument1 pageSop Guillotine Light Sheet MetalSudhan SudhanPowerTechNo ratings yet

- Sop Lathe MetalDocument1 pageSop Lathe MetalSales Creative EngineeringNo ratings yet

- Sop GrinderDocument1 pageSop Grinderafrin JalgaonkarNo ratings yet

- Core Java NotesDocument240 pagesCore Java NotesRavi Balusu100% (5)

- Design and Implementation of Coconut Maturity Prediction System Based On Naïve Bayes Classification Algorithm Using Arduino and A Sound SensorDocument10 pagesDesign and Implementation of Coconut Maturity Prediction System Based On Naïve Bayes Classification Algorithm Using Arduino and A Sound SensorInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Java™ Platform, Enterprise Edition 7 (Java EE 7) Web Profile SpecificationDocument20 pagesJava™ Platform, Enterprise Edition 7 (Java EE 7) Web Profile SpecificationRishi RaiNo ratings yet

- The Ultimate Guide To IBM Internships and IBM Extreme Blue - 2022 UpdateDocument15 pagesThe Ultimate Guide To IBM Internships and IBM Extreme Blue - 2022 UpdateSephiwe XabaNo ratings yet

- My LearningDocument6 pagesMy LearningArthur AndradeNo ratings yet

- ETIReport G7Document5 pagesETIReport G7darshanawale02No ratings yet

- A Comparative Study of Mixed-Integer Linear Programming and Genetic Algorithms For Solving Binary ProblemsDocument5 pagesA Comparative Study of Mixed-Integer Linear Programming and Genetic Algorithms For Solving Binary Problems1. b3No ratings yet

- Pintle Engine PDFDocument23 pagesPintle Engine PDFFahad AliNo ratings yet

- Quaid-E-Awam University: "Say No To Corruption"Document5 pagesQuaid-E-Awam University: "Say No To Corruption"Agha Khan DurraniNo ratings yet

- GC 4 Test I and IIDocument5 pagesGC 4 Test I and IIyihesakNo ratings yet

- Cleansheet Cheats For All ExamsDocument8 pagesCleansheet Cheats For All ExamsNee mamaNo ratings yet

- IoT ArchitectureDocument4 pagesIoT ArchitectureJaafar OmarNo ratings yet

- Show Attend and TellDocument10 pagesShow Attend and Tellbhavishya mittalNo ratings yet

- Liangqu Long, Xiangming Zeng Beginning Deep Learning With TensorFlowDocument727 pagesLiangqu Long, Xiangming Zeng Beginning Deep Learning With TensorFlowAnahi RomoNo ratings yet

- Rtu PDFDocument13 pagesRtu PDFKhushnoodNo ratings yet

- HPCL - GEC - C - EL - 014 - Rev.0B - ELECTRICAL SOQDocument10 pagesHPCL - GEC - C - EL - 014 - Rev.0B - ELECTRICAL SOQbecpavanNo ratings yet

- UNIT-II Notes Java ScriptDocument30 pagesUNIT-II Notes Java ScriptkrishnaNo ratings yet

- BH Session Task 1Document4 pagesBH Session Task 1RajNo ratings yet

- Stability of Slope Reinforced With Soil Nails: Project SettingsDocument7 pagesStability of Slope Reinforced With Soil Nails: Project SettingsMuhammad AfrasiyabNo ratings yet

- Manitowoc 8500-1 Parts Manual PDFDocument1,046 pagesManitowoc 8500-1 Parts Manual PDFnamduong368100% (1)

- Introduction To Control Systems 1580158626Document421 pagesIntroduction To Control Systems 1580158626NahlaNo ratings yet

- Pilih Jawapan Yang Terbaik Untuk Melengkapkan Ayat Berikut.: Section A Questions 1 - 6Document10 pagesPilih Jawapan Yang Terbaik Untuk Melengkapkan Ayat Berikut.: Section A Questions 1 - 6Asmohaina MohamedNo ratings yet

- Demu BogieDocument41 pagesDemu BogieLove TodkarNo ratings yet

- Digital Marketing GuideDocument17 pagesDigital Marketing Guidetejaswini.sahyadreesofttechNo ratings yet

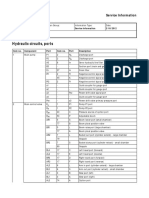

- Hydraulic Circuits, Ports: Service InformationDocument8 pagesHydraulic Circuits, Ports: Service InformationNaing Min HtunNo ratings yet

- RAL & British Standard Colour Charts PDFDocument5 pagesRAL & British Standard Colour Charts PDFMohamed NouzerNo ratings yet

- V6 User Manual - PK+BJDocument59 pagesV6 User Manual - PK+BJpetersolarteNo ratings yet