Professional Documents

Culture Documents

Hydraulic System For Bucket Wheel-Min

Hydraulic System For Bucket Wheel-Min

Uploaded by

sivasakti chp2Copyright:

Available Formats

You might also like

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Blasting and Painting Inspection and Test PlanDocument3 pagesBlasting and Painting Inspection and Test PlanNnamdi Amadi80% (5)

- Dept of WR., Govt. of OdhishaDocument3 pagesDept of WR., Govt. of OdhishaNaveen NagisettiNo ratings yet

- DISI-QA-ITPG-ME-MS-004 Rev 0, ITP For Field Application For External Heat-Shrinkable Coating of Steel Pipe Fitting and JointsDocument5 pagesDISI-QA-ITPG-ME-MS-004 Rev 0, ITP For Field Application For External Heat-Shrinkable Coating of Steel Pipe Fitting and JointsJamal Budeiri0% (1)

- Cm-Hot:hem F 471 Trr-4-w Irdi4-Br: Standard Specification FOR Air Conditioning SystemDocument42 pagesCm-Hot:hem F 471 Trr-4-w Irdi4-Br: Standard Specification FOR Air Conditioning SystemHriday AgarwalNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Svensk Standard SS-EN 13813: Fastställd 2002-10-25 Utgåva 1Document11 pagesSvensk Standard SS-EN 13813: Fastställd 2002-10-25 Utgåva 1Arvin Bhurtun100% (1)

- GETDocument688 pagesGETAya Jibo100% (1)

- 18.aph Gude Bearing B-Min-MinDocument5 pages18.aph Gude Bearing B-Min-MinAbhishek KumarNo ratings yet

- QAP Seamless PipeDocument2 pagesQAP Seamless Pipechetan85No ratings yet

- AB216Document1 pageAB216Amol PhadaleNo ratings yet

- Control Plan - Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Document4 pagesControl Plan - Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Himanshu MishraNo ratings yet

- AB11Document1 pageAB11Amol PhadaleNo ratings yet

- Lbe Oil Engine 250823Document1 pageLbe Oil Engine 250823yusufakbar55No ratings yet

- AB21Document1 pageAB21Amol PhadaleNo ratings yet

- AB067Document1 pageAB067Amol PhadaleNo ratings yet

- Tection Global 15W - 40Document2 pagesTection Global 15W - 40carmaNo ratings yet

- TDS 4241.67 Eng1Document2 pagesTDS 4241.67 Eng1lrtdNo ratings yet

- BSL AppNote RFM90 T Refractometer ASTM D 2140 en EN5Document4 pagesBSL AppNote RFM90 T Refractometer ASTM D 2140 en EN5seringwelskiNo ratings yet

- Asme Sec Ix AWS API ASME B 31.8Document25 pagesAsme Sec Ix AWS API ASME B 31.8smdriyazbashaNo ratings yet

- Updated Standard Manufacturing Quality Plan For Battery ChargersDocument4 pagesUpdated Standard Manufacturing Quality Plan For Battery ChargersAbhilash KumarNo ratings yet

- AB241Document1 pageAB241Amol PhadaleNo ratings yet

- PDS en-MY 20220811Document2 pagesPDS en-MY 20220811MUHAMMAD AMIR BIN RASIDNo ratings yet

- DETROITDIESELC93 K 214 SpecfinalDocument11 pagesDETROITDIESELC93 K 214 Specfinalfrancisco penaNo ratings yet

- Inspection Checklist: S.No Components Class Type of Check Quantum of CheckDocument8 pagesInspection Checklist: S.No Components Class Type of Check Quantum of CheckCheeragNo ratings yet

- Public Health and Municipal Engineering Department - NelloreDocument3 pagesPublic Health and Municipal Engineering Department - Nellorejuliyet strucNo ratings yet

- Everest 68 Synthetic Refrigeration Lubricant: Data SheetDocument3 pagesEverest 68 Synthetic Refrigeration Lubricant: Data SheetPhan Thiện HảoNo ratings yet

- 80mm Zigzag MTCDocument1 page80mm Zigzag MTCQAQC ZFNo ratings yet

- Saudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 3-Jul-18 CPDocument2 pagesSaudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 3-Jul-18 CPkarthi51289No ratings yet

- QAP Check ListDocument1 pageQAP Check Listbed passNo ratings yet

- PT Fuchs Lubricants (Arrow Asia-Aldaco Citrajaya) - Nissan-Samp PDFDocument1 pagePT Fuchs Lubricants (Arrow Asia-Aldaco Citrajaya) - Nissan-Samp PDFpinot san92No ratings yet

- SATR-X-3101 Rev 7Document3 pagesSATR-X-3101 Rev 7mustafa abdelshafiNo ratings yet

- Castrol Manual EP 80W-90: DescriptionDocument1 pageCastrol Manual EP 80W-90: Descriptionvicky kNo ratings yet

- Saudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 31-Mar-19 CPDocument2 pagesSaudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 31-Mar-19 CPAwais NaeemNo ratings yet

- Inspection Test PlanDocument141 pagesInspection Test PlanKoya ThangalNo ratings yet

- Technical Recommendation Form: Executed by Inspected by Approved byDocument3 pagesTechnical Recommendation Form: Executed by Inspected by Approved byMuhammad Faris NaufalNo ratings yet

- Saudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 24-Jul-18 CPDocument2 pagesSaudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 24-Jul-18 CPnadeem shaikhNo ratings yet

- Staircases & HandrailsDocument2 pagesStaircases & HandrailsPavul RajNo ratings yet

- PIPING R04 101022 DraftDocument2 pagesPIPING R04 101022 DraftPavul RajNo ratings yet

- Bpxe AbjfycDocument2 pagesBpxe AbjfycMuhNo ratings yet

- Oil Analysis Report: Power Mech Projects LTD Site: 2x600 MW CEPL-Tuticorin-Tamil NaduDocument11 pagesOil Analysis Report: Power Mech Projects LTD Site: 2x600 MW CEPL-Tuticorin-Tamil Nadudevi JammanaNo ratings yet

- Steam Trap QAPDocument2 pagesSteam Trap QAPPavul RajNo ratings yet

- CP WasherDocument2 pagesCP WasherMURALIDHRANo ratings yet

- Gathampur QapDocument3 pagesGathampur Qapaceengineering08No ratings yet

- Satr A 2001Document7 pagesSatr A 2001Naveed ShahNo ratings yet

- Everest 220 Synthetic Refrigeration Lubricant: Data SheetDocument3 pagesEverest 220 Synthetic Refrigeration Lubricant: Data SheetPhan Thiện HảoNo ratings yet

- Autran MBX-pds-EngDocument3 pagesAutran MBX-pds-EngVusal HasanovNo ratings yet

- PisssDocument1 pagePisssMie IkanNo ratings yet

- Multiplant 10W30Document2 pagesMultiplant 10W30carmaNo ratings yet

- Key To Abbreviations: Ac - Acceptable Qu - Questionable Un - Unacceptable Rs - ResampleDocument2 pagesKey To Abbreviations: Ac - Acceptable Qu - Questionable Un - Unacceptable Rs - ResampleChristianNo ratings yet

- SUPPORT (Scaph, Ducting) QAP R02 080822Document2 pagesSUPPORT (Scaph, Ducting) QAP R02 080822Pavul RajNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Data Book de BombaDocument7 pagesData Book de BombaSharon Botiny100% (1)

- Elite Cosmos A5 b5 5w-30 enDocument1 pageElite Cosmos A5 b5 5w-30 enAnderson MatioliNo ratings yet

- Tensile Test Report: CMSS/18/556 CMSS/TT/18/455 30-04-2018 03-05-2018Document12 pagesTensile Test Report: CMSS/18/556 CMSS/TT/18/455 30-04-2018 03-05-2018nareshNo ratings yet

- Cepsa Supermultigrado SHPD 15W40Document1 pageCepsa Supermultigrado SHPD 15W40RamonNo ratings yet

- Vp-15-109-001-A01-P-237-004abc-C-010 Performance Curve For PumpDocument3 pagesVp-15-109-001-A01-P-237-004abc-C-010 Performance Curve For PumpRicardo NapitupuluNo ratings yet

- EPX RangeDocument2 pagesEPX RangecarmaNo ratings yet

- QAP-NI-IJ-346-21 R1-MS New Eoan AssociatesDocument2 pagesQAP-NI-IJ-346-21 R1-MS New Eoan AssociatesParampreet singhNo ratings yet

- Piping Qap R03 250822Document2 pagesPiping Qap R03 250822Pavul RajNo ratings yet

- Op13 - Engine Oil ChangeDocument1 pageOp13 - Engine Oil ChangeAmirSyafiqNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- SLEWDocument5 pagesSLEWsivasakti chp2No ratings yet

- Acti9 Itl A9c34811Document3 pagesActi9 Itl A9c34811sivasakti chp2No ratings yet

- LED Nomenclature of MCC MICOMDocument9 pagesLED Nomenclature of MCC MICOMsivasakti chp2No ratings yet

- CHP ProtectionDocument50 pagesCHP Protectionsivasakti chp2No ratings yet

- Axial NP B05 SpecificationDocument2 pagesAxial NP B05 Specificationsivasakti chp2No ratings yet

- GID-208-ME-LCN-XS-51302 R1 Info (GA - INVERTED BUCKET STEAM TRAP PT25-IBR)Document3 pagesGID-208-ME-LCN-XS-51302 R1 Info (GA - INVERTED BUCKET STEAM TRAP PT25-IBR)sivasakti chp2No ratings yet

- MCC SLD DetailsDocument12 pagesMCC SLD Detailssivasakti chp2No ratings yet

- ABB - VFD - Common - Parameters SettingsDocument7 pagesABB - VFD - Common - Parameters Settingssivasakti chp2No ratings yet

- Notice 1 - List of Candidates For Personal Discussion-LabDocument4 pagesNotice 1 - List of Candidates For Personal Discussion-Labsivasakti chp2No ratings yet

- LT Motor Drive and Nondrive - 02.02.2024Document1 pageLT Motor Drive and Nondrive - 02.02.2024sivasakti chp2No ratings yet

- Ht. Drive End - 02.02.2024Document1 pageHt. Drive End - 02.02.2024sivasakti chp2No ratings yet

- Customer - GID-208-CI-EAC-BS-54131 - R2 - PF Control PhilosophyDocument9 pagesCustomer - GID-208-CI-EAC-BS-54131 - R2 - PF Control Philosophysivasakti chp2No ratings yet

- Customer - GID - 208-CI-EAU-BS-54165 REV-2 - CSU Control PhilosophyDocument7 pagesCustomer - GID - 208-CI-EAU-BS-54165 REV-2 - CSU Control Philosophysivasakti chp2No ratings yet

- GID-208-CI-EC-BS-4040 R4 CHP Control PhilosophyDocument17 pagesGID-208-CI-EC-BS-4040 R4 CHP Control Philosophysivasakti chp2No ratings yet

- Design Considerations For A Gear DriveDocument17 pagesDesign Considerations For A Gear Driveمحمدفیضان چوہدریNo ratings yet

- Improve Pumps Performance With Composite Wear ComponentsDocument0 pagesImprove Pumps Performance With Composite Wear ComponentsDelfinshNo ratings yet

- 26-Hardox 600 The - Ultimate Wear Plate PDFDocument4 pages26-Hardox 600 The - Ultimate Wear Plate PDFlazaroccsNo ratings yet

- GB TP0500 LRDocument20 pagesGB TP0500 LRGristarNo ratings yet

- Microtest MT Pin-On-Disk TribometerDocument8 pagesMicrotest MT Pin-On-Disk TribometerMIGUEL LOPEZNo ratings yet

- Understanding Dental Wear: Emmanuel d'INCAU, Paul SAULUEDocument19 pagesUnderstanding Dental Wear: Emmanuel d'INCAU, Paul SAULUERaghav PratapNo ratings yet

- Bucket Teeth AdaptersDocument36 pagesBucket Teeth AdaptersSzilárd S100% (1)

- Offer For Meat Equipments (Pr-8, Fessman Smoke House, G330A and TC-350)Document4 pagesOffer For Meat Equipments (Pr-8, Fessman Smoke House, G330A and TC-350)Esther KashungNo ratings yet

- Materials of Construction ConstructionDocument6 pagesMaterials of Construction ConstructionIlkuNo ratings yet

- 1Document16 pages1Saurabh PatelNo ratings yet

- Flowshield LXP System Data Sheet (en-GB)Document2 pagesFlowshield LXP System Data Sheet (en-GB)nblinoNo ratings yet

- Thermal Spray Powders - March 2019 - 2438HOGDocument36 pagesThermal Spray Powders - March 2019 - 2438HOGRavi ViswanadhaNo ratings yet

- Diatest 9Document86 pagesDiatest 9tungNo ratings yet

- Wartsila 32 Bearing AssessmentDocument8 pagesWartsila 32 Bearing AssessmentVito Digeo100% (2)

- MECH4428-practice 1-Metal Corrosion PDFDocument19 pagesMECH4428-practice 1-Metal Corrosion PDFjasmine97No ratings yet

- WA Hardlite™: Ultra-Thin Composite WearplatesDocument5 pagesWA Hardlite™: Ultra-Thin Composite WearplatesFernando MilmanNo ratings yet

- 2017 - Ge - Etal - The Impact Wear-Resistance Enhancement Mechanism of Medium Manganese Steel and Its Applications in Mining MachinesDocument8 pages2017 - Ge - Etal - The Impact Wear-Resistance Enhancement Mechanism of Medium Manganese Steel and Its Applications in Mining MachinesDiego MartinezNo ratings yet

- Persta Gate Valves PDFDocument52 pagesPersta Gate Valves PDFSalah InhgaruoNo ratings yet

- BECHEM High Performance Chain Oils 2015 GBDocument7 pagesBECHEM High Performance Chain Oils 2015 GBduy tanNo ratings yet

- GREASEDocument12 pagesGREASEKarthikeyanNo ratings yet

- Study On Mechanical and Wear Properties of Al 7075-Al2O3-Graphite Hybrid CompositesDocument8 pagesStudy On Mechanical and Wear Properties of Al 7075-Al2O3-Graphite Hybrid CompositesSrijan PrabhakarNo ratings yet

- Wear and RepairDocument12 pagesWear and RepairmtonellyNo ratings yet

- Belt Conveyor Idler LifeDocument19 pagesBelt Conveyor Idler LifehimanshumalNo ratings yet

- Chapter - 06 - EN - Edizione 07-2008Document52 pagesChapter - 06 - EN - Edizione 07-2008Waleed LemsilkhiNo ratings yet

- Premalube XtremeDocument2 pagesPremalube Xtremerobertoalfaro492023No ratings yet

- Influence of Parameters and Wear Analysis of Aluminium-Bronze (Cual8Fe3) by Taguchi MethodDocument13 pagesInfluence of Parameters and Wear Analysis of Aluminium-Bronze (Cual8Fe3) by Taguchi MethodAvinash ChandraNo ratings yet

- Handbook For Failure AnalysisDocument2 pagesHandbook For Failure AnalysisLilian RoseNo ratings yet

- Vishwakarma Institute of TechnologyDocument42 pagesVishwakarma Institute of TechnologyAnkush RatnaparkheNo ratings yet

Hydraulic System For Bucket Wheel-Min

Hydraulic System For Bucket Wheel-Min

Uploaded by

sivasakti chp2Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydraulic System For Bucket Wheel-Min

Hydraulic System For Bucket Wheel-Min

Uploaded by

sivasakti chp2Copyright:

Available Formats

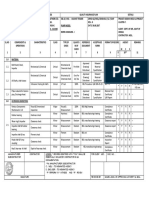

MVS ACMEI Technologies Pvt Ltd

LAB REPORT ON IN-SERVICE LUBE CM ANALYSIS

PROGNOSTIC EXPERTS IN FLUID TECHNOLOGIES

Client's Name : ODISHA POWER GENERATION CO.LTD (OPGC-II) Client's Plant Location : BANHARPALI

MACHINE

Job Details Related to Client Equipment Information CONDITION

Department/Equipment Hydraulic System for

Coal Handling Plant Name of Equipment

Location Bucket Wheel

Type of Job ARC Equipment Code of Client

Sample Sl.No 143 Function of Equipment

Sample Date Nov 30, 2019 Oil Sample Taken from Tank Top

Sample Received at Lab Dec 07, 2019 Oil/Grease Operating Temp

Lab Sent Report Dec 30, 2019 Last Date of Major Failure

LUBRICANT

Additional Information for proper Analysis & Recommendation CONDITION

Type of Oil/Grease Hydraulic System Type of Gear

Oil Viscosity Grade SS 100 Type of Bearing

Grease Grade Filter Mesh Size

Top-Up Last Date Oil Pr. Across Filter

Replacement Date Motor KW Rating

Heat Exchanger Motor RPM

Sump/Tank/MOT

255 L

Capacity (Litres)

SNAP-SHOT - IN-SERVICE LUBE CONDITION MONITORING STATUS (CURRENT + PREVIOUS THREE) :

Current

Previous Three Samples

Type of Analysis & Test Method/ Sample

Testing Parameters

(UOM) ASTM Ref. Sample Dated Sample Dated Sample Dated Sample Dated

Nov 30, 2019

Quantitative Analysis Physio-Chemical Analysis

Kinematic Viscosity

centiStoke(cSt) ASTM D-445 67.5 A

@400 C

Kinematic Viscosity

centiStoke(cSt) ASTM D-445

@1000 C

Viscosity Index Ratio ASTM D 2270

ASTM

TAN mgKOH/gm 0.29 N

D-664/974

ASTM

TBN mgKOH/gm

D-2896/4739

ASTM

Moisture Content Parts Per Million(PPM) 433.5 N

D-6304/1744

Quantitative Analysis Cleanliness Level

NAS 1638 Class 8N

ISO 4406 Level

Qualitative Analysis Wear Debris Analysis ASTM D7690

Machine Condition

Analytical Ferrography 3.00 N

Index

Abbrevations : N-Normal C-Caution A-Alert

CREATING VALUE WITH INTEGRATED RELIABILITY MAINTENANCE SERVICES

MVS ACMEI TECHNOLOGIES PVT.LTD., Mail: oilcm@acmeirm.com, Web: www.mvsgroup.co.in

Regd Office : #31, Leeven Heights, Jubilee Enclave, Madhapur Hyderabad-500081,Telangana

MVS ACMEI Technologies Pvt Ltd

LAB REPORT ON IN-SERVICE LUBE CM ANALYSIS

PROGNOSTIC EXPERTS IN FLUID TECHNOLOGIES

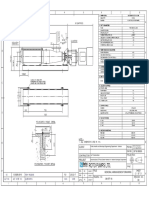

Name of Equipment Equipment Code of Client Lab Sample Code Oil Viscosity/Grease Grade

Hydraulic System for Bucket

CC118S0142V2 SS 100

Wheel

Analytical Ferrography / Wear Debris Analysis

MACHINE CONDITION INDEX : 3.00 Range & Limit : 7.00 - 11.00 Normal

TYPE OF WEAR

SLNO N N-F F F-M M M-H H FERROGRAM - 500X

PARTICLES

1 Normal Rubbing Wear ✔

2 Fatigue Wear ✔

3 Spheres ✔

4 Laminar Particles ✔

5 Severe Sliding Wear ✔

6 Catastrophic Wear ✔

7 Cutting Wear Particles ✔

8 Red Oxide ✔

9 Dark Metal Oxide ✔

10 Black Oxide ✔

11 Non-Ferrous Metallic ✔

12 Non-Metallic Crystals ✔

Non-Metallic

13 ✔

Amorphous

14 Friction Polymers ✔

15 Fibers ✔

16 Copper Wear Debris ✔

Legend: N=NONE (0); N-F=NON to FEW (0.5); F=FEW (1); F-M=FEW to MODERATE (1.5); M=MODERATE (2); M-H=MODERATE to HEAVY (2.5); H=HEAVY (3)

Observations

Normal rubbing wear particles observed rated None to Few.

Non Metallic crystal (sand/dirt) particles are observed rated Few.

Black oxides are observed was rated None to Few.

Recommendations

Maintain Normal Operation.

CREATING VALUE WITH INTEGRATED RELIABILITY MAINTENANCE SERVICES

MVS ACMEI TECHNOLOGIES PVT.LTD., Mail: oilcm@acmeirm.com, Web: www.mvsgroup.co.in

Regd Office : #31, Leeven Heights, Jubilee Enclave, Madhapur Hyderabad-500081,Telangana

MVS ACMEI Technologies Pvt Ltd

LAB REPORT ON IN-SERVICE LUBE CM ANALYSIS

PROGNOSTIC EXPERTS IN FLUID TECHNOLOGIES

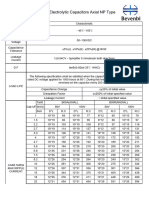

Name of Equipment Equipment Code of Client Lab Sample Code Oil Viscosity/Grease Grade

Hydraulic System for Bucket Wheel CC118S0142V2 SS 100

Physio-Chemical Analysis of In-Service Lube Oil Properties

OIL STATUS Alert

TEST RESULT RANGE & LIMIT CONDITION STANDARD

Viscosity @ 400 C in cSt 67.5 92.50 - 110.00 Alert ASTM-D445

Viscosity @ 1000 C in cSt ASTM-D445

Moisture in PPM 433.5 500.00 Normal (KF) ASTM-D6304/1744

TAN mgKOH/gm 0.29 0.00 - 1.50 Normal ASTM-D664/974

O.E.M Recommendation can also be followed for Turbine Oil(in particular)

O.E.M Recommendation to be referred for Designal consideration.

Lube oil Properties Observations

Viscosity test results are found Low, Remaining test results are found Normal.

In-Service Lube Oil Contamination Level Analysis

Particle Count NAS 1638 System Standard

Contamination Status Normal

Particle Size Range No. of Particles/100ml

2-5 Microns

5-15 Microns 36792

15-25 Microns 1000

25-50 Microns 155

50-100 Microns 101

>100 Microns 10

System NAS Level Class : 8

In-Service Lube Oil Contamination Level Observations

Particle Count NAS test results are found Normal.

Trending for Physio-Chemical Analysis

Recommendations

Continue to Monitor.

CREATING VALUE WITH INTEGRATED RELIABILITY MAINTENANCE SERVICES

MVS ACMEI TECHNOLOGIES PVT.LTD., Mail: oilcm@acmeirm.com, Web: www.mvsgroup.co.in

Regd Office : #31, Leeven Heights, Jubilee Enclave, Madhapur Hyderabad-500081,Telangana

MVS ACMEI Technologies Pvt Ltd

LAB REPORT ON IN-SERVICE LUBE CM ANALYSIS

PROGNOSTIC EXPERTS IN FLUID TECHNOLOGIES

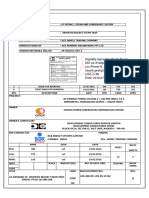

Analytical Ferrography Trends

Note :

Our in-Service Lube Condition Monitoring Report Observations and Recommendations are limited to Scope of Analysis offered in the Client prescribed AMC

Contract/Service Call W.O., Sample Collection Scope, extent of Oil & Equipment Data/Information furnished by Client as desired in our Report Format and/also

corrective action taken as per our earlier Reports (as the case may be).

CREATING VALUE WITH INTEGRATED RELIABILITY MAINTENANCE SERVICES

MVS ACMEI TECHNOLOGIES PVT.LTD., Mail: oilcm@acmeirm.com, Web: www.mvsgroup.co.in

Regd Office : #31, Leeven Heights, Jubilee Enclave, Madhapur Hyderabad-500081,Telangana

You might also like

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Blasting and Painting Inspection and Test PlanDocument3 pagesBlasting and Painting Inspection and Test PlanNnamdi Amadi80% (5)

- Dept of WR., Govt. of OdhishaDocument3 pagesDept of WR., Govt. of OdhishaNaveen NagisettiNo ratings yet

- DISI-QA-ITPG-ME-MS-004 Rev 0, ITP For Field Application For External Heat-Shrinkable Coating of Steel Pipe Fitting and JointsDocument5 pagesDISI-QA-ITPG-ME-MS-004 Rev 0, ITP For Field Application For External Heat-Shrinkable Coating of Steel Pipe Fitting and JointsJamal Budeiri0% (1)

- Cm-Hot:hem F 471 Trr-4-w Irdi4-Br: Standard Specification FOR Air Conditioning SystemDocument42 pagesCm-Hot:hem F 471 Trr-4-w Irdi4-Br: Standard Specification FOR Air Conditioning SystemHriday AgarwalNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Svensk Standard SS-EN 13813: Fastställd 2002-10-25 Utgåva 1Document11 pagesSvensk Standard SS-EN 13813: Fastställd 2002-10-25 Utgåva 1Arvin Bhurtun100% (1)

- GETDocument688 pagesGETAya Jibo100% (1)

- 18.aph Gude Bearing B-Min-MinDocument5 pages18.aph Gude Bearing B-Min-MinAbhishek KumarNo ratings yet

- QAP Seamless PipeDocument2 pagesQAP Seamless Pipechetan85No ratings yet

- AB216Document1 pageAB216Amol PhadaleNo ratings yet

- Control Plan - Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Document4 pagesControl Plan - Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Himanshu MishraNo ratings yet

- AB11Document1 pageAB11Amol PhadaleNo ratings yet

- Lbe Oil Engine 250823Document1 pageLbe Oil Engine 250823yusufakbar55No ratings yet

- AB21Document1 pageAB21Amol PhadaleNo ratings yet

- AB067Document1 pageAB067Amol PhadaleNo ratings yet

- Tection Global 15W - 40Document2 pagesTection Global 15W - 40carmaNo ratings yet

- TDS 4241.67 Eng1Document2 pagesTDS 4241.67 Eng1lrtdNo ratings yet

- BSL AppNote RFM90 T Refractometer ASTM D 2140 en EN5Document4 pagesBSL AppNote RFM90 T Refractometer ASTM D 2140 en EN5seringwelskiNo ratings yet

- Asme Sec Ix AWS API ASME B 31.8Document25 pagesAsme Sec Ix AWS API ASME B 31.8smdriyazbashaNo ratings yet

- Updated Standard Manufacturing Quality Plan For Battery ChargersDocument4 pagesUpdated Standard Manufacturing Quality Plan For Battery ChargersAbhilash KumarNo ratings yet

- AB241Document1 pageAB241Amol PhadaleNo ratings yet

- PDS en-MY 20220811Document2 pagesPDS en-MY 20220811MUHAMMAD AMIR BIN RASIDNo ratings yet

- DETROITDIESELC93 K 214 SpecfinalDocument11 pagesDETROITDIESELC93 K 214 Specfinalfrancisco penaNo ratings yet

- Inspection Checklist: S.No Components Class Type of Check Quantum of CheckDocument8 pagesInspection Checklist: S.No Components Class Type of Check Quantum of CheckCheeragNo ratings yet

- Public Health and Municipal Engineering Department - NelloreDocument3 pagesPublic Health and Municipal Engineering Department - Nellorejuliyet strucNo ratings yet

- Everest 68 Synthetic Refrigeration Lubricant: Data SheetDocument3 pagesEverest 68 Synthetic Refrigeration Lubricant: Data SheetPhan Thiện HảoNo ratings yet

- 80mm Zigzag MTCDocument1 page80mm Zigzag MTCQAQC ZFNo ratings yet

- Saudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 3-Jul-18 CPDocument2 pagesSaudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 3-Jul-18 CPkarthi51289No ratings yet

- QAP Check ListDocument1 pageQAP Check Listbed passNo ratings yet

- PT Fuchs Lubricants (Arrow Asia-Aldaco Citrajaya) - Nissan-Samp PDFDocument1 pagePT Fuchs Lubricants (Arrow Asia-Aldaco Citrajaya) - Nissan-Samp PDFpinot san92No ratings yet

- SATR-X-3101 Rev 7Document3 pagesSATR-X-3101 Rev 7mustafa abdelshafiNo ratings yet

- Castrol Manual EP 80W-90: DescriptionDocument1 pageCastrol Manual EP 80W-90: Descriptionvicky kNo ratings yet

- Saudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 31-Mar-19 CPDocument2 pagesSaudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 31-Mar-19 CPAwais NaeemNo ratings yet

- Inspection Test PlanDocument141 pagesInspection Test PlanKoya ThangalNo ratings yet

- Technical Recommendation Form: Executed by Inspected by Approved byDocument3 pagesTechnical Recommendation Form: Executed by Inspected by Approved byMuhammad Faris NaufalNo ratings yet

- Saudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 24-Jul-18 CPDocument2 pagesSaudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 24-Jul-18 CPnadeem shaikhNo ratings yet

- Staircases & HandrailsDocument2 pagesStaircases & HandrailsPavul RajNo ratings yet

- PIPING R04 101022 DraftDocument2 pagesPIPING R04 101022 DraftPavul RajNo ratings yet

- Bpxe AbjfycDocument2 pagesBpxe AbjfycMuhNo ratings yet

- Oil Analysis Report: Power Mech Projects LTD Site: 2x600 MW CEPL-Tuticorin-Tamil NaduDocument11 pagesOil Analysis Report: Power Mech Projects LTD Site: 2x600 MW CEPL-Tuticorin-Tamil Nadudevi JammanaNo ratings yet

- Steam Trap QAPDocument2 pagesSteam Trap QAPPavul RajNo ratings yet

- CP WasherDocument2 pagesCP WasherMURALIDHRANo ratings yet

- Gathampur QapDocument3 pagesGathampur Qapaceengineering08No ratings yet

- Satr A 2001Document7 pagesSatr A 2001Naveed ShahNo ratings yet

- Everest 220 Synthetic Refrigeration Lubricant: Data SheetDocument3 pagesEverest 220 Synthetic Refrigeration Lubricant: Data SheetPhan Thiện HảoNo ratings yet

- Autran MBX-pds-EngDocument3 pagesAutran MBX-pds-EngVusal HasanovNo ratings yet

- PisssDocument1 pagePisssMie IkanNo ratings yet

- Multiplant 10W30Document2 pagesMultiplant 10W30carmaNo ratings yet

- Key To Abbreviations: Ac - Acceptable Qu - Questionable Un - Unacceptable Rs - ResampleDocument2 pagesKey To Abbreviations: Ac - Acceptable Qu - Questionable Un - Unacceptable Rs - ResampleChristianNo ratings yet

- SUPPORT (Scaph, Ducting) QAP R02 080822Document2 pagesSUPPORT (Scaph, Ducting) QAP R02 080822Pavul RajNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Data Book de BombaDocument7 pagesData Book de BombaSharon Botiny100% (1)

- Elite Cosmos A5 b5 5w-30 enDocument1 pageElite Cosmos A5 b5 5w-30 enAnderson MatioliNo ratings yet

- Tensile Test Report: CMSS/18/556 CMSS/TT/18/455 30-04-2018 03-05-2018Document12 pagesTensile Test Report: CMSS/18/556 CMSS/TT/18/455 30-04-2018 03-05-2018nareshNo ratings yet

- Cepsa Supermultigrado SHPD 15W40Document1 pageCepsa Supermultigrado SHPD 15W40RamonNo ratings yet

- Vp-15-109-001-A01-P-237-004abc-C-010 Performance Curve For PumpDocument3 pagesVp-15-109-001-A01-P-237-004abc-C-010 Performance Curve For PumpRicardo NapitupuluNo ratings yet

- EPX RangeDocument2 pagesEPX RangecarmaNo ratings yet

- QAP-NI-IJ-346-21 R1-MS New Eoan AssociatesDocument2 pagesQAP-NI-IJ-346-21 R1-MS New Eoan AssociatesParampreet singhNo ratings yet

- Piping Qap R03 250822Document2 pagesPiping Qap R03 250822Pavul RajNo ratings yet

- Op13 - Engine Oil ChangeDocument1 pageOp13 - Engine Oil ChangeAmirSyafiqNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- SLEWDocument5 pagesSLEWsivasakti chp2No ratings yet

- Acti9 Itl A9c34811Document3 pagesActi9 Itl A9c34811sivasakti chp2No ratings yet

- LED Nomenclature of MCC MICOMDocument9 pagesLED Nomenclature of MCC MICOMsivasakti chp2No ratings yet

- CHP ProtectionDocument50 pagesCHP Protectionsivasakti chp2No ratings yet

- Axial NP B05 SpecificationDocument2 pagesAxial NP B05 Specificationsivasakti chp2No ratings yet

- GID-208-ME-LCN-XS-51302 R1 Info (GA - INVERTED BUCKET STEAM TRAP PT25-IBR)Document3 pagesGID-208-ME-LCN-XS-51302 R1 Info (GA - INVERTED BUCKET STEAM TRAP PT25-IBR)sivasakti chp2No ratings yet

- MCC SLD DetailsDocument12 pagesMCC SLD Detailssivasakti chp2No ratings yet

- ABB - VFD - Common - Parameters SettingsDocument7 pagesABB - VFD - Common - Parameters Settingssivasakti chp2No ratings yet

- Notice 1 - List of Candidates For Personal Discussion-LabDocument4 pagesNotice 1 - List of Candidates For Personal Discussion-Labsivasakti chp2No ratings yet

- LT Motor Drive and Nondrive - 02.02.2024Document1 pageLT Motor Drive and Nondrive - 02.02.2024sivasakti chp2No ratings yet

- Ht. Drive End - 02.02.2024Document1 pageHt. Drive End - 02.02.2024sivasakti chp2No ratings yet

- Customer - GID-208-CI-EAC-BS-54131 - R2 - PF Control PhilosophyDocument9 pagesCustomer - GID-208-CI-EAC-BS-54131 - R2 - PF Control Philosophysivasakti chp2No ratings yet

- Customer - GID - 208-CI-EAU-BS-54165 REV-2 - CSU Control PhilosophyDocument7 pagesCustomer - GID - 208-CI-EAU-BS-54165 REV-2 - CSU Control Philosophysivasakti chp2No ratings yet

- GID-208-CI-EC-BS-4040 R4 CHP Control PhilosophyDocument17 pagesGID-208-CI-EC-BS-4040 R4 CHP Control Philosophysivasakti chp2No ratings yet

- Design Considerations For A Gear DriveDocument17 pagesDesign Considerations For A Gear Driveمحمدفیضان چوہدریNo ratings yet

- Improve Pumps Performance With Composite Wear ComponentsDocument0 pagesImprove Pumps Performance With Composite Wear ComponentsDelfinshNo ratings yet

- 26-Hardox 600 The - Ultimate Wear Plate PDFDocument4 pages26-Hardox 600 The - Ultimate Wear Plate PDFlazaroccsNo ratings yet

- GB TP0500 LRDocument20 pagesGB TP0500 LRGristarNo ratings yet

- Microtest MT Pin-On-Disk TribometerDocument8 pagesMicrotest MT Pin-On-Disk TribometerMIGUEL LOPEZNo ratings yet

- Understanding Dental Wear: Emmanuel d'INCAU, Paul SAULUEDocument19 pagesUnderstanding Dental Wear: Emmanuel d'INCAU, Paul SAULUERaghav PratapNo ratings yet

- Bucket Teeth AdaptersDocument36 pagesBucket Teeth AdaptersSzilárd S100% (1)

- Offer For Meat Equipments (Pr-8, Fessman Smoke House, G330A and TC-350)Document4 pagesOffer For Meat Equipments (Pr-8, Fessman Smoke House, G330A and TC-350)Esther KashungNo ratings yet

- Materials of Construction ConstructionDocument6 pagesMaterials of Construction ConstructionIlkuNo ratings yet

- 1Document16 pages1Saurabh PatelNo ratings yet

- Flowshield LXP System Data Sheet (en-GB)Document2 pagesFlowshield LXP System Data Sheet (en-GB)nblinoNo ratings yet

- Thermal Spray Powders - March 2019 - 2438HOGDocument36 pagesThermal Spray Powders - March 2019 - 2438HOGRavi ViswanadhaNo ratings yet

- Diatest 9Document86 pagesDiatest 9tungNo ratings yet

- Wartsila 32 Bearing AssessmentDocument8 pagesWartsila 32 Bearing AssessmentVito Digeo100% (2)

- MECH4428-practice 1-Metal Corrosion PDFDocument19 pagesMECH4428-practice 1-Metal Corrosion PDFjasmine97No ratings yet

- WA Hardlite™: Ultra-Thin Composite WearplatesDocument5 pagesWA Hardlite™: Ultra-Thin Composite WearplatesFernando MilmanNo ratings yet

- 2017 - Ge - Etal - The Impact Wear-Resistance Enhancement Mechanism of Medium Manganese Steel and Its Applications in Mining MachinesDocument8 pages2017 - Ge - Etal - The Impact Wear-Resistance Enhancement Mechanism of Medium Manganese Steel and Its Applications in Mining MachinesDiego MartinezNo ratings yet

- Persta Gate Valves PDFDocument52 pagesPersta Gate Valves PDFSalah InhgaruoNo ratings yet

- BECHEM High Performance Chain Oils 2015 GBDocument7 pagesBECHEM High Performance Chain Oils 2015 GBduy tanNo ratings yet

- GREASEDocument12 pagesGREASEKarthikeyanNo ratings yet

- Study On Mechanical and Wear Properties of Al 7075-Al2O3-Graphite Hybrid CompositesDocument8 pagesStudy On Mechanical and Wear Properties of Al 7075-Al2O3-Graphite Hybrid CompositesSrijan PrabhakarNo ratings yet

- Wear and RepairDocument12 pagesWear and RepairmtonellyNo ratings yet

- Belt Conveyor Idler LifeDocument19 pagesBelt Conveyor Idler LifehimanshumalNo ratings yet

- Chapter - 06 - EN - Edizione 07-2008Document52 pagesChapter - 06 - EN - Edizione 07-2008Waleed LemsilkhiNo ratings yet

- Premalube XtremeDocument2 pagesPremalube Xtremerobertoalfaro492023No ratings yet

- Influence of Parameters and Wear Analysis of Aluminium-Bronze (Cual8Fe3) by Taguchi MethodDocument13 pagesInfluence of Parameters and Wear Analysis of Aluminium-Bronze (Cual8Fe3) by Taguchi MethodAvinash ChandraNo ratings yet

- Handbook For Failure AnalysisDocument2 pagesHandbook For Failure AnalysisLilian RoseNo ratings yet

- Vishwakarma Institute of TechnologyDocument42 pagesVishwakarma Institute of TechnologyAnkush RatnaparkheNo ratings yet