Professional Documents

Culture Documents

Jis G3457

Jis G3457

Uploaded by

Jihoom ShinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jis G3457

Jis G3457

Uploaded by

Jihoom ShinCopyright:

Available Formats

UDC 669.14-962:621.791.75:621.

644

r'JIS INDUSTRIAL

JAPANESE STANDARD

Arc Welded Carbon

Steel Pipes

@ JIS G 3457-1988

--

Translated and Published

by

Japanese Standards Association

COPYRIGHT Japanese Standards Association

Licensed by Information Handling Services

JIS G*3457 8 8 m 4933608 0048333 3 m

In the event of any doubt arising,

the original Standard in Japanese is to be final authority.

COPYRIGHT Japanese Standards Association

Licensed by Information Handling Services

UDC 669.14-962:621.791.75:621.644

JAPANESE INDUSTRIAL STANDARD J I S

Arc Welded Carbon S t e e l Pipes G 3457-1988

1. Scope

This Japanese Industrial Standard specifies t h e a r c welded carbon steel pipes,

hereinafter referred t o as t h e "pipes", used f o r piping for steam, water, gas, air,

etc. of comparatively low working pressure.

Remark: The units and numerical values given in { } in this Standard a r e

based on t h e International System of Units ( S I ) and a r e appended

for informative reference.

Further, t h e traditional units accompanied by numerical values

in this Standard shall be converted t o t h e SI units and numerical

values on Jan. 1, 1991.

1, 2. Grade and Designation

The pipes shall be classified into one grade and its letter symbol shall be as

given in Table 1-1 or Table 1-2.

Table 1-1. Letter Symbol of Grade

(Applicable till t h e end of 1990)

Letter symbol of grade

STPY 41

Table 1-2. Letter Symbol of Grade

(Applicable on and a f t e r Jan. 1, 1991)

Letter symbol (For reference)

of grade Traditional symbol

~~

STPY 400 STPY 41

Applicable Standards: S e e page 10.

COPYRIGHT Japanese Standards Association

Licensed by Information Handling Services

J I S Gu3457 88 W 4933608 0048333 5 E !

2

G 3457-1988

3. Chemical ComDosition

The pipes shall be tested in accordance with 9.1 and t h e resulting ladle

analysis values shall conform t o Table 2-1 o r Table 2-2.

Table 2-1. Chemical Composition

(Applicable till t h e end of 1990)

Unit: %

I I I

Letter symbol

of grade I c I p I s

STPY 41 I 0.25 max. I 0.040 max. I 0.040 max.

Table 2-2. Chemical Composition

(Applicable on and a f t e r Jan. 1, 1991)

Unit: %

Letter symbol

of grade I C P S

STPY 400 0.25 max. 0,040 max. 0.040 max.

4. Mechanical Properties

4.1 Tensile Strength, Yield Point or Proof Stress and Elongation The pipes

or either t h e steel strips o r steel plates used for t h e pipes shall be tested in

accordance with 9.2 and t h e resulting tensile strength, yield point or proof stress

and elongation shall comply with Table 3-1 or Table 3-2.

4.2 Tensile Strength of Welds The welds of t h e pipes shall be tested in

accordance with 9.3 and t h e resulting tensile strength shall comply with Table 3-1

o r Table 3-2.

COPYRIGHT Japanese Standards Association

Licensed by Information Handling Services

3

G 3457-1988 .

Table 3-1. Mechanical Properties

(Applicable till t h e end of 1990)

Yield point or

Tensile strength Elongation %

Letter symbol proof stress

No. 5 test piece,

of grade kgf/mm2

{N/mmzl Kgf /mm { N/mm2 J

transverse

STPY 41 41 (4021 min. 23 .I2261 min. 18 min.

Remarks 1. The minimum value of elongation for t h e pipes under 8 mm in wall

thickness shall be calculated by nominally subtracting 1.5 % from t h e

elongation rates given in Table 3-1 for each decrease of 1 mm from

8 mm in wall thickness, and rounded off t o an integer in accordance

with JIS Z 8401. Calculation examples are given in Informative

Reference Table.

ib 2. The test piece shall be taken from t h e portion which does not

involve welded seams.

Table 3-2. Mechanical Properties

(Applicable on and after Jan. 1, 1991)

Letter ----L.-’

of 1

I I I

STPY 400 I 400 min. I 225 min.

I 18 min.

Remarks 1. The minimum value of elongation for t h e pipes under 8 mm in wall

thickness shall be calculated by nominally subtracting 1.5 % from t h e

elongation rates given in Table 3-2 f o r each decrease of 1 mm from

8 mm in wall thickness, and rounded off t o an integer in accordance

with J I S Z 8401. Calculation examples are given in Informative

Reference Table.

2. The test piece shall be taken from t h e portion which does not

involve welded seams.

Informative Reference Table. Calculation Examples of Elongation of

No. 5 Test Piece (Transverse) for

Pipes under 8 mm in Wall Thickness

Division of Over 7 mm, Over 6 mm, up Over 5 mm, up

wall thickness up to 8 mm t o and incl. 7 mm to and incl. 6 mm

Elongation % 18 16 15

COPYRIGHT Japanese Standards Association

Licensed by Information Handling Services

J I S G*3457 8 8 4933608 0048335 9

4

G 3457-1988

5. Hydrostatic Characteristic or Nondestructive Characteristic

The pipes shall be tested in accordance with 9.4 and t h e resulting hydrostatic

characteristic or nondestructive characteristic shall conform to t h e following

alternative, preference being committed either to t h e purchaser's designation or to

t h e discretion of t h e manufacturer.

5.1-1 Hydrostatic Characteristic (Applicable till t h e end of 1990) When a

hydrostatic pressure of 25 kgf/cm2 125 bar} (,l) is applied, t h e pipes shall withstand

it without leakage.

Note (I) 1 bar = 105 Pa

5.1-2 Hydrostatic Characteristic (Applicable on and a f t e r Jan. 1, 1991) When

a hydrostatic pressure of 2.5 MPa is applied, t h e pipes shall withstand it without

leakage.

5.2 Nondestructive Characteristic The pipes shall be subjected to t h e

nondestructive examination in t h e form of t h e ultrasonic test, and, t h e r e shall be no

signal greater than those produced by t h e artificial defects of t h e reference test

block graded UY of t h e working sensitivity division specified in J I S G 0584.

6. Dimensions, Mass and Dimensional Tolerances

6.1 Dimensions and Mass The outside diameter, wall thickness and mass of

t h e pipes shall be as specified in Attached Table.

6.2 Dimensional Tolerances The tolerances on outside diameter and wall

thickness of t h e pipes shall be as specified in Table 4.

COPYRIGHT Japanese Standards Association

Licensed by Information Handling Services

5

G 3457-1988

Table 4. Tolerances on Outside Diameter and Wall Thickness

Division I Tolerances %

2 0.5 Measurement

Outside diameter based on t h e length of

circumference.

Nominal diameter + 15

Wall U p to and incl. 450 A - 12.5

thickness Nominal diameter t 15

Over 450 A - 10

where n=3.1416

2. To the portions under repairs and the like, t h e

above tolerances on outside diameter shall not be

actually applied provided it is confirmed that t h e

wall thickness is within t h e tolerance range.

6.3 Pipe Length The length of each pipe shall be 4000 mm or over.

7. Appearance

The appearance of pipe shall be as follows:

(1) The pipe shall be straight f o r practical purposes, and its both ends shall be

at right angles to its axis.

(2) The inside and outside surfaces of t h e pipe shall be well-finished, and f r e e

from defects t h a t are detrimental to practical use.

8. Method of Manufacture

The method of manufacture of pipe shall be as follows:

(1) The pipes shall be manufactured by t h e spiral seam or t h e straight seam

welding. In either case, t h e internal and external surfaces of t h e pipe shall

be automatic submerged arc welded in a butt joint,

(2) The pipes shall be either as welded or as cold-expanded after welding, and,

as a rule, should not be subjected to heat treatments.

(3) Both ends of t h e pipe shall be finished plain ended or bevel ended (2).

Note (2) Unless otherwise specified, t h e shape of t h e bevel end shall be

as shown in Figure.

COPYRIGHT Japanese Standards Association

Licensed by Information Handling Services

J I S G*3457 88 = 4933b08 0048337 2 9

6

G 3457-1988

Figure. Shape of Bevel End

2.4 m m max.

t : thickness 22 .mm max.

9. Test

-

9.1 Chemical Analysis

9.1.1 Chemical Analysis General matters common t o chemical analysis and

method of sampling specimens for analysis shall be in accordance with 3. of J I S G

0303.

9.1.2 Analytical Method The analytical method shall be in accordance with

one of t h e following Standards:

J I S G 1211, J I S G 1214, JIS G 1215, J I S G 1253,

JIS G 1256, JIS G 1257.

9.2 Tensile Test

9.2.1 Test Piece The test specimen shall be No. 5 test piece specified in

JIS Z 2201 t o be c u t off from t h e pipe by either of t h e following methods:

(1) The test piece shall be c u t off transversely from t h e pipes for cold

expansion and finished into a f l a t piece.

( 2 ) The test piece shall be c u t off transversely from t h e pipes other than

those f o r cold expansion and finished into a f l a t piece or cut off from

t h e steel strip in coil or steel plate used for t h e pipe.

9.2.2 Test Method The test method shall be as specified in J I S Z 2241.

9.3 Tensile Test of Welds

9.3.1 Test Piece The test piece shall be No. 1 test piece specified in J I S

Z 3121 to be cut off from t h e pipe o r from t h e test specimen prepared from t h e

end of t h e tubular one welded under t h e same conditions as t h e pipe itself, and

shall be finished into a f l a t piece.

9.3.2 Test Method The test method shall be in accordance with JIS Z

2241.

COPYRIGHT Japanese Standards Association

Licensed by Information Handling Services

J I S G*3457 88 W 4 9 3 3 b 0 8 0048338 4

~ ~~

7

G 3457-1988

9.4 Hydrostatic Test or Nondestructive Examination Conduct either t h e

hydrostatic test or t h e nondestructive examination in accordance with t h e respective

requirements below:

(1) The pipe is subjected t o a hydrostatic pressure, kept under t h e specified

pressure and checked f o r any leakage.

(2) The test method of t h e nondestructive examination shall be as specified

in JIS G 0584.

10. Inspection

10.1 Inspection The inspection shall be as follows:

(1) General matters of inspection shall be as specified in JIS G 0303.

(2) The chemical composition, mechanical properties, hydrostatic or

nondestructive characteristic, dimensions and appearance of t h e pipes shall

conform to 3., 4., 5., 6., and 7.

However, for t h e cold-expanded pipes, omission of t h e tensile test for

t h e welds may be agreed upon by t h e purchaser and t h e manufacturer.

(3) Either t h e hydrostatic test or t h e nondestructive examination shall be

performed for each pipe.

(4) The method of sampling test specimens and t h e number of test pieces for

t h e tensile test and t h e tensile test f o r welds shall be as specified in

Table 5 and Table 6.

Table 5. Method of Sampling Test Specimens and Number of

Test Pieces (In Case of Tensile Test)

~~ ~ ~ ~~ ~

To be taken from To be taken from t h e To be taken from

t h e pipe steel strip in coil t h e steel plate

Take one test specimen Take one test specimen Take one test specimen

for each 1200 m or its from each lot of t h e from each lot of t h e same

fraction from t h e pipes same heat and thickness, heat of t h e maximum

of t h e same dimensions and t a k e one test piece thickness of t h e plate

( 3 ) , and then t a k e one from it. However, t a k e within twice t h e minimum

test piece from it. two test specimens from thickness. However, t a k e

each lot exceeding 50 t. t w o test specimens from

each lot exceeding 50 t.

~ ~~ ~~

Note (3 ) The term "same dimensions" means t h e same wall thickness combined

with t h e same outside diameter.

COPYRIGHT Japanese Standards Association

Licensed by Information Handling Services

J I S G*3457 B A W 4 9 3 3 6 0 8 0048339 b E

8

G 3457-1988

Table 6. Method of Sampling Test Specimens and Number of

Test Pieces (In t h e Case of Tensile Test of Welds)

To be taken from t h e end of tubular

To be taken from t h e pipe one welded under t h e same conditions

as t h e pipe

Take one test specimen from e a c h Take, one test specimen from e a c h quan-

1200 m or its fraction of t h e pipes t i t y equivalent to 1200 m or its fraction

of t h e same dimensions ( 3 ) , and then of t h e pipes of t h e same dimensions ( 1,

t a k e one test piece f o r tensile test and t a k e one test piece f o r tensile test

f o r welds from it. for welds from it.

10.2 Reinspection The pipe is entitled to a retest specified in 4.4 of J I S G

0303 for final acceptance.

11. Marking

Each pipe having passed t h e inspection shall be marked with t h e following

items. The order of arranging t h e items is not specified.

With t h e approval of t h e purchaser, t h e items may be partially omitted.

(1) Letter symbol of grade

( 2 ) Dimensions ( 4,

(3) Manufacturer's name or identifying brand

Note (4) The dimensions shall be expressed as follows:

Nominal diameter x wall thickness or outside diameter x wall

thickness

Example: 400 A x 6.4

12. Report

The manufacturer shall, as a rule, submit to t h e purchaser t h e report on t h e

test results, ordered dimensions, quantity and work lot number traceable to t h e

manufacturing conditions, etc.

COPYRIGHT Japanese Standards Association

Licensed by Information Handling Services

9

G 3457-1988

Attached Table. Dimensions and Unit Mass of Arc

Welded Carbon Steel Pipes

Unit: kg/m

Wall

- - -- --- - - --

Nominal thick.

diameter

- 6.0 6.4 7.1 7.9 8.7 9.5 10.3 11.1 11.9 12.7 13.1 15.1 15.9

--A

350 14

B ia. m m

355.6 51.7 55.1 61.0 67.7

- - -

400 16 4.06.4 59.2 63.1 69.9 77.6

450 18 457.2 66.8 71.1 78.8 87.5

- -

500 20

550 22

508,O

558.8

74.3

81.8

79.2

87.2

87.7

96.6

97.4

107

107

118

117

129 139

-

150

-

160 171

600 24 609.6 89.3 95.2 105 117 129 141 152 164 175 187

650 26 660.4 96.8 103 114 127 140 152 165 178 190 203

700 28 711.2

- 119 132 147

104 111 123 137 151 164 178 192 205 219

750 30 ,762.0 162 176 191 206 220 235 '

- -

800 32

850 34

812.8

863.6

-

127

-

141 157

167

173

183

188

200

204

217

219

233

235

250

251

266

258

275

297

316

312

332

900 36 914.4 177 194 212 230 247 265 282 291 335 352

lo00 4Q 1016.0

--

216

196 236 255 275 295 314 324 373 392

1100 44 1117.6 260 281 303 324 34.6 357 411 432

1200 4.8

1350 54

1219.2

1371.6

-

283

-

307

-

331 3%

399

378

426

390

439

44a

505

472

532

1500 60

1600 64

1524.0

1625.6

444

-

473 4a8

521

562

600

591

631

1800 72 1828.8

-

587 675 711

--

2o00 80 2032.0

-- - - -- -- ---

751

-

791

Remarks 1. To indicate t h e nominal diameter of t h e pipe, either t h e letter A

or B shall be used, A or B being suffixed t o t h e figures of nominal

diameter for identification.

2. The value of mass shall be calculated from t h e following formula

assuming 1 cm3 of steel t o be 7.85 g and rounded off to 3

significant digits in accordance with JIS Z 8401. However, t h e

value exceeding 1000 kg/m shall be rounded off t o a whole number

of kg/m.

W=0.02466 t (D-t)

where w : unit mass of pipe (kg/m)

t : wall thickness of pipe (mm)

D : outside diameter of pipe (mm)

3. When t h e dimensions not given in t h e above table are necessary,

agreement shall b e made between t h e purchaser and t h e

manufacturer.

COPYRIGHT Japanese Standards Association

Licensed by Information Handling Services

J I S Gx3457 88 = 4933608 0048343 4

10.

G 3457-1988

Applicable Standards:

JIS G 0303-General Rules for Inspection of S t e e l

JIS G 0584-Ultrasonic Examination for Arc Welded S t e e l Pipes

J I S G 1211-Methods for Determination of Carbon in Iron and S t e e l

J I S G 1214-Methods for Determination of Phosphorus in Iron and S t e e l

J I S G 1215-Methods for Determination of Sulfur in Iron and S t e e l

J I S G 1253-Method for Photoelectric Emission Spectrochemical Analysis

of Iron and S t e e l

JIS G 1256-Method for X-Ray Fluorescence Spectrometric Analysis of

Iron and S t e e l

JIS G 1257-Atomic Absorption Spectrochemical Analysis of Iron and Steel

J I S Z 2201-Test Pieces for Tensile Test for Metallic Materials

J I S Z 2241-Method of Tensile Test for Metallic Materials

JIS Z 3121-Method of Tension Test for B u t t Welded Joint

J I S Z 8401-Rules for Rounding off of Numerical Values

COPYRIGHT Japanese Standards Association

Licensed by Information Handling Services

.

G 3457-1988

Edition 1

Japanese Text

Established by Minister of International Trade and Industry

D a t e of Establishment: 1962-03-01

D a t e of Revision: 1988-08-01

Date of Public Notice in Official Gazette: 1988-08-02

Investigated by: Japanese Industrial Standards Committee

Divisional Council on Iron and Steel

. Technical Committee on Steel Pipes

This English translation is published by:

Japanese Standards Association

4

1-24, Akasaka 4, Minato-ku,

Tokyo 107 Japan

O JSA, 1989

Printed in Tokyo by

Hohbunsha Co., Ltd.

COPYRIGHT Japanese Standards Association

Licensed by Information Handling Services

You might also like

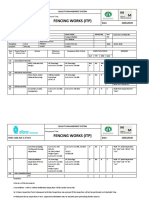

- Inspection and Test Plan - Fencing C-015Document2 pagesInspection and Test Plan - Fencing C-015Furqan100% (1)

- E192-15 Standard Reference Radiographs of Investment Steel Castings For Aerospace ApplicationsDocument4 pagesE192-15 Standard Reference Radiographs of Investment Steel Castings For Aerospace ApplicationsMohammed BoucherbaNo ratings yet

- Color of Pavement Marking Materials: Standard Specification ForDocument4 pagesColor of Pavement Marking Materials: Standard Specification Formohammed karasnehNo ratings yet

- Astm e 192Document6 pagesAstm e 192Bryan Jimenes DorantesNo ratings yet

- Astm b165 PDFDocument6 pagesAstm b165 PDFSagent IncNo ratings yet

- Easa Part 145 Moe Checklist: 1. ScopeDocument54 pagesEasa Part 145 Moe Checklist: 1. ScopeTDHNo ratings yet

- Jis G3456Document19 pagesJis G3456Jihoom ShinNo ratings yet

- Jis G3455Document21 pagesJis G3455Jihoom ShinNo ratings yet

- Jis G3454Document18 pagesJis G3454Jihoom ShinNo ratings yet

- E1320-15 Radiografías de Referencia Estándar para Piezas de Fundición de Titanio1Document4 pagesE1320-15 Radiografías de Referencia Estándar para Piezas de Fundición de Titanio1fredy lopezNo ratings yet

- Jis G3452Document12 pagesJis G3452Jihoom ShinNo ratings yet

- Acp Testing Acceptance Procedure PDFDocument21 pagesAcp Testing Acceptance Procedure PDFRoland James ArimadoNo ratings yet

- Reporting Properties For Plastics and Thermoplastic ElastomersDocument4 pagesReporting Properties For Plastics and Thermoplastic ElastomersAndres Camilo BenitezNo ratings yet

- (JISF) : Japanes E IndustrialDocument19 pages(JISF) : Japanes E IndustrialTrịnh Thanh TùngNo ratings yet

- Recommended Unit Symbols, SI Prefixes, and Abbreviations: A VIIDocument3 pagesRecommended Unit Symbols, SI Prefixes, and Abbreviations: A VIIBOURAS Ihabe - بوراس إيهابNo ratings yet

- Jis g3141Document19 pagesJis g3141thanhNo ratings yet

- J W 1177BDocument25 pagesJ W 1177BAnonymous kmtnBvDtNo ratings yet

- 1280a4-8230-Sp-0001 Rev F3Document18 pages1280a4-8230-Sp-0001 Rev F3Stephen LowNo ratings yet

- Steel Castings Up To 2 In. (50.8 MM) in Thickness: Standard Reference Radiographs ForDocument5 pagesSteel Castings Up To 2 In. (50.8 MM) in Thickness: Standard Reference Radiographs ForTECHNICAL LABNo ratings yet

- Driven Fasteners: Nails, Spikes, and Staples: Standard Specification ForDocument4 pagesDriven Fasteners: Nails, Spikes, and Staples: Standard Specification ForcsanchezptyNo ratings yet

- Iso 2341-1986Document8 pagesIso 2341-1986Azadeh AliabadiNo ratings yet

- Indian Standard Compression Type Tubular In-Line Connectors FOR Aluminium Conductors of Insulated Cables-Specification (First Revision)Document5 pagesIndian Standard Compression Type Tubular In-Line Connectors FOR Aluminium Conductors of Insulated Cables-Specification (First Revision)josephNo ratings yet

- Global Marketing For Tube & Pipe: JIS G3465 Seamless Steel Tubes For DrillingDocument5 pagesGlobal Marketing For Tube & Pipe: JIS G3465 Seamless Steel Tubes For DrillingGerardo Emmanuel Romana BrianoNo ratings yet

- Nickel Rod and Bar: Standard Specification ForDocument6 pagesNickel Rod and Bar: Standard Specification FormahfuzNo ratings yet

- Iso 4379 1993Document9 pagesIso 4379 1993gökhan tanrıseverNo ratings yet

- 1599 PDFDocument12 pages1599 PDFIndira BanerjeeNo ratings yet

- JIS G 3141 (2005) Cold-Reduced Carbon Steel Sheets and Strip (SPCC SPCD SPEC)Document15 pagesJIS G 3141 (2005) Cold-Reduced Carbon Steel Sheets and Strip (SPCC SPCD SPEC)Robert SumińskiNo ratings yet

- TokyoSteel EPD HRC 20191204Document13 pagesTokyoSteel EPD HRC 20191204Bruno MarquesNo ratings yet

- Astm B 32 - 00Document9 pagesAstm B 32 - 00kaminaljuyuNo ratings yet

- Design, Manufacture, and Material Grouping Classification of Hole-Type Image Quality Indicators (IQI) Used For RadiologyDocument7 pagesDesign, Manufacture, and Material Grouping Classification of Hole-Type Image Quality Indicators (IQI) Used For RadiologyMuhammad KhairuddinNo ratings yet

- Centrifugally Cast Austenitic Steel Pipe For High-Temperature ServiceDocument5 pagesCentrifugally Cast Austenitic Steel Pipe For High-Temperature Serviceist93993No ratings yet

- High Strength Steel Castings in Heavy Sections: Standard Specification ForDocument5 pagesHigh Strength Steel Castings in Heavy Sections: Standard Specification ForDarwin DarmawanNo ratings yet

- Astm b160Document6 pagesAstm b160Kevin Almeida100% (1)

- SWTH, D120 - TS5-01, Issue 05Document10 pagesSWTH, D120 - TS5-01, Issue 05droftahsps4No ratings yet

- ET 7409 103 - e PDFDocument21 pagesET 7409 103 - e PDFGerald See TohNo ratings yet

- Smartline: Coplanar Adapter Kit (Cpk-1) Specification 34-St-03-114Document6 pagesSmartline: Coplanar Adapter Kit (Cpk-1) Specification 34-St-03-114CRISTINANo ratings yet

- Mechanical Completion L.V. Power, Control and Telecomm / Instrument CablesDocument4 pagesMechanical Completion L.V. Power, Control and Telecomm / Instrument CablesJalal AlbadriNo ratings yet

- Astm A-252Document9 pagesAstm A-252Dayana HernandezNo ratings yet

- Jis G 3505 LC W RodsDocument1 pageJis G 3505 LC W RodsRamesh DattaNo ratings yet

- Manual E-Structure - R5-2 - ENDocument29 pagesManual E-Structure - R5-2 - ENlaura gavanNo ratings yet

- JIS B 8313-1981 End Suction Centrifugal PumpDocument25 pagesJIS B 8313-1981 End Suction Centrifugal PumpTsani TsaniNo ratings yet

- Astm 533Document4 pagesAstm 533JOSEPH REFUERZONo ratings yet

- Electrod 5Document3 pagesElectrod 5RAMESH PANDARINo ratings yet

- Astm A153Document5 pagesAstm A153IsabelaNo ratings yet

- E192-15 Standard Reference Radiographs of Investment Steel Castings For Aerospace ApplicationsDocument4 pagesE192-15 Standard Reference Radiographs of Investment Steel Castings For Aerospace ApplicationsudomNo ratings yet

- TCVN 1651 2 2018Document33 pagesTCVN 1651 2 2018Francesco PaternosterNo ratings yet

- Iso 6412 1 1989 e PDFDocument16 pagesIso 6412 1 1989 e PDFAgrael100% (1)

- Astm A139Document6 pagesAstm A139banglvhNo ratings yet

- Load-Indicating Externally Threaded Fasteners: Standard Specification ForDocument4 pagesLoad-Indicating Externally Threaded Fasteners: Standard Specification ForLeviGatsosNo ratings yet

- Astm D4956 01Document4 pagesAstm D4956 01srivastavadarsh232774No ratings yet

- Jis B-1186Document21 pagesJis B-1186nate anantathatNo ratings yet

- E-CTFE-Fluoroplastic Molding, Extrusion, and Coating MaterialsDocument5 pagesE-CTFE-Fluoroplastic Molding, Extrusion, and Coating MaterialsEver Antonio MorenoNo ratings yet

- Spec TN-2534Document37 pagesSpec TN-2534dharm rajNo ratings yet

- Standard A252 PDFDocument7 pagesStandard A252 PDFtromixNo ratings yet

- High Strength Steel Castings in Heavy Sections: Standard Specification ForDocument5 pagesHigh Strength Steel Castings in Heavy Sections: Standard Specification ForagustinNo ratings yet

- Welded and Seamless Steel Pipe Piles: Standard Specification ForDocument7 pagesWelded and Seamless Steel Pipe Piles: Standard Specification Forsharon blushteinNo ratings yet

- NTF (Vendedor)Document11 pagesNTF (Vendedor)SICAAM QUERETARONo ratings yet

- PNP Switching Silicon Transistor: 2N2904 (A) and 2N2905 (A)Document7 pagesPNP Switching Silicon Transistor: 2N2904 (A) and 2N2905 (A)icucutaNo ratings yet

- Driven Fasteners: Nails, Spikes, and Staples: Standard Specification ForDocument47 pagesDriven Fasteners: Nails, Spikes, and Staples: Standard Specification ForMohammed EldakhakhnyNo ratings yet

- D 746 - 98 - Rdc0ni1sruqDocument11 pagesD 746 - 98 - Rdc0ni1sruqMiguel Angel Perez EsparzaNo ratings yet

- Ete Esterdan FM BicapaDocument15 pagesEte Esterdan FM BicapaRubiiKzzNo ratings yet

- Adroit Environment Consultants LTD.: Approval of The DocumentDocument17 pagesAdroit Environment Consultants LTD.: Approval of The DocumentAdroit Consultant100% (1)

- Blohm Voss Spider 500 Ton 753000Document74 pagesBlohm Voss Spider 500 Ton 753000yelmustafaaliNo ratings yet

- Architecture & Planning Building Design & Engineering Project & Cost Management Industrial & Process EngineeringDocument24 pagesArchitecture & Planning Building Design & Engineering Project & Cost Management Industrial & Process Engineeringsherly dpgNo ratings yet

- 6b. Rice and Other Crop Processing MachineryDocument130 pages6b. Rice and Other Crop Processing MachineryNiño Evangelista FranciscoNo ratings yet

- APQP Format NationalDocument53 pagesAPQP Format NationalqualityNo ratings yet

- Boiler Asset Integrity ManagementDocument34 pagesBoiler Asset Integrity ManagementWalid Ahsan100% (1)

- DS 02-02-07 L3 OCW 011932 OCW Personal Protective EquipmentDocument3 pagesDS 02-02-07 L3 OCW 011932 OCW Personal Protective EquipmentAzman OyobNo ratings yet

- TATA - 3598 Celsius Overview Brochure Update DEC21Document16 pagesTATA - 3598 Celsius Overview Brochure Update DEC21isan.structural TjsvgalavanNo ratings yet

- Cheryl Lou O. Santiago P-2, Paitan, Quezon, Bukidnon 09552779028 Report #1Document9 pagesCheryl Lou O. Santiago P-2, Paitan, Quezon, Bukidnon 09552779028 Report #1Cheryl Lou SantiagoNo ratings yet

- Documented Routine and Type Testing For Transformers To IEC 60076 1 PDFDocument1 pageDocumented Routine and Type Testing For Transformers To IEC 60076 1 PDFMando MandoNo ratings yet

- HSE MASTER LIST Rev 20Document5 pagesHSE MASTER LIST Rev 20Agung Tri SugihartoNo ratings yet

- UFC 3-601-02 08 Sep 2010Document65 pagesUFC 3-601-02 08 Sep 2010Brandon TrocNo ratings yet

- TTLM 01. Manage Safety and Environmental ProtectionDocument62 pagesTTLM 01. Manage Safety and Environmental ProtectionEyobNo ratings yet

- AGM 1602F-212: Specification Specification Specification Specification FOR FOR FOR FOR LCM LCM LCM LCM ModuleDocument25 pagesAGM 1602F-212: Specification Specification Specification Specification FOR FOR FOR FOR LCM LCM LCM LCM Modulealess2056No ratings yet

- Sachin AroraDocument4 pagesSachin Arorabhanu prakashNo ratings yet

- WR020 enDocument2 pagesWR020 enАнатолий РябухаNo ratings yet

- 11FB2E000002C3.filename - Walk The Line Workshop June 2016Document58 pages11FB2E000002C3.filename - Walk The Line Workshop June 2016mrdolanNo ratings yet

- Inspection and Test Plan (ITP) : Dges Dges Dges Dges Dges Dges Dges Dges Dges Dges DgesDocument2 pagesInspection and Test Plan (ITP) : Dges Dges Dges Dges Dges Dges Dges Dges Dges Dges DgesPja ShanthaNo ratings yet

- Technology Update No. 3: SSPC: The Society For Protective CoatingsDocument11 pagesTechnology Update No. 3: SSPC: The Society For Protective CoatingsAlejandro 20100% (1)

- GBT 38069-2019 (Shortening)Document11 pagesGBT 38069-2019 (Shortening)hildaNo ratings yet

- Zhejiang Marco Valve Co., Ltd. IntroductionDocument48 pagesZhejiang Marco Valve Co., Ltd. Introductionesmeralda diazNo ratings yet

- XYfF8HMBUaAYcS0UsXrglSYUoEZtvZYuZvm5GnRI0JFLOQSW8PJRB1RnxfkcvsOP3fPe2voGc0SQz3bWL9jHVvQz3WXcBvmZpZOnOcH8 PDFDocument5 pagesXYfF8HMBUaAYcS0UsXrglSYUoEZtvZYuZvm5GnRI0JFLOQSW8PJRB1RnxfkcvsOP3fPe2voGc0SQz3bWL9jHVvQz3WXcBvmZpZOnOcH8 PDFrommelNo ratings yet

- SIAUE3007 Inspect and Service Steering Systems.Document9 pagesSIAUE3007 Inspect and Service Steering Systems.Harry DaogaNo ratings yet

- Liftex Catalog 2016Document60 pagesLiftex Catalog 2016Alberth Mauricio Casteblanco GomezNo ratings yet

- Kertas Penerangan c01 - Composite Material Preparation P (1-2)Document7 pagesKertas Penerangan c01 - Composite Material Preparation P (1-2)Muhammad ZulfamiNo ratings yet

- Quantum of Check of Material&WorkmanshipDocument35 pagesQuantum of Check of Material&Workmanshipsanjay vidhateNo ratings yet