Professional Documents

Culture Documents

CF-1000 SCMH-Approved With Minor Comments

CF-1000 SCMH-Approved With Minor Comments

Uploaded by

Umer KhanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CF-1000 SCMH-Approved With Minor Comments

CF-1000 SCMH-Approved With Minor Comments

Uploaded by

Umer KhanCopyright:

Available Formats

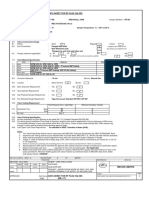

DATA SHEET FOR CARTRIDGE FILTER

CLIENT : M/S. PURBA BHARTI GAS PVT LTD

1.0 PROJECT :

2.0 JOB NO.: JIG-1495

23SA ITEM TAG NO.: CF- 101&102

3.0 VENDOR: M/S*INEL GAS CONTROLS PVT LTD. QUANTITY: 2AS

PER SKID

PER P&ID

4.0 OPERATING CONDITIONS:

4.1 FILTER: CARTRIDGE TYPE: HORIZONTAL

VENDOR TO CARTRIDGE

SPECIFY FILTER

4.2 FLUID HANDLED: NATURAL GAS VAPOUR FLUID DENSITY (@ P&T) Kg/m3 : 10.6 Kg/ m3

4.3 MOLECULAR WEIGHT: 17.355 ** FLOW RATE (SCMH): 1000 As per P&ID

4.4 Cp/Cv :- 1.27 FLUID VISC., CENTI-POISE : 0.014

** cP

4.5 INLET SIZE (NB) : As per P&ID

2", SCH 160 COMPRESSIBILITY FACTOR (Z) : 0.92 **

4.6 OPER. PR., KG/CM2G: 10-35

As per P&ID OUTLET SIZE (NB): 2",As SCH

per160

P&ID

4.7 PARTICLE/ MESH SIZE, MICRON > 3 MICRON OPER. TEMP., °C: 0- 55

4.8 PR. DROP KG/CM2, CLEAN/ DIRTY: 0.2/ 0.5 Max. (SEE NOTE-2) FILTRATION EFF. %: 99.5

4.9 CORROSION ALLOWANCE, MM: 3.0 For Carbon Steel Parts DUST CONC: 0 - 0.2 mg/SM3 OF GAS

CORROSIVE/ TOXIC COMPONENT: Tot Sulphur incl. H2S (max.)-10 PPM (by wt)

5.0 MATERIAL OF CONSTRUCTION H2S content (max)- 5PPM (by wt.)

5.1 SHELL: SA 106 Gr B

SA-515/SA-516 Gr. 60/70 SHELL FLANGE: SA - 105

5.2 HEAD: SA*105 HEAD FLANGE: SA -105

5.3 BOTTOM: SA 234 GrSA-516

SA515/ WPB Gr. 60/70,SA 234 Gr.WPB PERFORATED SHEET: NA

5.4 NOZZLES: SA-106 GR. B NOZZLE FLANGES: SA - 105

5.5 GASKET: SS-304/316 SPIRAL WOUND WITH GRAFOILRING INNER SS Outer CS FASTENER: SA-193 Gr. B7, SA-194 Gr. 2H

5.6 OTHER INTERNALS: * SUPPORT: SA516Gr.60/ SA 283 Gr. C/ IS:2062

FITTING: SA 234 Gr. WPB

5.7 FILTER ELEMENT: FIBRE GLASS MEDIA TO SUIT GAS QUALITY.

6.0 DESIGN AND CONSTRUCTION

6.1 DESIGN CODE: ASME SEC-VIII DIV-1 (LATEST EDITION) 2019

6.2 DESIGN PR., KG/CM2 (G): 49AS PER P&ID DESIGN TEMP., °C: (-)29 to (+) 65

6.3 NO. OF CARTRIDGE ELEMENT:1 No. (SEE NOTE-2) O.D. (MM) X LENGTH (MM) XTHICKNESS(MM): *4.5" X 12"

6.4 MAKE: AS PER VENDOR LIST IN MECON T.S.

PECO (FG-312) FILTER PR. DROP, KG/CM2(G) : 0.2 * (SEE NOTE-2)

6.5 FIXING DETAILS: NUTS & BOLTS DUST/DIRT HOLDING CAPACITY OF EACH CARTRIDGE ELEMENT: 0.478 * kg

6.6 NAME OF VESSEL MANUFACTURER: IGCPL TOTAL GROSS FILTERING AREA OF CARTRIDGE ELEMENTS: 0.1133 sq.m

* *

6.7 FLANGE RATING: 300#AS PER P&ID FLANGE FINISH: 125 * to 250 AARH

6.8 FLANGE TYPE: SWRF PSV SIZE :1" * DPG SIZE: 1/2" *

6.9 VENT SIZE: 1"As per P&ID, DRAIN SIZE: 1" As per P&ID, UC SIZE: NR FLUSHING CONNECTION: NA

6.10 HEAD (TOP COVER) CONNECTION: FLANGE

6.11 QOC REQUIRED: NA

7.0 OVERALL DIMENSION & WEIGHT:

7.1 OVERALL LENGTH, MM : ~ 989 mm INLET FLANGE TO OUTLET FLANGE: ~ 255mm *

7.2 OVERALL HEIGHT, MM : ~ 828 mm * SHELL DIA, MM: 6" NB

7.3 EMPTY WEIGHT, KGS : ~ 115 Kg OPERATING WT., KGS: ~ 115 Kg

7.4 HYDROTESTWEIGHT : ~ 130 Kg

8.0 ACCESSORIES

8.1 DAVIT: YES

8.2 LIFTING LUGS: YES

8.3 ANCHOR BOLTS& NUTS YES

8.4 BLIND FLANGE, GASKET, BOLTS&NUTS FOR VENTS& DRAINS: YES

8.5 LADDER&PLATEFORM: NOT--- APPLICABLE

9.0 PAINTING: SUITABLE TO CORROSIVE INDUSTRIAL ENVIRONMENT REF. MECON T.S.

10.0 INSPECTION & TESTING: AS PER MECON T.S & Approved QAP.

* VENDOR TO SPECIFY/ CONFIRM

** GAS COMPOSITION & OTHER PROPERTIES WILL BE PROVIDED TO SUCESSFUL BIDDER.

NOTES: -

1) THE TOTAL INTERNAL CROSS-SECTIONAL AREA OF MOUNTED CARTRIDGE SHALL NOT BE LESS THAN INLET NOZZLE AREA.

2) SUCCESSFUL BIDDER SHALL SUBMIT MECHNICAL DESIGN CALCULATION FOR FILTER & PROCESS CALCULATION (ALONG WITH DETAILED

PRESSURE DROP CALCULATION) OF CARTRIDGE FILTER & CARTRIDGE ELEMENT (INCLUDING RELEVANT GRAPH, CATALOGUE ETC.) FOR MECON CLEARANCE.

3) BIDDER SHALL SUBMIT SAMPLE CALCULATIONS (FOR CATRIDGE ELEMENT SIZING & PRESSURE DROP ACROSS THE FILTER) ALONG WITH OFFER.

4)VENDOR TO SELECT/CONFIRM THE MATERIAL CONSIDERING "-29 °C TO 65 °C" TEMPERATURE. A CHARPY V-NOTCH TEST SHALL BE CONDUCTED ON

3 SAMPLE HAVING ENERGY VALUE OF 27 J AVERAGE AND MINIMUM 22 J AT 0°C.

5) FILTER ELEMENT MUST WITHSTAND A DIFFERENTIAL PRESSURE OF 1 KG/CM2 (G) WITHOUT CRACKING AND FAILING.

6) MANDATORY SPARES SHALL BE AS PER RELEVANT CLAUSE SPECIFIED IN TENDER DOCUMENT.

7)FILTER ELEMENT SHALL BE OF SINGLE PIECE CONSTRUCTION WITH NO JOINTS IN THE ELEMENT. STACKING OF FILTER ELEMENT IS NOT ALLOWED.

8)ALL CS MATERIALS SHALL BE OF FULLY KILLED QUALITY.

9) FLANGE SHALL CONFIRM TO ASME B 16.5.

10)GASKETS SHALL CONFORM TO ASME B 16.20

11) FREQUENCY OF CLEANING SHALL BE MINIMUM 30 DAYS FOR FILTER ELEMENT DESIGN.

12) PWHT REQUIRED AS PER ASME SEC-VII (DIV-I)

REV. DATE ZONE DESCRIPTIONS BY APPRD

REVISIONS REFERENCES DRG. NO.

SECTION : OIL & GAS (LDP)

DRS

NAME DATE CHKD DATE MECON LIMITED

DSGN TP 05-04-2021 VL 12-10-20 1000 SCMH

DRWN

CARTRIDGE FILTER SCALE: REV

APPROVED DATA SHEET NO.: MEC/23SX/05/28/M/001/DS-017/001 0

This document and the design it covers are the property of MECON and issued for the specific project mentioned therein. This is not to be copied or used for other

projects unless expressly permitted by MECON.

DOC. NO IGCPL/JIG/1495/CF/101

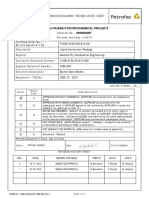

FILTER ELEMENET SIZING CALCULATION Job NO.:- JIG 1495

DRS TYPE DRS-1000 SCMH

1) CALCULATION OF NUMBER OF FILTER ELEMENT -MAKE PECO

REQUIRED MAX. GAS FLOW RATE = 1000 SCMH @ 10.00 KG/CM2 G

REFER FLOW GRAPH FG-312 FOR GAS FLOW TRATE THROUGH THE :

FG-312 FILTER ELEMENT AT 0.1406 KG/CM2G(2.0 PSI) PRESSURE DROP CONSIDERING

CORRECTION FACTORS FOR SG,TEMPRETURE & PRESSURE DROP.

FROM GRAPH : ELEMENT OD XID. 4.5" 3.12"

UNCORRECTED FLOW RATE FOR FG -312 = 560 SCFM

UNCORRECTED FLOW RATE FOR FG -312 = 952 SCMH

REQ, NO. OF ELEMENT FOR FLOW RATE OF 1000 SCMH

PRESSURE DROP : 0.18KG/CM2G ; S.G. OF GAS :0.6@ 65 degree F, HENCE

CORRECTION FACTOR FOR SG,TEMP. & PR. DROP CAN BE CALCULATED AS

A CORRECTION FACTOR FOR SPECIFIC GRAVITY = Sqrt. Of (0.6/sg) = 1.040833

B CORRECTION FACTOR FOR TEMPERATURE = = 0.947916667

C CORRECTION FACTOR FOR PRESSURE DROP = = 1.13137085

CORRECTION FACTOR FOR SG,TEMP. & PR. DROP = AxBxC 1.116236443

Ke . D .V1 ² / 2 G-312 FC = = 1062.657094

REQUIRED TOTAL FLOW ACROSS FILTER Fm = 1000 SCMH

THEREFORE NO. OF ELEMENTS REQUIRED = Fm/Fc= 1000 / 1062.657094

= 0.9410

= 1 NOS. OF FG- 312

SELECTED NO. OF FILTER ELEMENTS = 1 OF FG-312

DOC. NO Job NO.:-

FILTER ELEMENET SIZING CALCULATION JOB NO DRS TYPE

SKID TYPE DRS-1000 SCMH

PRESSURE DROP AT INLET/OUTLET DUE TO EXPANSION/CONTRACTION

ACTUAL FLOW RATE AM= 107.9513353 1000 SCMH @ 10.00 KG/CM2 G

AS= 0.029986482 M3/SEC

INLET PIPE BORE A1= 0.001440069 M2 2" Sch. 160

SHELL C.S AREA A2 = 0.01682421 M2 6" Sch.80

i) VELOCITY OF GAS IN INLET PIPE V1 = AS/A1 = 20.8229526 M/SEC

ii) VELOCITY OF GAS IN SHELL V2 = AS/A1 = 1.782341154 M/SEC

1) PRESSURE DROP DUE TO SUDDEN EXPANSION

DELTA P(Exp.) = Ke . D .V1 ² / 2 Pa ( 105 Pa=1.109 KG/CM2G)

WHERE

Ke = (1-R)2 560 0.836136458

R = CONTRACTION AREA RATIO ( A1 / A2 ) = 0.085595025

V1 = MEAN VELOCITY IN PIPE M/SEC = 20.8229526

G = ACCELERATION DUE TO GRAVITY M/SEC2 = 9.81

PRESSURE DROP : 0.18KG/CM2G ; S. DENSITY OF GAS KG/M3 = 7.437 @

10.0 KG/CM2

DELTA P(Exp.) = 0.013481232 KG/CM2G Sqrt. Of (0.6/sg)

2) PRESSURE DROP DUE TO SUDDEN CONTRACTION

DELTA P(Con.) = Ke . D .V1 ² / 2 Pa ( 105 Pa=1.109 KG/CM2G)

WHERE

Ke = (1-R)2 = 0.457202487

R = CONTRACTION AREA RATIO ( A1 / A2 ) = 0.085595025

V1 = MEAN VELOCITY IN PIPE M/SEC = 20.8229526

G = ACCELERATION DUE TO GRAVITY M/SEC2 = 9.81

D = DENSITY OF GAS KG/M3 = 7.437 @

10.0 KG/CM2

DELTA P(Conc.). = 0.0073715869327823 KG/CM2G

TOTAL PRESSURE DROP ACROSS THE FILTER =

= DELTA P (Cart.) + DELTA P (Exp.) + DELTA P (Conc.)

= 0.18 0.013481232 0.0073715869

= 0.200852818 @ 10.00 KG/CM2G

3) DUST HOLDING CAPACITY OF FILTER

Dust Holding capacity of element = 0.478 Kg

Number of element = 1 NOS.

Total dust Holding capacity of filter = 0.478 x 1 .=0.478 Kg

Dust concentration in GAS = 0.2 mg/Sm3/hr

Dust collection capacity of filter = Dust Holding capacity/

Dust Concentration Per day 99.58 Days

2 14-05-2021 FOR INFORMATION TP VL VL

1 30-04-2021 FOR INFORMATION TP VL VL

0 13-10-2020 FOR INFORMATION TP VL VL

REV DATE REVISION PREPARED CHEKED APPROVED

You might also like

- 01-0202-01 System 5000 Methods ManualDocument76 pages01-0202-01 System 5000 Methods ManualRobert Larry Cordova DiazNo ratings yet

- Tank DatasheetDocument4 pagesTank DatasheetAlvin Smith67% (6)

- Sample FET To ISO 15848-1 PDFDocument4 pagesSample FET To ISO 15848-1 PDFVivi Oktavianti100% (1)

- PIPE 1 (July 29, 2018)Document15 pagesPIPE 1 (July 29, 2018)Rowin Mark SabornidoNo ratings yet

- Data Sheet 2 Less 800#-BV - FB - SW - NT-76 PDFDocument1 pageData Sheet 2 Less 800#-BV - FB - SW - NT-76 PDFSachin KumarNo ratings yet

- Level Gauge-Bicolor DrumDocument4 pagesLevel Gauge-Bicolor DrumJKKNo ratings yet

- 2009 BV SocketWelded DatasheetDocument2 pages2009 BV SocketWelded DatasheetAqib Khan VCSPNo ratings yet

- Data Sheet 2 Less 800# PV - SW - LT-76Document1 pageData Sheet 2 Less 800# PV - SW - LT-76Sachin KumarNo ratings yet

- Injection Pump Specification ©: Use Latest Revision For All Referenced DocumentsDocument4 pagesInjection Pump Specification ©: Use Latest Revision For All Referenced DocumentsCenter Bombas InjetorasNo ratings yet

- 501abcde 016Document30 pages501abcde 016husen123 alhusadaNo ratings yet

- BAS - GAS TREATMENT-rev1Document21 pagesBAS - GAS TREATMENT-rev1ariawan habibi.abNo ratings yet

- GFL-N2-12-R.0-Data Sheet of HCL Feed Pump (P-164 DE) 24.10.17 PDFDocument1 pageGFL-N2-12-R.0-Data Sheet of HCL Feed Pump (P-164 DE) 24.10.17 PDFSavit KulshreshthaNo ratings yet

- Drain Pump, Data Sheet and Performance Curve: Genral Arrangement ofDocument11 pagesDrain Pump, Data Sheet and Performance Curve: Genral Arrangement ofAshish Gupta100% (1)

- Data Sheet 2 More 300# PV - RF - NT-79 PDFDocument1 pageData Sheet 2 More 300# PV - RF - NT-79 PDFSachin KumarNo ratings yet

- Design BasisDocument1 pageDesign BasismuhdqasimNo ratings yet

- Singgar Mulia Engineering: Vertical Separator Design BasisDocument2 pagesSinggar Mulia Engineering: Vertical Separator Design BasisElias EliasNo ratings yet

- Data Sheet Item 2Document3 pagesData Sheet Item 2Bagus SigitNo ratings yet

- QPE002342 - Technical BidDocument136 pagesQPE002342 - Technical BidMuhammed TamerNo ratings yet

- Client: Data Sheet Fire Dampers: GeneralDocument1 pageClient: Data Sheet Fire Dampers: GeneralAlif FirdausNo ratings yet

- Tank DatasheetDocument5 pagesTank DatasheetGandhi AlamsyahNo ratings yet

- A758 608 79 DS 1902SPC - 0Document2 pagesA758 608 79 DS 1902SPC - 0rajanjisri2259No ratings yet

- NDT Request - RT DTD 06.05.19Document81 pagesNDT Request - RT DTD 06.05.19Kushal PraviraNo ratings yet

- Specification Sheet: Case I Case Ii Operating ConditionsDocument1 pageSpecification Sheet: Case I Case Ii Operating ConditionsKailas NimbalkarNo ratings yet

- Injection Pump Specification ©: Use Latest Revision For All Referenced DocumentsDocument4 pagesInjection Pump Specification ©: Use Latest Revision For All Referenced Documentsjohnny sabinNo ratings yet

- 4.31 Data Sheet Insulating Joints Rev ADocument2 pages4.31 Data Sheet Insulating Joints Rev AAWANI SRIVASTAVANo ratings yet

- DS-02 - LR BendsDocument1 pageDS-02 - LR BendsMecon LtdNo ratings yet

- DS-01 - LR BendsDocument1 pageDS-01 - LR BendsMecon LtdNo ratings yet

- DataSheet 2 More 300# BV - FB - BW - NT-77 PDFDocument1 pageDataSheet 2 More 300# BV - FB - BW - NT-77 PDFSachin KumarNo ratings yet

- #0Ttoc2Tcenehfnf6Bcbqfd: Vérifié / ReviewedDocument2 pages#0Ttoc2Tcenehfnf6Bcbqfd: Vérifié / ReviewedBruno GerbasiNo ratings yet

- Data Sheet 2 Less 800# PV - SW - NT-77Document1 pageData Sheet 2 Less 800# PV - SW - NT-77Sachin KumarNo ratings yet

- MCC Comments 1 TechDocument55 pagesMCC Comments 1 TechSUDDHA CHAKRABARTYNo ratings yet

- Cartridge Filter DatasheetDocument5 pagesCartridge Filter DatasheetSuaib VCSNo ratings yet

- Datahseet For Strainer With Air EliminatorDocument4 pagesDatahseet For Strainer With Air Eliminatorvinoj chandranNo ratings yet

- Data Sheet For MercuryDocument5 pagesData Sheet For MercuryMohamed hamza souissiNo ratings yet

- Rabigh Phase Ii Petrochemical Project: Michael HaddadDocument22 pagesRabigh Phase Ii Petrochemical Project: Michael HaddadsonalisabirNo ratings yet

- CO2 Data SheetDocument2 pagesCO2 Data SheetArul PrasaadNo ratings yet

- Summary Table For Dimensions and External Loads SSP01NDocument2 pagesSummary Table For Dimensions and External Loads SSP01NJ A S JASNo ratings yet

- Heat Exchanger SpecificationsDocument1 pageHeat Exchanger SpecificationsPankaj PandeyNo ratings yet

- Waste Heat Recovery System: Ecuador 192Mw PpsDocument30 pagesWaste Heat Recovery System: Ecuador 192Mw PpsjuanpabloizuNo ratings yet

- Data Sheet For Absorber Reflux Drum (GTPT-V-250-003)Document4 pagesData Sheet For Absorber Reflux Drum (GTPT-V-250-003)Mohamed hamza souissiNo ratings yet

- Anex 1Document59 pagesAnex 1rotatic_engineerNo ratings yet

- Strainer PDFDocument7 pagesStrainer PDFvinoj chandranNo ratings yet

- s5113 Mm41 Plate CoolerDocument79 pagess5113 Mm41 Plate CoolerJorge AguilarNo ratings yet

- Specs Sheet Duplicate 9655021-3-4 & AD993180Document8 pagesSpecs Sheet Duplicate 9655021-3-4 & AD993180Fathan KarimanNo ratings yet

- Data Sheet Basket Filter-ATF R2Document4 pagesData Sheet Basket Filter-ATF R2Suaib VCSNo ratings yet

- Serial Number:: Document TypeDocument19 pagesSerial Number:: Document TypeAhmed KhairiNo ratings yet

- 4.3 Exhaust Silencer DatasheetDocument4 pages4.3 Exhaust Silencer Datasheetabuya3kubmNo ratings yet

- Client: Data Sheet Manual Damper: GeneralDocument1 pageClient: Data Sheet Manual Damper: GeneralAlif FirdausNo ratings yet

- FlowmeterDocument22 pagesFlowmeterAnandNo ratings yet

- Quo12039 Wbh-BoguraDocument1 pageQuo12039 Wbh-BoguraMD. MAHMUDUL HASAN 39-044No ratings yet

- BLG-SNT-M-INST-DSH-001-A4 Rev. 0 (Mechanical Datasheet) PDFDocument6 pagesBLG-SNT-M-INST-DSH-001-A4 Rev. 0 (Mechanical Datasheet) PDFEdy AlamNo ratings yet

- 4 Way Fire Brigade - C.I. - GM NRVDocument2 pages4 Way Fire Brigade - C.I. - GM NRVuday245No ratings yet

- Quo12039 Wbh-IshwardiDocument1 pageQuo12039 Wbh-IshwardiMD. MAHMUDUL HASAN 39-044No ratings yet

- SizingDocument4 pagesSizingAlberto ReyesNo ratings yet

- Filter CoalescerDocument1 pageFilter CoalescerAlif FirdausNo ratings yet

- Data Sheet For Special Piping Parts: (Strainer)Document2 pagesData Sheet For Special Piping Parts: (Strainer)dimas prasetyoNo ratings yet

- Tech Specs-1000M3 LNG TankDocument1 pageTech Specs-1000M3 LNG Tankf09aiNo ratings yet

- Amapetco-Seal Unit - 001: Signature DateDocument4 pagesAmapetco-Seal Unit - 001: Signature DateMohamed HashemNo ratings yet

- MIN FLOW CalculationDocument6 pagesMIN FLOW Calculationdilip matalNo ratings yet

- B 84567 SB MM2 DSR ST 60 0013 2 AOC Seal Gas Filter CoalescerDocument11 pagesB 84567 SB MM2 DSR ST 60 0013 2 AOC Seal Gas Filter CoalescerpragatheeskNo ratings yet

- Exhaust Gas EconomizerDocument59 pagesExhaust Gas EconomizerThái Phan TrọngNo ratings yet

- Ni 23110018 CRV 03 R0Document3 pagesNi 23110018 CRV 03 R0Umer KhanNo ratings yet

- FA-For ReferenceDocument1 pageFA-For ReferenceUmer KhanNo ratings yet

- GJ2497 IoclDocument6 pagesGJ2497 IoclUmer KhanNo ratings yet

- Operation & Control PhiliosphyDocument12 pagesOperation & Control PhiliosphyUmer KhanNo ratings yet

- QAP PSV Approved As NotedDocument3 pagesQAP PSV Approved As NotedUmer KhanNo ratings yet

- Report On Hydraulic Simulation-Capacity Determination-Agra CGD-R0Document29 pagesReport On Hydraulic Simulation-Capacity Determination-Agra CGD-R0Umer KhanNo ratings yet

- PSV R1 ApprovedDocument6 pagesPSV R1 ApprovedUmer KhanNo ratings yet

- PMS KKBMPLDocument28 pagesPMS KKBMPLUmer KhanNo ratings yet

- PSV-Scrapper TrapDocument1 pagePSV-Scrapper TrapUmer KhanNo ratings yet

- IS 11006 Flame ArrestorDocument4 pagesIS 11006 Flame ArrestorUmer KhanNo ratings yet

- Operation and Maintenance Guidelines For PL and Compressor Booster StationsDocument83 pagesOperation and Maintenance Guidelines For PL and Compressor Booster StationsUmer Khan100% (1)

- At 03835 FAQ Pipe Flow Hydraulic AnalysisDocument7 pagesAt 03835 FAQ Pipe Flow Hydraulic AnalysisphantanthanhNo ratings yet

- Ial Phy U5 Thermal Energy MCQDocument11 pagesIal Phy U5 Thermal Energy MCQAnamikaAhmedNo ratings yet

- Boyle's Law Problems and SolutionsDocument1 pageBoyle's Law Problems and SolutionsBasic PhysicsNo ratings yet

- CivilDocument223 pagesCivil123No ratings yet

- Geh 6811Document30 pagesGeh 6811wednetox100% (2)

- Gas Turbines Operation, Maintenance and TroubleshootingDocument2 pagesGas Turbines Operation, Maintenance and TroubleshootingTony Eduok0% (1)

- Thermochemistry - Chapter 6Document45 pagesThermochemistry - Chapter 6Gokul MukundaNo ratings yet

- Chemistry ReflectionDocument2 pagesChemistry Reflectionapi-301500945No ratings yet

- Tubing DesignDocument12 pagesTubing Designakshitppe11No ratings yet

- ExamSlip - 148865 - 20190401 - 1520 VladDocument23 pagesExamSlip - 148865 - 20190401 - 1520 VladNikolaus PanjaitanNo ratings yet

- Combustion - Part 1 - WatermarkedDocument30 pagesCombustion - Part 1 - Watermarked84105851No ratings yet

- This Content Downloaded From 115.27.201.150 On Wed, 03 May 2023 02:50:06 +00:00Document14 pagesThis Content Downloaded From 115.27.201.150 On Wed, 03 May 2023 02:50:06 +00:00llllllistenyxNo ratings yet

- Introduction CavitationDocument19 pagesIntroduction CavitationArturoNo ratings yet

- Compressed Gas Cylinder Safety Manual: Document Number: EHS-DOC500.01Document22 pagesCompressed Gas Cylinder Safety Manual: Document Number: EHS-DOC500.01Sandeep ShettyNo ratings yet

- Unit 8 - Behavior of GasesDocument24 pagesUnit 8 - Behavior of GasesNenbon NatividadNo ratings yet

- Quirino State University: Self-Paced Learning ModuleDocument22 pagesQuirino State University: Self-Paced Learning ModuleMaden betoNo ratings yet

- PresPressure and Volume With A SyringeDocument4 pagesPresPressure and Volume With A SyringeSaid AbbaouiNo ratings yet

- CT2 2008 - API 618 Standard 5th Ed Part1 3 PDFDocument11 pagesCT2 2008 - API 618 Standard 5th Ed Part1 3 PDFAnonymous KpVxNXsNo ratings yet

- Pranic HealingDocument73 pagesPranic HealingShah Alam67% (3)

- Net Co2Document4 pagesNet Co2hocolonkoNo ratings yet

- The Effect of Perforating Conditions On Well PerformanceDocument12 pagesThe Effect of Perforating Conditions On Well PerformanceCarlos RodriguezNo ratings yet

- SF Service Equipment For Filling, Cleaning and Recovery of SF Gas Model GPU-B-2000Document4 pagesSF Service Equipment For Filling, Cleaning and Recovery of SF Gas Model GPU-B-2000denny yusufNo ratings yet

- Pressure Temperature PhETDocument6 pagesPressure Temperature PhETMiNH HayatNo ratings yet

- Condensate and Sediment TrapDocument3 pagesCondensate and Sediment TrapRahul PillaiNo ratings yet

- Heat TransferDocument32 pagesHeat TransferHassanKMNo ratings yet

- SPE 173016 MS - PDF Casing UnlockedDocument14 pagesSPE 173016 MS - PDF Casing UnlockedJorge FernandoNo ratings yet

- Science 8 Activity Sheet No. 2Document2 pagesScience 8 Activity Sheet No. 2Hannah Bridget OberesNo ratings yet

- Utilization of Support Vector Machine To Calculate Gas Compressibility FactorDocument14 pagesUtilization of Support Vector Machine To Calculate Gas Compressibility FactorekeneNo ratings yet