Professional Documents

Culture Documents

Weldwell WW Hi Ten 8 Data Sheet 2019

Weldwell WW Hi Ten 8 Data Sheet 2019

Uploaded by

Alireza TakrimiCopyright:

Available Formats

You might also like

- PowerBond PVL-144 Technical Data Sheet enDocument2 pagesPowerBond PVL-144 Technical Data Sheet en5ermmNo ratings yet

- SAFT Msds Nicd Europe 2003-10 enDocument7 pagesSAFT Msds Nicd Europe 2003-10 enDiego Francisco Castañeda ViñasNo ratings yet

- The Actinides in Homeopathy Patricia Le RouxDocument8 pagesThe Actinides in Homeopathy Patricia Le RouxTzadiNo ratings yet

- FabCO 811N1 PDFDocument2 pagesFabCO 811N1 PDFAlejandroAcuñaMaureiraNo ratings yet

- Weldwell Supercast NI FE Data Sheet 2019Document1 pageWeldwell Supercast NI FE Data Sheet 2019Alireza TakrimiNo ratings yet

- Silicon 5 Watt Zener Diodes: 1N5333B Thru 1N5388BDocument5 pagesSilicon 5 Watt Zener Diodes: 1N5333B Thru 1N5388Bameer_jaburNo ratings yet

- Nexans - Indeco Welding Cable WS 105 6...Document5 pagesNexans - Indeco Welding Cable WS 105 6...Roberto VillegaaNo ratings yet

- 1SMA10CAT3G Series, SZ1SMA10CAT3G Series 400 Watt Peak Power Zener Transient Voltage SuppressorsDocument5 pages1SMA10CAT3G Series, SZ1SMA10CAT3G Series 400 Watt Peak Power Zener Transient Voltage SuppressorsvinyroseNo ratings yet

- Conector de Resorte Azul-Naranja 22-12 AWGDocument4 pagesConector de Resorte Azul-Naranja 22-12 AWGAndrés FloresNo ratings yet

- bzg03c M SeriesDocument5 pagesbzg03c M SeriesKholilNo ratings yet

- 147-168 62gb SeriesDocument22 pages147-168 62gb SeriesJdhdkdidbdjdubdnjfbebeirhrbNo ratings yet

- 1.4462 PropertiesDocument1 page1.4462 PropertiesutreshwarmiskinNo ratings yet

- Amphenol 62GB Series: Mil-Dtl-26482 Performance Without Mis-MatingDocument3 pagesAmphenol 62GB Series: Mil-Dtl-26482 Performance Without Mis-MatingOsamaAliBangashNo ratings yet

- Smaj 530Document5 pagesSmaj 530EdgarNo ratings yet

- Se80pwtg Se80pwtjDocument5 pagesSe80pwtg Se80pwtjsureshNo ratings yet

- 22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeDocument7 pages22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeOnM deptNo ratings yet

- CONECTORDocument2 pagesCONECTORhdbryansNo ratings yet

- 1N8149US MicrosemiDocument6 pages1N8149US Microsemithuco.18No ratings yet

- 147-168 62gb Series 62GB-57A14-15SNDocument22 pages147-168 62gb Series 62GB-57A14-15SNwiradesNo ratings yet

- The Australian Welding Guide PDFDocument220 pagesThe Australian Welding Guide PDFThành Nguyễn Xuân100% (1)

- 425ºC AHT: Ower EATDocument2 pages425ºC AHT: Ower EATSivagurunathan SpNo ratings yet

- Description Appearance: Silicon 5 Watt Zener DiodesDocument3 pagesDescription Appearance: Silicon 5 Watt Zener DiodesJosé RodríguezNo ratings yet

- mmbz5225-mmbz5267 VishayDocument5 pagesmmbz5225-mmbz5267 Vishayreza yousefiNo ratings yet

- Indeco Welding Cable WS-105 600 V: DescriptionDocument3 pagesIndeco Welding Cable WS-105 600 V: DescriptionElmer Leodan Rojas CachayNo ratings yet

- Spec 55: ApplicationsDocument10 pagesSpec 55: ApplicationsfrdrfdederNo ratings yet

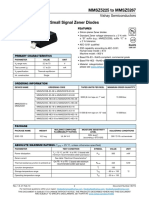

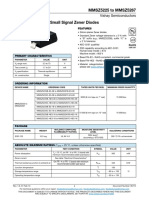

- MMSZ5225 To MMSZ5267: Vishay SemiconductorsDocument5 pagesMMSZ5225 To MMSZ5267: Vishay SemiconductorsAsadNo ratings yet

- MMSZ5225 To MMSZ5267: Vishay SemiconductorsDocument3 pagesMMSZ5225 To MMSZ5267: Vishay SemiconductorsИван ЧипNo ratings yet

- Medium Voltage Cables: Refineries & Petrochemical - OnshoreDocument2 pagesMedium Voltage Cables: Refineries & Petrochemical - OnshoreSriniNo ratings yet

- LDS 0159Document6 pagesLDS 0159aliabNo ratings yet

- Zeron SmawDocument4 pagesZeron SmawJoe FizzoNo ratings yet

- TE Connectivity DEUTSCH 983 Series/EN2997 Series Connectors: ApplicationsDocument20 pagesTE Connectivity DEUTSCH 983 Series/EN2997 Series Connectors: ApplicationsNgân Hàng Ngô Mạnh TiếnNo ratings yet

- Smbj12Aon 600 Watt Peak Power Zener Transient Voltage SuppressorDocument6 pagesSmbj12Aon 600 Watt Peak Power Zener Transient Voltage SuppressorBboyJeanko MarichalesNo ratings yet

- S3A, S3B, S3D, S3G, S3J, S3K, S3M: Vishay General SemiconductorDocument4 pagesS3A, S3B, S3D, S3G, S3J, S3K, S3M: Vishay General SemiconductorRevanNo ratings yet

- MBRA1H100T3G, NRVBA1H100T3G Surface Mount Schottky Power RectifierDocument5 pagesMBRA1H100T3G, NRVBA1H100T3G Surface Mount Schottky Power RectifierSebastian ChaileNo ratings yet

- Ei4728lf4 TDSDocument2 pagesEi4728lf4 TDSigor brocaNo ratings yet

- LDS 0300 1-1592307Document6 pagesLDS 0300 1-1592307eduardo rodriguesNo ratings yet

- SS5P9, SS5P10: Vishay General SemiconductorDocument5 pagesSS5P9, SS5P10: Vishay General Semiconductorkhawar mukhtarNo ratings yet

- Description Appearance: Axial-Leaded 1.5 Watt Zener DiodesDocument4 pagesDescription Appearance: Axial-Leaded 1.5 Watt Zener DiodesJorge VillanuevaNo ratings yet

- MSQA6V1W5T2 Quad Array For ESD Protection: A at 3 VoltDocument4 pagesMSQA6V1W5T2 Quad Array For ESD Protection: A at 3 VoltZoltán ÁgostonNo ratings yet

- DatasheetDocument5 pagesDatasheetsajad hejaziNo ratings yet

- Am PhenolDocument24 pagesAm Phenolglauberaquino1977No ratings yet

- X-Tract Electrical Submersible Pump CableDocument2 pagesX-Tract Electrical Submersible Pump CableHarry RincónNo ratings yet

- 1SMB5.0AT3 Series 600 Watt Peak Power Zener Transient Voltage SuppressorsDocument8 pages1SMB5.0AT3 Series 600 Watt Peak Power Zener Transient Voltage SuppressorsedgardoNo ratings yet

- S3A, S3B, S3D, S3G, S3J, S3K, S3M: Vishay General SemiconductorDocument4 pagesS3A, S3B, S3D, S3G, S3J, S3K, S3M: Vishay General Semiconductormahbub metulNo ratings yet

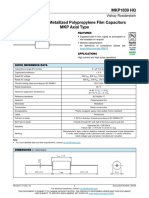

- MKP1839 HQ: Vishay RoedersteinDocument13 pagesMKP1839 HQ: Vishay RoedersteinSTE ABMCNo ratings yet

- DS IEC Low Voltage GP Ferrule Fuse Links 10x38 GG 400 To 690VAC enDocument18 pagesDS IEC Low Voltage GP Ferrule Fuse Links 10x38 GG 400 To 690VAC enberliani navitasNo ratings yet

- Vdrs Series: Vishay BccomponentsDocument20 pagesVdrs Series: Vishay BccomponentsAmir SoleimanyNo ratings yet

- Partida 7. FSL-10415D SOR 900 Series Flow Switches BrochureDocument4 pagesPartida 7. FSL-10415D SOR 900 Series Flow Switches BrochureAndree' WsNo ratings yet

- 1 N 4728 ADocument4 pages1 N 4728 Atommy99No ratings yet

- thông số smbj trong cameraDocument6 pagesthông số smbj trong cameraCanh NguyenNo ratings yet

- VM85Document226 pagesVM85Omaha KKNo ratings yet

- 8537 Sicherheitsschalter 60 100 enDocument12 pages8537 Sicherheitsschalter 60 100 enHatem HusseinNo ratings yet

- NSI50350AST3G, NSV50350AST3G Constant Current Regulator & LED DriverDocument8 pagesNSI50350AST3G, NSV50350AST3G Constant Current Regulator & LED DriverHacker4300No ratings yet

- V DeltaloyDocument2 pagesV Deltaloycatalin_adinaNo ratings yet

- Diode Zener 1n4728a PDFDocument3 pagesDiode Zener 1n4728a PDFDaniel OsorioNo ratings yet

- S5A, S5B, S5D, S5G, S5J, S5K, S5M: Vishay General SemiconductorDocument5 pagesS5A, S5B, S5D, S5G, S5J, S5K, S5M: Vishay General SemiconductorAIDA SJAMSUDINNo ratings yet

- DOC012928842Document5 pagesDOC012928842sultanov.vjNo ratings yet

- Anderson PowerDocument2 pagesAnderson Powerxlnc1No ratings yet

- VDRH Series: Vishay BccomponentsDocument25 pagesVDRH Series: Vishay BccomponentsAmir SoleimanyNo ratings yet

- Technical Information PDFDocument24 pagesTechnical Information PDFroyclhorNo ratings yet

- Asymptote Reference Card (J. C. Bowman) (v1.1 - May 2014)Document3 pagesAsymptote Reference Card (J. C. Bowman) (v1.1 - May 2014)Alireza TakrimiNo ratings yet

- An Introduction To TeX For New Users (A. Hoenig) (1992)Document6 pagesAn Introduction To TeX For New Users (A. Hoenig) (1992)Alireza TakrimiNo ratings yet

- The Canvas Learning Management System and L Texml: The L TEX Work Ow Is Still The BestDocument34 pagesThe Canvas Learning Management System and L Texml: The L TEX Work Ow Is Still The BestAlireza TakrimiNo ratings yet

- ConTeXt User Module - Document Titles (W. Schuster) (Oct. 4, 2011)Document4 pagesConTeXt User Module - Document Titles (W. Schuster) (Oct. 4, 2011)Alireza TakrimiNo ratings yet

- Hyperref Package Options (S. Rahtz, H. Oberdiek, Et Al.) (July 28, 2012)Document3 pagesHyperref Package Options (S. Rahtz, H. Oberdiek, Et Al.) (July 28, 2012)Alireza TakrimiNo ratings yet

- Arcwel Gold-600-Sg-GmawDocument1 pageArcwel Gold-600-Sg-GmawAlireza TakrimiNo ratings yet

- Siunitx: Past, Present and Future: Joseph WrightDocument24 pagesSiunitx: Past, Present and Future: Joseph WrightAlireza TakrimiNo ratings yet

- E 7016 Product-SheetDocument1 pageE 7016 Product-SheetAlireza TakrimiNo ratings yet

- Slide #2: What's To Stay, What's To Go A Quarter Century of Doc Frank Mittelbach Rio, July 2018Document3 pagesSlide #2: What's To Stay, What's To Go A Quarter Century of Doc Frank Mittelbach Rio, July 2018Alireza TakrimiNo ratings yet

- KoWey Clinker TransportDocument12 pagesKoWey Clinker TransportAlireza TakrimiNo ratings yet

- Slide #2: What'S To Stay, What'S To Go Compatibility in The Latex World Frank Mittelbach Rio, July 2018Document4 pagesSlide #2: What'S To Stay, What'S To Go Compatibility in The Latex World Frank Mittelbach Rio, July 2018Alireza TakrimiNo ratings yet

- Through The Looking Glass, and What Joseph Found There: Joseph Wright L TEX ProjectDocument24 pagesThrough The Looking Glass, and What Joseph Found There: Joseph Wright L TEX ProjectAlireza TakrimiNo ratings yet

- Ball Mill Maintenance and Installation Manual Procedure Guide PDFDocument14 pagesBall Mill Maintenance and Installation Manual Procedure Guide PDFAlireza TakrimiNo ratings yet

- Magnetic Bolt Hole & Bore Bracket - Magnetic Bracket Set For Shaft & Bore AlignmentDocument1 pageMagnetic Bolt Hole & Bore Bracket - Magnetic Bracket Set For Shaft & Bore AlignmentAlireza TakrimiNo ratings yet

- Equivalent Plastic Strain For The Hill's Yield CriterionDocument45 pagesEquivalent Plastic Strain For The Hill's Yield CriterionAlireza TakrimiNo ratings yet

- L TEX Table Columns With Fixed WidthsDocument2 pagesL TEX Table Columns With Fixed WidthsAlireza TakrimiNo ratings yet

- ProTex Filter MediaDocument2 pagesProTex Filter MediaAlireza TakrimiNo ratings yet

- AUMUND Bucket ElevatorsDocument16 pagesAUMUND Bucket ElevatorsAlireza TakrimiNo ratings yet

- Kolmetz Handbook of Process Equipment Design Natural Gas Liquid Units (NGL) (Engineering Design Guideline)Document31 pagesKolmetz Handbook of Process Equipment Design Natural Gas Liquid Units (NGL) (Engineering Design Guideline)giraulNo ratings yet

- Chemistry - Semester 1 - Experiment 1Document3 pagesChemistry - Semester 1 - Experiment 1Rawid GoshanNo ratings yet

- Billing Excel - Master-124Document20 pagesBilling Excel - Master-124akshay bhagatNo ratings yet

- 9701 - s14 - QP - 22 (Kairos)Document11 pages9701 - s14 - QP - 22 (Kairos)MCHNo ratings yet

- Vaccine Excipient & Media Summary: Excipients Included in U.S. Vaccines, by VaccineDocument4 pagesVaccine Excipient & Media Summary: Excipients Included in U.S. Vaccines, by VaccineZeljko RasoNo ratings yet

- MSDSDocument6 pagesMSDSMari Sherlin Salisi-ChuaNo ratings yet

- Automotive Gray Iron Castings: Standard Specification ForDocument5 pagesAutomotive Gray Iron Castings: Standard Specification Foralucard375No ratings yet

- APPLIED CHEMISTRY Lab ManualDocument50 pagesAPPLIED CHEMISTRY Lab ManualHarshit RajNo ratings yet

- 4105 DatasheetDocument2 pages4105 DatasheetAsad NaeemNo ratings yet

- The T6 Heat Treatment of Semi-Solid Metal Processed Alloy A356Document5 pagesThe T6 Heat Treatment of Semi-Solid Metal Processed Alloy A356tumoyeNo ratings yet

- 1 Salt Analysis - 1Document8 pages1 Salt Analysis - 1HER OICNo ratings yet

- Mode of Action Chemical Family Active Ingredient Hrac & Wssa Code Retired Hrac CodeDocument9 pagesMode of Action Chemical Family Active Ingredient Hrac & Wssa Code Retired Hrac CodeArysta Miguel Enrique Alvarez VargasNo ratings yet

- Technical Specifications: Chemical CompositionDocument2 pagesTechnical Specifications: Chemical CompositionEmir BećirovićNo ratings yet

- LEVOXIN eDocument1 pageLEVOXIN ejim_corbet1211No ratings yet

- Group 4Document6 pagesGroup 4Jeanette Mendoza RaymundoNo ratings yet

- Carbon Dioxide Solubility in Water: ConclusionsDocument4 pagesCarbon Dioxide Solubility in Water: ConclusionsDaniel MoralesNo ratings yet

- Organic Supplies Catalog 203-828 PDFDocument32 pagesOrganic Supplies Catalog 203-828 PDFDeyvid Rodriguez TapiaNo ratings yet

- Adsorption of Fatty Acids UsingDocument43 pagesAdsorption of Fatty Acids UsingmlermantovNo ratings yet

- Perrycollins 140 14320bruemmerDocument4 pagesPerrycollins 140 14320bruemmerJoyce FortalezaNo ratings yet

- BTech Alloy Weld On Instructions WebDocument1 pageBTech Alloy Weld On Instructions Webwalid mahmoudNo ratings yet

- Sample Problem #6Document4 pagesSample Problem #6Dozdi100% (2)

- IMF Answer Keys Revised 2014Document6 pagesIMF Answer Keys Revised 2014Monia AliNo ratings yet

- Grade 8 Sand and Salt Lab ReportDocument15 pagesGrade 8 Sand and Salt Lab ReportSafaa TatouNo ratings yet

- Preparation of Fluorine-Doped Tin Oxide by A Spray Pyrolysis Deposition and Its Application To The Fabrication of Dye-Sensitized Solar Cell ModuleDocument1 pagePreparation of Fluorine-Doped Tin Oxide by A Spray Pyrolysis Deposition and Its Application To The Fabrication of Dye-Sensitized Solar Cell ModuleFahad ArefeenNo ratings yet

- 1.smaw All PDFDocument76 pages1.smaw All PDFkaviatchennaiNo ratings yet

- Determinación Volta Plomo, Cadmio, Cu, ZNDocument13 pagesDeterminación Volta Plomo, Cadmio, Cu, ZNMrd DavidNo ratings yet

- Extrinsic Factors That Effect The Preservation of Bone: Digitalcommons@University of Nebraska - LincolnDocument9 pagesExtrinsic Factors That Effect The Preservation of Bone: Digitalcommons@University of Nebraska - LincolnLucas RossiNo ratings yet

- Types of S CompoundsDocument36 pagesTypes of S CompoundsMahesh sinhaNo ratings yet

Weldwell WW Hi Ten 8 Data Sheet 2019

Weldwell WW Hi Ten 8 Data Sheet 2019

Uploaded by

Alireza TakrimiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Weldwell WW Hi Ten 8 Data Sheet 2019

Weldwell WW Hi Ten 8 Data Sheet 2019

Uploaded by

Alireza TakrimiCopyright:

Available Formats

PRODUCT DATA SHEET

PROBLEM STEEL ELECTRODES

WW HI-TEN 8 1G

2G 3G

4G

2F

SUMMARY TYPICAL ALL WELD METAL CHEMICAL ANALYSIS

High toughness and wear resistance C Mn Ni Cr S

Exceptionally good where high strength, impact, 0.1 0.8 9 30 0.03

heat and corrosion resistance are required

High anti-cracking properties

Deposits little or no spatter TYPICAL ALL WELD METAL MECHANICAL ANALYSIS

IDENTIFICATION Yield Strength Up to 625 MPa

Up to 825 MPa

Coating - Light Blue Tip - Light Blue Tensile Strength

Up to 1200 MPa (work hardened)

Imprint - WW Hi-Ten 8

Elongation Min 22%

CLASSIFICATION

PACKAGING DATA

AS/NZS 4854B ES312-16

AWS A5.4 E312-16

ELECTRODE PACKAGING APPROX. PART NO.

SIZE (MM) NO. OF

DESCRIPTION AND APPLICATION RODS

PER KG

The Weldwell HI-TEN 8 has a special coating which permits KG PER PACKETS

PACKET PER

smooth, dense deposits, porosity free and with little or no

CARTON

spatter. Welds are made with highest possible speed using the

lowest practical amperage, the deposit will take a high polish. 2.5 2.5 5 151 WWHT825

3.2 2.5 5 74 WWHT832

Exceptionally good where high strength, impact, heat and

corrosion resistance are required. It is very insensitive to The information contained or otherwise referenced herein is presented only as

“typical” without guarantee or warranty, and Weldwell expressly disclaims any liability

cracking. Recommended for use when the analysis of the

incurred from any reliance thereon. Typical data is obtained when welded and tested

various stainless steels is unknown or doubtful, the repair of in accordance with the AWS and or AS/NZS specification. Other tests and procedures

die and tool steels. Weldwell Hi-Ten 8 cannot be heat treated may produce different results. No data is to be construed as a recommendation for

any welding condition or technique by Weldwell.

but can be work hardened to over 1200 MPa tensile strength.

Issue CA - May 2019

OPERATIONAL DATA

ELECTRODE SIZE ELECTRODE WELD. CURRENT RANGE

(MM) LENGTH (MM) * (A)

2.5 300 40 -75

3.2 350 75 - 125

*Recommended for DC +/- or AC (minimum 50 OCV).

Voltage is determined by arc current and electrode arc length.

Arc voltage shown is typical and is only to be used as a guide.

weldwell.co.nz 0800 WELDWELL

You might also like

- PowerBond PVL-144 Technical Data Sheet enDocument2 pagesPowerBond PVL-144 Technical Data Sheet en5ermmNo ratings yet

- SAFT Msds Nicd Europe 2003-10 enDocument7 pagesSAFT Msds Nicd Europe 2003-10 enDiego Francisco Castañeda ViñasNo ratings yet

- The Actinides in Homeopathy Patricia Le RouxDocument8 pagesThe Actinides in Homeopathy Patricia Le RouxTzadiNo ratings yet

- FabCO 811N1 PDFDocument2 pagesFabCO 811N1 PDFAlejandroAcuñaMaureiraNo ratings yet

- Weldwell Supercast NI FE Data Sheet 2019Document1 pageWeldwell Supercast NI FE Data Sheet 2019Alireza TakrimiNo ratings yet

- Silicon 5 Watt Zener Diodes: 1N5333B Thru 1N5388BDocument5 pagesSilicon 5 Watt Zener Diodes: 1N5333B Thru 1N5388Bameer_jaburNo ratings yet

- Nexans - Indeco Welding Cable WS 105 6...Document5 pagesNexans - Indeco Welding Cable WS 105 6...Roberto VillegaaNo ratings yet

- 1SMA10CAT3G Series, SZ1SMA10CAT3G Series 400 Watt Peak Power Zener Transient Voltage SuppressorsDocument5 pages1SMA10CAT3G Series, SZ1SMA10CAT3G Series 400 Watt Peak Power Zener Transient Voltage SuppressorsvinyroseNo ratings yet

- Conector de Resorte Azul-Naranja 22-12 AWGDocument4 pagesConector de Resorte Azul-Naranja 22-12 AWGAndrés FloresNo ratings yet

- bzg03c M SeriesDocument5 pagesbzg03c M SeriesKholilNo ratings yet

- 147-168 62gb SeriesDocument22 pages147-168 62gb SeriesJdhdkdidbdjdubdnjfbebeirhrbNo ratings yet

- 1.4462 PropertiesDocument1 page1.4462 PropertiesutreshwarmiskinNo ratings yet

- Amphenol 62GB Series: Mil-Dtl-26482 Performance Without Mis-MatingDocument3 pagesAmphenol 62GB Series: Mil-Dtl-26482 Performance Without Mis-MatingOsamaAliBangashNo ratings yet

- Smaj 530Document5 pagesSmaj 530EdgarNo ratings yet

- Se80pwtg Se80pwtjDocument5 pagesSe80pwtg Se80pwtjsureshNo ratings yet

- 22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeDocument7 pages22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeOnM deptNo ratings yet

- CONECTORDocument2 pagesCONECTORhdbryansNo ratings yet

- 1N8149US MicrosemiDocument6 pages1N8149US Microsemithuco.18No ratings yet

- 147-168 62gb Series 62GB-57A14-15SNDocument22 pages147-168 62gb Series 62GB-57A14-15SNwiradesNo ratings yet

- The Australian Welding Guide PDFDocument220 pagesThe Australian Welding Guide PDFThành Nguyễn Xuân100% (1)

- 425ºC AHT: Ower EATDocument2 pages425ºC AHT: Ower EATSivagurunathan SpNo ratings yet

- Description Appearance: Silicon 5 Watt Zener DiodesDocument3 pagesDescription Appearance: Silicon 5 Watt Zener DiodesJosé RodríguezNo ratings yet

- mmbz5225-mmbz5267 VishayDocument5 pagesmmbz5225-mmbz5267 Vishayreza yousefiNo ratings yet

- Indeco Welding Cable WS-105 600 V: DescriptionDocument3 pagesIndeco Welding Cable WS-105 600 V: DescriptionElmer Leodan Rojas CachayNo ratings yet

- Spec 55: ApplicationsDocument10 pagesSpec 55: ApplicationsfrdrfdederNo ratings yet

- MMSZ5225 To MMSZ5267: Vishay SemiconductorsDocument5 pagesMMSZ5225 To MMSZ5267: Vishay SemiconductorsAsadNo ratings yet

- MMSZ5225 To MMSZ5267: Vishay SemiconductorsDocument3 pagesMMSZ5225 To MMSZ5267: Vishay SemiconductorsИван ЧипNo ratings yet

- Medium Voltage Cables: Refineries & Petrochemical - OnshoreDocument2 pagesMedium Voltage Cables: Refineries & Petrochemical - OnshoreSriniNo ratings yet

- LDS 0159Document6 pagesLDS 0159aliabNo ratings yet

- Zeron SmawDocument4 pagesZeron SmawJoe FizzoNo ratings yet

- TE Connectivity DEUTSCH 983 Series/EN2997 Series Connectors: ApplicationsDocument20 pagesTE Connectivity DEUTSCH 983 Series/EN2997 Series Connectors: ApplicationsNgân Hàng Ngô Mạnh TiếnNo ratings yet

- Smbj12Aon 600 Watt Peak Power Zener Transient Voltage SuppressorDocument6 pagesSmbj12Aon 600 Watt Peak Power Zener Transient Voltage SuppressorBboyJeanko MarichalesNo ratings yet

- S3A, S3B, S3D, S3G, S3J, S3K, S3M: Vishay General SemiconductorDocument4 pagesS3A, S3B, S3D, S3G, S3J, S3K, S3M: Vishay General SemiconductorRevanNo ratings yet

- MBRA1H100T3G, NRVBA1H100T3G Surface Mount Schottky Power RectifierDocument5 pagesMBRA1H100T3G, NRVBA1H100T3G Surface Mount Schottky Power RectifierSebastian ChaileNo ratings yet

- Ei4728lf4 TDSDocument2 pagesEi4728lf4 TDSigor brocaNo ratings yet

- LDS 0300 1-1592307Document6 pagesLDS 0300 1-1592307eduardo rodriguesNo ratings yet

- SS5P9, SS5P10: Vishay General SemiconductorDocument5 pagesSS5P9, SS5P10: Vishay General Semiconductorkhawar mukhtarNo ratings yet

- Description Appearance: Axial-Leaded 1.5 Watt Zener DiodesDocument4 pagesDescription Appearance: Axial-Leaded 1.5 Watt Zener DiodesJorge VillanuevaNo ratings yet

- MSQA6V1W5T2 Quad Array For ESD Protection: A at 3 VoltDocument4 pagesMSQA6V1W5T2 Quad Array For ESD Protection: A at 3 VoltZoltán ÁgostonNo ratings yet

- DatasheetDocument5 pagesDatasheetsajad hejaziNo ratings yet

- Am PhenolDocument24 pagesAm Phenolglauberaquino1977No ratings yet

- X-Tract Electrical Submersible Pump CableDocument2 pagesX-Tract Electrical Submersible Pump CableHarry RincónNo ratings yet

- 1SMB5.0AT3 Series 600 Watt Peak Power Zener Transient Voltage SuppressorsDocument8 pages1SMB5.0AT3 Series 600 Watt Peak Power Zener Transient Voltage SuppressorsedgardoNo ratings yet

- S3A, S3B, S3D, S3G, S3J, S3K, S3M: Vishay General SemiconductorDocument4 pagesS3A, S3B, S3D, S3G, S3J, S3K, S3M: Vishay General Semiconductormahbub metulNo ratings yet

- MKP1839 HQ: Vishay RoedersteinDocument13 pagesMKP1839 HQ: Vishay RoedersteinSTE ABMCNo ratings yet

- DS IEC Low Voltage GP Ferrule Fuse Links 10x38 GG 400 To 690VAC enDocument18 pagesDS IEC Low Voltage GP Ferrule Fuse Links 10x38 GG 400 To 690VAC enberliani navitasNo ratings yet

- Vdrs Series: Vishay BccomponentsDocument20 pagesVdrs Series: Vishay BccomponentsAmir SoleimanyNo ratings yet

- Partida 7. FSL-10415D SOR 900 Series Flow Switches BrochureDocument4 pagesPartida 7. FSL-10415D SOR 900 Series Flow Switches BrochureAndree' WsNo ratings yet

- 1 N 4728 ADocument4 pages1 N 4728 Atommy99No ratings yet

- thông số smbj trong cameraDocument6 pagesthông số smbj trong cameraCanh NguyenNo ratings yet

- VM85Document226 pagesVM85Omaha KKNo ratings yet

- 8537 Sicherheitsschalter 60 100 enDocument12 pages8537 Sicherheitsschalter 60 100 enHatem HusseinNo ratings yet

- NSI50350AST3G, NSV50350AST3G Constant Current Regulator & LED DriverDocument8 pagesNSI50350AST3G, NSV50350AST3G Constant Current Regulator & LED DriverHacker4300No ratings yet

- V DeltaloyDocument2 pagesV Deltaloycatalin_adinaNo ratings yet

- Diode Zener 1n4728a PDFDocument3 pagesDiode Zener 1n4728a PDFDaniel OsorioNo ratings yet

- S5A, S5B, S5D, S5G, S5J, S5K, S5M: Vishay General SemiconductorDocument5 pagesS5A, S5B, S5D, S5G, S5J, S5K, S5M: Vishay General SemiconductorAIDA SJAMSUDINNo ratings yet

- DOC012928842Document5 pagesDOC012928842sultanov.vjNo ratings yet

- Anderson PowerDocument2 pagesAnderson Powerxlnc1No ratings yet

- VDRH Series: Vishay BccomponentsDocument25 pagesVDRH Series: Vishay BccomponentsAmir SoleimanyNo ratings yet

- Technical Information PDFDocument24 pagesTechnical Information PDFroyclhorNo ratings yet

- Asymptote Reference Card (J. C. Bowman) (v1.1 - May 2014)Document3 pagesAsymptote Reference Card (J. C. Bowman) (v1.1 - May 2014)Alireza TakrimiNo ratings yet

- An Introduction To TeX For New Users (A. Hoenig) (1992)Document6 pagesAn Introduction To TeX For New Users (A. Hoenig) (1992)Alireza TakrimiNo ratings yet

- The Canvas Learning Management System and L Texml: The L TEX Work Ow Is Still The BestDocument34 pagesThe Canvas Learning Management System and L Texml: The L TEX Work Ow Is Still The BestAlireza TakrimiNo ratings yet

- ConTeXt User Module - Document Titles (W. Schuster) (Oct. 4, 2011)Document4 pagesConTeXt User Module - Document Titles (W. Schuster) (Oct. 4, 2011)Alireza TakrimiNo ratings yet

- Hyperref Package Options (S. Rahtz, H. Oberdiek, Et Al.) (July 28, 2012)Document3 pagesHyperref Package Options (S. Rahtz, H. Oberdiek, Et Al.) (July 28, 2012)Alireza TakrimiNo ratings yet

- Arcwel Gold-600-Sg-GmawDocument1 pageArcwel Gold-600-Sg-GmawAlireza TakrimiNo ratings yet

- Siunitx: Past, Present and Future: Joseph WrightDocument24 pagesSiunitx: Past, Present and Future: Joseph WrightAlireza TakrimiNo ratings yet

- E 7016 Product-SheetDocument1 pageE 7016 Product-SheetAlireza TakrimiNo ratings yet

- Slide #2: What's To Stay, What's To Go A Quarter Century of Doc Frank Mittelbach Rio, July 2018Document3 pagesSlide #2: What's To Stay, What's To Go A Quarter Century of Doc Frank Mittelbach Rio, July 2018Alireza TakrimiNo ratings yet

- KoWey Clinker TransportDocument12 pagesKoWey Clinker TransportAlireza TakrimiNo ratings yet

- Slide #2: What'S To Stay, What'S To Go Compatibility in The Latex World Frank Mittelbach Rio, July 2018Document4 pagesSlide #2: What'S To Stay, What'S To Go Compatibility in The Latex World Frank Mittelbach Rio, July 2018Alireza TakrimiNo ratings yet

- Through The Looking Glass, and What Joseph Found There: Joseph Wright L TEX ProjectDocument24 pagesThrough The Looking Glass, and What Joseph Found There: Joseph Wright L TEX ProjectAlireza TakrimiNo ratings yet

- Ball Mill Maintenance and Installation Manual Procedure Guide PDFDocument14 pagesBall Mill Maintenance and Installation Manual Procedure Guide PDFAlireza TakrimiNo ratings yet

- Magnetic Bolt Hole & Bore Bracket - Magnetic Bracket Set For Shaft & Bore AlignmentDocument1 pageMagnetic Bolt Hole & Bore Bracket - Magnetic Bracket Set For Shaft & Bore AlignmentAlireza TakrimiNo ratings yet

- Equivalent Plastic Strain For The Hill's Yield CriterionDocument45 pagesEquivalent Plastic Strain For The Hill's Yield CriterionAlireza TakrimiNo ratings yet

- L TEX Table Columns With Fixed WidthsDocument2 pagesL TEX Table Columns With Fixed WidthsAlireza TakrimiNo ratings yet

- ProTex Filter MediaDocument2 pagesProTex Filter MediaAlireza TakrimiNo ratings yet

- AUMUND Bucket ElevatorsDocument16 pagesAUMUND Bucket ElevatorsAlireza TakrimiNo ratings yet

- Kolmetz Handbook of Process Equipment Design Natural Gas Liquid Units (NGL) (Engineering Design Guideline)Document31 pagesKolmetz Handbook of Process Equipment Design Natural Gas Liquid Units (NGL) (Engineering Design Guideline)giraulNo ratings yet

- Chemistry - Semester 1 - Experiment 1Document3 pagesChemistry - Semester 1 - Experiment 1Rawid GoshanNo ratings yet

- Billing Excel - Master-124Document20 pagesBilling Excel - Master-124akshay bhagatNo ratings yet

- 9701 - s14 - QP - 22 (Kairos)Document11 pages9701 - s14 - QP - 22 (Kairos)MCHNo ratings yet

- Vaccine Excipient & Media Summary: Excipients Included in U.S. Vaccines, by VaccineDocument4 pagesVaccine Excipient & Media Summary: Excipients Included in U.S. Vaccines, by VaccineZeljko RasoNo ratings yet

- MSDSDocument6 pagesMSDSMari Sherlin Salisi-ChuaNo ratings yet

- Automotive Gray Iron Castings: Standard Specification ForDocument5 pagesAutomotive Gray Iron Castings: Standard Specification Foralucard375No ratings yet

- APPLIED CHEMISTRY Lab ManualDocument50 pagesAPPLIED CHEMISTRY Lab ManualHarshit RajNo ratings yet

- 4105 DatasheetDocument2 pages4105 DatasheetAsad NaeemNo ratings yet

- The T6 Heat Treatment of Semi-Solid Metal Processed Alloy A356Document5 pagesThe T6 Heat Treatment of Semi-Solid Metal Processed Alloy A356tumoyeNo ratings yet

- 1 Salt Analysis - 1Document8 pages1 Salt Analysis - 1HER OICNo ratings yet

- Mode of Action Chemical Family Active Ingredient Hrac & Wssa Code Retired Hrac CodeDocument9 pagesMode of Action Chemical Family Active Ingredient Hrac & Wssa Code Retired Hrac CodeArysta Miguel Enrique Alvarez VargasNo ratings yet

- Technical Specifications: Chemical CompositionDocument2 pagesTechnical Specifications: Chemical CompositionEmir BećirovićNo ratings yet

- LEVOXIN eDocument1 pageLEVOXIN ejim_corbet1211No ratings yet

- Group 4Document6 pagesGroup 4Jeanette Mendoza RaymundoNo ratings yet

- Carbon Dioxide Solubility in Water: ConclusionsDocument4 pagesCarbon Dioxide Solubility in Water: ConclusionsDaniel MoralesNo ratings yet

- Organic Supplies Catalog 203-828 PDFDocument32 pagesOrganic Supplies Catalog 203-828 PDFDeyvid Rodriguez TapiaNo ratings yet

- Adsorption of Fatty Acids UsingDocument43 pagesAdsorption of Fatty Acids UsingmlermantovNo ratings yet

- Perrycollins 140 14320bruemmerDocument4 pagesPerrycollins 140 14320bruemmerJoyce FortalezaNo ratings yet

- BTech Alloy Weld On Instructions WebDocument1 pageBTech Alloy Weld On Instructions Webwalid mahmoudNo ratings yet

- Sample Problem #6Document4 pagesSample Problem #6Dozdi100% (2)

- IMF Answer Keys Revised 2014Document6 pagesIMF Answer Keys Revised 2014Monia AliNo ratings yet

- Grade 8 Sand and Salt Lab ReportDocument15 pagesGrade 8 Sand and Salt Lab ReportSafaa TatouNo ratings yet

- Preparation of Fluorine-Doped Tin Oxide by A Spray Pyrolysis Deposition and Its Application To The Fabrication of Dye-Sensitized Solar Cell ModuleDocument1 pagePreparation of Fluorine-Doped Tin Oxide by A Spray Pyrolysis Deposition and Its Application To The Fabrication of Dye-Sensitized Solar Cell ModuleFahad ArefeenNo ratings yet

- 1.smaw All PDFDocument76 pages1.smaw All PDFkaviatchennaiNo ratings yet

- Determinación Volta Plomo, Cadmio, Cu, ZNDocument13 pagesDeterminación Volta Plomo, Cadmio, Cu, ZNMrd DavidNo ratings yet

- Extrinsic Factors That Effect The Preservation of Bone: Digitalcommons@University of Nebraska - LincolnDocument9 pagesExtrinsic Factors That Effect The Preservation of Bone: Digitalcommons@University of Nebraska - LincolnLucas RossiNo ratings yet

- Types of S CompoundsDocument36 pagesTypes of S CompoundsMahesh sinhaNo ratings yet