Professional Documents

Culture Documents

Side Construction

Side Construction

Uploaded by

mohamedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Side Construction

Side Construction

Uploaded by

mohamedCopyright:

Available Formats

Prof.

Khaled Atua Ship Construction

4. Side Construction

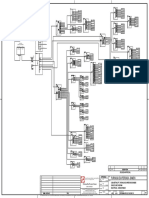

Transverse Side

Framing

Transverse Side Frames help

to resist water loads applied to

the outside of the shell, they

serve to stiffen the side plating

against buckling. They furnish

vertical support to the

outboard ends of the beams

supporting the several decks.

In addition, side frames resist

loads imposed by contact with

piers, docks, and lock sides.

The brackets used for these

connections must be carefully

Detail B designed to avoid

discontinuities and provide for

the proper transition of loads.

Another function of side

Detail A frames is that of contributing

Detail D resistance to racking stresses

caused by rolling of the ship

and by impact of seas against

Detail E the topsides especially when

the transverse bulkheads are

widely spaced or omitted

entirely.

Detail C

729664138.doc Prof. Khaled Atua 13

Prof. Khaled Atua Ship Construction

Detail A

Tween Deck Frame

A-A: Connection between lower

and upper frames and tween deck A

729664138.doc Prof. Khaled Atua 14

Lapped Knee Bracket

Prof. Khaled Atua Ship Construction

Types of Knee Brackest

Connections

Lapped Knee Bracket

Butt Knee Bracket Perfect Lapped Bracket

Stronger when subjected to tension Longer line of contact, hence, greater amount

Attachment of the beam to the frame of weld and greater connectivity

Support the outboard end of the beam by reducing Firmer fixation of corner between deck and

the effective span side plating

Minor resistance to ship’s racking Smoother stress flow between deck

transverse and side frame through bracket

Sec. B-B

Detail D

Continuous Bracket Flanged Butt KneeBBracket

Detail

Only at web frame and transverse deck web beam Flanges are provided

B-B: Knee Bracket to create greater support

Made of a built T section (welded plates to form the instead of fitting a larger bracket

bracket flange) Flange also helps to decrease the thickness of the

Perfect stress flow between deck transverse beam bracket

B B

and side web frame

729664138.doc Prof. Khaled Atua 15

Prof. Khaled Atua Ship Construction

Tween-deck Frames. The section modulus of tween-deck frames plus plating,

depends on the height and vertical locaion of the tween decks and the spacing of the

frames. Detail A.

Sections Used for Side Framing. The sections most commonly used for frames are

flat bars, inverted angles, bulb plates, and T-sections. The inverted angle may be either a

rolled section or cut from a channel

Bevel of Side Framing. The webs of side frames are set normal to the longitudinal

center plane of the ship, and, as a result, are not normal to the shell. This facilitates

alignment with transverse members, while the angularity at the shell does not cause a

severe construction problem.

Looking Ford

Sec. C-C Sec. C-C

Looking Aft

Bevel of Side

Framing

C CC C

Detail C Detail C

Bevel Side Stringer Straight Side Stringer

729664138.doc Prof. Khaled Atua 16

Prof. Khaled Atua Ship Construction

Lower Connections of Hold Frames. As shown in Fig A. The web of the

bracket is welded to the inner bottom and the flange cut clear of the inner bottom.

Where the hold frame brackets interfere with cargo stowage, they are eliminated by

running the frame down to the inner bottom and welding it. In this case, the flange must

be welded down and a chock provided. Fig. B shows the bilge bracket used as a

connection for the lower end of the hold frame in cargo ships with a longitudinally

framed double bottom. The bilge bracket is fitted at every frame not having a solid

floor. The scantlings of the frame must be increased when the hold bracket is eliminated

due to the longer span considered, since, for rule purposes, the length is measured to the

top of the bracket

B A

Joints in Side Frames. The hold frames are generally longer, and therefore

heavier, than is necessary for the upper 'tween-deck frames, and, even if the hold size

could be carried through in one long length, considerations of subassembly and erection

729664138.doc Prof. Khaled Atua 17

Prof. Khaled Atua Ship Construction

usually make it desirable to fit the frames in more than one piece. At the resulting joints,

effective continuity should be maintained. In welded construction, it might seem that a

100-percent butt-welded joint could be accepted at any desired place in the frame, but a

backing strip should be used to ensure full penetration of the weld in the back side of the

Hange, where welder's access and visibility are poor. ABS will accept a frame butt made

in way of a deck or Hat, as in Fig. 30 (C). when there is assurance that the frames above

and below the decks are lined up accurately. Careful workmanship, checked by

inspection, is necessary in this connection. Where the frame is not considered as a

continuous beam and the depth of the frame changes by more than about 25 mm (1 in.),

provision should be made to maintain continuity of the Hanges. This can be done either

by widening the shallower section, as in Fig. 30 (A), or, if the difference in depth of

section is considerable, by fitting chocks on the deeper frame opposite the Hange of the

shallower frame, as shown in Fig. 30 (B). Side frames should not pierce the tops of deep

tanks; they should be cut, with the tank top continuous out to the shell to ensure its

tightness.

729664138.doc Prof. Khaled Atua 18

Prof. Khaled Atua Ship Construction

Crossing of Side Framing and Welded Shell Seams.

Wherever a welded frame crosses an erection seam weld in the shell plating, the web of

the frame should be notched out to permit the seam weld to pass the frame intact and

continuous, as shown in Fig. 31. This should be done generally where a nontight welded

member crosses a continuous weld in a tight structure, such as stiffeners on a bulkhead or

longitudinals crossing shell butts, except in the case of sub assembled plates, discussed in

Subsection 14.5.

Detail E

Side Framing and Welded Shell Seams.

Scallops are provided to avoid

intersection of two welding seams

E E

View E-E

Transversely framed Side Construction of a General Cargo Ship

729664138.doc Prof. Khaled Atua 19

Prof. Khaled Atua Ship Construction

Transversely framed Side Construction with a Side Stringer for a General

Cargo Ship

Longitudinally framed Side Construction of an Oil Tanker

729664138.doc Prof. Khaled Atua 20

Prof. Khaled Atua Ship Construction

Combined framed midship section of a General Cargo Ship

For oil tankers, bulk carriers, general cargo vessels, containerships, and Great Lakes ore

carriers, longitudinal framing is generally adopted, at least for the strength deck plating

and bottom shell

Transversely framed Side Construction of a Bulk Carrier

729664138.doc Prof. Khaled Atua 21

Prof. Khaled Atua Ship Construction

729664138.doc Prof. Khaled Atua 22

You might also like

- General Ship KnowledgeDocument7 pagesGeneral Ship Knowledgezalads100% (3)

- Deflection LimitDocument12 pagesDeflection LimitPiyush Bhardwaj100% (2)

- Side ConstructionDocument10 pagesSide ConstructionarmanimamsNo ratings yet

- Bulkhead ConstructionDocument8 pagesBulkhead ConstructionarmanimamsNo ratings yet

- 03 BulkheadDocument9 pages03 BulkheadLucky BoatNo ratings yet

- Fenders For Locks, Dry Docks & Jetty Corners: M H & R GDocument3 pagesFenders For Locks, Dry Docks & Jetty Corners: M H & R GIsma VSNo ratings yet

- 14.for and Aft ConstructionDocument20 pages14.for and Aft Constructionarmanimams100% (2)

- CIE 815 Plated Structures Lecture NoteDocument19 pagesCIE 815 Plated Structures Lecture NoteHenry DiyokeNo ratings yet

- Understanding Watertight Bulkheads in Ships Construction and SOLAS RegulationsDocument10 pagesUnderstanding Watertight Bulkheads in Ships Construction and SOLAS RegulationsGiorgi KandelakiNo ratings yet

- Woodspec Final - Section BDocument58 pagesWoodspec Final - Section BmcbluedNo ratings yet

- Notes On Ship ConstructionDocument23 pagesNotes On Ship Constructionpimpampum111100% (4)

- 01 4 132Document5 pages01 4 132cmkohNo ratings yet

- Design of BeamsDocument28 pagesDesign of BeamsNayan Fatania100% (2)

- Ship Construction Structure NotesDocument106 pagesShip Construction Structure NotesBiplabananda Talukdar100% (2)

- Bottom Repairs On Single Hatch Ships or On Ships With Relatively Long HatchesDocument18 pagesBottom Repairs On Single Hatch Ships or On Ships With Relatively Long HatchesaliNo ratings yet

- Konstruksi Dasar KapalDocument31 pagesKonstruksi Dasar KapalrizkiNo ratings yet

- Design and Fabrication of All Welded Bridge CranesDocument4 pagesDesign and Fabrication of All Welded Bridge Cranesaiyubi2No ratings yet

- Ship Design For Efficiency and Economy-7-226-13-18Document6 pagesShip Design For Efficiency and Economy-7-226-13-18galin8575No ratings yet

- Hull Structure - HandoutDocument15 pagesHull Structure - HandoutSamNo ratings yet

- SMSC-1400-01 - Answer KeysDocument5 pagesSMSC-1400-01 - Answer KeysAmir SoleimanyNo ratings yet

- FramingDocument8 pagesFramingpramod.bNo ratings yet

- Lecture 9.5 - Stressed Skin DesignDocument21 pagesLecture 9.5 - Stressed Skin DesignsoulsellNo ratings yet

- Abut DesignDocument28 pagesAbut Designrgscribd61No ratings yet

- Shell and Deck PlatingDocument22 pagesShell and Deck PlatingVijay DamleyNo ratings yet

- Azlan (Bridge Substructure Piers) 07-08Document36 pagesAzlan (Bridge Substructure Piers) 07-08khoohuikiangNo ratings yet

- Unit 8 Design of Beams PDFDocument28 pagesUnit 8 Design of Beams PDFveenuNo ratings yet

- Seam 1 Assessment (Catch Up) - UnansweredDocument11 pagesSeam 1 Assessment (Catch Up) - UnansweredJohn Paul FebreroNo ratings yet

- Na-II Ship ConstructionDocument16 pagesNa-II Ship ConstructionmichaelrithishNo ratings yet

- ShipCo Notes - Phase 1 MMDDocument52 pagesShipCo Notes - Phase 1 MMDGurjit Singh100% (1)

- Mooring Assessment FormDocument4 pagesMooring Assessment FormSAGAMINo ratings yet

- CHAPTER 2 - Cross Section ClasificationDocument21 pagesCHAPTER 2 - Cross Section ClasificationHalina HamidNo ratings yet

- Vertical Breakwaters PDFDocument80 pagesVertical Breakwaters PDFMonika Nathawat na18b027No ratings yet

- Lec 3 Basic Ship StructureDocument52 pagesLec 3 Basic Ship StructureHasnain AnisNo ratings yet

- Plate GirederDocument5 pagesPlate GirederDr.B. NarenderNo ratings yet

- Design and Analysis of Retaining WallsDocument38 pagesDesign and Analysis of Retaining WallsMohamed MuayidNo ratings yet

- Structural Design QuestionnaireDocument7 pagesStructural Design QuestionnaireDessNo ratings yet

- Lec 5 (1) - Design of BeamsDocument62 pagesLec 5 (1) - Design of BeamsMuhammad Faisal AsifNo ratings yet

- Tied-Arch Bridges - Steelconstruction - InfoDocument14 pagesTied-Arch Bridges - Steelconstruction - InfoAlfredo Romero G100% (1)

- Ship ConstructionDocument11 pagesShip ConstructionCadet ABDUL REHMANNo ratings yet

- Ship Construction: Second Mates - HANDOUTDocument117 pagesShip Construction: Second Mates - HANDOUTmaneeshNo ratings yet

- Structural Design and Analysis of FPSO Topside Module SupportsDocument10 pagesStructural Design and Analysis of FPSO Topside Module SupportsSettuNo ratings yet

- Structural Corrosion Issues in Aggregate Processing PlantsDocument16 pagesStructural Corrosion Issues in Aggregate Processing PlantsLarry DeemNo ratings yet

- Fleetrite: The Rite Parts, Right NowDocument12 pagesFleetrite: The Rite Parts, Right NowEdinson BolivarNo ratings yet

- Dapped Ends of Prestressed Concrete Thin-Stemmed Members - Part 1, Experimental Testing and BehaviorDocument22 pagesDapped Ends of Prestressed Concrete Thin-Stemmed Members - Part 1, Experimental Testing and BehaviorcrvishnuramNo ratings yet

- Unit - I - Plate Girder - Sci1309: School of Building and Environment Department of Civil EngineeringDocument55 pagesUnit - I - Plate Girder - Sci1309: School of Building and Environment Department of Civil Engineeringvijay kumarNo ratings yet

- Handout Stern ConstructionDocument3 pagesHandout Stern ConstructionSamNo ratings yet

- Buttress DamsDocument7 pagesButtress Damskibiralew DestaNo ratings yet

- Ship Structure-Hull, Bottom, Bulkheads, FloorsDocument108 pagesShip Structure-Hull, Bottom, Bulkheads, FloorsChristopher Hawley100% (1)

- FWD and Aft Structural PartsDocument49 pagesFWD and Aft Structural Partslisa noviantyNo ratings yet

- Bro TLP WebDocument20 pagesBro TLP WebCristian BNo ratings yet

- Improved Steel Beam-Column Connections in Industrial StructuresDocument6 pagesImproved Steel Beam-Column Connections in Industrial StructuresSufyan Berinyuy WiysahnyuyNo ratings yet

- Railway Bridge Design Assessment - Design of Plate Girders-1Document79 pagesRailway Bridge Design Assessment - Design of Plate Girders-1Mohamed ShabibNo ratings yet

- Superstructure of Ships-Module4Document9 pagesSuperstructure of Ships-Module4Pramod Kumar MallyaNo ratings yet

- Chapter 10 PDFDocument56 pagesChapter 10 PDFAdolfo ElizondoNo ratings yet

- General Stability QuestionsDocument33 pagesGeneral Stability QuestionsAnonymous nF3tseUAGe100% (1)

- N.W.F.P. University of Engineering and Technology Peshawar: Lecture 13: Plate GirderDocument79 pagesN.W.F.P. University of Engineering and Technology Peshawar: Lecture 13: Plate GirderNeilNo ratings yet

- ch8 Retaining Walls PDFDocument15 pagesch8 Retaining Walls PDFMahdi ValaeeNo ratings yet

- Shear Force and Bending Moment Calculation by IldDocument15 pagesShear Force and Bending Moment Calculation by IldBadri NathNo ratings yet

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- Bottom ConstructionDocument6 pagesBottom ConstructionmohamedNo ratings yet

- Ship Types and FeaturesDocument6 pagesShip Types and FeaturesmohamedNo ratings yet

- How Read Pump CurvesDocument5 pagesHow Read Pump CurvesmohamedNo ratings yet

- The Level Measurement: Sachin MewaraDocument32 pagesThe Level Measurement: Sachin MewaramohamedNo ratings yet

- Shantilal Shah Engineering College BhavnagarDocument49 pagesShantilal Shah Engineering College BhavnagarmohamedNo ratings yet

- Level Measuring DevicesDocument18 pagesLevel Measuring DevicesmohamedNo ratings yet

- 06-076-080 Ring Joints RTJDocument5 pages06-076-080 Ring Joints RTJmohamedNo ratings yet

- UR Z23 Rev2 pdf1040Document30 pagesUR Z23 Rev2 pdf1040mohamedNo ratings yet

- Instrumentation & Process Control: Topic: Liquid Level MeasurementDocument8 pagesInstrumentation & Process Control: Topic: Liquid Level MeasurementmohamedNo ratings yet

- Norsk Standard NS 2520: Sjøteknikk Låsfeste For Dører Og Luker Av StålDocument8 pagesNorsk Standard NS 2520: Sjøteknikk Låsfeste For Dører Og Luker Av StålmohamedNo ratings yet

- Sea Cort Jan Dix Seal Ring GasketsDocument5 pagesSea Cort Jan Dix Seal Ring GasketsmohamedNo ratings yet

- Form 2 Notice of Expected Implementation Date in The Rules and Practices As at June 2008Document9 pagesForm 2 Notice of Expected Implementation Date in The Rules and Practices As at June 2008mohamedNo ratings yet

- Is It Simple To Explain Simple Experiments The Heavy Newspaper' Stick BreakDocument6 pagesIs It Simple To Explain Simple Experiments The Heavy Newspaper' Stick Break이온유No ratings yet

- C9 Engines For Motor Graders CaterpillarDocument7 pagesC9 Engines For Motor Graders Caterpillarspelz 1No ratings yet

- Prestressed Concrete With Internal or External Tendons Behaviour and AnalysisDocument294 pagesPrestressed Concrete With Internal or External Tendons Behaviour and AnalysisLuis Pablo Ramirez ZavalaNo ratings yet

- Main Control Valve, Specifications: Service InformationDocument2 pagesMain Control Valve, Specifications: Service InformationKo ZayNo ratings yet

- Microscope Laboratory Activities 2023Document7 pagesMicroscope Laboratory Activities 2023Izzy Dale Cagas SilangaNo ratings yet

- Jurnal Fatimah SimbolonDocument8 pagesJurnal Fatimah SimbolonFatimah SimbolonNo ratings yet

- 05 - ARISTONCAVI - Mining Tunneling CablesDocument55 pages05 - ARISTONCAVI - Mining Tunneling CablesJuan AdrianzenNo ratings yet

- RadioaktivlikDocument3 pagesRadioaktivlikgultaczaurNo ratings yet

- 2U Rack Mount Novec 1230 DataSheet 1.5Document5 pages2U Rack Mount Novec 1230 DataSheet 1.5prakistaoNo ratings yet

- Acceleration QuizDocument4 pagesAcceleration QuizSimar OberoiNo ratings yet

- Science Subject For High School Inter American Water Day InfographicsDocument35 pagesScience Subject For High School Inter American Water Day InfographicsJorge Enrique Garcia PinzonNo ratings yet

- CSE 28363 - Structural Concrete Design: Lecture 10: Shear and ServiceabilityDocument44 pagesCSE 28363 - Structural Concrete Design: Lecture 10: Shear and ServiceabilityBitch CarrieNo ratings yet

- QBR Operation ManualDocument8 pagesQBR Operation Manualmahmoudebrahim96745No ratings yet

- Hempels - Anti Condens - 617usDocument3 pagesHempels - Anti Condens - 617usnarmathaNo ratings yet

- 12.2 Motion CIE IGCSE Physics Ext Theory MsDocument5 pages12.2 Motion CIE IGCSE Physics Ext Theory MsasifshahanaNo ratings yet

- F. Trigonometric Leveling1Document6 pagesF. Trigonometric Leveling1Russell AyaquilNo ratings yet

- Zps Stock 230109Document4 pagesZps Stock 230109Insaat MakineleriNo ratings yet

- Pepbwn 001 Elc SLD 001.0 - Singel Line Diargram (New Expanse)Document1 pagePepbwn 001 Elc SLD 001.0 - Singel Line Diargram (New Expanse)Rian ArfanNo ratings yet

- A MODIFIED PENG ROBINSON EQUATION OF STATE FOR ELV 20519 FTP PDFDocument16 pagesA MODIFIED PENG ROBINSON EQUATION OF STATE FOR ELV 20519 FTP PDFalex rene cardonaNo ratings yet

- AMATH FunctionDocument11 pagesAMATH FunctionLeneNo ratings yet

- Electrochemical Biosensors: Modern and Future Approaches To Medical DiagnosticsDocument33 pagesElectrochemical Biosensors: Modern and Future Approaches To Medical DiagnosticskrishnasamytextNo ratings yet

- Service Manual of CS-T180 CS-T240Plus Auto-Chemistry Analyzer REV.2021-08Document248 pagesService Manual of CS-T180 CS-T240Plus Auto-Chemistry Analyzer REV.2021-08Albeiro PiraquiveNo ratings yet

- 24-Flow Meters and Flow SensorsDocument4 pages24-Flow Meters and Flow SensorsSigfrido Bader GNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological UniversityBhagirath sinh ZalaNo ratings yet

- Baku Higher Oil Schoo Report Number 5Document18 pagesBaku Higher Oil Schoo Report Number 5Tahir ƏskərliNo ratings yet

- FEM of Mechanical Fuse PDFDocument6 pagesFEM of Mechanical Fuse PDFAmit Kumar BishwakarmaNo ratings yet

- Sauter Steam Regulating Valve PurifierDocument6 pagesSauter Steam Regulating Valve PurifierCRIS SEDANTONo ratings yet

- Holy Childhood High School Chemistry 601 Topic: Electronic StructureDocument6 pagesHoly Childhood High School Chemistry 601 Topic: Electronic StructureBriana BartonNo ratings yet

- MANUEL Devidoir MillerDocument36 pagesMANUEL Devidoir MillerBrice DreessenNo ratings yet

- Table B.2. Constants For Antoine EquationsDocument2 pagesTable B.2. Constants For Antoine Equationshoran8750No ratings yet