Professional Documents

Culture Documents

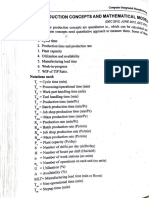

Manufacturing Lead Time and WIP Formulas

Manufacturing Lead Time and WIP Formulas

Uploaded by

irtikadar20030 ratings0% found this document useful (0 votes)

12 views2 pagesThe document presents several formulas for calculating manufacturing lead time (MLT) and work-in-process (WIP). MLT is calculated at the part/product level and plant level based on setup times, batch quantities, cycle times, and non-operation times. WIP is then calculated based on the plant production rate and average MLT.

Original Description:

Original Title

Manufacturing_Lead_Time_and_WIP_Formulas

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document presents several formulas for calculating manufacturing lead time (MLT) and work-in-process (WIP). MLT is calculated at the part/product level and plant level based on setup times, batch quantities, cycle times, and non-operation times. WIP is then calculated based on the plant production rate and average MLT.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

12 views2 pagesManufacturing Lead Time and WIP Formulas

Manufacturing Lead Time and WIP Formulas

Uploaded by

irtikadar2003The document presents several formulas for calculating manufacturing lead time (MLT) and work-in-process (WIP). MLT is calculated at the part/product level and plant level based on setup times, batch quantities, cycle times, and non-operation times. WIP is then calculated based on the plant production rate and average MLT.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

Formulas for Manufacturing Lead Time and Work-In-Process

MLTj = ∑(T_suj + Q_jT_cj + T_noj)

Where:

MLTj = Manufacturing lead time for a batch of part or product j, min

T_suj = Setup time for operation i on part or product j, min

Q_j = Batch quantity of part or product j

T_cj = Cycle time for operation i on part or product j, min/pc

T_noj = Nonoperation time associated with operation i, min

MLT = ∑(MLTj)/n_b

Where:

MLT = Average manufacturing lead time, min

n_b = Number of batches

MLT = n_o(T_su + QT + T_no)

Where:

MLT = Average manufacturing lead time for all parts or products in the plant, min

n_o = Number of operations

T_su = Setup time, min

QT = Total cycle time for all parts, min

T_no = Nonoperation time, min

MLT = n_o(Max T_j + T_r) + T_no

Where:

MLT = Time between start and completion of a given work unit on the line, min

n_o = Number of operations on the line

Max T_j = Maximum time of the production line, min/pc

T_r = Transfer time, min

T_no = Nonoperation time, min

MLT = n(Max T_j + T_r) + T_no

Where:

n = Number of workstations

WIP = R_pph(MLT)

Where:

WIP = Work-in-process in the plant, pc

R_pph = Hourly plant production rate, pc/hr

MLT = Average manufacturing lead time, hr

You might also like

- Os PFDocument20 pagesOs PFdivine rockyNo ratings yet

- Implementation of Scheduling Algorithms (FCFS, SJF) : Register No: 190801001 Page No: 1Document8 pagesImplementation of Scheduling Algorithms (FCFS, SJF) : Register No: 190801001 Page No: 1dillip muraliNo ratings yet

- Lab FileDocument40 pagesLab FileKS SiddhantNo ratings yet

- Module 01 NumericalsDocument12 pagesModule 01 NumericalsRahulNo ratings yet

- Production Performance Metrics FormulasDocument2 pagesProduction Performance Metrics Formulasirtikadar2003No ratings yet

- Unit-10 Time and Cost AnalysisDocument29 pagesUnit-10 Time and Cost AnalysisFaizanNo ratings yet

- C OSlmDocument21 pagesC OSlmKrunal MakwanaNo ratings yet

- OS Experiments New - 1554792526Document30 pagesOS Experiments New - 1554792526Rajendra WaskelNo ratings yet

- Economics of Metal Cutting 1Document11 pagesEconomics of Metal Cutting 1Bangladeshi Boy KNo ratings yet

- C++ Program For SJF SchedulingDocument9 pagesC++ Program For SJF SchedulingDaniyal RindNo ratings yet

- Ui22Cs57 Lab 5 TejkumarDocument8 pagesUi22Cs57 Lab 5 Tejkumarui22cs57No ratings yet

- Chapter 3 - Lecture NotesDocument14 pagesChapter 3 - Lecture Noteszaccaro_86No ratings yet

- Shortest Job FirstDocument12 pagesShortest Job Firstakh yadNo ratings yet

- Manufacturing Models and MetricsDocument41 pagesManufacturing Models and MetricsHildandi NlgögmhnNo ratings yet

- Lab 4Document7 pagesLab 4Abhinav SharmaNo ratings yet

- Os CodeDocument10 pagesOs CodegamebymrinmoyNo ratings yet

- Experiments 4th and 5thDocument18 pagesExperiments 4th and 5thamandeep.j2050No ratings yet

- Name: Mehedi Hasan Moni Admission Number: - 19SCSE1140001 B.tech CSE With CNCS, Sem: VDocument64 pagesName: Mehedi Hasan Moni Admission Number: - 19SCSE1140001 B.tech CSE With CNCS, Sem: VMEHEDI HASANNo ratings yet

- Experiment No 03Document7 pagesExperiment No 03Raj AdsulNo ratings yet

- Operating Systems Lab DA-2: Assignment - 2Document16 pagesOperating Systems Lab DA-2: Assignment - 2Rishitej rao KulakarniNo ratings yet

- Os Lab - 5Document5 pagesOs Lab - 5Mariya BabuNo ratings yet

- Unit 2 Manufacturing Operations: SectionsDocument27 pagesUnit 2 Manufacturing Operations: SectionsSaeed AlshamsiNo ratings yet

- Os Practicals Copy 3Document32 pagesOs Practicals Copy 3rolate5285No ratings yet

- Os Lab ProgramsDocument23 pagesOs Lab ProgramsCseB NecnNo ratings yet

- Lab 5 - cs604Document2 pagesLab 5 - cs604asifa AdilNo ratings yet

- Oriental College of Technology: Department of Computer Science & EngineeringDocument38 pagesOriental College of Technology: Department of Computer Science & Engineeringritika makhijaNo ratings yet

- OS LAB MANUAL September 2023 VbitDocument65 pagesOS LAB MANUAL September 2023 Vbit22p61a6649No ratings yet

- Os PGMDocument14 pagesOs PGMmuzzammil4422No ratings yet

- Shortest Processing Time (SPT)Document2 pagesShortest Processing Time (SPT)Asdfghjkl qwertyuiopNo ratings yet

- B.tech 3-2 Sem (2010-2011)Document47 pagesB.tech 3-2 Sem (2010-2011)Md Abid Ali100% (1)

- CC 2.1 AlassoDocument7 pagesCC 2.1 AlassoNitesh KumarNo ratings yet

- Os Programs CDocument41 pagesOs Programs CYashaswiniPrashanthNo ratings yet

- CPU Scheduling Process Burst Time Priority P1 P2 P3 P4 P5 5 24 16 10 3 2 5 1 3 4 FCFS AlgorithmDocument3 pagesCPU Scheduling Process Burst Time Priority P1 P2 P3 P4 P5 5 24 16 10 3 2 5 1 3 4 FCFS Algorithmchintalapati sreeram varmaNo ratings yet

- Computer Science &: Department ofDocument7 pagesComputer Science &: Department ofShantanu RaiNo ratings yet

- OS Lab ManualDocument38 pagesOS Lab ManualpocalocomocoNo ratings yet

- OS Lab Ex.5a, 5b, 5c, 5dDocument8 pagesOS Lab Ex.5a, 5b, 5c, 5dGodunagNo ratings yet

- Economics of Metal Cutting 1Document11 pagesEconomics of Metal Cutting 1ζοβαγεπ ἯοΣΣαῖηNo ratings yet

- Dr. B.R. Ambedkar National Institute of Technology JalandharDocument16 pagesDr. B.R. Ambedkar National Institute of Technology JalandharGaurav SachdevaNo ratings yet

- SRF2Document22 pagesSRF2OktaRianiNo ratings yet

- Os 1Document2 pagesOs 1Jai JadhavNo ratings yet

- Operating System ProgramsDocument6 pagesOperating System Programssaravanan_dijucsNo ratings yet

- CPU Scheduling: First Come First Serve (FCFS), Shortest Job First (SJF) and Priority SchedulingDocument7 pagesCPU Scheduling: First Come First Serve (FCFS), Shortest Job First (SJF) and Priority SchedulingZubair ImranNo ratings yet

- Operating System Lab ETCS 352: Maharaja Surajmal Institute of Technology, C-4 Janak Puri, New Delhi 110058Document59 pagesOperating System Lab ETCS 352: Maharaja Surajmal Institute of Technology, C-4 Janak Puri, New Delhi 110058Harkirat SinghNo ratings yet

- OS NotesDocument16 pagesOS NotesKomal TariqNo ratings yet

- Unit 2 Manufacturing Operations: SectionsDocument27 pagesUnit 2 Manufacturing Operations: SectionsJayesh BarveNo ratings yet

- 4 B - C - D - ProgramDocument6 pages4 B - C - D - ProgramSREESAIARJUN KOSINEPALLINo ratings yet

- Os Lab - 6Document5 pagesOs Lab - 6Mariya BabuNo ratings yet

- Assignment 1Document9 pagesAssignment 1AnimagusNo ratings yet

- 02b. Manufacturing OperationsDocument27 pages02b. Manufacturing OperationsUnmesh UnnikrishnanNo ratings yet

- OS Complete-4-7Document4 pagesOS Complete-4-7abhishekgunwant17No ratings yet

- Ex - No:7 (A) Date: Aim:: Cpu Scheduling AlgorithmsDocument16 pagesEx - No:7 (A) Date: Aim:: Cpu Scheduling AlgorithmsMaheshwaranNo ratings yet

- Ass 3Document17 pagesAss 3jasssaini1527No ratings yet

- Topic:-Cpu Scheduling AlgorithmsDocument5 pagesTopic:-Cpu Scheduling AlgorithmsShubhankar ChavanNo ratings yet

- Practical-1: ProgramDocument7 pagesPractical-1: ProgramNinja AppuNo ratings yet

- Name: Abdul Saboor ROLL NO.: SP18-BCS017 Assignment Lab OsDocument14 pagesName: Abdul Saboor ROLL NO.: SP18-BCS017 Assignment Lab Osafsdf fdfsdfNo ratings yet

- Cpu SchedulingDocument10 pagesCpu Schedulingharikrishnaarun5No ratings yet

- Takt Time: A Guide to the Very Basic Lean CalculationFrom EverandTakt Time: A Guide to the Very Basic Lean CalculationRating: 5 out of 5 stars5/5 (2)

- Takt Time - Understanding the Core Principle of Lean Manufacturing: Toyota Production System ConceptsFrom EverandTakt Time - Understanding the Core Principle of Lean Manufacturing: Toyota Production System ConceptsRating: 5 out of 5 stars5/5 (1)