Professional Documents

Culture Documents

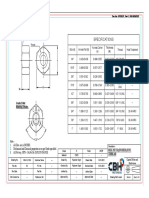

Tate Grid Specification Imperial

Tate Grid Specification Imperial

Uploaded by

Michel PortocarreroOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tate Grid Specification Imperial

Tate Grid Specification Imperial

Uploaded by

Michel PortocarreroCopyright:

Available Formats

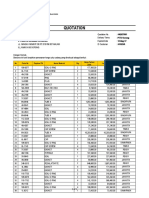

Tate, Inc.

Data Center Structural Ceiling Grid

SECTION 09 54 00

SPECIALTY CEILINGS

PART 1. GENERAL

1.1 WORK INCLUDED

A. Section Includes: Extruded aluminum suspended ceiling grid system including:

1. Aluminum ceiling grid.

2. Grid connectors and fasteners.

3. Wall angle and edge trim.

1.2 DESIGN REQUIREMENTS

A. Ceiling system shall be capable of directly supporting cable trays, utilities, light fixtures,

HVAC registers and other accessories as indicated per area of work.

1.3 WARRANTY

A. Structural ceiling grid shall be warranted against defects in materials and workmanship for a

period of 12 months from shipment.

PART 2. PRODUCTS

2.1 MANUFACTURERS

A. Basis of Design: Product specified is the Structural Ceiling Grid shall be factory as

manufactured by Tate, Inc.

2.2 DESIGN FEATURES: Structural Ceiling grid shall include the following features:

A. 2ˊ x 2ˊ OR 2ˊ x 4ˊ centered grid system with continuous threaded 1/4 ̋ - 20 OR 3/8 ̋ - 20 slot.

B. 12ˊ Main Runners and 4ˊ Structural Tees shall be notched on 24 ̋ centers for easy system

installation and positive positioning of 24 ̋ and 48 ̋ Structural Tees.

C. Connectors to include ribs to align system with grid on 24 ̋ OR 48 ̋ center and prevent

racking.

D. System is capable of fitting most commonly supplied 23.45 ̋ square +/- 1/8 ̋ size ceiling tiles,

light fixtures and HVAC registers.

Tate. Rev C 09/2021

E. 24 ̋ and 48 ̋ Structural Tees shall be cut back for vertical support through flange grid contact

to 12 ̋ Main Runners.

F. Accepts standard 60cm ceiling panels and light fixtures.

G. Connectors include 3/8 ̋ -16 threaded turnbuckle connections

H. On site modifiable connectors for perimeter installation.

I. Connectors shall be constructed of high strength cast aluminum parts.

J. Field XL Connector shall be utilized for 12ˊ Main Runner splice locations.

K. Optional gasket.

L. 3/32” thick x 3/8” closed cell polyethylene gasket tape shall be provided to improve leakage

through system at various air pressures.

M. 1/4 ̋ - 20 button head Philips head screws with lock washer shall be utilized to secure

connectors to Main Runners, Structural Tees, and Perimeter Angles.

N. System Weight: i. 2’x2’ Grid: 0.9 lb/ft2

ii. 2’x4’ Grid: 0.7 lb/ft2

2.3 STRUCTURE

A. Structural Ceiling grid shall be installed with a Fixed OR a Floating OR no perimeter angle

condition option and on a 2 ˊ x 2ˊ OR 2 ˊ x 4 ˊ grid supported with spacing of 4 ˊ x 4 ˊ connection to

structure above.

B. Main Runners, Structural Tees, and Perimeter Angles shall be constructed of 6063-T6

extruded aluminum and have white, black, or silver painted aluminum finish.

C. Connectors: Field, Field XL, and Perimeter connectors shall be constructed of high strength

cast aluminum with corrosion resistant finish which is silver in color.

D. Ceiling system shall be capable of supporting a uniform load up to 50lbs/ft2.

E. Ceiling system shall be capable of a maximum static point load of 380 lbs with standard duty

connector.

F. Ceiling system shall be capable of a maximum static point load of 800 lbs with heavy duty

connector in line with turnbuckle connection to building structure.

G. Turnbuckle connection shall be capable of a maximum point load connection to building

structure of 800 lbs.

PART 3. EXECUTION

Tate. Rev C 09/2021

3.1 EXAMINATION

A. Verify ceiling support rod anchors are properly installed in structure above.

3.2 STRUCTURAL CEILING INSTALLATION

A. Structural Ceiling grid shall be installed on a 2ˊ x 2ˊOR 2ˊ x 4ˊgrid supported with spacing of

4ˊ x 4ˊ connection to decking.

B. Grid spacing shall be defined by installation of 24 ̋ Structural Tees.

C. Support Spacing shall be defined by positioning of turnbuckle connections offset from one

another starting from one corner of the interior structural grid assembly and spaced evenly throughout.

Additional supports shall be provided as required along the perimeter and at any critical areas or as per

seismic or code requirements or considerations.

D. 12ˊ Main Runners shall be installed on 48 ̋ centers and all main runners shall be parallel to

one another. 48” Structural Tees shall be installed perpendicular to 12ˊ Main runners. Finally, for 2ˊ x 2ˊ

layouts, a 24 ̋ Structural Tees shall be installed perpendicular to the 48 ̋ Structural Tees.

E. All work shall be coordinated with all other trades including but not limited to electrical,

mechanical, fire protection and furniture.

3.3 PERIMETER INSTALLATION

A. Structural Ceiling grid shall be installed with a Fixed OR a Floating perimeter condition

option.

B. Fixed perimeter installation: Perimeter Angles shall be mounted at level height to interior

ceiling grid within 0.10 ̋ overall and 0.06 ̋ over any 10ˊ distance. Perimeter Angles shall be fastened to

perimeter wall with appropriate wall type fasteners. Perimeter Angles can be field cut with non-ferrous

carbide tipped blade. Joints shall fit with no more than .08 ̋ gaps.

C. Floating perimeter installation: Perimeter Angles shall be supported from structure at level

height to interior ceiling grid within 0.10 ̋ overall and 0.06 ̋over any 10ˊ distance. Perimeter Angles shall

be fastened to Main Runners and Structural Tees with perimeter connectors and suspended from

structure above. Perimeter Angles shall be field cut with non-ferrous carbide tipped blade. Joints shall

fit with no more than .125 ̋ gaps.

3.4. CLEANING

A. Inspect above and below installed ceiling system. Remove paint splatters and other spots,

dirt, and debris. Touch-up scratches and mars of finish to match original finish.

END OF SECTION

Tate. Rev C 09/2021

Tate. Rev C 09/2021

You might also like

- C636-Installation of Metal Ceiling Suspension SystemsDocument4 pagesC636-Installation of Metal Ceiling Suspension SystemswahyuniarsihNo ratings yet

- Electrical Manhole and Handhole Design GuideDocument8 pagesElectrical Manhole and Handhole Design Guidelilama45-1100% (2)

- Hebel Specs 04240Document7 pagesHebel Specs 04240Manuj JindalNo ratings yet

- Method of Statement For Conduit InstallationDocument15 pagesMethod of Statement For Conduit InstallationMohd MuksinNo ratings yet

- EN 566 enDocument1 pageEN 566 enMauricio GaviriaNo ratings yet

- 09 5100 BSD-Suspended Acoustical CeilingsDocument4 pages09 5100 BSD-Suspended Acoustical CeilingsSivaram KottaliNo ratings yet

- How to Build a Global Model Earthship Operation II: Concrete WorkFrom EverandHow to Build a Global Model Earthship Operation II: Concrete WorkNo ratings yet

- 1-Kinroad XT250GK-2 Parts ManualDocument16 pages1-Kinroad XT250GK-2 Parts Manualoakstr0% (1)

- ARC National Product CatalogueDocument65 pagesARC National Product Cataloguekaphk21823No ratings yet

- AcousticDocument10 pagesAcousticKurnianda Dian WulandariNo ratings yet

- Suspended Ceiling 401Document4 pagesSuspended Ceiling 401johnking5555No ratings yet

- Click HereDocument9 pagesClick HereronaljkNo ratings yet

- Section 09100 Metal Framing SystemDocument5 pagesSection 09100 Metal Framing Systemestimasi100% (1)

- Terracotta Rainscreen CladdingDocument9 pagesTerracotta Rainscreen CladdingAbdul Hafeez100% (1)

- Busbar Trunking System (Busways)Document6 pagesBusbar Trunking System (Busways)saravana3kumar3ravic100% (1)

- C 636 - 04 Installation of Metal Ceiling Suspension Systems ForDocument4 pagesC 636 - 04 Installation of Metal Ceiling Suspension Systems ForJavier Salinas SepúlvedaNo ratings yet

- Underground Ducts and Raceways For Electrical SystemsDocument13 pagesUnderground Ducts and Raceways For Electrical SystemsRainier AyapNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 05810-1 Expansion Joint Cover AssembliesDocument5 pagesITCC in Riyadh Residential Complex J10-13300 05810-1 Expansion Joint Cover AssembliesuddinnadeemNo ratings yet

- Calcium BoardDocument9 pagesCalcium BoardKurnianda Dian WulandariNo ratings yet

- 27 00 00 Communications Design Guideline (03-01-2017)Document15 pages27 00 00 Communications Design Guideline (03-01-2017)Amer AlmansoryNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 09547-1 Metal CeilingDocument5 pagesITCC in Riyadh Residential Complex J10-13300 09547-1 Metal CeilinguddinnadeemNo ratings yet

- Wms Acmv Duct WorksDocument8 pagesWms Acmv Duct Worksfahmi_majid_2No ratings yet

- Car TutorialDocument3 pagesCar TutorialFILE 1131No ratings yet

- Architextures - Barrisol Stretch Ceilings SpecDocument4 pagesArchitextures - Barrisol Stretch Ceilings SpecMohammed Abdul BaseerNo ratings yet

- Electrical Work Procedure Manual: A Novoue Solutions Inc. PropertyDocument20 pagesElectrical Work Procedure Manual: A Novoue Solutions Inc. Propertyeric maestroNo ratings yet

- National Greenhouse Specifications Series E 11 2008Document8 pagesNational Greenhouse Specifications Series E 11 2008G.Senthil KumaranNo ratings yet

- Mozaik Climbing Wall Performance SpecDocument5 pagesMozaik Climbing Wall Performance SpecHarryDammanickNo ratings yet

- Aluminum Composite PanelsDocument4 pagesAluminum Composite PanelsSaurav ChaudharyNo ratings yet

- XHC-000-Rev 2.0 T3 Precision Pre-Installation Requiements DocumentDocument13 pagesXHC-000-Rev 2.0 T3 Precision Pre-Installation Requiements DocumentBill MtsyNo ratings yet

- Technical Specifications: Excavation, Backfilling Site WorksDocument4 pagesTechnical Specifications: Excavation, Backfilling Site WorksHazim AhmadNo ratings yet

- Lightning Protection SystemDocument6 pagesLightning Protection SystemnadamohamedsayedNo ratings yet

- Panel BoardDocument6 pagesPanel BoardSherif M. ElgebalyNo ratings yet

- Division 22: PlumbingDocument6 pagesDivision 22: PlumbingRaya VillafloresNo ratings yet

- Basic MaterialsDocument7 pagesBasic MaterialsCristina Marie BatoNo ratings yet

- SPC Occ 221423 MeDocument4 pagesSPC Occ 221423 Metarekhisham1234No ratings yet

- Design For Crack Control: B. Control Joints. To Control Shrinkage CrackingDocument3 pagesDesign For Crack Control: B. Control Joints. To Control Shrinkage CrackinghamzasaeedvirkNo ratings yet

- Section 26 05 33.13-Electrical Boxes and Fittings PDFDocument8 pagesSection 26 05 33.13-Electrical Boxes and Fittings PDFmasoodaeNo ratings yet

- Frame Supported Membrane Structure Part 1 - General 1.1 Related DocumentsDocument13 pagesFrame Supported Membrane Structure Part 1 - General 1.1 Related Documentsloc nguyenNo ratings yet

- Earthing and Bonding For Electrical SystemDocument2 pagesEarthing and Bonding For Electrical SystemvaraNo ratings yet

- 27-0543-underground-duct-and-raceways-08.2023Document9 pages27-0543-underground-duct-and-raceways-08.2023Chimban ChappuNo ratings yet

- 16127-Underground Ducts and Utility StructuresDocument5 pages16127-Underground Ducts and Utility StructuresYousif AbdalhalimNo ratings yet

- Standard SpecificationDocument3 pagesStandard SpecificationAreeb WaseemNo ratings yet

- Asm XDocument6 pagesAsm XAlijihad2001aoNo ratings yet

- 16100-Basic Materials & MethodDocument6 pages16100-Basic Materials & Methodtristan guarinoNo ratings yet

- T-Zone Installation GuideDocument24 pagesT-Zone Installation GuidethermaltechnologiesNo ratings yet

- TSS Building MethodDocument7 pagesTSS Building MethodAnubhav Hem Kumar JainNo ratings yet

- 230517-Sleeves and Sleeve Seals for Hvac PipingDocument6 pages230517-Sleeves and Sleeve Seals for Hvac PipingMohamed SokarNo ratings yet

- Grounding and Bonding of Electrical SystemDocument5 pagesGrounding and Bonding of Electrical SystemMohammed Hussain OMNo ratings yet

- #1 Requirement FlooringDocument3 pages#1 Requirement Flooringnatee8632No ratings yet

- Math TutorialDocument2 pagesMath TutorialFILE 1131No ratings yet

- 15056-Builder's WorkDocument5 pages15056-Builder's WorkAdamNo ratings yet

- Barrier Cable Systems SpecificationsDocument8 pagesBarrier Cable Systems SpecificationsJason GrossNo ratings yet

- ConstructionDocument8 pagesConstructionGaspar Lig-ang TolomiaNo ratings yet

- Sleeves and Sleeve Seals For Fire-Suppression PipingDocument5 pagesSleeves and Sleeve Seals For Fire-Suppression PipingdiribaNo ratings yet

- Cable Tray SystemDocument26 pagesCable Tray SystemAldrien CabinteNo ratings yet

- Oib Technical Spec 21,22,23Document586 pagesOib Technical Spec 21,22,23kali highNo ratings yet

- SECTION 26 05 36.26 Wireways For Radiology EquipmentDocument5 pagesSECTION 26 05 36.26 Wireways For Radiology EquipmentEzana EzanaNo ratings yet

- Pip STF-05520Document7 pagesPip STF-05520mahmoodhassan79563100% (2)

- 238219-FAN-COIL UNITSDocument9 pages238219-FAN-COIL UNITSMohamed SokarNo ratings yet

- ArcWall ACM SpecDocument6 pagesArcWall ACM SpecRam CaceresNo ratings yet

- Frame Supported Membrane StructureDocument11 pagesFrame Supported Membrane StructureSushil DhunganaNo ratings yet

- 27 05 00 Common Work Results For CommunicationsDocument16 pages27 05 00 Common Work Results For CommunicationsMohamed Abou El hassanNo ratings yet

- 3.1. Upper Well Completion - OilfieldWikiDocument3 pages3.1. Upper Well Completion - OilfieldWikiHuỳnh Nguyễn Hiếu NghĩaNo ratings yet

- Thermo King Parts Manual CF-II M53 (uPA+) - P PDFDocument93 pagesThermo King Parts Manual CF-II M53 (uPA+) - P PDFSerhiiNo ratings yet

- 03mill SlidesDocument21 pages03mill SlidesNael El SayyadNo ratings yet

- Kumera Girth Gear Technical ManualDocument12 pagesKumera Girth Gear Technical ManualBhaskar Reddy100% (1)

- D85EX-15 Hydraulic FanDocument9 pagesD85EX-15 Hydraulic FanQuy Le Thanh67% (3)

- Π- The American Society Of: Asme BI.5-1997Document12 pagesΠ- The American Society Of: Asme BI.5-1997bachrul ulumNo ratings yet

- Material Name Elastic Modulus Ultimate Strength Yield Strength Strain at BreakDocument3 pagesMaterial Name Elastic Modulus Ultimate Strength Yield Strength Strain at Breakkrishnakant gargNo ratings yet

- MV Atlanna-Survey Status-13032024Document12 pagesMV Atlanna-Survey Status-13032024projectmasternigNo ratings yet

- Specifications: Hex Nuts (Inches) Unc ThreadDocument2 pagesSpecifications: Hex Nuts (Inches) Unc ThreadqualityNo ratings yet

- 44Q037661-PT. Surya Kusuma Perkasa PDFDocument5 pages44Q037661-PT. Surya Kusuma Perkasa PDFRachmatSanusiNo ratings yet

- Tools and Machines Used in Carpentry Lab Part 5Document10 pagesTools and Machines Used in Carpentry Lab Part 5Lo M'hNo ratings yet

- Manual de Partes (1997) - 2000 Series PDFDocument8 pagesManual de Partes (1997) - 2000 Series PDFmarlon diaz100% (1)

- I N - S e R V I C e A C T I V I T I e S R e P o R TDocument17 pagesI N - S e R V I C e A C T I V I T I e S R e P o R TromixrayzenNo ratings yet

- STEK Claim Form - V1Document11 pagesSTEK Claim Form - V1STEK AutomotiveNo ratings yet

- Mechanical Power Transmission Fundamentals-R1Document33 pagesMechanical Power Transmission Fundamentals-R1V SquareNo ratings yet

- Asme Ansi b16.9 DimensionDocument13 pagesAsme Ansi b16.9 DimensionarisandiyusufNo ratings yet

- Pemko Products Condensed Catalog PDFDocument28 pagesPemko Products Condensed Catalog PDFforbsathishNo ratings yet

- Understanding Shimano Front Derailleur SpecificationsDocument4 pagesUnderstanding Shimano Front Derailleur SpecificationsJohn McGillisNo ratings yet

- Sanayi A.Ş. MVD İnan Takım Tezgahları Sanayi A.ŞDocument13 pagesSanayi A.Ş. MVD İnan Takım Tezgahları Sanayi A.ŞMOISESNo ratings yet

- ED-5820 ED-5840: Refrigeration & Air Conditioning DemonstratorDocument2 pagesED-5820 ED-5840: Refrigeration & Air Conditioning DemonstratorFatima Essai0% (1)

- Multipurpose Building ConstructionDocument5 pagesMultipurpose Building Constructionnazi1945No ratings yet

- Ti Spec FedStd H28 1969Document2 pagesTi Spec FedStd H28 1969Nick TsikasNo ratings yet

- Lloyd Industries Inc.: Installation InstructionsDocument6 pagesLloyd Industries Inc.: Installation InstructionsDongNo ratings yet

- Perhitungan Sambungan Baja BautDocument9 pagesPerhitungan Sambungan Baja BautDica Rasyid MaulidhaniNo ratings yet

- Maneurop® Reciprocating Compressors: MT/MTZDocument34 pagesManeurop® Reciprocating Compressors: MT/MTZLevi Lr'sNo ratings yet

- The Power of Precision What Makes The Most Iconic Watch Model Stand Out Among Its CompetitorsDocument3 pagesThe Power of Precision What Makes The Most Iconic Watch Model Stand Out Among Its CompetitorsBro CraftNo ratings yet

- Pilling Quality Assurance and Quality ControllDocument28 pagesPilling Quality Assurance and Quality ControllTehani Vindya100% (1)