Professional Documents

Culture Documents

Hopper Cleaning Set Up Set Down Merge

Hopper Cleaning Set Up Set Down Merge

Uploaded by

Riolan SinantraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hopper Cleaning Set Up Set Down Merge

Hopper Cleaning Set Up Set Down Merge

Uploaded by

Riolan SinantraCopyright:

Available Formats

HOPPER CLEANING & MOLD SET-UP/SET DOWN

MACHINE NUMBER :

TECHNICIAN / QC

CLEAN HOPPER / CHANGE COLOUR DOWN MOLD UP MOLD

START UP / CHANGE COLOUR

1ST SHOT SUBMIT TO SAMPLE

BY APPROVAL BY QC APPROVAL

BY BY APPROVAL BY

SHIFT

SHIFT

SHIFT

START END SET UP / START END START END TECHNICAL PRE-HEAT

DATE DATE MOLD NO. SET UP REMARKS DATE MOLD NO. SET UP REMARKS MOLD NO. QC SUPERVISOR REMARKS

TIME TIME MH TIME TIME TIME TIME SUPERVISOR (START TIME)

(NAME) (NAME) (NAME)

(NAME) (NAME)

TIME DATE TIME DATE

NOTE : CM : Change Mould CC : Change Colour RM : Repair Mould DM : Down Mold UM : Up Mold SU : Start Up CL : Change Label YB - MLD- MSUSD-0001 REV 02

CR : Change Raw part CI : Change Insert CRM : Change Raw Material AR : After Repair - / NA : Not Applicable

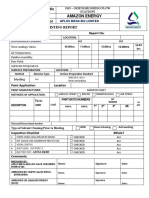

Report: YB - 01 - PROC - GEN - 23 - 0040 REV 00

PT. YEAKIN PLASTIC

HOPPER CLEANING & MOLD SET-UP / SET DOWN By : Riolan Sinantra

FLOW CHART Page : 1 of 1

PROD'N INJECTION

Date : 29-Nov-2023

*Unload the previous material and make sure the hopper is empty

1. Turunkan material sebelumnya dan pastikan hopper dalam kondisi kosong

*Open the hopper

2. Buka Hopper

Cleaning Hopper/ Change *Clean Filter by Vacum Cleaner

Material or Colour 3. Bersihkan Saringan menggunakan penyedot debu

*Clean by Air Gun

4. Bersihkan dengan semprot angin

*Close the hopper again as before

5. Tutup kembali Hopper seperti semula

*Filling material into the hopper according to the material to be used

6. Pengisian material ke hopper sesuai dengan material yang akan digunakan

*Make sure the barrel is cleaned from the previous material, if the material to be used is different

7. Pastikan barrel dibersihkan dari material sebelumnya, jika material yang akan digunakan berbeda.

* Turn on the hopper

1. Nyalakan Hopper

*Setting hopper temperature according to material type & follow molding parameter

Pre-Heat Material 2. Atur Temp. Hopper sesuai jenis material & ikut molding parameter

Start Time *Wait for it to heat according to the specified time

3. Tunggu Panas Sesuai waktu yang telah ditentukan

*If ok, progress to Start-Up

4. Jika OK, proses untuk Start-Up

*If there is a check for moisture

1. Jika ada pengecekan untuk moisture

Check Material use moisture analyzer *Only for Dehumidifier Hopper. Follow to form no.YB - MLD- MSUSD-0001 REV 02.

2. Khusus untuk Dehumidifier Hopper. Ikut ke form no.YB - MLD- MSUSD-0001 REV 02.

*Flushing the cooling hose

1. Bersihkan selang cooling

*Spray anti rust, after the mold temperature decreases

2. Lakukan proses anti rust, setelah suhu mold menurun.

Down Mold *Install elbow for the process down mold

3. Pemasangan elbow untuk proses penurunan mold.

*then direct the mold directly to the storage area

4. Kemudian arahkan mold langsung ke tempat penyimpanan

*Process of taking mold according to the job order given.

1. Proses pengambilan mold sesuai Job Order yang diberikan.

*Install the mold to the machine in the right position

2. Pemasangan mold ke mesin dengan posisi yang presisi.

*Make sure the machine ejector rod has the appropriate mold to be used.

3. Pastikan ejector rod mesin dengan mold, sesuai yang akan digunakan.

*Do the mold binding with clamps

4. Lakukan pengikatan mold dengan clamp.

*Make sure the safety between the mold core and cavity has been removed

Up Mold 5. Pastikan safety antara mold core dan cavity sudah dilepaskan.

*Before open mold (if there Hydraulic Core). Immediately report to supervisor.

6. Sebelum open mold (jika ada Hydraulic Core). segera informasikan ke Supervisor

*After open mold, adjust the clamping.

7. Setelah open mold, lakukan adjust clamping.

*Installation of cooling after the mold is closed

Start-Up Mold 8. Pemasangan cooling setelah mold dalam keadaan tertutup.

*Then reinstall the limit switch ejector, slide, core, intallation hottip and shut-off (If there)

9. Kemudian, pasang kembali limit switch ejector, slide, core, pemasangan hottip dan shut-

off (Jika ada).

Submit for QC approval

QC

NG Check OK Approved Running production

WRITTEN RIOLAN.S

APPROVED JOJO

REMARK

Lot 20 Jalan Gaharu Mukakuning BIP

Property of PT Yeakin Plastic Industry

YB - MLD- MSUSD-0001 REV 00

You might also like

- Downtown Albany Transit Center - Report Feasibility - 20221014Document16 pagesDowntown Albany Transit Center - Report Feasibility - 20221014shughes080No ratings yet

- Supplier:Neel Metal Products Ltd. (Faridabad) : Process FmeaDocument1 pageSupplier:Neel Metal Products Ltd. (Faridabad) : Process FmearohitNo ratings yet

- Pt. Multi Karya Engineering: Pt. Riau Andalan Pulp & PapperDocument1 pagePt. Multi Karya Engineering: Pt. Riau Andalan Pulp & PapperImade Subagianta100% (1)

- Komunikasi Laporkan Kejadian Dan Estimasi Waktu Normalisasi: Check / ActionDocument3 pagesKomunikasi Laporkan Kejadian Dan Estimasi Waktu Normalisasi: Check / ActionAdhityaNaufalFirdausNo ratings yet

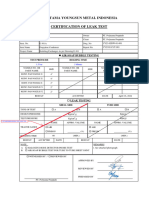

- Cert of Leak Test - Comment ADNDocument3 pagesCert of Leak Test - Comment ADNsrpri55No ratings yet

- PTF FormDocument1 pagePTF FormSMCS16No ratings yet

- Invoice 1Document1 pageInvoice 1alsheatingandairNo ratings yet

- Flow Chart of ProductionDocument1 pageFlow Chart of Productionharsha bardhanNo ratings yet

- Assuit Supercritical Power Plant 1X650Mw: Chemical Area To Waste WaterDocument1 pageAssuit Supercritical Power Plant 1X650Mw: Chemical Area To Waste WaterHussein MohamedNo ratings yet

- XF416 Installation and Users GuideDocument28 pagesXF416 Installation and Users Guidelacarguy55No ratings yet

- Dimensi Panel-Cad-2010-MIT-Rev-04-SD-MIT-FABS-CCEP-EL-HVAC-013Document1 pageDimensi Panel-Cad-2010-MIT-Rev-04-SD-MIT-FABS-CCEP-EL-HVAC-013Wijaya GultomNo ratings yet

- A Training On HFO (Heavy Fuel OilDocument25 pagesA Training On HFO (Heavy Fuel Oilshafinur04100% (1)

- Onkyo CR 305 TX Service ManualDocument20 pagesOnkyo CR 305 TX Service ManualJorgeNo ratings yet

- PfmeaDocument40 pagesPfmeaMadhuseptember2022No ratings yet

- Daily Worksheet 5010051816-28-Mar 2022Document1 pageDaily Worksheet 5010051816-28-Mar 2022Sumesh DethanNo ratings yet

- FM ST 09 (Material Receipt Note)Document1 pageFM ST 09 (Material Receipt Note)akash.vd.1603No ratings yet

- Air Cooled Heat Exchanger: General InformationDocument2 pagesAir Cooled Heat Exchanger: General Informationcorey jacobsNo ratings yet

- F-YLFCCS-QC-10-010 CONCRETE POURING MONITORING REPORTDocument1 pageF-YLFCCS-QC-10-010 CONCRETE POURING MONITORING REPORTMark Joey DavidNo ratings yet

- Kanoida Tecnoplast Pvt. Ltd. Holography Log Book: Ideal TimeDocument1 pageKanoida Tecnoplast Pvt. Ltd. Holography Log Book: Ideal Timeuppals1No ratings yet

- Aplus Coating Report FormatDocument1 pageAplus Coating Report FormatNnamdi AmadiNo ratings yet

- Repport UT CS - 7Document1 pageRepport UT CS - 7daemsalNo ratings yet

- FormP-005 - Pile Load TestDocument1 pageFormP-005 - Pile Load Testkrishna KumarNo ratings yet

- Process Flow Diagram (Yakult Phiippines Sbr-Iceas WWTF)Document1 pageProcess Flow Diagram (Yakult Phiippines Sbr-Iceas WWTF)Darwin FabonNo ratings yet

- Daily Time SheetDocument26 pagesDaily Time SheetYasirNo ratings yet

- 01/10/2012 Ultrasonic Examination Certificate: in Salah Gas Sout Fields Developments ProjectDocument2 pages01/10/2012 Ultrasonic Examination Certificate: in Salah Gas Sout Fields Developments ProjectdaemsalNo ratings yet

- Bato-Cogon Pertcpm (Final)Document1 pageBato-Cogon Pertcpm (Final)MANNY CARAJAYNo ratings yet

- OOMF REV. 2d AranDocument2 pagesOOMF REV. 2d AranSMCS16No ratings yet

- Daily Worksheet 5010051816-24-Mar 2022Document1 pageDaily Worksheet 5010051816-24-Mar 2022Sumesh DethanNo ratings yet

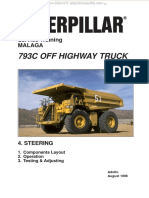

- Material Caterpillar 793c Mining Truck Off Highway Steering Components PartsDocument21 pagesMaterial Caterpillar 793c Mining Truck Off Highway Steering Components PartsИгорь ИвановNo ratings yet

- Manual Onkyo - Drc500Jp-SmDocument56 pagesManual Onkyo - Drc500Jp-SmAugus BeCaNo ratings yet

- Oomf Rev. 2 AranDocument2 pagesOomf Rev. 2 AranSMCS16No ratings yet

- Piping BOQDocument8 pagesPiping BOQEr Amit SolankiNo ratings yet

- 22-DS-R-004 Rev 0 P-2230 Diesel Fuel Transfer Pump ElecDocument48 pages22-DS-R-004 Rev 0 P-2230 Diesel Fuel Transfer Pump ElecChike NwachukwuNo ratings yet

- Jacobs Zate: Drawing Control 14-Sep-21Document1 pageJacobs Zate: Drawing Control 14-Sep-21WaqarNo ratings yet

- Blanko LaporanDocument6 pagesBlanko LaporanArif DermawanNo ratings yet

- 10/10/2012 Ultrasonic Examination Certificate: in Salah Gas Sout Fields Developments ProjectDocument4 pages10/10/2012 Ultrasonic Examination Certificate: in Salah Gas Sout Fields Developments ProjectdaemsalNo ratings yet

- Painampuram, Muthukurmandal, S.P.S.R. Nellore District, A.PDocument53 pagesPainampuram, Muthukurmandal, S.P.S.R. Nellore District, A.Pkkumar_717405No ratings yet

- Data Sheet Valve Actuator: Site Specific ConditionsDocument1 pageData Sheet Valve Actuator: Site Specific ConditionsRob StorrowNo ratings yet

- Flow Serve Mechanical SealDocument5 pagesFlow Serve Mechanical SealMohamed MusaNo ratings yet

- Supplier:Neel Metal Products Ltd. (Faridabad) : Process FmeaDocument1 pageSupplier:Neel Metal Products Ltd. (Faridabad) : Process FmearohitNo ratings yet

- Painting Inspection FormDocument1 pagePainting Inspection FormMarhendraNo ratings yet

- Repport UT CS - 11Document4 pagesRepport UT CS - 11daemsalNo ratings yet

- Daily Worksheet 5010051816-23-Mar 2022Document1 pageDaily Worksheet 5010051816-23-Mar 2022Sumesh DethanNo ratings yet

- Equipamento de Processo-ModelDocument1 pageEquipamento de Processo-ModelAna Carolina AlvesNo ratings yet

- Sinsina Manufacturing Workshop Liquid Penetrant Test Report: Piping SpoolDocument2 pagesSinsina Manufacturing Workshop Liquid Penetrant Test Report: Piping Spoolsoomro.hafeez45No ratings yet

- Seal & Seat Matrix-Floating-LatestDocument5 pagesSeal & Seat Matrix-Floating-LatestdennykvgNo ratings yet

- Jacobs Zate: Drawing Control 14-Sep-21Document1 pageJacobs Zate: Drawing Control 14-Sep-21WaqarNo ratings yet

- Khu - 11 - G - Bac20 - Ea - 004 - 2Document18 pagesKhu - 11 - G - Bac20 - Ea - 004 - 2Shafiqul IslamNo ratings yet

- Bush Pressing MCDocument1 pageBush Pressing MCShreekant GurlakattiNo ratings yet

- Transformer Polarization Index (Pi) Test: Nameplate DataDocument3 pagesTransformer Polarization Index (Pi) Test: Nameplate DataReneMartinezGutierrezNo ratings yet

- Pumps SheduleDocument1 pagePumps SheduleriyasudheenmhNo ratings yet

- 03 (SQ) - Process Product Audit ReportDocument2 pages03 (SQ) - Process Product Audit ReportDEVENDERNo ratings yet

- EXAVATORDocument1 pageEXAVATORrochimun0% (1)

- CRV ApprovedDocument4 pagesCRV ApprovedUmer KhanNo ratings yet

- Se-Pn-12 Panel Load Schedule - 12 (Cp-Fac-4)Document1 pageSe-Pn-12 Panel Load Schedule - 12 (Cp-Fac-4)Văn VươngNo ratings yet

- Time Sheet Ameer LuqmanDocument1 pageTime Sheet Ameer LuqmanmdroslisyukurNo ratings yet

- PSIPL-PRD-02 Hourly Produciton Report (Blow)Document1 pagePSIPL-PRD-02 Hourly Produciton Report (Blow)cghodake1No ratings yet

- Certificado de Teste de Instrumentação Teste de Multicabo: Instrument Test Certification Multi-Cable TestDocument1 pageCertificado de Teste de Instrumentação Teste de Multicabo: Instrument Test Certification Multi-Cable TestJohn TerryNo ratings yet

- Acc - Fqap - P3011 - R2 - RewaDocument2 pagesAcc - Fqap - P3011 - R2 - RewaHema NandhNo ratings yet

- Cement EvaluationDocument19 pagesCement EvaluationDiego PalaciosNo ratings yet

- Presentation Case Studies TaipeiDocument16 pagesPresentation Case Studies TaipeiBanoth Shankar ce19b005No ratings yet

- Anisa Yuniarti - 41033403200012 - Akuntansi A - PR AkmenDocument4 pagesAnisa Yuniarti - 41033403200012 - Akuntansi A - PR AkmenAnisa YuniartiNo ratings yet

- Sumeeko Product CatalogDocument116 pagesSumeeko Product CatalogShelly ChenNo ratings yet

- Camiao Grua - ManualDocument156 pagesCamiao Grua - ManualMiguel SilvaNo ratings yet

- DPR - Volume II - Main Report - Part B (Version 2.1)Document607 pagesDPR - Volume II - Main Report - Part B (Version 2.1)Jobins JamesNo ratings yet

- Update The Covid-19 Situation in IndonesiaDocument24 pagesUpdate The Covid-19 Situation in IndonesiaMesha FerzicaNo ratings yet

- MANSCIE Cases Term3Document9 pagesMANSCIE Cases Term3Karl delos Santos100% (1)

- IC Home Construction Budget Template 8540Document2 pagesIC Home Construction Budget Template 8540melanie pereiraNo ratings yet

- JIT CostingDocument2 pagesJIT CostinghellokittysaranghaeNo ratings yet

- Module 3 - Assessment ActivitiesDocument2 pagesModule 3 - Assessment Activitiesaj dumpNo ratings yet

- Design of Single Phase To Three Phase Static Power ConverterDocument7 pagesDesign of Single Phase To Three Phase Static Power Converterderbalijalel100% (1)

- IB Economics Exam NotesDocument30 pagesIB Economics Exam NotesNica Calvert100% (11)

- Shredder / Granulator Combination: y y y yDocument8 pagesShredder / Granulator Combination: y y y yMIGUEL ANGEL BUITRAGO PARRANo ratings yet

- Topic 03 - ZUTTER - Smart - 15e - ch05 TVOM (Part 1) Rv1.2Document70 pagesTopic 03 - ZUTTER - Smart - 15e - ch05 TVOM (Part 1) Rv1.2Omar SanadNo ratings yet

- Economic Way of Thinking 13th Edition Heyne Test BankDocument26 pagesEconomic Way of Thinking 13th Edition Heyne Test BankGaryHessgdbe100% (55)

- Ad-90.0-E-02057-Pdf Lighting Protection Details 1Document1 pageAd-90.0-E-02057-Pdf Lighting Protection Details 1mcaslamNo ratings yet

- Boysen EstimatesDocument36 pagesBoysen Estimatesdasmin anne depacaquiboNo ratings yet

- Writing Integers - Print - QuizizzDocument4 pagesWriting Integers - Print - QuizizzAsri BahariNo ratings yet

- Equilibrium Level of National Income in Two Sector Economy .Document5 pagesEquilibrium Level of National Income in Two Sector Economy .Kushal NaskarNo ratings yet

- Test 1Document5 pagesTest 1nesrineNo ratings yet

- Balance Sheet 1.infosysDocument10 pagesBalance Sheet 1.infosysmoonlight3t31No ratings yet

- Important Aptitude Questions With Answers: Show AnswerDocument4 pagesImportant Aptitude Questions With Answers: Show Answerasre bekeleNo ratings yet

- Rojgar Mela CVDocument19 pagesRojgar Mela CVGanga Bdr BishwakarmaNo ratings yet

- Shenzhen Wei Jia Sheng Logistic Equipment Co.,Ltd: Payment Term:50% by T/T (The Balance Before Loading The Container)Document50 pagesShenzhen Wei Jia Sheng Logistic Equipment Co.,Ltd: Payment Term:50% by T/T (The Balance Before Loading The Container)teffoarmand133No ratings yet

- Final ReportDocument11 pagesFinal ReportAmit KumarNo ratings yet

- Compulsory Paper - IV Statistical Analysis: Time: Three Hours)Document8 pagesCompulsory Paper - IV Statistical Analysis: Time: Three Hours)Kulshaan BhatiaNo ratings yet

- Flowchart Cash ReceiptDocument4 pagesFlowchart Cash Receiptalif nur irvanNo ratings yet

- All HR HeadsDocument27 pagesAll HR HeadsPrasad Krishnamurthy100% (1)

- Lecture II-identification of Entrepreneurial OpportunityDocument43 pagesLecture II-identification of Entrepreneurial Opportunitydonkhalif13No ratings yet