Professional Documents

Culture Documents

ENGG5024-1985 Electronic Systems Mini Project

ENGG5024-1985 Electronic Systems Mini Project

Uploaded by

Alfred LiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ENGG5024-1985 Electronic Systems Mini Project

ENGG5024-1985 Electronic Systems Mini Project

Uploaded by

Alfred LiCopyright:

Available Formats

Electronic System

Table of contents

1. Aims and objectives

2. Introduction

3. Methodology

4. Implementations

5. System integration and testing

6. Results and discussions.

7. Conclusions

8. References

Appendices:

Department of Engineering 2021-22

Electronic System

1. Aims and objectives

This mini-project aims to enable the participants to design and build an electronic system consisting

of analogue and digital system components. The digital system components will be described using a

hardware descriptive language and implemented within FPGA technology.

2. Introduction

(i) Overview of the project, methods, implementations, and alternatives.

An ultrasonic distance measurer has an ultrasonic emitter and an ultrasonic receiver.

The electronics include an output to drive the emitter at optimal frequencies. In this project, a

frequency of 40 kHz is selected. Ultrasonic transducers measure the time taken for the pulse to

travel to the target surface and return to the receiver. With the time between the pulse leaving the

emitter and collected by the receiver, the distance between the device and the target surface can be

determined. This circuit calculates the distance based on the speed of sound at 343m/s. With the

distance determined, it will be displayed using seven segment display.

This mini-project demonstrates the outcome by simulating the design instead of building it in

actuality. Figure 3a shows the conceptual arrangement of the ultrasound distance meter. Figure 3b

shows the system block diagram, where the components in red were not required to

design/simulated in this project.

(ii) Specifications

-Speed of sound assumed at 343m/s

-Detection range of 0~3m

-Minimum resolution of 1cm (0.01m)

-Controlled by digital logic within DE2-115

-Display by Seven segment display on DE2-115

-LM567 Tone Decoder to convert the amplified signal from AC to DC

Department of Engineering 2021-22

Electronic System

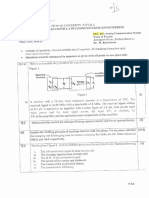

(iii) Block diagrams and supporting materials etc

Figure 3a: Conceptual arrangement

Figure 3b: System Block Diagram (components that do not have to design/ simulate in coloured in

red)

Department of Engineering 2021-22

Electronic System

3 Methodology

The technique of distance measurement using ultrasonic in air includes continuous wave & pulse echo

technique. In the pulse echo method, a burst of pulses is sent through the transmission medium & is

reflected by an object kept at a special distance. The time taken for the pulse to propagate from transmitter

to receiver is proportional to the distance of the object. For contact less measurement of distance, the

device has to rely on the target to reflect the pulse back to itself. The target needs to have a proper

orientation, that is it needs to be perpendicular to the direction of propagation of the pulses. The amplitude

of the received signal gets significantly attenuated and is a function of nature of the medium and the

distance between the transmitter and target. The pulse echo or time-of-flight method of range

measurement is subject to high levels of signal attenuation when used in an air medium, thus limiting its

distance range.

4. Implementations

Analog Section: (with supporting diagram and flow of design) Includeallyour test results, data,

screenshots etc

(i) Ultrasound transducers characteristics, in terms of directivity, sensitivity, and support with

diagrams and data.

(ii) Receiver circuit and its specifications.

(iii) Detector circuits and its specifications.

(iv) Driver circuit.

(v) Power Supply Used.

(vi) BCDto 7-segments conversion.

(vii) 7-segments display drivers and design.

A Seven-Segment Display (SSD) decoder is used to convert the distance measured in the distance

counter into signals that can generate decimal numbers output on the Seven-Segment Display on the

DE2-115.

Department of Engineering 2021-22

Electronic System

(viii) Misc. supporting circuits

Fig 4.x One digit on the seven -segment display

Fig 4.x Truth table for common cathode type BCD to seven segment decoder

5. System integration and testing

There are reasons that the performance of the measuring device not as good as

planned:

● The accuracy is affected by temperature

●

● The frequency range sensors use are roughly from 20 khz to 200 khz.

The lower limit of 20 khz set to be above human hearing. Forty kilohertz

has become a compromise. It’s well above the best human hearing and

reflects off of most materials. On industrial type sensors, you can often

hear the chirp or clicking sound of the transducer.

● There is a lower and upper range the sensor will work. The bigger the

range, the longer the update time will be.

● There is a difference between ultrasonic distance and proximity sensors.

The latter only indicates something is within a distance range. These are

common in smart phones to let the phone know you have it up against

your ear or to be able to see gestures.

● Noise rejections will always be a problem. We may not be able to hear

the clutter of ultrasonic background noise, but a sensor does and is often

confused by this. Water rushing through a pipe, motors and insects

make contribute to this unheard background noise.

6. Results and discussions.

7. Conclusions

Department of Engineering 2021-22

Electronic System

8. References

- Md. Shamsul Arefin, Tajrian Mollick (2013)Design of an Ultrasonic Distance Meter, International

Journal of Scientific & Engineering Research Volume 4, Issue3,

-Eden, JohnGlendale & Telan, Elijah & Pancho, Jim & Bongolan, Riyadh & Mendoza, Elyzar (2019)

Ultrasonic Distance Measuring Device Study

-Luis Puebla Palma (2008)Ultrasonic Distance Measurer Implemented with the MC9RS08KA2

Freescale Semiconductor Application Note Document Number: AN3481

-Muhammad RezDuan Bin Othman (2012) Smart Distance Measurement Detector. Faculty of

Electrical and Electronics Engineering University Malaysia Pahang

Department of Engineering 2021-22

Electronic System

Appendices:

Appendix 1: Data of your devices used

Appendix 2: Lab-1, BJT amplifiers

Appendix 3: Lab-2, PWM and scalars designs and testing.

Department of Engineering 2021-22

Electronic System

Appendix 1

1.1 Datasheet for Tone Decoder - LM567

1.2 Datasheet for Control and display - DE2-115

1.3 Datasheet for Programmable Oscillator - LTC6907

1.4 Datasheet for Ultrasonic ranging module HC - SR04

Department of Engineering 2021-22

You might also like

- Eec 128Document23 pagesEec 128Adetayo Salawu67% (3)

- Room Noise DetectorDocument17 pagesRoom Noise Detectorithrohit67% (6)

- Synopsis 1Document7 pagesSynopsis 1ashu yadavNo ratings yet

- PBL Project ReportDocument7 pagesPBL Project ReportAhmed HassanNo ratings yet

- Wireless Oscilloscope Using ZigbeeDocument4 pagesWireless Oscilloscope Using ZigbeemichaelNo ratings yet

- FinalDocument17 pagesFinalHuxtle RahulNo ratings yet

- 6 II February 2018Document6 pages6 II February 2018oyukiisaacNo ratings yet

- Project Review On Ultrasonic Distance Measurement: Prakhar Shrivastava, Praveen Kumar, Ankit TiwariDocument3 pagesProject Review On Ultrasonic Distance Measurement: Prakhar Shrivastava, Praveen Kumar, Ankit TiwarirajatpreetNo ratings yet

- Major Project Stage-1Document23 pagesMajor Project Stage-1Priya GadirajuNo ratings yet

- Review 1 (Phase II) - Batch-02 ModifiedDocument27 pagesReview 1 (Phase II) - Batch-02 ModifiedVi LNo ratings yet

- PIC Based Wireless Sensor NetworkDocument5 pagesPIC Based Wireless Sensor NetworkMustafa KhairallahNo ratings yet

- Ultrasonic Sound Reflecting Means of Distance MeasurementDocument73 pagesUltrasonic Sound Reflecting Means of Distance MeasurementhimanshuNo ratings yet

- Review 1 (Phase II) - Batch-02 ModifiedDocument27 pagesReview 1 (Phase II) - Batch-02 ModifiedVi LNo ratings yet

- Ijece - Sewage Block Identification and Rescue System Using Wireless Sensor - 1Document6 pagesIjece - Sewage Block Identification and Rescue System Using Wireless Sensor - 1iaset123No ratings yet

- Acoustic Source Localization Based On Time-Delay Estimation MethodDocument5 pagesAcoustic Source Localization Based On Time-Delay Estimation Methodscribd1235207No ratings yet

- Taimoor Inayat Assi 3Document10 pagesTaimoor Inayat Assi 3Charsi 1080No ratings yet

- Design For Visually Impaired To Work at Industry Using RFID TechnologyDocument5 pagesDesign For Visually Impaired To Work at Industry Using RFID Technologyilg1No ratings yet

- Ultrasonic Distance SensorDocument6 pagesUltrasonic Distance SensorJunaid AhmedNo ratings yet

- PBL Project ProposalDocument4 pagesPBL Project ProposalAhmed HassanNo ratings yet

- SDR BasedSystemforSatelliteRangingMeasurements DraftDocument11 pagesSDR BasedSystemforSatelliteRangingMeasurements Draftmisaeljonatasandrade27No ratings yet

- Assistive Infrared Sensor Based Smart Stick For Blind PeopleDocument6 pagesAssistive Infrared Sensor Based Smart Stick For Blind PeopleجعفرالشموسيNo ratings yet

- Smart Sensor Nodes For Airborne Particulate Concentration DetectionDocument10 pagesSmart Sensor Nodes For Airborne Particulate Concentration DetectionSergio MitmaNo ratings yet

- Exp. No.: 4 Date: Arduino Based Ultrasonic Distance Sensor AIMDocument8 pagesExp. No.: 4 Date: Arduino Based Ultrasonic Distance Sensor AIMYenigalla Kireeti SaiNo ratings yet

- A GPS Based Real-Time Tracking System JQ2bDocument4 pagesA GPS Based Real-Time Tracking System JQ2bPraveena R. JaiswalNo ratings yet

- Design of Light Intensity Detection System Based On STM32: Yunhua ZhouDocument5 pagesDesign of Light Intensity Detection System Based On STM32: Yunhua Zhouff314wcpkNo ratings yet

- CHNDDocument22 pagesCHNDchandhuNo ratings yet

- Jurnal Kimia Radiasi - F1C1 17 009 - Dicky SaputraDocument5 pagesJurnal Kimia Radiasi - F1C1 17 009 - Dicky Saputradicky saputraNo ratings yet

- Report 151220202107Document11 pagesReport 151220202107barisozksmn06No ratings yet

- Hazardous Gas Pipeline Leakage Detection Based On Wireless TechnologyDocument7 pagesHazardous Gas Pipeline Leakage Detection Based On Wireless TechnologysubiNo ratings yet

- Panja Mini ProjectDocument3 pagesPanja Mini ProjectLil KidNo ratings yet

- 5988 6254ej W 2Document140 pages5988 6254ej W 2poorna434No ratings yet

- Improvement of Optical Fiber Communication System Using A Parallel Interface CircuitDocument6 pagesImprovement of Optical Fiber Communication System Using A Parallel Interface CircuitHimanshu PalNo ratings yet

- Partial Discharge Measurements On Generators Using A Noise Gating SystemDocument6 pagesPartial Discharge Measurements On Generators Using A Noise Gating Systemreza515heiNo ratings yet

- Paper 20Document4 pagesPaper 20Mohamed AhmiedNo ratings yet

- Virtual EyeDocument7 pagesVirtual EyeraviNo ratings yet

- Implementation of Human Health Monitoring Using ZigbeeDocument4 pagesImplementation of Human Health Monitoring Using ZigbeeIjarcsee JournalNo ratings yet

- Auto-Smart Obstacle DetectionDocument5 pagesAuto-Smart Obstacle DetectionIJSTENo ratings yet

- Sensor TechonologyDocument15 pagesSensor Techonologyrameshsiri111No ratings yet

- 2 - No Parking AlertDocument6 pages2 - No Parking Alertعمل الخيرNo ratings yet

- Development of An Embedded System For Distance Measuring Using Ultrasonic SensorDocument4 pagesDevelopment of An Embedded System For Distance Measuring Using Ultrasonic SensornikhithaNo ratings yet

- Remote Control of Electrical Appliances Using GSM Networks: Abah O. Sunday Visa M. Ibrahim Abah JoshuaDocument8 pagesRemote Control of Electrical Appliances Using GSM Networks: Abah O. Sunday Visa M. Ibrahim Abah JoshuaIJERDNo ratings yet

- GSM Based Garbage Monitoring System: IjarcceDocument4 pagesGSM Based Garbage Monitoring System: IjarcceRoborocks ComputerssNo ratings yet

- Lecture 3 - 2022 - FinalDocument67 pagesLecture 3 - 2022 - FinalFrancis LubangoNo ratings yet

- Design and Implementation of 3-Lead ECG Machine For Rural MedificationDocument7 pagesDesign and Implementation of 3-Lead ECG Machine For Rural Medificationlibya freeNo ratings yet

- Algoritmos de Localizacion IEEEDocument6 pagesAlgoritmos de Localizacion IEEEJhon NogueraNo ratings yet

- Est 3Document115 pagesEst 3Diane BasilioNo ratings yet

- ITS Background Info Dens-Itometer GUI 7.0 v1 - DDE20220117Document12 pagesITS Background Info Dens-Itometer GUI 7.0 v1 - DDE20220117Angel Miguel Olaya VasquezNo ratings yet

- Inkjet-Printed "Zero-Power" Wireless SensorDocument4 pagesInkjet-Printed "Zero-Power" Wireless Sensordamian.wronski.95.dwsNo ratings yet

- Train Collision Avoiding SystemDocument7 pagesTrain Collision Avoiding SystemIJRASETPublicationsNo ratings yet

- Ubiquitous Networking Full ReportDocument24 pagesUbiquitous Networking Full ReportSurangma ParasharNo ratings yet

- Report SampleDocument13 pagesReport SampleAbuzar KhanNo ratings yet

- Phase II Batch10Document22 pagesPhase II Batch10S SREENATHNo ratings yet

- Analysis of Bluetooth-Based Wireless Sensor Networks Performance in Hospital EnvironmentsDocument6 pagesAnalysis of Bluetooth-Based Wireless Sensor Networks Performance in Hospital EnvironmentsRehan MalikNo ratings yet

- Design 2Document25 pagesDesign 2Fatih Mehmet FerahNo ratings yet

- Application of Neuro-Fuzzy Techniques in Oil Pipeline Ultrasonic Nondestructive TestingDocument11 pagesApplication of Neuro-Fuzzy Techniques in Oil Pipeline Ultrasonic Nondestructive TestingNordin SuhadatNo ratings yet

- Implementation of Wireless Sensor Network For Medical ApplicationsDocument11 pagesImplementation of Wireless Sensor Network For Medical ApplicationsFanta StyleNo ratings yet

- CIRED2011 1286 Final Universidad de OviedoDocument4 pagesCIRED2011 1286 Final Universidad de OviedopipotxNo ratings yet

- UHF Surface Dynamics Parameters Radar Design and ExperimentDocument3 pagesUHF Surface Dynamics Parameters Radar Design and ExperimentmenguemengueNo ratings yet

- Sciencedirect: Security Based DomoticsDocument7 pagesSciencedirect: Security Based Domoticsz3ppelinNo ratings yet

- Linearization and Efficiency Enhancement Techniques for Silicon Power Amplifiers: From RF to mmWFrom EverandLinearization and Efficiency Enhancement Techniques for Silicon Power Amplifiers: From RF to mmWNo ratings yet

- Software Radio: Sampling Rate Selection, Design and SynchronizationFrom EverandSoftware Radio: Sampling Rate Selection, Design and SynchronizationNo ratings yet

- 3477lecture 17 2 2013 Up To VSBaaaaDocument79 pages3477lecture 17 2 2013 Up To VSBaaaaabdul.azeezNo ratings yet

- Simpson 479Document36 pagesSimpson 479SlackomaticNo ratings yet

- Sample Docu - FM DesignDocument95 pagesSample Docu - FM DesignMark Vincent Fortaleza100% (2)

- DewesoftX 2021.2 RELEASE-210430 Offline Installer (64-Bit) - Release NotesDocument22 pagesDewesoftX 2021.2 RELEASE-210430 Offline Installer (64-Bit) - Release NotesbenNo ratings yet

- McIntosh Catalog 038-961Document28 pagesMcIntosh Catalog 038-961Monty^No ratings yet

- Lab Model Exam QP NewDocument7 pagesLab Model Exam QP Newhasini sNo ratings yet

- Assignment-1 Sub: Basic Electronics SUB CODE: 2110016Document15 pagesAssignment-1 Sub: Basic Electronics SUB CODE: 2110016khyatichavdaNo ratings yet

- IOT Based Accident Prevention and Detection System Using GSM-GPS, Eye Blink, and Alcohol SensorDocument8 pagesIOT Based Accident Prevention and Detection System Using GSM-GPS, Eye Blink, and Alcohol SensorIJRASETPublicationsNo ratings yet

- Accelerometer Based Gesture RobotDocument3 pagesAccelerometer Based Gesture RobotjaiNo ratings yet

- Smart Kit 1009 (1W Transmitter)Document5 pagesSmart Kit 1009 (1W Transmitter)Zeljko VukovicNo ratings yet

- TV Analyzer R&S Fsh3-Tv: Operating ManualDocument445 pagesTV Analyzer R&S Fsh3-Tv: Operating ManualqiqeonNo ratings yet

- Fs Ct6b RemoteDocument22 pagesFs Ct6b RemoteNeilNo ratings yet

- Installation and Operation Manual Hunter Ceiling FansDocument35 pagesInstallation and Operation Manual Hunter Ceiling FanstylerdurdaneNo ratings yet

- R10Xxx-R11X PortflotDocument90 pagesR10Xxx-R11X Portflotmrservice7782No ratings yet

- Day 2 - Q2 - Module 4 Radio Waves and MicrowavesDocument70 pagesDay 2 - Q2 - Module 4 Radio Waves and MicrowavesMarilyn Castro LaquindanumNo ratings yet

- 5G Deployment Options Keysight May19Document8 pages5G Deployment Options Keysight May19Muhammad KaleemNo ratings yet

- Underwater Optical Wireless Audio Transceiver PDFDocument43 pagesUnderwater Optical Wireless Audio Transceiver PDFkomal phulpotoNo ratings yet

- VSX 1019AH K Operating Instructions 0128Document128 pagesVSX 1019AH K Operating Instructions 0128James ChurchNo ratings yet

- Manpack HFDocument128 pagesManpack HFMushtaq AhmadNo ratings yet

- Design and Implementation of FM TransmitterDocument51 pagesDesign and Implementation of FM Transmitteryewlsew97% (37)

- Ultrasonic Flaw Detector NOVOTEST UD2301Document3 pagesUltrasonic Flaw Detector NOVOTEST UD2301Ashish SrivastavaNo ratings yet

- Uec401 2017Document2 pagesUec401 2017g SinghNo ratings yet

- CMT2219A Datasheet - EN V1.3 202311Document40 pagesCMT2219A Datasheet - EN V1.3 202311Cesare RossiNo ratings yet

- Vehicle To Vehicle Communication Using RF & Ir TechnologyDocument51 pagesVehicle To Vehicle Communication Using RF & Ir TechnologyClassic PrintersNo ratings yet

- MTR2000 SCM Field Service 6881096E32-EDocument16 pagesMTR2000 SCM Field Service 6881096E32-EOscar EscobarNo ratings yet

- Low-Power Analog IC Design Activities at CNM: Justo SabadellDocument31 pagesLow-Power Analog IC Design Activities at CNM: Justo SabadellicdaneNo ratings yet

- Analog Dialogue - Volume31-Number2Document25 pagesAnalog Dialogue - Volume31-Number2ElcidsNo ratings yet

- Amplifier Installation GuideDocument22 pagesAmplifier Installation Guidejcglamas55No ratings yet

- SLN Ec2252 CT QBDocument38 pagesSLN Ec2252 CT QBMercado Mica100% (1)