Professional Documents

Culture Documents

Method Statement For Installaation of Hydronic Piping With Specialities

Method Statement For Installaation of Hydronic Piping With Specialities

Uploaded by

anwarCopyright:

Available Formats

You might also like

- Water Penetration TestDocument4 pagesWater Penetration TestIgnatius PathulaNo ratings yet

- HVAC Duct Work Installation Method StateDocument3 pagesHVAC Duct Work Installation Method StateAlexander GomezNo ratings yet

- Farooqi Mohammed Yousuf Saudi Arabia 17.00 YrsDocument5 pagesFarooqi Mohammed Yousuf Saudi Arabia 17.00 YrsKirkD'costaNo ratings yet

- PROJECT QC PLAN - AGAN (Revision Submission As Per RCRC Comments)Document172 pagesPROJECT QC PLAN - AGAN (Revision Submission As Per RCRC Comments)mohamed balasmehNo ratings yet

- HVAC BrochureDocument2 pagesHVAC BrochureJustin GarciaNo ratings yet

- Irrigation Pump Installation Method StatementDocument3 pagesIrrigation Pump Installation Method StatementhassanabunafeesahNo ratings yet

- 01 Mes Mep 002 Ms+for+Water+Supply+WorksDocument12 pages01 Mes Mep 002 Ms+for+Water+Supply+WorksJeffersonDeGuiaNo ratings yet

- Naffco - Prequlification-Part2Document73 pagesNaffco - Prequlification-Part2ahmad.suliman.saeedNo ratings yet

- Saudi TraderDocument2 pagesSaudi TraderMuhammad AliNo ratings yet

- Method Statement Duct InstallationDocument5 pagesMethod Statement Duct Installationcharles d100% (1)

- Testing and Commissioning of Fire Alarm System InstallationDocument34 pagesTesting and Commissioning of Fire Alarm System InstallationAbdul JabbarNo ratings yet

- ED-P1 Licensing and Competency Authorization PDFDocument22 pagesED-P1 Licensing and Competency Authorization PDFRiad Saad RiadNo ratings yet

- Project Execution Plan - R0Document17 pagesProject Execution Plan - R0Karan GnaniNo ratings yet

- Construction Estimate Templat3Document5 pagesConstruction Estimate Templat3nakatomi 88No ratings yet

- Hvac Testing Adjusting BalancingDocument7 pagesHvac Testing Adjusting Balancingarour.mokraneNo ratings yet

- Pervez Ahmad Khan: Job ObjectiveDocument6 pagesPervez Ahmad Khan: Job ObjectivePERVEZ AHMAD KHANNo ratings yet

- Method Statement For Installation of Emt Conduit-OldDocument13 pagesMethod Statement For Installation of Emt Conduit-OldSalman SaifuddinNo ratings yet

- MEP - DetailDocument14 pagesMEP - DetailsyedtalhamehmoodNo ratings yet

- Cgk063 Rfa Mos M XXX - Cooling Tower InstallationDocument24 pagesCgk063 Rfa Mos M XXX - Cooling Tower Installationdiki anggriawanNo ratings yet

- MEP Payment Breakup Desired - APDocument1 pageMEP Payment Breakup Desired - APbalabhaviniNo ratings yet

- Method Statement For Installation of UPVC Ducts.Document22 pagesMethod Statement For Installation of UPVC Ducts.Haggag AbouelkhairNo ratings yet

- MST-M-0070 Hot Water CalorifiersDocument10 pagesMST-M-0070 Hot Water CalorifiersJERINNo ratings yet

- Building Permit Process Awareness Training: Qatar Design ConsortiumDocument18 pagesBuilding Permit Process Awareness Training: Qatar Design ConsortiumSarah Smith100% (1)

- Method Statement of Hvac Duct System: Class 1Document20 pagesMethod Statement of Hvac Duct System: Class 1EntegharNo ratings yet

- 4) Method Statement For HVAC Copper Piping & Drain PipingDocument16 pages4) Method Statement For HVAC Copper Piping & Drain PipingIzaaz AhamedNo ratings yet

- Authority Tracking LogDocument12 pagesAuthority Tracking Loghit2284100% (1)

- Lps 01 Hti MST Me 022 Chemical Dosing SystemDocument24 pagesLps 01 Hti MST Me 022 Chemical Dosing SystemJomy JohnyNo ratings yet

- Internal Approval of Method StatementsDocument12 pagesInternal Approval of Method Statementsmidhun muraliNo ratings yet

- Material SubmittalDocument4 pagesMaterial SubmittalshoaibNo ratings yet

- Survey Works Rev 1Document12 pagesSurvey Works Rev 1Abraham JyothimonNo ratings yet

- Mechnical InspectorDocument3 pagesMechnical InspectorAdil AzizNo ratings yet

- R07-HC3C05-FET-MTS-ME-0012 - C1 Method Statement For Installation of DX UnitsDocument46 pagesR07-HC3C05-FET-MTS-ME-0012 - C1 Method Statement For Installation of DX Unitslike saddamNo ratings yet

- Aramco Construction Safety ManualDocument49 pagesAramco Construction Safety Manualatiq0592No ratings yet

- Mos Hvac Ductwork Chilled Water Pipework 1650884167Document56 pagesMos Hvac Ductwork Chilled Water Pipework 1650884167Prabesh ShresthaNo ratings yet

- Method Statement For Installation of Electrical DB, SMDB and MDB PanelboardsDocument6 pagesMethod Statement For Installation of Electrical DB, SMDB and MDB Panelboardsnidhinm92No ratings yet

- Estimation Engineer - Scope and FutureDocument19 pagesEstimation Engineer - Scope and FutureBehram Ciodia100% (1)

- HVAC QA QC EngineerDocument3 pagesHVAC QA QC Engineermalik hafeez100% (1)

- Majid CVDocument7 pagesMajid CVAbdul Ahad LoneNo ratings yet

- CV - Draftsman - Ahamed CV-1Document3 pagesCV - Draftsman - Ahamed CV-1Ziad EzzeddineNo ratings yet

- List of Materials and Equipment and Compliance To SpecificationDocument4 pagesList of Materials and Equipment and Compliance To SpecificationNguyen Chi ThanhNo ratings yet

- Paper Supplies Store AT Berkat AL Awamer: Qatar International Islamic Bank (QIIB)Document7 pagesPaper Supplies Store AT Berkat AL Awamer: Qatar International Islamic Bank (QIIB)Congson JeffNo ratings yet

- Wms Acmv Duct WorksDocument8 pagesWms Acmv Duct Worksfahmi_majid_2No ratings yet

- Certificado Ul - BeldenDocument1 pageCertificado Ul - BeldenEdwin Villegas JimenezNo ratings yet

- LEED V4 Sustainable Materials Questionnaire - Exit 10 Al Hamra Development 10.03.2024Document3 pagesLEED V4 Sustainable Materials Questionnaire - Exit 10 Al Hamra Development 10.03.2024IB KNo ratings yet

- Method Statement and Rams For Fire Fighting System Pipes (Internal & External)Document39 pagesMethod Statement and Rams For Fire Fighting System Pipes (Internal & External)mohdshahul543No ratings yet

- Evaluations of VendorsDocument4 pagesEvaluations of VendorsWael_Barakat_3179No ratings yet

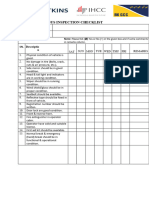

- Hot Work ChecklistDocument1 pageHot Work ChecklistanwarNo ratings yet

- Al AMAL COMPANY PROFILE 2022-2023Document31 pagesAl AMAL COMPANY PROFILE 2022-2023Anas sabbaghNo ratings yet

- CVDocument3 pagesCVSyed ShahbazNo ratings yet

- Bms & Hvac SystemDocument41 pagesBms & Hvac Systemislam OkilNo ratings yet

- Substation LayoutDocument1 pageSubstation LayoutMohamedNo ratings yet

- Method Statement For Testing and Commissioning Cold Water Plumbing System REV02 (KTAT)Document54 pagesMethod Statement For Testing and Commissioning Cold Water Plumbing System REV02 (KTAT)henryedwinNo ratings yet

- ITP For Access Control SystemTesting and CommissioningDocument1 pageITP For Access Control SystemTesting and CommissioningTamer EidNo ratings yet

- Pervez Ahmad Khan: Job Objective Areas of ExpertiseDocument6 pagesPervez Ahmad Khan: Job Objective Areas of ExpertisePERVEZ AHMAD KHANNo ratings yet

- Chiller Secondary Pump ControlDocument1 pageChiller Secondary Pump Controlshrikanth5singhNo ratings yet

- BTU Meter Installation GuideDocument1 pageBTU Meter Installation GuidePraveen SagayarajNo ratings yet

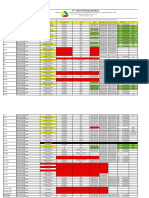

- FORM D-Manpower (Final With Histogram) - Form D1Document2 pagesFORM D-Manpower (Final With Histogram) - Form D1manoranjan dasNo ratings yet

- Aleem CV Mechanic EXPDocument3 pagesAleem CV Mechanic EXPmohd nadeem ahmedNo ratings yet

- Method Statement For HDPE Pipe InstallationDocument19 pagesMethod Statement For HDPE Pipe Installationqwertykey3991No ratings yet

- YGFC Catalog - EN - PUBL-8212 (1218)Document16 pagesYGFC Catalog - EN - PUBL-8212 (1218)jotace469No ratings yet

- MSRA-Site Office Mobilisation-00Document27 pagesMSRA-Site Office Mobilisation-00anwarNo ratings yet

- Aisels of MaterialsDocument2 pagesAisels of MaterialsanwarNo ratings yet

- WI HSE 015 (Ladder Inspection Checklist) Issue 1.0Document1 pageWI HSE 015 (Ladder Inspection Checklist) Issue 1.0anwarNo ratings yet

- Hot Work ChecklistDocument1 pageHot Work ChecklistanwarNo ratings yet

- Bus Inspection ChecklistDocument1 pageBus Inspection ChecklistanwarNo ratings yet

- Tds-Al-Jazeera Thinner 507Document1 pageTds-Al-Jazeera Thinner 507anwarNo ratings yet

- Tds-Al-Jazeera Fast Drying Enamel GlossDocument2 pagesTds-Al-Jazeera Fast Drying Enamel GlossanwarNo ratings yet

- Polywater WX SDS EUR enDocument8 pagesPolywater WX SDS EUR enanwarNo ratings yet

- Soil Stabilization Using Lime, Bitumen, Industrial WastesDocument36 pagesSoil Stabilization Using Lime, Bitumen, Industrial WastesAnupam SharmaNo ratings yet

- IHCDocument193 pagesIHCluluNo ratings yet

- 64mx44m Multi-Span Film Greenhouse Quotation - HUIJING GREENHOUSEDocument2 pages64mx44m Multi-Span Film Greenhouse Quotation - HUIJING GREENHOUSEBiopeca EpsNo ratings yet

- Appurtenant Structures For Dams PDFDocument55 pagesAppurtenant Structures For Dams PDFpggopal_85No ratings yet

- ST Nerf 26 66 KV Transformer Detail ST Nerf 26Document1 pageST Nerf 26 66 KV Transformer Detail ST Nerf 26mhazarath murariNo ratings yet

- Mechanical Properties of Solids - Mind Map - Arjuna NEET 2.0 2024Document1 pageMechanical Properties of Solids - Mind Map - Arjuna NEET 2.0 2024abiparakalNo ratings yet

- 6 Ten States Standards 2004 - Chapter 30 - Design of SewersDocument12 pages6 Ten States Standards 2004 - Chapter 30 - Design of SewersCowbeak7959No ratings yet

- 3 Space Truss - MeroDocument7 pages3 Space Truss - MeroWahid OmarNo ratings yet

- Tugas Jembatan 1Document74 pagesTugas Jembatan 1Faisol FirmansyahNo ratings yet

- S-15A Detail of CanopyDocument1 pageS-15A Detail of CanopygoldieNo ratings yet

- Civil Management Project Bengoh Dam - Group 3Document16 pagesCivil Management Project Bengoh Dam - Group 3NazrinNo ratings yet

- Seismic Assignement-1Document28 pagesSeismic Assignement-1Chai DirectNo ratings yet

- E1105Document5 pagesE1105Sig BlackhysteriaNo ratings yet

- Cable Stayed BridgeDocument17 pagesCable Stayed BridgePrashant PalNo ratings yet

- Well PlanningDocument18 pagesWell PlanningBrahim Letaief100% (3)

- RetarderDocument10 pagesRetarderAshe100% (1)

- EP SG 4 3-0035 Drilling Well Control Manual PDFDocument465 pagesEP SG 4 3-0035 Drilling Well Control Manual PDFJérôme Tsang100% (2)

- Appendix G - Horizontal Directional Drill and Contingency Plan FINAL 2013 0604Document15 pagesAppendix G - Horizontal Directional Drill and Contingency Plan FINAL 2013 0604Thomas BennettNo ratings yet

- Boiler Tube Failure Mechanisms - Case Studies-Springer (2023)Document136 pagesBoiler Tube Failure Mechanisms - Case Studies-Springer (2023)RDSetyawan100% (1)

- Gravity Base Foundations For The Wind Turbines On The Thorntonbank - BelgiumDocument18 pagesGravity Base Foundations For The Wind Turbines On The Thorntonbank - BelgiumUsable ToolsNo ratings yet

- Reid Products 2012Document96 pagesReid Products 2012Marianna Morozova0% (1)

- Price Als & Afs Jomon UpdateDocument4 pagesPrice Als & Afs Jomon UpdateSugiharto RichardNo ratings yet

- Single-Span Beam Analysis: Loading Functions Evaluated at X LDocument2 pagesSingle-Span Beam Analysis: Loading Functions Evaluated at X LAngelo AguinaldoNo ratings yet

- Design of Stairs 2021 Lecture NotesDocument12 pagesDesign of Stairs 2021 Lecture NotesstevenNo ratings yet

- Full Hand Calculation, Analysis and Design of Multi Story Building IIDocument2 pagesFull Hand Calculation, Analysis and Design of Multi Story Building IIMuhammed Sarwar Hussin RosunNo ratings yet

- May 2022 Ce Board Exam Policarpio 3: Eview NnovationsDocument3 pagesMay 2022 Ce Board Exam Policarpio 3: Eview NnovationsKian InductivoNo ratings yet

- Building Bye-Laws Commercial/ Mixed Use: B.Arch, V SemesterDocument34 pagesBuilding Bye-Laws Commercial/ Mixed Use: B.Arch, V SemesterUjjwal AmawatNo ratings yet

- Hunter Expressway Eastern Sec Cms07Document25 pagesHunter Expressway Eastern Sec Cms07Syerifaizal Hj. MustaphaNo ratings yet

- BioumaandumaraniprofileDocument19 pagesBioumaandumaraniprofilesumethasakuraNo ratings yet

Method Statement For Installaation of Hydronic Piping With Specialities

Method Statement For Installaation of Hydronic Piping With Specialities

Uploaded by

anwarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement For Installaation of Hydronic Piping With Specialities

Method Statement For Installaation of Hydronic Piping With Specialities

Uploaded by

anwarCopyright:

Available Formats

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

PROJECT NAME: Shurayrah Island Resorts – Golf Clubhouse and Villa

SITE NAME: Golf Club House and Villas

METHOD OF STATEMENT

DOC # MT0034 Rev.: 00 Submittal Date:

DISCIPLINE GENERAL STRUCTURAL ✘ MECHANICAL ARCHITECTURAL ELECTRICAL

SUBJECT:

WE SUBMIT THE FOLLOWING:

Method Statement for Installation of Hydronic Piping with Specialties.

OTHER REMARKS:

Contractor’s Engineer /QC Engineer/Construction Mgr.: Contractor’s Project Manager:

Name: Hafiz Mohd Basheer Name: Manish Jain

Signature: Signature:

Date: 09-April-23 Date: 09-April-23

CONSULTANT’S COMMENTS

Architect / Engineer's review is for general conformance with the design intent and contract documents. Markings or

comments shall not relieve the Contractor / Subcontractor from compliance with the project plans and specifications,

nor deviations therefrom. The Contractor / Subcontractor remains responsible for details and accuracy.

Action Code LEED CONSULTANT: Action Code SITE CONSULTANT:

Arch/Civil Electrical /Mechanical Arch/Civil Electrical /Mechanical EHS

Code- Code-A

EHS

A Code-B Name:

Code- Name: Code-C

Signature:

B Code-D

Signature:

Code- Date:

C

PRINCIPAL CONSULTANT: PRINCIPAL CONSULTANT:

Arch/Civil Electrical / Mechanical Arch/Civil Electrical /Mechanical EHS

EHS

Name:

Name:

Signature:

Signature:

Date:

Date:

A Approved B Approved as Noted C Revise and Resubmit D Rejected

1

Building Knowledge General Contracting Company LLC - KSA

A BK Gulf Group of Companies

WI PM 028 Issue 1.00 / May.2022

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

Method Statement for Installation of Hydronic

Piping with Specialties.

Document Number MT0034

Status For Approval

Version 0

Date 09-04-2023

Authored by:

Sayed Saifi Akhtar Name:

QA QC Manager Role:

Signed:

09-04-2023 Date:

Reviewed by:

Hafiz Mohd Basheer Name:

Construction Manager Mechanical Role:

Signed:

09-04-2023 Date:

Authorized for issue by:

Manish Jain Name:

Project Manager Role:

Signed:

09-04-2023 Date:

2

Building Knowledge General Contracting Company LLC - KSA

A BK Gulf Group of Companies

WI PM 028 Issue 1.00 / May.2022

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

S.No INDEX Page

No.

1 DESCRIPTION OF WORKS 4

2 LOCATION AND WORK LIMITS (AREA/SITE SPECIFIC LAYOUT) 4

3 PROTECTION AND ISOLATION ARRANGEMENTS (E.G 3RD PARTIES) 4

4 RESPONSIBILITY 4

5 TASK SPECIFIC EMERGENCY ARRANGEMENTS 5

6 WORK METHODOLOGY 5

7 RESOURCES 15

8 INTERFACES – OTHER SITES, WORK ACTIVITIES, GENERAL PUBLIC ETC. 16

9 PERMITS 17

10 REFERENCES DRAWINGS / SPECIFICATIONS / OTHER 17

11 RISK ASSESSMENT 22

12 ANNEXES 42

3

Building Knowledge General Contracting Company LLC - KSA

A BK Gulf Group of Companies

WI PM 028 Issue 1.00 / May.2022

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

1. Description of Works

Describe the works covered by this Method Statement. Include or attach sketches, maps, drawings if applicable.

This method statement covers the detailed procedure for installation of Chilled Water Pipe Works and Fittings. This

procedure defines the method used to ensure that the pipe work and fittings installation has been carried out as per the

contract specification requirements and meet both British and ASTM Standards.

2. Location and Work Limits (Area/Site Specific Layout)

State the work location and work limits this Method Statement includes. Include sketches, maps, drawings if applicable.

Golf Club House

Villas

3. Protection and Isolation Arrangements (e.g., 3rd Parties)

Protection/Isolation Measures Area

Hard barricades Site Work for Golf Club House and

Soft barricades (red & white warning tape with rope) Villas

Underground marking and survey.

Signage’s

4. RESPONSIBILITY

Project Manager:

To ensure that all the preparation and application works are carried out according to the Contract Specification

and the approved drawings.

To ensure that the progress of work is carried out according to the planned program and as per the approved

method of statement.

To ensure that all the equipment and material required to execute the work are available according to the

planned construction program.

To coordinate with Site Engineer and Safety Officer, for a safe and proper execution of the works.

Construction Manager:

Overseeing the logistical requirements of a project.

Delegating work to colleagues within your team.

Meeting regularly with clients, third parties and other managers to report on progress.

Setting targets, objectives, and responsibilities for all supervised staff.

Regularly reviewing timings, budget, labor, risk and project plans to ensure work stays on track.

Setting and agreeing budgets.

Conducting site visits to inspect work, check materials and ensure staff are following health and safety guidelines.

Dealing with contracts and mitigating the impact of any issues.

Ensuring the delivery of high-quality work within contract timescales.

Working in an office and on a construction site.

4

Building Knowledge General Contracting Company LLC - KSA

A BK Gulf Group of Companies

WI PM 028 Issue 1.00 / May.2022

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

Site Engineer:

To ensure that the works are carried out according to the Contract Specification, approved method statement the

shop drawings.

To provide all necessary information and distribute responsibilities to his construction team.

To monitor the progress of work in relation to the work program and to report to the project manager.

To coordinate with the Safety Officer and to ensure that the work is carried out in safe practicing methods.

Foreman:

The foreman will carry out his duties by maintaining continuous coordination with the Site Engineer on daily basis

and ensure proper distribution of the workforce in the required and planned locations.

To ensure that his group is aware of the job requirements, and they have enough information to carry out their

duties properly.

To ensure that the daily work is progressing as planned and advise the Site Engineer of any requirement for

additional resources.

To control disposal of waste materials according to the instructions received from the Site Engineer.

To ensure full coordination with the Safety Officer to maintain safe working and proper housekeeping of the site,

following the approved safety measures and further ensure that all his work team are aware of the same to

prevent accidents and losses.

To inform the Site Engineer about the areas ready for inspection. Distribution and the control of material shall be

monitored by Foreman and storekeeper.

Quality Engineer:

Shall ensure that the quality of the work is accordance to the project’s specification & standard.

The process was performed to ensure conformance with contract requirements & Quality Standards.

This process includes quality planning, operational techniques, training, providing clear decisions and directions,

constant supervision operational / Techniques, immediate review of completed activities for accuracy and

completeness, and documenting all decisions, assumptions, and recommendations.

The Safety Officer:

Shall ensure that safety of the workers is always taken into consideration. He shall make sure that all materials

used must be in safe condition.

5. Task Specific Emergency Arrangements

Describe any task specific emergency arrangements in place for this work e.g. method of rescuing

a worker from a confined space.

Emergency procedure in the case of fire, accident, and medical evacuation on site .

In an emergency every Supervisors shall ensure the following:

Stop work immediately.

All BKGCC workers and visitors should evacuate the working area to the nearest assembly point.

Switch off all the running equipment (mobile or non-mobile) and vehicles.

Park vehicles on the side of the road that shall not block the access road.

Notify MIS representative at the same time as the emergency case.

Call all emergency disciplines like Ambulance or Police or the Civil Defense Unit.

5

Building Knowledge General Contracting Company LLC - KSA

A BK Gulf Group of Companies

WI PM 028 Issue 1.00 / May.2022

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

Report the accident to client representative.

No one shall be allowed to come near the fire or accident area except for the authorized.

persons only (ERT)

Head counting shall be done in the assembly area by site supervisor.

All person shall stay in assembly area until all clear alarm activated or someone responsible person gives

information of all clear.

Ambulance

997

Traffic

Police Civil

Defense

998

993 Emergency

without

mobile SIM

card

112

Police Road

Safety

999 996

SEC

933

6. Work Methodology

Activity Description and sequencing Number

Material Inspection, Handling/Storage 6.1

Pre-Installation Check 6.2

Installation 6.3

Installation of Pipe Support 6.4

Pressure/Temperature Test Point 6.5

Automatic Air Vent 6.6

Drain point 6.7

Visual Inspection of Installed Pipe Work 6.8

Painting 6.9

Hydrotesting 6.10

6

Building Knowledge General Contracting Company LLC - KSA

A BK Gulf Group of Companies

WI PM 028 Issue 1.00 / May.2022

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

Clean up-Site 6.11

The work methodology associated with the installation process of according to project specification section.

In procedure BKGCC will follow the project standard specification. Our main target will be to work at.

1. Construction Quality Plan.

2. MIS Drawings/ Shop Drawings.

3. MIS Project’s Specifications.

4. Manufacture Installation Procedure.

5. Material Control Procedure.

6. Inspection and Test Plan.

6.1 Material Inspection, Handling/Storage.

6.1.1. MATERIAL INSPECTION

a. In case of any damages in preliminary inspection, Report will be issued.

b. If the materials are found defective, it shall not be installed at the job site and shall be returned to the supplier

for replacement.

c. On Delivery of the material, it must be inspected and ascertained that it is in good Condition and avoid of

manufacturer defects.

d. Material inspection will be carried out to ensure that no damage has occurred to the materials.

e. All Material shall be inspected by BKGCC QA/QC team prior to requesting Consultant inspection.

f. Once the Material has been thoroughly inspected for compliance the Consultant shall be invited to inspect.

6.1.2. HANDLING/STORAGE

a. The materials shall be handled with care and shall be stored in designated areas.

b. The Pipes & Fittings will be handled and stored in accordance with the manufacturer’s instructions.

c. Pipes will be stacked on a flat surface free from sharp projections, stones, or other objects likely to cause point

loading or pipe deformation.

d. The pipes can be laid on stout timber blocks, placed at not more than 1 m max centres along the length of the

pipe.

e. The storage area should be a clean, dry space and have adequate air circulation and protected from dirt,

fumes, water. The storage area should be free of vehicle traffic to prevent physical damage to the products. All

stored materials should be lifted off the floors.

6.2 PRE-INSTALLATION CHECK

6.2.1 Ensure that all safety requirements are in place in accordance with the project safety plan.

6.2.2 On receipt of the material at site, QA / QC Engineer/ Site Engineer shall inspect the material for any physical

damage, dents & scratches internally and inspection shall be offered to the Engineer for approval in MIR (Material

Inspection Request) form.

7

Building Knowledge General Contracting Company LLC - KSA

A BK Gulf Group of Companies

WI PM 028 Issue 1.00 / May.2022

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

6.2.3 Ensure all the materials used have passed receiving inspection in accordance with QA procedures and are not

damaged or defective. Any non-conforming materials must be labeled by storekeeper and returned to quarantine

area in accordance with procedure.

6.2.4 Ensure that all pipe fitters and helpers are aware of the correct materials handling and installation procedure to

ensure the best quality of workmanship. Training shall be provided by Site engineer/Supervisor as and when

required.

6.2.5 All Pipe and fittings will be cleaned before installation.

6.2.6 The Main Contractor to ensure that prior to installation of piping, all building surfaces to which supports are fixed

are completed to acceptable tolerance and are in a suitably clean and dry condition. Any unsatisfactory conditions

are to be reported to the Project Manager and installation shall not proceed until corrective action measures have

been taken by him.

6.2.7 Ladders, Step ladders and scaffolding during construction shall be used at site as per the safety plan.

6.2.8 Prior to starting the work, HVAC engineer/ supervisor from the execution team shall ensure that the latest

approved shop drawings are available at site.

6.2.9 Installation of piping will be coordinated with architectural, structural, and other MEP services work. Any deviation

shall be intimated to the Engineer for approval prior to installation.

6.2.10 Supervisor shall ensure equipment and correct tools are available for installation-operation and to achieve

compliance with contract requirement.

6.3 INSTALLATION PIPES AND FITTINGS

6.3.1 Before installing any pipe work at high level, site engineer shall Ensure Removal of scale, slag, dirt, and debris

from inside and outside of pipe and fittings before assembly.

6.3.2 Ream ends of pipes and tubes and remove burrs. Bevel plain ends of steel pipe.

6.3.3 All the pipes shall be joined with other pipes with approved jointing material and method as specified below.

6.3.4 Install dielectric coupling and nipple fittings to connect piping materials of dissimilar metals.

6.3.5 Chilled water Pipes & fittings, DN 50 and Smaller: Schedule 40 steel pipe with threaded joints & DN 65 and larger

will be joined with grooved mechanical-joint couplings. All concealed joints below the slab or located in shafts

must be welded joints.

6.3.6 Threaded Joints: Thread pipe with tapered pipe threads according to British Standards. Cut threads full and clean

using sharp dies. Ream threaded pipe ends to remove burrs and restore full ID.

8

Building Knowledge General Contracting Company LLC - KSA

A BK Gulf Group of Companies

WI PM 028 Issue 1.00 / May.2022

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

6.3.7 The pipes shall be tightened with pipe wrench to the required tightening pressure protecting the outer surface of

pipe from the damage of wrench teeth.

6.3.8 Install sleeves for pipes passing through concrete and masonry walls and concrete floor and roof slabs. Install

sleeves that are large enough to provide 6.4 mm annular clear space between sleeve and pipe or pipe insulation.

Use Steel Pipe Sleeves: For pipes smaller than DN 150.

6.3.9 All joints shall be carefully reamed and jointed with jute with boss white compound on male thread only.

6.3.10 Install piping as indicated unless deviations to layout are approved on Coordination Drawings.

6.3.11 Install piping indicated to be exposed and piping in equipment rooms and service areas at right angles or parallel

to building walls. Diagonal runs are prohibited unless specifically indicated otherwise.

6.3.12 Install piping above accessible ceilings to allow sufficient space for ceiling panel removal, to permit valve

servicing, free of sags and bends, to allow application of insulation. Install fittings for changes in direction and

branch connections. Reduce pipe sizes using eccentric reducer fitting installed with level side up.

6.3.13 Install unions, in piping DN 50 and smaller, adjacent to each valve and at final connection to each piece of

equipment.

6.3.14 Install flanges, in piping DN 65 and larger, adjacent to flanged valves and at final connection to each piece of

equipment.

6.3.15 Unless otherwise indicated, install branch connections to mains using tee fittings in main pipe, with the takeoff

coming out the bottom of the main pipe. For up-feed risers, install the takeoff coming out the top of the main pipe.

6.3.16 Provide adequate provision for expansion and contraction in portions of the piping systems, to prevent undue

strains on piping and connected equipment.

6.3.17 Provide approved bolted, gasketed flanges for each piece of equipment to permit easy connection and

disconnection. Screwed unions with steel faces may be used on piping 1 inch and smaller.

6.3.18 Inlet/outlet piping connections to coils and equipment shall be provided with offsets and shutoff valves arranged

such that equipment can be serviced or removed without dismantling the pipe.

6.3.19 Ensure and confirm the jointing between lengths of pipe work and fittings shall be carried out in such a manner

that a continuous smooth bore is maintained within the joint.

6.3.20 If pipes are being joined together using nuts & bolts, bolt should be of correct length and diameter.

6.3.21 After tightening of the bolts end of the bolts should be either beyond the nut or it should be flushing with the nut

face.

6.3.22 All valves, flexible connections and as far as possible all piping shall be easily accessible for inspection,

maintenance, and operation.

6.3.23 Install drain valves at all points for draining and locate where easily accessible. Dirt pocket to be provided at

lowest level of each riser.

6.3.24 Lifting of pipes shall be carried out using approved lifting equipment based on the size, length, and specific

location of installation with appropriate briefing to the personals involved in the activity as per HSE guidelines.

9

Building Knowledge General Contracting Company LLC - KSA

A BK Gulf Group of Companies

WI PM 028 Issue 1.00 / May.2022

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

6.3.25 Pipes of smaller size and shorter in length shall be installed in position by manually and larger diameter pipes

shall be lifted on to the installation by using chain blocks or appropriate lifting mechanism complying with HSE

guidelines.

6.3.26 Appropriate work at height platforms shall be used for safe working at heights.

6.3.27 Provide gates, double regulating and check valves in all piping systems as required for satisfactory operation and

control of equipment.

6.3.28 Approved types of inserts shall be provided at support locations in line with the thickness of insulation materials

for the chilled water pipe works. For insulated piping, rubber support inserts shall be provided at all pipe support

locations to prevent crushing of insulation.

6.3.29 Insulation shall be applied on chilled water pipe work without as per approved schedule ensuring no air gap

between insulation, pipe surface and at the adjoining support insert locations to prevent any sort of condensation.

6.3.30 Pipe joints shall be left uninsulated till the completion of pressure testing of chilled water pipe works and insulation

shall be completed on approval of installation.

6.3.31 Provide strainer upstream of each pump suction with blow-off valve and as shown in the drawings.

6.3.32 Pressure gauges with a gauge cock & pressure snubber and thermometers shall be installed in the piping as per

the locations shown in the approved shop drawings.

6.3.33 Bypass connections between the supply and return pipe works shall be provided in appropriate locations as

indicated in approved shop drawing for flushing and chemical cleaning applications.

6.3.34 All pipes shall be fixed and run in vertical risers in parallel in-service shaft and provide easy access to repair and

maintenance free. All pipes shall be supported on the wall with thrust supports to bear and hold the weight of

risers.

6.3.35 All pipes shall be inspected for cleanliness prior to installation and cleaning shall be carried out by using approved

cleaning agent and further cleaning shall be carried out after the works completed.

6.3.36 Valves and other inline equipment shall be installed as indicated as per the manufacturer’s recommendation and

in line with flow direction.

6.3.37 All open ends shall be protected by plastic caps and shall be removed at the time of straight joints for successive

pipe connection.

6.3.38 All open ends shall be protected by plastic caps and shall be removed at the time of straight joints for successive

pipe connection.

6.3.39

6.4 Installation of Metallic pipe works by grooved mechanical-joint.

6.4.1 The Floor where the grooving machine is placed will be protected with a cover of PVC sheets to avoid oil splash

portion on the concrete floor.

6.4.2 The roller of the grooving machine will be checked for wear and tear.

6.4.3 Pipes will be inspected to ensure plain ends. (NO Beveled ends). Grooving will be provided to DN 65 and larger

pipe sizes.

6.4.4 The OD of the groove will be measured. The OD of the groove should be within the manufacturer recommended

range. Before assembly, the grooved joints will be cleaned from any dust, debris, etc.

6.4.5 Before assembly, the grooved joints will be cleaned from any dust, debris, etc. The branches will be assembled at

the fabrication shop or on spot. All the ends will be plugged.

6.4.6 Fabrication of Pipe at Location of Mechanical Tee

The pipe will be marked at the location of the mechanical Tee.

The pipe will be holed drilled to the suitable size of the branch and in accordance with the manufacturer’s

recommendations.

The hole will be filed to assure soft surface.

10

Building Knowledge General Contracting Company LLC - KSA

A BK Gulf Group of Companies

WI PM 028 Issue 1.00 / May.2022

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

6.4.7 Coupling Installation

Groove the pipe ends according to the project specification and consultant’s approval.

Pipe must be free from indentations, projections or roll marks on exterior from the ends to the groove, to

assure a leak tight seat for the gasket.

Place gasket over pipe ends, being sure gasket lip does not overhang pipe end.

Place gasket over pipe ends, being sure gasket lip does not overhang pipe end.

Loosely assemble all segments leaving one nut and bolt off to allow for “swing-over” feature.

With 1 nut and 1 bolt removed, use the “swing-over” feature to position housings over gasket and into the

grooves on both pipes.

Insert the remaining bolt to allow easy tightening of the nut. Be sure track head engages into housing

recess.

Tighten nuts alternately and equally maintaining metal-to-metal contact at the angle bolt pads. Tighten

securely to ensure a rigid joint.

6.4.8 Flange Fitting Installation

Check studs, nuts, and flange/nut contact surfaces for cleanliness and burrs. Clean them using a wire

brush.

Check flange nut bearing surfaces. Clean the flange nut contact surfaces around the entire bolt circle

using a wire brush. Ensure that these contact faces are free of scratches, dirt, scale, burrs, and other

protrusions. Remove defects by grinding.

Uniformly lubricate the stud and nut threads on all contact surfaces, including the nut bearing surface

that contacts the flange.

Check the condition of flange faces. Clean gasket seating surface on flange face using a wire brush.

Ensure that the surface is free from scratches, dirt, scale, remnants of old gaskets, and other

protrusions.

Check flange-to-flange alignment to verify that it is within the specified tolerances (±5mm). Excessive

flange misalignment increases the likelihood of in-service leakage.

Check flange faces for proper gasket insertion gap. The gap between flanges should be just sufficient to

allow for gasket insertion. Excessive gap will result in needing to force the flanges together, which will

increase the likelihood of in-service leakage.

Install studs in the lower half of the flange to support the gasket when it is inserted.

Insert the gasket between the flanges and ensure its proper placement (i.e., centering in the joint), taking

care not to damage the gasket.

Install remaining studs and nuts and ensure that there is complete thread engagement in both nuts.

6.4.9 Screw Fitting Installation

Check the pipe length required based on the approved shop drawing.

Mark the desired length on the pipe and cut it. Make sure the pipe ends are square.

Place the pipe in the threading machine and thread it accordingly. Make sure the thread of the pipe is in good

condition.

Remove the oil from the pipe end after the threading procedure and wrap it with Jute, Boss white or Teflon tape.

Install the pipe to the screw fitting.

11

Building Knowledge General Contracting Company LLC - KSA

A BK Gulf Group of Companies

WI PM 028 Issue 1.00 / May.2022

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

6.5 Installation of Metallic pipe works using Threaded Fittings

6.5.1 Threaded fitting shall be used for chilled water pipes of sizes including DN 50 and smaller.

6.5.2 Threaded fittings of approved type and size shall be used for the installation of chilled water pipework.

6.5.3 Pipe ends shall be threaded for installation of threaded fittings while joining the pipes.

6.5.4 Pipes shall be installed on routes as indicated in approved shop drawings.

6.5.5 Threaded surfaces of the pipes and fitting shall be cleaned properly prior to joining the pipes using threaded

fittings.

6.5.6 Appropriate thread sealant shall be applied on the treaded face of the pipes for proper installation of the threaded

fittings.

6.5.7 Threaded joints on the pipe works shall be left uninsulated to carry-out the pressure testing of the pipework and

insulation shall be completed upon approval of pressure testing of pipe works.

6.6 Installation of Pipe Supports

6.6.1 Pipe Support spacing shall be provided as per the approved shop drawing and supporting details and sections.

given in the specification.

6.6.2 Drill holes with rotary impact hammer drills using carbide-tipped bits. The drill bits shall be of diameters as

specified by the anchor manufacturer. Unless otherwise shown on the Drawings, all holes shall be drilled

perpendicular to the concrete surface. Exercise care in drilling to avoid damaging existing reinforcing or

embedded items.

6.6.3 Piping shall be braced to resist seismic forces as per the ‘Seismic Restraint Requirements’ Provide a seismic

bracing system to restrain piping from excessive motion when subjected to horizontal seismic forces, to prevent

damage to adjacent equipment and building structure. Bracing shall permit thermal expansion of pipe and ensure

that vibration isolators, if present, are not short circuited.

6.6.4 Pipelines, which are not subject to thermal expansion, shall be supported directly to the building fabric.

6.6.5 Chilled water or hot water pipe runs of over 20m without changes in direction shall always be supported on roller

based or sliding supports.

6.6.6 Heavy-duty steel trapezes to support multiple pipes shall be designed for the combined weight of pipe, water and

adjacent fittings, and field fabricated from ASTM A36 structural steel channel.

6.6.7 Vibration isolators shall be provided at first five pipe hangers and support locations adjacent to isolated rotating

mechanical equipment, to minimize transmission of noise and vibration to the building structure.

6.6.8 Riser clamps (MSS Type 8) shall be provided at each floor to support steel riser pipe which has not been installed

with engineered acoustic riser anchors and guides. For steel riser piping installed with acoustic anchors and

guides, riser clamps shall be provided for stabilization of pipe at all floors where riser guides are not present.

6.6.9 For insulated pipes where effective outer diameter does not correspond to a standard pipe size, intermediate

sizes of riser clamps shall be provided to ensure a close fit. Oversized clamps will not be accepted.

6.6.10 Maximum horizontal support spacing for grooved steel pipe is 6 meters.

6.6.11 Provide hanger or support within 300 mm of horizontal elbows and tees. Install additional hangers at concentrated

loads including valves, flanges, strainers, expansion joints and other pipeline ancillaries. Install spring hangers in

header piping at the location of all suction and discharge drop risers to pumps, chillers, heat exchangers.

6.6.12 Pipe supports to the beam shall be provided with two number clamp type fasteners on each side of beam.

6.6.13 Pipeline supports shall not be attached to any plant or terminal unit.

6.6.14 All supporting arrangements shall be provided with proper fixing arrangements.

6.6.15 All angles/u-channels, threaded rods, bolts, nuts, washers should be galvanized iron material.

6.6.16 Any galvanized iron material if cut & fabricated at site should be painted with galvafroid zinc rich paint.

12

Building Knowledge General Contracting Company LLC - KSA

A BK Gulf Group of Companies

WI PM 028 Issue 1.00 / May.2022

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

6.7 INSTALLATION PROCEDURE FOR CHILLED WATER SPECIALITIES

6.7.1 Installation of Valves, Strainers, Air vent, Expansion tank, Pressurization Unit, Gauges, Meters & Specialties.

Valves/Accessories of approved type and model as per approved material submittal/Shop drawing

schedule/details shall be used for the installation on the chilled water pipework.

Temperature test points shall be mounted via isolating ball valve which shall allow clear passage of the

test flow in the open position.

Typical installation details for valve packages at various equipment connections shall be following for the

installation of valve packages in chilled water pipe work.

Install manual air vents at high points in piping, at heat-transfer coils, and elsewhere as required for

system air venting.

Test Points will be installed in the main flow and return connections of each main circuit and each branch

circuit throughout the installation.

Install piping from boiler air outlet, air separator, or air purger to expansion tank with a 2 percent upward

slope toward tank.

Install automatic air vents at high points of system piping in mechanical equipment rooms only. Install

manual vents at heat-transfer coils and elsewhere as required for air venting.

The drain valves shall be installed to blow-off sediments from strainers and tanks at lower level. Install

drains, consisting of a tee fitting, DN 20 ball valve, and short DN 20 threaded nipples with cap, at low

points in piping system mains and elsewhere as required for system drainage.

The drain points shall be provided at low points and drop & rise which forms a loop for draining and

locate where easily accessible.

Install in-line air separators in pump suction. Install drain valve on air separators NPS 2 (DN 50) and

larger.

Install tangential air separator in pump suction. Install blowdown piping with gate or full-port ball valve;

extend full size to nearest floor drain.

Install expansion tanks on the floor. Vent and purge air from hydronic system and ensure that tank is

properly charged with air to suit system Project requirements.

6.8 Visual Inspection of Installed Pipe Work

13

Building Knowledge General Contracting Company LLC - KSA

A BK Gulf Group of Companies

WI PM 028 Issue 1.00 / May.2022

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

The system shall be visually inspected by Contractor to ensure that the correct installation procedures have

been followed and that the pipes and fittings are adequately supported and restrained in the prescribed

manner. The inspection shall be offered for Engineer’s approval.

6.9 Painting

Pipes and fittings shall be wire brushed to remove scale & rust and will be painted with approved primer.

6.10Hydro-Testing

6.10.1Ensure that all testing equipment is calibrated and ready for use.

6.10.2Take all due precautions to prevent damage to the building. Tests shall apply full test pressure to the piping for a

sufficient period to detect leaks and defects (minimum 24 hours).

6.10.3Ensure that clean water source is available without unwanted sediments for hydro-test.

6.10.4Ensure that the piping to be tested is supported properly as per the approved support details. Temporary anchor

points are provided near the bends and tee to withhold the thrust exerted by the line pressure.

6.10.5Ensure and confirm that automatic air vents and any other sensitive instruments are either removed or blanked off

prior to hydro test.

6.10.6Tests shall be conducted prior to the installation of any required fitting insulation. If delicate control mechanisms,

not including control valves, are installed in the piping, they shall be removed to prevent shock damage.

6.10.7Pressure shall be applied to the system by means of a hand pump drawing from a water container. The pump

discharge shall be connected to the system through pressure relief or safety valve, a globe valve, check valve

and recently calibrated pressure gauge of suitable range to have the pointer read in the middle of the range.

6.10.8The section of piping to be tested shall be brought up to the specified test pressure. If the test pressure falls more

than the specified amount during the test period, the point of leakage shall be found, repaired and the test

repeated. This procedure shall be repeated until the piping system has been proved tight.

6.10.9After the required test pressure is achieved, the pump shall be blocked off by closing the globe valve and the

variations of line pressure in the system monitored on the pressure gauge.

6.10.10Check the pipes, pipe joints and accessories for the leakage of water while pumping and if there is any sign of

leaks, to be rectified.

6.10.11Leaks shall be repaired by removing the valve, fitting, joint or section which is leaking and reinstalling new

materials and joints as specified. Use of mastic, "no-leak" compounds or other temporary means of repairing

leaks shall not be permitted.

14

Building Knowledge General Contracting Company LLC - KSA

A BK Gulf Group of Companies

WI PM 028 Issue 1.00 / May.2022

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

6.10.12Ensure and confirm that the air vent installed at higher point to release the air while the water pressure build up

gradually during water pumping under pressure test.

6.10.13For riser, testing shall be done in such a way that the pressure builds up due to water head does not count in

testing pressure.

6.10.14One pressure gauge will be fixed near the pump and another gauge will be fixed at the highest point of pipe work.

6.10.15Drains installed at low points shall be used to completely draining of test liquid as required while carrying out or

completion of pressure test. We make sure that drain of water shall be carried out in different locations if possible

and gradually through drain valves.

6.10.16Expansion tanks in the chilled water system shall be isolated from the testing and ensure that the pipe work

network under pressure test is filled with water.

6.10.17Pipe works shall be pressurized in steps to a hydrostatic test pressure of not less than 1.5 times of the system's

working pressure.

6.10.18 The range of the pressure gauge shall be twice as the rated test pressure.

6.10.19 Inspections shall be offered for Engineer inspection and approval for full insulation of pipework.

6.10.20 Ensure all the leakages are rectified after the correction is made, the pressure test shall be repeated until a

completely tight system is ensured and the testing procedure shall follow as:

a) Pressure line at 1035 KPa (10.0 bar) pressure or pressure not less than 1.5 times the working pressure,

whichever is greater, shall be maintained for 24 hours.

b) Ensure that during hydro testing, calibrated pressure gauges are used. After obtaining the required

test pressure without any leak up to 24 hrs, the system will be offered to the Engineer for inspection

and approval.

6.10.21Pressure testing documentation shall be submitted along with inspection request for consultant’s approval.

6.11 CLEAN UP THE JOB SITE

Prevent development of safety hazards.

Pick up all equipment and tools from the activity area after use.

Store tools, equipment, and unused materials properly at the end of the workday.

Collect and dispose of remaining pieces of used pipes.

7. Resources

a. Site Key Personnel and Workforce

Task Specific Training Required (if applicable) No. Required Title

Red man Green man, LCT training, and site driving rules Engineer/Supervisor

Red man Green man, LCT training, and site driving rules QC Engineer

15

Building Knowledge General Contracting Company LLC - KSA

A BK Gulf Group of Companies

WI PM 028 Issue 1.00 / May.2022

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

Red man Green man, LCT training, and site driving rules Supervisor

Red man Green man, LCT training, and site driving rules Plumper

Red man Green man, LCT training, and site driving rules and third party Operator and Driver

certificates

Red man Green man, LCT training, Surveyor and Chainman

b. Plant and Equipment

Specific Requirements Item

Daily Inspection/ Checklist Pick-Up truck

Daily Inspection/ Checklist Dayna truck

Daily Inspection/ Checklist Fork-lift

c. Materials and Tools

Reason for use Item

Project Requirements Carbon Steel Pipes and Fittings

Project Requirements Channels, angles and threaded rods

Project Requirements Threading Compound

Project Requirements Paints/Primer

Project Requirements Masking Tape

(Inspected and color-coded) Power Tools Kit

(Inspected and color-coded) Hand Tools

d. Chemicals Required

Specific Requirements MSDS Number Item

N/A

e. Task Specific PPE Required (Refer control measures from Risk Assessment)

Reason for use Item

For Head protection Safety Helmet

For eye protection Safety Glasses

Feet protection Safety shoes

Body protection Coverall

For visibility Safety Vest

For hand protection Cotton Gloves

Protect fall from height Body Harness

Note that all works require mandatory PPE as follows Hardhat, safety boots, hi-vis vest.

8. Interfaces – Other sites, work activities, general public etc.

Interfacing party or activity Description of Interface

N/A

16

Building Knowledge General Contracting Company LLC - KSA

A BK Gulf Group of Companies

WI PM 028 Issue 1.00 / May.2022

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

9. Permits

Any Permits Required (from MIS ESH Manual or 3rd Party)

Additional Information (Reference No. etc) Issued By Permit Type

HSE Lifting permit

HSE Plant checklist

Work supervisor STARRT CARD

Lifting Supervisor Lifting calculation sheet/lifting plan

10.References Drawings / Specifications / Other

Title Document Number

17

Building Knowledge General Contracting Company LLC - KSA

A BK Gulf Group of Companies

WI PM 028 Issue 1.00 / May.2022

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

11. Risk Assessment

Attached

The Risk Assessment must include all Environmental, Safety and Health Hazards and

controls/mitigation for the works.

7. APPENDICES

Include sketches or other documents needed to perform work safely.

Acknowledgement Signatures

The personnel listed below confirm receipt of the method statement and have had the contents

explained to them, understand it and are aware of the site ES&H requirements.

Name Employer Date Signature

Note to FE, CS & FCS – Any significant change from this method statement requires it to be

revised and resubmitted before work can commence.

18

Building Knowledge General Contracting Company LLC - KSA

A BK Gulf Group of Companies

WI PM 028 Issue 1.00 / May.2022

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

SAFE SEQUENCE OF WORK

ACTIONS DETAILS

Brief description of the work and location Installation of Hydronic Piping and Specialties

Sequence of Work and how operations are controlled. 1. Site Preparation

Ensure that all safety requirements are in place in

accordance with project safety plan

Ensure site is ready to start the work.

Ensure all materials have passed incoming inspection.

Ensure all tools and tackles are ready and available at

site prior to start the work.

Ensue site operatives are well aware of activities to be

carried out.

Sequence of Work and how operations are controlled. 2. Installation of barricade and sign boards

Adequate supervision and HSSE coverage

Area should be proper Barricaded during the work.

Other necessary signage also posted on the site according to the site

condition.

3. Lifting operation with crane/ boom truck

• Do not stand under the suspended load.

• Provide the certified rigger.

• All rigging gear must be inspected by 3rd party

• Crane must be inspected by 3rd party.

• Ground level must be compacted.

• Lifting checklist and permit must be available with.

• Lifting Area barricaded with lifting signage’s.

If lifting is near the road area, provide flagman to give direction to

the vehicles.

19

Building Knowledge General Contracting Company LLC - KSA

A BK Gulf Group of Companies

WI PM 028 Issue 1.00 / May.2022

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

4. Transportation of material.

• Only drive to the designated areas.

• Ensure all personnel have undertaken the site induction, ensure all

personnel have the correct PPE hard hat, safety glasses, coveralls or

covered clothing, safety footwear, Hand gloves and ear protection.

• Once you have access to the project access roads you must use the

correct speed limit 20 KPH inside working areas.

• Ensue that the driver is trained and competent and must hold KSA

licenses.

• Check that the vehicle is fit for purpose and must be inspected prior

to going on site.

• Driver must obey the project speed limits 40KPH for access roads

and 20 KPH in work area and must obey site rules.

• Bring down the pole and detach apart from base to top.

load the conduits from warehouse to designated area

5. Housekeeping

• Housekeeping will be done on a regular basis.

• All the waste material will be segregate material wise and

disposed of at land fill area provided by the client.

• During the Works, HSH is to segregate waste into the

following categories:

• General Construction Waste (concrete, blocks, bricks, rubble,

wood, etc...)

• Metals, hazardous Waste (fuels, oils, paints, solvents, gas

bottles, etc…)

• Domestic Waste (plastics, food, bottles, cans, etc…)

• HSH will provide adequate number of skips or containers

(bins, etc…) clearly identifiable (preferably color-coded) for

each category of waste.

HSH will educate employees through toolbox talks and

signage on segregation of the above wastes and the use of

the waste receptacles.

8.

•

Site Supervision and arrangement Project Manager Manish Jain +966 535431642

Site Engineer Hafiz Mohd Basheer +966 539367781

Safety Engr. Eid Jaan +966 535734188

Pre-Task briefing

Work permit.

Equipment Checklist

Individual responsible for control and monitoring. Project Manager

Construction Manager

Site engineers

Safety Engr.

20

Building Knowledge General Contracting Company LLC - KSA

A BK Gulf Group of Companies

WI PM 028 Issue 1.00 / May.2022

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

QA/QC Engr.

Plant and equipment to be used/ tools Carbon Steel Pipes and Fittings Measuring Tape.

Channel, Angle, Threaded Rods. Power Tools.

Paint/Primer Ladders/Scaffolding.

Operator training requirements The supervisor shall conduct a prestart meeting (STARRT) prior to

commencing equipment operation and he must deliver enough

knowledge to workers about the task. The operator shall also attend

the meeting and sign the attendance sheet. Operator competency

certificate and SAG heavy licenses.

Flag man Training, life critical requirement training, and Safe driving

on the job

Risk Assessment Attached

All equipment and operators shall be registered in HSE office along

with third party’s valid certificate.

No Equipment can operate at site without ES&H inspection, and

authorization.

All equipment and operators shall be oriented for the project "Life

Critical” training shall be conducted for all work force at site.

Provision of an approved method statement prior to starting the

work.

Field safety officers will be available throughout the activity, STARRT

Cards shall be implemented, and sign boards, barricades, Operator,

and rigger shall be insured and available at site.

All operators from third parties must be wear PPE on site all time

Environmental Control Housekeeping will be done on a regular basis.

All the waste material will be segregate material wise and disposed

of at land fill area provided by the client.

Spill kit available at work site.

Spill response training shall be conducted.

No repair to equipment activity will be done at the site.

Repairing of all equipment is allowed within the workshop areas

If there is dust in the area water spray will be done on a regular

basis.

Use dust extractor/ventilation fan

Area safety officer step by step analyze the activity and follow

hierarchy of hazard controls.

Protective and PPE requirement Safety Helmet Safety Shoes Safety Glasses

Face shield Safety visible Vest Safety Gloves

Emergency Procedure ACTIONS TO BE TAKEN ON HEARING THE EMERGENCY ALARM

In an emergency every Supervisors shall ensure the following:

Stop all work in the area of any kind of emergency at once.

Switch off all the running equipment (mobile or non-mobile) and

vehicles.

Park vehicles on side of the road that shall not block the access

road.

All men must be evacuated at the assembly point.

No one shall be allowed to come near the fire or accident area

except for the authorized.

persons only (ERT)

Head counting shall be done in the assembly area by the site

supervisor.

All people shall stay in the assembly area until all clear alarm

activated or someone responsible person give information of all

clear.

In case of emergency the work permit will be automatically cancel.

21

Building Knowledge General Contracting Company LLC - KSA

A BK Gulf Group of Companies

WI PM 028 Issue 1.00 / May.2022

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

22

Building Knowledge General Contracting Company LLC - KSA

A BK Gulf Group of Companies

WI PM 028 Issue 1.00 / May.2022

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

R04-R09C03-5010 Contract No.

SHURA ISLAND GOLF STATE & VILLAS Project Title

RA Reference

As required Next review date: 06 Nov 2022 RA Date

00 RA Revision No.

٭Task / Activity

Confined space Hazardous

N Y N Y Expected manpower

entry required? Chemical required? 10

required for the task:

(Tick as applicable) (Tick as applicable)

RISK MATRIX

Plant & Equipment involved: Measuring Tape, Pipe Cutters/Grinders, Portable Hand tools, Mobile crane,

Grooving Machine, Threading machine.

Likelihood (L) Power tools: As per the task required

5 4 3 2 1 Environmental OH&S Health Safety Loss & Environmental Impact

5 4 3 2 1 1

Severity (S)

10 8 6 4 2 2 Minor Minor / <3 Days Injury Low – L 1-3 Acceptable

15 12 9 6 3 3 Moderate Moderate / >3 Days Injury Medium - M 4-9 Before task commences

Major / Permanent Disability 10-16 Before task

20 16 12 8 4 4 Major Injury High - H commences

25 20 15 10 5 5 Catastrophic Catastrophic / Fatality Very High - VH 20-25 Immediate

Certain or Imminent Very May

Likely Unlikely

Likely Happen

Signature: Risk Assessed by:

Date: 09 / 04 / 2023 Designation: Engineer Name: Hafiz Mohd Basheer

(Engineer/Site Agent/CM)

Signature: Reviewed by:

Date: 09 / 04 / 2023 Designation: Manager Name: Eid Jaan

(HSE)

Signature: Approved by:

Date: 09 / 04 / 2023 Designation: Project Manager Name: Manish Jain

(Project Manager)

23

Building Knowledge General Contracting Company LLC - KSA

A BK Gulf Group of Companies

WI PM 028 Issue 1.00 / May.2022

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

٭Date: 06/11/2022 ٭Task: Installation of Hydronic Piping with Specialties

Rating

Risk

(see

Risk Value Value

enclosed Health and Safety

Hazard /Aspect Activity SN

legend Risk/Impact Risk

Existing / Required Controls & R=

page for from

Opportunities SXL

details) Environmental

(OHS & E)

OH&S Aspect Activity steps

SxL OHS & E OHS & E Risk is the harm Hazard is anything with

SXL (Break activity in work

resulting from the potential to cause harm or

sequence as in the

L S L S hazard. loss.

Method statement)

4 1 4 Driver shall have a KSA valid 16 4 4 Delivery of materials to

driving license and observing site

the site speed limits.

Driver should inspect the

condition of vehicle before

putting onto load operations.

Logistics team shall be

notified in advance prior to 1

bring the materials onto site.

Materials shall be secured by

latching belt before moving

the Truck/Trailer (inside

container latching belt not

required) delivering onto site.

Ensure no passenger to be

transported from the load

except the passenger seats.

When Truck / Vehicle reaching

the site, store in charge shall

provide Banks man for

24

Building Knowledge General Contracting Company LLC - KSA

A BK Gulf Group of Companies

WI PM 028 Issue 1.00 / May.2022

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

controlling the traffic.

Personnel are to stand clear of

load, good communication

between operator and banks

man, clear sight maintained

when using hand signal to

Driver and by passer on site.

Ensure the area is open and

clear prior to the operations

no people outgoing and

incoming passing close to the

plant.

Operatives must wear Hand

gloves (Rigger type) during

unloading the materials.

3 1 3 Safe manual handing 9 3 3 Muscle and Muscle and ligaments Manual Handling of 2

technique to be followed. ligaments tears can tears material- unloading

Load must be assessed before lead to corrective

lifting. Fracture

surgery / disability

Use mechanical systems if not treated Laceration

(trolley, forklift etc.) wherever

possible Fracture can lead Crushing of hands

PPE’s to be provided (hand to corrective

gloves, safety shoes, goggles surgery / disability Musculoskeletal injury

etc.) if not treated Dislocation or back

Sufficient operatives to be pain.

provided prior to lift. Laceration can lead

Rotational system to be to corrective

introduced surgery

25

Building Knowledge General Contracting Company LLC - KSA

A BK Gulf Group of Companies

WI PM 028 Issue 1.00 / May.2022

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

Crushing of hands

Works in a group avoid can lead to

twisting, bending, and disability

stooping.

Provide proper training to Musculoskeletal

operative for manual handling. injury

Task briefing to be conducted

by work supervisor prior to Dislocation or back

start the work. pain, can lead to

corrective surgery.

3 1 3 Materials and consumables 9 3 3 Moderate/ Minor Fire / Collapse of badly Storage and stacking of 3

shall be protected from the injury stacked materials materials

elements, stored on pallets, leading to impact or

and covered. Damage of

crushing injury

Items shall be stacked safely property

and secured.

Heavy items of equipment

shall not be stacked or stored

at high level and shall be

stored so that easy access is

available for the tele

handler / forklift.

Temporary storage at the site

should be agreed with

construction team.

No Materials to be stacked

such a way that it blocks the

pedestrian

walkway/Emergency Exit,

Access to the Fire point etc.

26

Building Knowledge General Contracting Company LLC - KSA

A BK Gulf Group of Companies

WI PM 028 Issue 1.00 / May.2022

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

Where possible, packaging

materials shall be removed

from site at the earliest

opportunity in order to

reduce the fire risk.

Access to the place of work

shall be by designated

pedestrian safe routes where

in place.

accessing works by

Work area to be kept clear of

means other than safe

non-essential tools &

equipment, construction Moderate/ Minor access /egress routes

3 1 3 material 12 4 3 injury provided and coming in Access to the work area 4

Provide a safe access to the to contact with site

area. hazard

Operative to be watchful, alert

Slip, trip & Fall

while walking through the

construction site of uneven

grounds.

Never take short cut

4 1 4 Options to reduce manual 12 3 4 - Musculoskeletal Accidental collision Handling of Pipes and 5

handling tasks. disorders, fatigue, with Personnel Specialties

Manual handling activities will neck and upper

be kept to a minimum. limb disorders

When it becomes obvious that

a load is too heavy or bulky for

one person to handle, team

handling must be utilized

where mechanical device is

27

Building Knowledge General Contracting Company LLC - KSA

A BK Gulf Group of Companies

WI PM 028 Issue 1.00 / May.2022

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

not practical.

Organize manual handling

tasks in safest way with

consideration size of the load,

task, involved individuals’

physical conditions with

working environments,

adequate rest and instructions

and trainings.

Strictly follow manual handling

techniques.

Do not twist bend and turn

the body, always face the

direction of travel, make sure

with a good grip before lifting

the weight.

Take care of Pinch point /

sharp edges while handling.

Visual inspection to be done

prior to use hydraulic pallet

trolley.

SWL to be followed while

using hydraulic pallet trolley.

Foreman & operatives shall

ensure the access is free from

obstruction before starting the

material shifting.

Close supervision &

monitoring should be on

28

Building Knowledge General Contracting Company LLC - KSA

A BK Gulf Group of Companies

WI PM 028 Issue 1.00 / May.2022

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

place.

Safety gloves to be worn in

additional to the project

mandatory PPE’s.

4 1 4 Only competent persons shall 12 3 4 Minor/Major 6

be used electrically operated Injury/fatality

plant / equipment. Working with damage Use of Electrically

User shall ensure that Respiratory illness electrical tools, wire, Powered tools -Drill

electrically operated tools and Electric shock, Fire. Machine for drilling the

Hand and arm wall / floor for fixing the

equipment are inspected daily

vibration exposure Moving tool bits, high brackets/supports/

and that damaged, or

nonfunctioning equipment is can lead to carpal speed blades and parts stands/frames etc.

returned to stores tunnel syndrome of machinery.

immediately. and other

All electrically operated tools Torque / sudden

ergonomic-related movement of tools

and equipment’s shall be 110

injuries, causes

V and inspected prior to the

work. direct injury to the Flying particles from

fingers and hand, the tools

Lifting/lowering of tools

should do by hand or ropes affecting feeling,

Dust

not with extension dexterity, and grip.

Leads/cables.

Vibration

All power tools must be

inspected periodically.

Slips, trips and fall Trailing electrical

Adequate cable management

cables causing trips and

to be followed. Colour coding Hearing loss due to slips

must be placed for machine noise Entanglement with

identification the inspection is

moving parts.

carried out plan on monthly

29

Building Knowledge General Contracting Company LLC - KSA

A BK Gulf Group of Companies

WI PM 028 Issue 1.00 / May.2022

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

basis. Noise.

Burns

A permit should be obtained Damaged or worn tools

to work with 220V operated Explosions, Heat / Fire.

equipment prior to use. Property damage

All tools must be turned off

immediately after the activity

to ensure energy consumption

is kept to minimum.

Protect all electrical cables,

tools, and equipment.

All power tools to be with

industrial sockets.

All electrical boards are

earthed with ELCB.

Ensure the use proper and

safe Electrical Accessories.

Limit the time spent of

workers with the vibrating

tool.

Suitable fire extinguishers

stored at strategic locations.

Trained personnel to carry out

work with power tools Tool

maintenance and record

keeping.

Use of suitable PPE (body /

hands / face / eyes /ears)

Workers and everyone

adjacent or near the work area

30

Building Knowledge General Contracting Company LLC - KSA

A BK Gulf Group of Companies

WI PM 028 Issue 1.00 / May.2022

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

should wear ear plugs and

dust mask.

Damaged equipment tagged

and taken out of service

Store equipment correctly so

that leads and connections are

protected from damage.

Proper cable management.

Provide face mask, eye

protection, when carrying out

the drilling operation.

Ensure no improvise tools to

be used for termination,

stripping or of cables.

Tools shall be of good quality

Sharp object / Contact

and shall be replaced if faulty

with sharp blade,

or broken Personnel injury. Use of hand tools for the

3 1 3 9 3 3 Handling sharp object 7

No homemade tools shall be Hand injury. installation purpose

with excessive force,

used.

Damage hand tools

Exclusion zone and safety

signage shall be in place.

Task involved all operatives

shall use Safety gloves.

5 1 5 Podium steps are height 20 4 5 Working at height – use 8

limited but shall be used in of podium steps/mobile

preference to stepladders as aluminum tower

they provide a safe working Falling Objects / Falling scaffolding.

platform. Persons / Overturning

Only competent persons shall

31

Building Knowledge General Contracting Company LLC - KSA

A BK Gulf Group of Companies

WI PM 028 Issue 1.00 / May.2022

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

be authorized to erect and over loading

inspect lightweight mobile

aluminum tower scaffold. Pushing scaffold while

Scaffold shall be inspected men / material on it

Major Physical

weekly or when altered by injuries / fatality

competent scaffold inspector

and a scaff-tag shall be used to property damage

record inspection.

Operatives shall ensure the

gate of the podium steps are

properly closed once on the

platform. If gates cannot be

closed properly the podium

steps shall not be used and

returned to store.

Do not stand on the railing to

attain additional height while

working on these

equipment’s.

Aluminum scaffold/ podium

steps shall not be used on

open edge of the slab.

Additional support shall be

provided when working on the

balconies to prevent tilting/

toppling etc.

Mobile Aluminum Scaffold

Towers-will be communicated

with the workforce who will

32

Building Knowledge General Contracting Company LLC - KSA

A BK Gulf Group of Companies

WI PM 028 Issue 1.00 / May.2022

DOCUMENT TYPE: METHOD OF STATEMENT Installation of Hydronic Piping with Specialties.

be using aluminum mobile

scaffold / podium steps

Do not push mobile scaffold

when men or material on top.

Do not use in inclined area.

4 1 4 MEWP will only be used by 12 3 4 Major Physical Falling objects / Falling 9

person trained and certified by injuries. Persons / Failure of

a competent third party. equipment / Collapse /

MEWP must be tested and property damage Collision /

certified by an approved third Overturning /

party. unauthorize to operate Use of mobile plant –

MEWP must be fitted with an MEWP (Mobile Elevating

automatic travel alarm a Work Platform)

flashing amber warning light.

Operator should carry out

daily checking of the

equipment.

Always ensure MEWP

operating floor area can

withstand the maximum