Professional Documents

Culture Documents

MDMay 2022

MDMay 2022

Uploaded by

deepamjal2020Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MDMay 2022

MDMay 2022

Uploaded by

deepamjal2020Copyright:

Available Formats

S.B. Roll. No…………………………………………………..

MACHINE DESIGN

th

6 Exam/Mech./5522/Jun'2022

Duration: 3Hrs. M.Marks:75

SECTION-A

Q1. Do as directed. 15x1=15

a. The ratio of ultimate stress to design stress is known as.

b. Define Stiffness.

c. Name the shaft which is directly connected to prime mover.

d. Give a brief about Stress Concentration.

e. Define Hardness.

f. Define Fatigue failure.

g. Give three Basic units examples.

h. Name three ways of manufacturing of shaft.

i. Define Shaft.

j. Give the formula of Torque.

k. Give the formula for Stress.

l. Name the component which is screw fastening and is round rod threaded at both ends.

m. In a screw thread name the surface joining crest and root.

o m

n. Give formula for Bending Moment is terms of solid shaft.

m

o. Name the material from which the knuckle joint is made of. .r c

o SECTION-B

p e

Q2. Attempt any six questions.

.r c a

6x5=30

i. A plate 100 mm wide and 10 mm thick is welded to another plate by means of double parallel fillets.

p

p e

stress does not exceed 50 MPA

b r

The plates are subjected to a static load of 100 KN. Find the length of weld if the permissible shear

a

ii. Describe Tentative Design Procedure.

iii. Give different modes of Rivet joint failure.

r p

iv. What is the necessity of a coupling and what are its advantages?

v. Explain the various factors required in design considerations.

b

vi. Differentiate between key and splines.

vii. Explain the terms Caulking and Fullering with neat and clean diagrams.

SECTION-C

Q3. Attempt any three questions. 3x10=30

a. Design a flange coupling required to connect two shafts transmitting 21.6 KW of power at 1000 rpm.

Allowable stresses in shaft are 50 N/mm2 and bolt are 30 N/mm2.

b. Find the diameter of solid shaft to transmit 10 kw at 150 rpm. The ultimate shear stress for steel is

300 MPA and factor of safety is 6. If the solid shaft is replaced by hollow one for same given

conditions and the ratio of inside to outside diameter is 0.5. Find both of the diameters.

c. Determine a suitable diameter of a solid shaft which is required to transmit 560 kW at 90 rpm. So

that neither the maximum shear stress nor the angle of twist may exceed from 100 MN/m2 and 1

degree in 1.5 m of length respectively. The shaft is likely to have a maximum torque of 40 percent

more than the mean, G = 8.5 x 104. Mn/mm2.

d. Design a rectangular key for a shaft diameter for a shaft of 50 mm diameter having shearing and

crushing stressing for the key material as 45 MPa and 65 MPa respectively.

e. Compare between design and undesigned work.

You might also like

- Bending Test On Wooden BeamDocument6 pagesBending Test On Wooden BeamAdil Javed Chaudhary85% (13)

- Itt Ac Fire PumpDocument5 pagesItt Ac Fire PumpedwinNo ratings yet

- Machine Design Question PaperDocument2 pagesMachine Design Question Papersushil.vgi100% (1)

- MD (6th) May20Document1 pageMD (6th) May20deepamjal2020No ratings yet

- Design of Machine ElementsDocument5 pagesDesign of Machine ElementsAshish DeotaleNo ratings yet

- Design of Machine ElementsDocument4 pagesDesign of Machine ElementsBinyamin ChinikamwalaNo ratings yet

- Diploma 6 Sem (Mechanical Engineering) Course Code: 601 Subject Name: Design of Machine Elements Important Questions Chapter-1Document4 pagesDiploma 6 Sem (Mechanical Engineering) Course Code: 601 Subject Name: Design of Machine Elements Important Questions Chapter-1suneel kumar rathoreNo ratings yet

- Midterm Exam (MEP521)Document6 pagesMidterm Exam (MEP521)Enriv YasiladNo ratings yet

- SOM (4th) May19Document1 pageSOM (4th) May19eshwariNo ratings yet

- Quiz 12Document6 pagesQuiz 12John Taylor BernasNo ratings yet

- ME374 - Final Examination 1Document2 pagesME374 - Final Examination 1Christian Breth BurgosNo ratings yet

- SOM Study MaterialDocument2 pagesSOM Study MaterialSakshamNo ratings yet

- 6TH Sem PapersDocument23 pages6TH Sem Papersrajkumarmeena9462No ratings yet

- Question PapersDocument89 pagesQuestion PapersDreamer ChavanNo ratings yet

- Mechanical Engineering: Total No. of Questions: 7Document7 pagesMechanical Engineering: Total No. of Questions: 7Sumeet TiwariNo ratings yet

- Ssc-Je Mains Online Test Series / Civil Engineering Som + TosDocument6 pagesSsc-Je Mains Online Test Series / Civil Engineering Som + TosRishi ChoudharyNo ratings yet

- WWW - Manaresults.Co - In: (Common To Me, MCT, MMT, Ae, Ame, MSNT)Document3 pagesWWW - Manaresults.Co - In: (Common To Me, MCT, MMT, Ae, Ame, MSNT)mahendra babu mekalaNo ratings yet

- MDID Machine Design GTU PaperDocument3 pagesMDID Machine Design GTU PaperjaydeepNo ratings yet

- Design of Machine Elements 2 Jan 2018 (2010 Scheme)Document2 pagesDesign of Machine Elements 2 Jan 2018 (2010 Scheme)KishoreNo ratings yet

- Polytechnic Diploma Second Year Main Examination, September 2013 (Mechanical Engineering) Strength of MaterialDocument3 pagesPolytechnic Diploma Second Year Main Examination, September 2013 (Mechanical Engineering) Strength of MaterialNiral MehtaNo ratings yet

- Design of Steel StructuresDocument6 pagesDesign of Steel StructuresRajiv BondeNo ratings yet

- 107503MEDocument7 pages107503MEPrathamNo ratings yet

- B3B032 Total Pages:2: (Answer Any Two Questions)Document11 pagesB3B032 Total Pages:2: (Answer Any Two Questions)Sourabh PradhanNo ratings yet

- MSschme 13 Aprl17Document2 pagesMSschme 13 Aprl17vishnu monarkNo ratings yet

- MTP 5Document4 pagesMTP 5tinku singhNo ratings yet

- SOM (4th) May2022Document1 pageSOM (4th) May2022Simarjeet SinghNo ratings yet

- Btech Me 6 Sem Machine Design Kme602 2022Document3 pagesBtech Me 6 Sem Machine Design Kme602 2022thunderstorm8853No ratings yet

- Me 331Document5 pagesMe 331arumugam_rNo ratings yet

- Me5 md1 Dec 2006Document1 pageMe5 md1 Dec 2006ajayinstyleNo ratings yet

- DSS1 May2019Document3 pagesDSS1 May2019BenclintonNo ratings yet

- At Least TWO Questions From Each Part.: (06 Marks)Document2 pagesAt Least TWO Questions From Each Part.: (06 Marks)nvnrevNo ratings yet

- Quiz 6Document1 pageQuiz 6Nikki Marie G OclaritNo ratings yet

- 5 Design Nov 2013 KeyDocument6 pages5 Design Nov 2013 KeyKenneth PadunanNo ratings yet

- Btech Mech 5 Sem Design of Machine Element Pme5i001 2018Document3 pagesBtech Mech 5 Sem Design of Machine Element Pme5i001 2018Rajeswar KumarNo ratings yet

- ECEE (5th) May2022Document1 pageECEE (5th) May2022hs099318No ratings yet

- 15ME101 Model Exam QP BMEDocument2 pages15ME101 Model Exam QP BMESachi DhanandamNo ratings yet

- MDS AssignmentDocument3 pagesMDS AssignmentRosina AdhikariNo ratings yet

- Design of Machine Elements: B.E. Seventh Semester (Aeronautical Engineering) (C.B.S.)Document2 pagesDesign of Machine Elements: B.E. Seventh Semester (Aeronautical Engineering) (C.B.S.)Rohit RangariNo ratings yet

- (Common To ME, AME) : 2 2 Ut 2 Yt 2 2Document2 pages(Common To ME, AME) : 2 2 Ut 2 Yt 2 2Faisal PashaNo ratings yet

- Torsion Engineering Mechanics Vol 2 Stresses Strains 12 Resolver TodosDocument12 pagesTorsion Engineering Mechanics Vol 2 Stresses Strains 12 Resolver TodosBryan ParadaNo ratings yet

- SheetDocument2 pagesSheetKhaled Gamal EL-SaftawyNo ratings yet

- Sample Question Paper EMD IschemeDocument6 pagesSample Question Paper EMD IschemeSayyad SayyadNo ratings yet

- Theory of Machines & Machine DesignDocument3 pagesTheory of Machines & Machine DesignAvilash JainNo ratings yet

- Elements of Machine DesignDocument6 pagesElements of Machine DesignSdoo7No ratings yet

- Question B.Tech (CE) PDFDocument148 pagesQuestion B.Tech (CE) PDFLawrence NgariNo ratings yet

- Dme Question BankDocument4 pagesDme Question BankRavi Patil100% (1)

- Mechanics of Solids Question PapersDocument10 pagesMechanics of Solids Question PapersNandu Sreekumar SNo ratings yet

- Set IDocument2 pagesSet IK Aruna me19d002No ratings yet

- DOME I Set-1 BE P.TDocument3 pagesDOME I Set-1 BE P.TchupchapNo ratings yet

- Gtustudies - FMD IMP Question BankDocument5 pagesGtustudies - FMD IMP Question BankJaideep ZalaNo ratings yet

- Design of Machine Members: Part-ADocument4 pagesDesign of Machine Members: Part-ARkrishna ANo ratings yet

- Machine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01Document10 pagesMachine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01The AIRS CreationsNo ratings yet

- DME1 (5th) Dec2017Document2 pagesDME1 (5th) Dec2017ritikshariya47No ratings yet

- DESIGN OF MACHINE MEMBERS - I Nov 2007 Question PaperDocument8 pagesDESIGN OF MACHINE MEMBERS - I Nov 2007 Question PaperelimelekNo ratings yet

- 4 Hours / 100 Marks: InstructionsDocument36 pages4 Hours / 100 Marks: InstructionsPandit BarelaNo ratings yet

- Design of Machine Elements 2 Jan 2014Document2 pagesDesign of Machine Elements 2 Jan 2014Prasad C M100% (1)

- Civil Engineering Department: P R E - B O A R D E X A M I N A T I O NDocument8 pagesCivil Engineering Department: P R E - B O A R D E X A M I N A T I O NBrian Unciano100% (1)

- MED (3rd) May21Document2 pagesMED (3rd) May21deepamjal2020No ratings yet

- Machine DesignDocument40 pagesMachine Designdeepamjal2020No ratings yet

- MD (6th) May20Document1 pageMD (6th) May20deepamjal2020No ratings yet

- InstrumentationDocument11 pagesInstrumentationdeepamjal2020No ratings yet

- MED1 (3rd) May2022Document2 pagesMED1 (3rd) May2022deepamjal2020No ratings yet

- BioRes 13 1 2139 Wei LXTMZWW Research Progress Machining Mechanism Milling Wood 11901Document11 pagesBioRes 13 1 2139 Wei LXTMZWW Research Progress Machining Mechanism Milling Wood 11901deepamjal2020No ratings yet

- BioRes 13 1 1042 Bandin CLIB Property Improvement Thin HDF Panels Door Skins 12906Document13 pagesBioRes 13 1 1042 Bandin CLIB Property Improvement Thin HDF Panels Door Skins 12906deepamjal2020No ratings yet

- A Method of Improving The Surface of HDF: Danuta Nicewicz, Sławomir MonderDocument3 pagesA Method of Improving The Surface of HDF: Danuta Nicewicz, Sławomir Monderdeepamjal2020No ratings yet

- Bending Strength of High-Density Fibreboards (HDF) Manufactured From Wood of Hard Broadleaved SpeciesDocument14 pagesBending Strength of High-Density Fibreboards (HDF) Manufactured From Wood of Hard Broadleaved Speciesdeepamjal2020No ratings yet

- XK12Document26 pagesXK12KartikNo ratings yet

- Cam Jump Phenomenon-1Document10 pagesCam Jump Phenomenon-1Dhairyasheel Bhutkar100% (1)

- Ооо "Промхимтех" Www.Promhimtech.Ru: S P E Ci F I Ca T I O N F O RDocument53 pagesОоо "Промхимтех" Www.Promhimtech.Ru: S P E Ci F I Ca T I O N F O RSiva baalan50% (2)

- Unbrako New Catalog PDFDocument16 pagesUnbrako New Catalog PDFirfanNo ratings yet

- Pressure Vessel-80S100Document2 pagesPressure Vessel-80S100IbrahimNo ratings yet

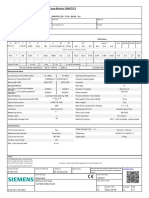

- 1LE7503-0CB32-3AA4 Datasheet enDocument1 page1LE7503-0CB32-3AA4 Datasheet enLuis RomeroNo ratings yet

- Design of Steel Structures Formula Notes 59Document36 pagesDesign of Steel Structures Formula Notes 59Ayesha RubianaNo ratings yet

- Motors in RoboticsDocument19 pagesMotors in RoboticsJBS SPOBINo ratings yet

- Manual PLC-01-05 2014 0219Document26 pagesManual PLC-01-05 2014 0219JanneDoee0% (1)

- Customer Po Number Pump Tag Number Pump Serial No.: MABRE 10 X 12 X 18 WPV-R FLUSH PLAN 11/13 1403-A-FLUSH 1:10 A3Document3 pagesCustomer Po Number Pump Tag Number Pump Serial No.: MABRE 10 X 12 X 18 WPV-R FLUSH PLAN 11/13 1403-A-FLUSH 1:10 A3Israel Gibran Cañas RodriguezNo ratings yet

- Steel SizesDocument15 pagesSteel SizesDermot BrennanNo ratings yet

- Seat Track FittingsDocument29 pagesSeat Track FittingsAmolPagdalNo ratings yet

- Assignment 2 V2 TM 18ME54Document1 pageAssignment 2 V2 TM 18ME54rudresh JmNo ratings yet

- Diy Build M72 LAW TagInn Airsoft Launcher 70Document5 pagesDiy Build M72 LAW TagInn Airsoft Launcher 70nick wilkinsonNo ratings yet

- Milling Collet Chuck: DIN 6388 # 25 SERIES MAS 403 Bt-Shank OZ-25 Collet Holder With Bt-ShankDocument10 pagesMilling Collet Chuck: DIN 6388 # 25 SERIES MAS 403 Bt-Shank OZ-25 Collet Holder With Bt-ShankJunior Salcedo MuñozNo ratings yet

- Specifications of Aluminum MaterialsDocument2 pagesSpecifications of Aluminum MaterialsTony C.No ratings yet

- GF-4172-QC-EI-FM-0005, Rev. 4 CHECKLIST FOR UNDERGROUND CABLE LAYING WORKS-ReplacedDocument3 pagesGF-4172-QC-EI-FM-0005, Rev. 4 CHECKLIST FOR UNDERGROUND CABLE LAYING WORKS-ReplacedsureshNo ratings yet

- Inhinyero Review CenterDocument2 pagesInhinyero Review CenterVincent NavaNo ratings yet

- UntitledDocument20 pagesUntitledango VossNo ratings yet

- Spooler De710 Parts Be00002544852Document1 pageSpooler De710 Parts Be00002544852Morgan DunnNo ratings yet

- Materials System SpecificationDocument8 pagesMaterials System Specificationnadeem shaikhNo ratings yet

- Lecture 3Document24 pagesLecture 3sadooonNo ratings yet

- Danger Under Crane BoomsDocument2 pagesDanger Under Crane Boomsابو محمد عليNo ratings yet

- Purchasing Packages Bidders Rev E 7mar14Document3 pagesPurchasing Packages Bidders Rev E 7mar14MarianoNo ratings yet

- Conval Clampseal Catalog 2019Document44 pagesConval Clampseal Catalog 2019Roger SeaverNo ratings yet

- Barnhart Moving TierneyDocument42 pagesBarnhart Moving TierneyHermon PakpahanNo ratings yet

- Steam BlowingDocument11 pagesSteam BlowingSamNo ratings yet

- Constructing Base FeaturesDocument42 pagesConstructing Base FeaturesAnil VaswaniNo ratings yet