Professional Documents

Culture Documents

Agp Ra

Agp Ra

Uploaded by

Tushar GuptaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Agp Ra

Agp Ra

Uploaded by

Tushar GuptaCopyright:

Available Formats

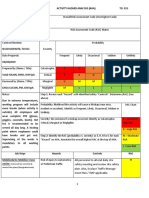

RISK ASSESSMENT(Ref Copy , To be used for the STS operation)

Each vessel involved in the operation will also prepare one Specific RA for the operation as well

Vessel / Department: STS operation between Vessels Date: Reference Copy Assessment Number: Ref Copy

Assessment Area Work Activity/Equipment PREPARED BY :

Navigation STS OPERATION

AGP team

Deck

Engine

Cargo REVIEWED AND APPROVED BY:

Cyber Security

AGP management

Other (Specify)

Risk Evaluation Risk Evaluation (S

(S x L = RF) ADDITIONAL CONTROL MEASURE x L = RF)

No. Hazard EXISTING CONTROL MEASURE

S L RF TO BE TAKEN S L RF

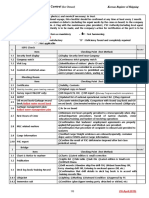

Upon arrival at the STS site both ships'

Information exchange between STS Organisers and other

condition to be ascertained and made

ship have been conducted. INTERTANKO Q88 form, mooring

1 Ship incompatibility 2 3 6 available to all parties in order to make 2 2 4

arrangement schemes have been submitted. STS C/L 1 has

sure it's optimal, adjustments to be made

been completed.

in case of list or unfavourable trim.

Proper understanding of signals and commands, adequate

communication between tankers (VHF Ch. ), including back-

up means (Via The Local Pilot), and responsible persons to

SMCP to be utilised during communication

be established. Language of operations to be agreed

with the receiving vessel. It's recognised

(English). Procedure for communication failure to be

that personnel should avoid

agreed. The manoeuvre to be aborted in case of

overcomplication of the information

communication breakdown. If communication is lost during

exchanged, so as to avoid any confusion

cargo transfer the emergency signal should be sounded and

and misunderstanding.

2 Insufficient communication all operations in progress should be suspended immediately 2 3 6 2 2 4

Officers and key personnel will make sure

if it is safe to do so. Operations should not be resumed until

that their radios are fully charged, spare

satisfactory communications have been re-established. It

battery and adequate cover is available in

should be confirmed that the portable radios on each ship

case of rain. PA system is tested according

are capable of working on the same frequencies,

to the PMS, and will act as a back-up

alternatively that one of the vessels have enough portable

communication measure.

devices to adequately supply both vessels. Ship's officers

responsible for mooring stations should be provided with

portable radios.

Before manoeuvre the engines, steering gear and

navigational equipment to be tested.

The age and fitness of the fenders should be ascertained.

The fender certificates should be made available to assist

with this. Fender moorings should be monitored frequently

and tended as necessary to ensure that they do not become

too slack or too taut and that the fenders remain in position.

All equipment is maintained in strict

The age and condition of hoses to be ascertained. Cargo

compliance with maker's instructions, PMS,

transfer hoses to be properly tested and certified. Hose

3 Equipment failure 2 3 6 company and legal requirements. Pre- 2 2 4

Certificate to be reviewed.

operational checks of the critical equipment

Mooring wires, ropes including ancillary equipment - rope

to be carried out by a qualified individual.

messengers, stoppers, heaving lines and strops to be

visually inspected for condition prior use. Winches and

windlasses to be in good order.

Lifting equipment to be confirmed in good working order.

Lifting Equipment Pre-Operation Check to be completed.

External lighting to be confirmed as fully operational.

Approach manoeuvre to be agreed. Shipping traffic in the

area to be checked (Via The GPA By VHF Ch.). A

navigational warning to be broadcast. Navigational signals

to be displayed. A bridge watch and / or an anchor watch The STS operations will be conducted

to be established. A proficient helmsman to be at the wheel. within the designated lightering area.

Course and speed information to be exchanged. Speed Bridge and deck parties will be additionally

4 Contact / Collision adjustment to be controlled. Proper lookout to be 2 3 6 trained and briefed on STS procedures to 2 2 4

maintained. STS Check List No.3 and No.5 to be completed. ensure their confidence and proficiency.

Berthing and mooring procedures to be agreed. Number and Critical tasks will be performed by suitably

type of mooring ropes to be agreed. All mooring personnel experienced crewmembners.

to be in position. The anchor on opposite side to transfer to

be ready for dropping. The method of unberthing and letting

go moorings to be agreed.

Cargo transfer should be conducted in compliance with the

relevant sections of the Deck and Cargo Operation Manual.

STS Check List No.4, Ship / Shore Safety Check List and

STS Pre-Transfer Meeting to be satisfactory completed.

Cargo operation plan, stowage plan and watch

arrangements to be prepared and exchanged between Pollution drill is conducted monthly and

tankers. The initial, maximum and topping off transfer rate covers vast majority of probable spills, it's

5 Accidental cargo release to be agreed. Cargo hoses to be properly drained prior to 2 3 6 considered that the crew is well trained in 2 2 4

hose disconnection. Cargo hoses and manifolds to be terms of containment, transfer, clean-up

blanked. Any leakage or spillage should be reported procedures.

immediately to the officers on cargo watch. The cargo

transfer to be stopped. In case of cargo spill, the

contingency plan within the SOPEP to cover pollution risks

will be activated.

The STS transfer operation should be suspended if cargo

vapour accumulation around the decks or manifolds of

either ship constitutes a risk to the ship or personnel, and

MSDS contents have been carefully

should not be resumed until it is considered safe to do so.

studied, first aid actions relevant for the

The receiving ship should, prior to cargo transfer, provide

cargo carried have been discussed. During

details of the ship's previous cargo to the discharging ship

the course of cargo operations routine

6 Gas accumulation on deck (STBL). This will enable the discharging ship's personnel to 2 2 4 2 2 4

atmosphere measurements will be

take suitable precautions in the event that the previous

conducted in order to ensure that any

cargo contained toxic vapours that could be displaced onto

vapour coming from the receiving vessel

the deck of the discharging ship. Particular attention should

dissipates to a safe extent.

be given to the potential of high H2S levels in the cargo

vapours and all necessary personal safety precautions

should be taken.

Weather forecasts to be obtained for transfer area. Effect of

the sea, swell and current to be considered. Visibility for

berthing operation to be confirmed as good enough.

Weather forecasts provided by STS

7 Weather deterioration Possibility of electrical storms to be assessed. If weather 2 3 6 2 2 4

OPERATIONS firm on daily basis.

conditions deteriorate, the following to be suspended as

appropriate: manoeuvring, cargo transfer, personnel

transfer between two vessels.

Extra precaution to be taken during handling static

accumulator cargoes in non-inert tanks. Precautions relating

to maximum flow rates, settling periods, bonding of gauging

/ sampling devices to be observed.

The potential for incentive arcing between the two ships

when presenting the hose string for connection to be

eliminated:

Both vessels operate with tanks inerted,

• a single insulating flange should be fitted within each hose

positive pressure maintained and safe

string (or at one ship's manifold); or

Static electricity during transfer / Ship-to- oxygen content level at all times. During

8 • one length of electrically discontinuous hose should be 1 3 3 1 2 2

Ship electric currents pre-transfer meeting same to be

fitted in each hose string; or

ascertained, and control measures

• hoses that are specially constructed to prevent static build-

establshed.

up or electrical currents transferring between ships should

be used.

Care should be taken to avoid low resistance ship-to-ship

electrical contact in the following areas:

• non-insulated metallic ladders or gangways between the

ships by the fitting of rubber ends.

• derrick or crane wire runners and hooks by careful

STS experience of the key personnel has

The Master and Deck Officers are fully familiar with STS been assessed, training appropriate for the

Operations Plan and STS Transfer Guide. An appropriate duties performed has been given.

Lack of experience of key personnel in STS training has been conducted prior to STS operation. The Personnel that have already participated in

9 1 3 3 1 2 2

operations crew has been briefed on the subject of mooring and cargo STS operations on the current

operations procedures. Master considers himself familiar ship/sisterships or with ships of the same

with STS transfer operations and sufficiently expirerenced. type of the receiving vessel has contributed

their valuable knowledge to the others.

No unnecessary routine, noisy jobs will be

carried out immediately prior to STS ops.

Personnel should comply with rest requirements of ILO / The crew was reminded on the subject of

STWC. The estimated duration of the operation should be management of their rest hours, need for

taken into consideration to ensure that all personnel have adequate sleep and rest. Mental health

10 Fatigue adequate hours of rest. Effective watch schedule and 2 2 4 issues have been discussed as well, it has 2 2 4

arrangements to be established. No simultaneous transfer been agreed that the crew should be task

from either side of the STBL is allowed unless additionally oriented and completely concentrated on

reviewed by risk assessment the duties performed. The crew

acknowledges role of each and every

individual in success of STS ops.

Procedure for transfer of personnel to be agreed. The

transfer of personnel between the two vessels to be kept to

the absolute minimum. Working life jackets must be worn It's recognised that company allows use

when transferring between the two vessels. If it is unsafe for only of that personnel transfer baskets

personnel to transfer between the two vessels then it should which have been adequately tested and

not under any circumstances be attempted. The cranes of properly certified. In case of transfer by

11 Hazards associated with personnel transfer vessels should not be used for personnel transfer unless an 2 2 4 boat all necessary precautions will be 2 2 4

alternative safe means, such as a workboat or gangway implemented. Any initiative to perform a

cannot be used, and the transfer is essential. Prior to a personnel transfer during periods of

transfer by basket Personnel Transfer Check List must be adverse or marginal conditions will be

fully completed and all sections answered. Personal vigorously rejected.

Transfer Operation Will Be C/Out Only By other

vessel PTB and Crane).

0 0

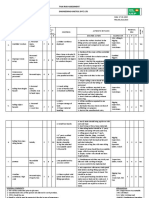

Severity (S)

To Personnel Health/Hygiene/Safety: To Environment: To Property:

Likelihood ( L )

(1) Negligible (1) Negligible: <10 ltrs (1) Negligible < $10,000 (1) Very Unlikely - practically impossible

(2) Minor: First aid case or minor health effect (2) Minor: 10-100 ltrs (2) Minor: $10,001 - $100,000 (2) Unlikely: Might occur every 10-20 years

(3) Significant: Medical treatment ashore (3) Significant:100-1000ltrs (3) Significant: $100,001 - $1,000,000 (3) Occasional: Might occur every 1-10 years

(4) Critical: Hospitalization, repatriation, disability (4) Critical: 1000-10000ltrs (4) Critical: $1,000,001 - $25,000,000) (4) Likely: Might occur once a year

(5) Catastrophic: Fatal injury or disease (5) Catastrophic:>10000 ltrs (5) Catastrophic: More than $25,000,000 (5) Certain: Might occur once every 6 months

RISK FACTOR SHORE PERSONNEL COMMENTS / INTRUCTIONS

No further measures required. The task or activity

Acceptable - LOW 1-4 can be carried out.

Requires Risk The risk factor should be reduced by implementing

Mitigation - MEDIUM

5 - 12 further risk controls prior to commencing the task.

Not acceptable:

Requires Risk 15 - 25 Do not start or continue work.

Mitigation - HIGH

OFFICE AUTHORIZATION : YES / NO NAME & SIGNATURE DATE:

You might also like

- HAZID Worksheet FORMDocument16 pagesHAZID Worksheet FORMSrikanth Bammidi100% (3)

- TACP TACSOP (27 Feb 13) PDFDocument136 pagesTACP TACSOP (27 Feb 13) PDFMárcio Medeiros100% (1)

- Vessel With Stern On Quay - A Simplified Method For Mooring Design - TheNavalArchDocument11 pagesVessel With Stern On Quay - A Simplified Method For Mooring Design - TheNavalArchFederico Babich0% (1)

- HAZID Worksheet FORMDocument16 pagesHAZID Worksheet FORMSrikanth Bammidi100% (1)

- Flight Warning Computers FWC 1 + 2: Leslie Manchanda April 2018Document12 pagesFlight Warning Computers FWC 1 + 2: Leslie Manchanda April 2018Devdatt SondeNo ratings yet

- Topic: Mooring System: Natural Gas: Offshore Production & HandlingDocument45 pagesTopic: Mooring System: Natural Gas: Offshore Production & HandlingHarshith RenikindhiNo ratings yet

- Pilot CardDocument4 pagesPilot CardAsifur Rahman100% (1)

- Mce - Project Risk RegisterDocument24 pagesMce - Project Risk Registeryono DaryonoNo ratings yet

- Risk Assessment Sand BlastingDocument7 pagesRisk Assessment Sand BlastingRohit Singh100% (7)

- Passage Planning .Dubai To SharjahDocument4 pagesPassage Planning .Dubai To SharjahKunal Singh100% (2)

- Guidance On Mooring System Management Plans (MSMP)Document39 pagesGuidance On Mooring System Management Plans (MSMP)PJ Apostol Alpacas100% (6)

- Tanker Management and Self Assessment 2: A Best-Practice Guide For Ship OperatorsDocument33 pagesTanker Management and Self Assessment 2: A Best-Practice Guide For Ship OperatorsJames Robbins100% (2)

- 004 - Vessel Inspection Checklist (Safety)Document16 pages004 - Vessel Inspection Checklist (Safety)Prabowo100% (2)

- Preparation For Arrival/Departure in PortDocument6 pagesPreparation For Arrival/Departure in PortSiddharth Hada100% (1)

- CFR 2014 Title33 Vol2 Sec164 11Document2 pagesCFR 2014 Title33 Vol2 Sec164 11Александр МельникNo ratings yet

- Wet Area Water Proofing WorkDocument8 pagesWet Area Water Proofing Worksarath SNo ratings yet

- DKO04-Small Craft Alongside - Incl Bunker Barge, Slop BargeDocument2 pagesDKO04-Small Craft Alongside - Incl Bunker Barge, Slop BargeNang D. VuNo ratings yet

- Tifani RCS Class Ssas ChecklistDocument1 pageTifani RCS Class Ssas Checklistmohamed arousNo ratings yet

- 033 Risk Assessment For Construction of Chilled Water ChamberDocument13 pages033 Risk Assessment For Construction of Chilled Water ChamberVIRUPAKSHA KOOLINo ratings yet

- JSA - Undergound MappingDocument2 pagesJSA - Undergound Mappingshamierrul shahliNo ratings yet

- All Personnel To Attend Daily Site Safety Meeting and Review Site Safety Plan. Also, in Place Traffic Manage-Ment Plan / TMP ApplicableDocument6 pagesAll Personnel To Attend Daily Site Safety Meeting and Review Site Safety Plan. Also, in Place Traffic Manage-Ment Plan / TMP ApplicablecrnkarlosNo ratings yet

- #204 Navigation Through High Risk Piracy AreaDocument2 pages#204 Navigation Through High Risk Piracy AreaTolias EgwNo ratings yet

- Checklist For Port State Control: - ISPS CheckDocument5 pagesChecklist For Port State Control: - ISPS CheckTan DatNo ratings yet

- JSA Mobile Crane Pipe Installation Tandem LiftDocument3 pagesJSA Mobile Crane Pipe Installation Tandem LiftSyed HarisNo ratings yet

- 18 - RA Roadworks Risk AssessmentDocument1 page18 - RA Roadworks Risk AssessmentkumarNo ratings yet

- Roadworks - Risk AssessmentDocument1 pageRoadworks - Risk AssessmentMohammed Amer PashaNo ratings yet

- Risk Assessment ReportsummaryDocument8 pagesRisk Assessment ReportsummaryRitesh PratapNo ratings yet

- CamScanner 03-23-2023 12.06 - 0Document1 pageCamScanner 03-23-2023 12.06 - 0Ndipo BecklyNo ratings yet

- Frequently Asked Questions: F LA SHDocument4 pagesFrequently Asked Questions: F LA SHDavid WongNo ratings yet

- Communication Is Key: Bridge PilotDocument1 pageCommunication Is Key: Bridge PilotenglisgoNo ratings yet

- Ssas ChecklistDocument2 pagesSsas ChecklistAnupam MaityNo ratings yet

- Ship Arrival Checklist Sample ReportDocument5 pagesShip Arrival Checklist Sample ReportrohanNo ratings yet

- Em'cy-018-Distress MessageDocument5 pagesEm'cy-018-Distress MessagelaNo ratings yet

- GMDSS-RPT (Rev.7)Document5 pagesGMDSS-RPT (Rev.7)sandeep bagulNo ratings yet

- 0418MC 04.17.19 Form 25 CPM Flagging Checklist 28th STDocument3 pages0418MC 04.17.19 Form 25 CPM Flagging Checklist 28th STMohammed Jahanzeb ChoudaryNo ratings yet

- Form - Job Safety Analys - Share-1Document3 pagesForm - Job Safety Analys - Share-1bernard transafeNo ratings yet

- Ra 69 Safe Ship To Ship OperationsDocument6 pagesRa 69 Safe Ship To Ship OperationsArif Ayub100% (1)

- NavegacionDocument7 pagesNavegacionlmur12No ratings yet

- Jsa For Tie-In Tp-950Document11 pagesJsa For Tie-In Tp-950rexivyNo ratings yet

- RA - Emcy Anchoring in Deep Waters.Document5 pagesRA - Emcy Anchoring in Deep Waters.Nikos Stratis100% (1)

- Automatic Identification System: ModelDocument6 pagesAutomatic Identification System: ModelAsael Marquez100% (1)

- NMLC Course TimetableDocument12 pagesNMLC Course TimetableEnong Mannie VasquezNo ratings yet

- Arad - LRARDocument23 pagesArad - LRARRăzvan Florin ConstantinNo ratings yet

- JHA Stacks EDG Substation r0 14 August 2017 EdittedDocument5 pagesJHA Stacks EDG Substation r0 14 August 2017 EdittedJeniffer Ong100% (1)

- Checklist Audit Ism Kapal EngDocument11 pagesChecklist Audit Ism Kapal EngAji ArnowoNo ratings yet

- 103 Preparation For SeaDocument1 page103 Preparation For SeaMr-SmithNo ratings yet

- L2 Risk Assessment Leakage HVAC Ducting Rectification - PlanDocument5 pagesL2 Risk Assessment Leakage HVAC Ducting Rectification - PlanHaris Risdiana100% (2)

- Item - 3 - 23042020 - 4 - Incident Management - Operational - MRA - CommercialDocument2 pagesItem - 3 - 23042020 - 4 - Incident Management - Operational - MRA - CommercialAlex Ambomo100% (1)

- Competence Knowledge, Understanding and Proficiency Performance Performance StandardsDocument3 pagesCompetence Knowledge, Understanding and Proficiency Performance Performance StandardsManny Vasquez100% (1)

- Oceanic ChecklistDocument2 pagesOceanic ChecklistPlanetPlaneNo ratings yet

- Job Risk Assesment OfftakeDocument7 pagesJob Risk Assesment OfftakeIhwan Asrul100% (1)

- Safety Management System Risk Management Manual Machinery Breakdown and FailureDocument3 pagesSafety Management System Risk Management Manual Machinery Breakdown and FailuredonnyNo ratings yet

- Gmdss Radio InsatallationDocument8 pagesGmdss Radio InsatallationHoàng VũNo ratings yet

- Rayheon Pathfinder ST MK II RadarDocument208 pagesRayheon Pathfinder ST MK II RadarAkhil ViswanathanNo ratings yet

- TRA For Blasting and PaintingDocument6 pagesTRA For Blasting and Paintingrizvidawar220No ratings yet

- HSE-TBRA-OP15 - Offloading Riser To Storage Yard & Dismantling of RiserDocument5 pagesHSE-TBRA-OP15 - Offloading Riser To Storage Yard & Dismantling of Riserhseassistant.cgaNo ratings yet

- TRA of Ladder & PlatformDocument2 pagesTRA of Ladder & PlatformASIF MUZAFFARNo ratings yet

- PCG FormE5Man - OverboardDocument8 pagesPCG FormE5Man - Overboardjohn mark manuel magalonaNo ratings yet

- RB Safety DriveDocument6 pagesRB Safety DriveSRDEEOP BSPNo ratings yet

- Survey Report FormDocument28 pagesSurvey Report FormJavier Rayleigh100% (2)

- CTRA-23-STM-093 - TK - 11-995 - Bund Wall CuttingDocument3 pagesCTRA-23-STM-093 - TK - 11-995 - Bund Wall CuttingMohamed RizwanNo ratings yet

- Rondom AccexDocument7 pagesRondom Accexrichard celinoNo ratings yet

- JSA For Scaffolding Erection Dismantling and Modification WorkDocument30 pagesJSA For Scaffolding Erection Dismantling and Modification Workkmohamedkeita906No ratings yet

- #501 Bunkering OperationsDocument5 pages#501 Bunkering OperationsTolias EgwNo ratings yet

- Airports, Docks, Harbours & TunnelsDocument10 pagesAirports, Docks, Harbours & TunnelsHARISH KANNANo ratings yet

- ArubaDocument4 pagesArubaAlin StanciuNo ratings yet

- Safe Practice For Vessel Positioning With Mooring Analysis (Orcaflex)Document19 pagesSafe Practice For Vessel Positioning With Mooring Analysis (Orcaflex)KhoironSyamdatuNo ratings yet

- Instruction Manual GPS GWIM01-10 Amd 02Document8 pagesInstruction Manual GPS GWIM01-10 Amd 02Suelen BarbosaNo ratings yet

- Best Practice Report - Mooring of Floating Marine Renewable Energy PDFDocument30 pagesBest Practice Report - Mooring of Floating Marine Renewable Energy PDFpradewoNo ratings yet

- Palfinger Marine Product Brochure 2021 Doublepages LowresDocument39 pagesPalfinger Marine Product Brochure 2021 Doublepages LowresSreekanthNo ratings yet

- Optimoor: Mooring Analysis So Ware For Ships & BargesDocument2 pagesOptimoor: Mooring Analysis So Ware For Ships & BargesTam Jun HuiNo ratings yet

- Solar Floating at EGAT 'S ProjectDocument41 pagesSolar Floating at EGAT 'S ProjectChong Jiazhen50% (2)

- LMP ManualDocument63 pagesLMP ManualAndrey PonomarevNo ratings yet

- Important Guidelines To Carry Out Anchoring Procedure Safety and SmoothlyDocument7 pagesImportant Guidelines To Carry Out Anchoring Procedure Safety and SmoothlyyeimiNo ratings yet

- Floating Breakwater DesignDocument15 pagesFloating Breakwater DesignLazaros NtoanidisNo ratings yet

- Statics of Mooring LinesDocument43 pagesStatics of Mooring LinesS Bharat SelvamNo ratings yet

- How To Fill Up A Ships LogbookDocument33 pagesHow To Fill Up A Ships LogbookMr LeeNo ratings yet

- Port Regulation PDM EN - Rev1 2Document20 pagesPort Regulation PDM EN - Rev1 2NDMNo ratings yet

- Mooring Line Management PlanDocument3 pagesMooring Line Management Planghonwa hammodNo ratings yet

- CSL - SPM Hawser CatalogDocument14 pagesCSL - SPM Hawser CatalogEkoNo ratings yet

- Practical Assessment 5 Mooring OperationDocument4 pagesPractical Assessment 5 Mooring OperationDzenrhe ParanNo ratings yet

- Mooring AnalysisDocument37 pagesMooring AnalysisJOSÉ FERNANDONo ratings yet

- Q88 Js-Cougar - Gas-Form-C-LPG - 28oct2020Document5 pagesQ88 Js-Cougar - Gas-Form-C-LPG - 28oct2020Александр ШуваловNo ratings yet

- Chapter 1. General InformationDocument33 pagesChapter 1. General InformationaliNo ratings yet

- Siemens Aerator CatalogDocument16 pagesSiemens Aerator CatalogNwfal Cielers-Philharmonic Vergaze-RasyidiNo ratings yet

- Open Abu Dhabi Maritime Mpa Guide 2020Document32 pagesOpen Abu Dhabi Maritime Mpa Guide 2020alkaabi.khalidNo ratings yet

- Design For Sanitary Standards ART023GEN - PPT - Port - Design PDFDocument63 pagesDesign For Sanitary Standards ART023GEN - PPT - Port - Design PDFshakirhamid6687No ratings yet

- General - Algeria AlgeriaDocument8 pagesGeneral - Algeria Algeriawaleed yehiaNo ratings yet