Professional Documents

Culture Documents

CS137A Snack-Make Web

CS137A Snack-Make Web

Uploaded by

Rifai IndraswariOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CS137A Snack-Make Web

CS137A Snack-Make Web

Uploaded by

Rifai IndraswariCopyright:

Available Formats

Automated Spray System Helps Snack Maker Improve Product

Quality and Reduce Monthly Operating Expenses by US$3,000

Problem:

A manufacturer of gourmet baked snacks needed to apply a light, even coating of sunflower

oil to potato crisps before the snacks were baked. Uniform oil coating is essential to maintain

product appearance and taste.

The manufacturer was using a spray system of its own design which injected air into the liquid

line before the oil was atomized using a hydraulic nozzle. The system, which required daily

maintenance, produced an erratic spray which wasted oil and resulted in poor product quality.

Solution:

Spraying Systems Co.’s solution uses air atomizing nozzles controlled by an AutoJet® Modular

Spray System. The easy-to-use AutoJet Model 1550 Modular Spray System is equipped with

an air-operated double diaphragm pump. The pump efficiently moves the viscous oil from a

supply tote to two 1/4JAUCO automatic air atomizing nozzles. Flow rate is easily adjusted and

the external mix air atomizing nozzles provide uniform coverage of the crisps on the conveyor

below. The nozzles are equipped with clean-out needles to prevent plugging of the nozzle

orifice.

Automatic

air atomizing

nozzles

1550 Aut

Modular

Spray

oJet

System

Atomizing

Air

Liquid

Fan Air

AutoJet Model 1550

Modular Spray System

Oil tote

Experts in Spray Technology

Spray Spray Spray Spray

Nozzles Control Analysis Fabrication

Automated Spray System Helps Snack Maker

Improve Product Quality and Reduce Monthly

Operating Expenses by US$3,000 – Continued

Results:

The AutoJet® Modular Spray System has improved both the quality and quantity of the

potato crisps produced. Spray coverage is consistent and uniform resulting in improved

product appearance and lower reject rates. In addition, less oil is used in the coating

process. Maintenance downtime is reduced significantly – almost two hours of labor per

day spent maintaining the previous spray system has been eliminated. The reduced oil use,

increased product yield and decreased maintenance time have combined to generate a

savings of more than US$3,000 per month. The cost of the system was offset in less than

three months.

A CLOSER LOOK AT THE SYSTEM

AutoJet Model 1550 Modular

Spray System regulates the liquid

pressure and the atomizing air pressure

to maintain a consistent coating of

sunflower oil on the snacks.

Two 1/4JAUCO automatic air atomizing nozzles

are used to cover the entire width of the conveyor.

The air-actuated nozzles cycle up to 180 times per

minute and feature a clean-out needle to prevent

nozzle plugging.

Uniquely Qualified to Generate Results

Unmatched Global Engineering, Manufacturing and Technical Support

Nozzles | Control Systems | Headers & Injectors | Research & Testing

Experts in Spray Technology

North Avenue and Schmale Road, P.O. Box 7900, Wheaton, IL 60187-7901 USA

Tel: 1.800.95.SPRAY Intl. Tel: 1.630.665.5000

Fax: 1.888.95.SPRAY Intl. Fax: 1.630.260.0842

www.spray.com

Case Study No. 137 Printed in the U.S.A. ©Spraying Systems Co. 2011

You might also like

- Automatic Lubrication SystemDocument6 pagesAutomatic Lubrication SystemHarry HarryNo ratings yet

- B350 OhDocument132 pagesB350 OhAyrton Nobile100% (2)

- CS122A Misting Pizza Toppings WebDocument2 pagesCS122A Misting Pizza Toppings WebRifai IndraswariNo ratings yet

- Bakery-Reduce OilDocument2 pagesBakery-Reduce OilRifai IndraswariNo ratings yet

- MPF PDocument7 pagesMPF POniruddho Shagor100% (1)

- CS127A Pan Coating Choc Centers WebDocument2 pagesCS127A Pan Coating Choc Centers WebRifai IndraswariNo ratings yet

- CS198B Oil Use Cut in Half With Electrostatic Spray System WebDocument2 pagesCS198B Oil Use Cut in Half With Electrostatic Spray System Webmartalogi19No ratings yet

- B524E Food ProcessingDocument16 pagesB524E Food ProcessingridoNo ratings yet

- Concept of Automatic Lubrication System and Comparison With Conventional Lubrication SystemDocument4 pagesConcept of Automatic Lubrication System and Comparison With Conventional Lubrication SystemHerrera Jorge AgustínNo ratings yet

- Aircontrol 20Document28 pagesAircontrol 20Fer De La VegaNo ratings yet

- B779 AutoJet 1750+ Bakery ApplicationsDocument2 pagesB779 AutoJet 1750+ Bakery Applicationsjenriel catulingNo ratings yet

- NAL Manual New Automatic Spray System (12.04.2019)Document32 pagesNAL Manual New Automatic Spray System (12.04.2019)sunil0% (1)

- Oil Mist Manual PDFDocument34 pagesOil Mist Manual PDFWong DaNo ratings yet

- Alemite Oil Mist Application ManualDocument34 pagesAlemite Oil Mist Application ManualCatalina SaldarriagaNo ratings yet

- CS132A Bakery-Increases-Production WebDocument2 pagesCS132A Bakery-Increases-Production WebRifai IndraswariNo ratings yet

- Multi Point Grease GunDocument5 pagesMulti Point Grease Gunchockalingam athilingamNo ratings yet

- SKF LubriLean Minimal Quantity LubricationDocument4 pagesSKF LubriLean Minimal Quantity LubricationEdwin Casadiego AvilaNo ratings yet

- CTS Essentials 09.2020 en LRDocument4 pagesCTS Essentials 09.2020 en LRChicago PneumaticNo ratings yet

- 1335 - SpiralAir - SEA Leaflet - HRDocument8 pages1335 - SpiralAir - SEA Leaflet - HRDonny Yudisthira PutraNo ratings yet

- Oil Analyzers: Fluid Analysis ProgramDocument16 pagesOil Analyzers: Fluid Analysis ProgramIBRAHIM ALMANLANo ratings yet

- Service Manual: Common Rail System For ISUZU 4HK1 / 6HK1 Type EngineDocument49 pagesService Manual: Common Rail System For ISUZU 4HK1 / 6HK1 Type EngineLeonardo Medina100% (1)

- Trabajo Final Ingles TecnicoDocument9 pagesTrabajo Final Ingles TecnicoEduardo smith Mercado aguilarNo ratings yet

- User Manual: 300 / 500 SERIESDocument22 pagesUser Manual: 300 / 500 SERIESjolupeco44No ratings yet

- Beverly Tourer 250 IeDocument318 pagesBeverly Tourer 250 IeIvan CerovsekNo ratings yet

- Aerospray Pro (7152) Brochure 60-0036-01BDocument4 pagesAerospray Pro (7152) Brochure 60-0036-01BCarla YcoNo ratings yet

- Liberty 50 4tempi 2008Document195 pagesLiberty 50 4tempi 2008Vincent RoyNo ratings yet

- Air Compressor ApplicationDocument3 pagesAir Compressor Applicationprabhanshu241991No ratings yet

- Oil Mist LubricationDocument15 pagesOil Mist Lubricationchetan_thakur4278No ratings yet

- Service Station Manual: X8 400 Euro 3Document394 pagesService Station Manual: X8 400 Euro 3Miroslaw Gabalix GabalisNo ratings yet

- A Procedure For Lube Oil FlushingDocument2 pagesA Procedure For Lube Oil FlushingchrisNo ratings yet

- b356b Pulp PaperDocument24 pagesb356b Pulp PaperFer De La VegaNo ratings yet

- Process Pigging SystemDocument22 pagesProcess Pigging Systemkingathur26681100% (1)

- Mp3 500 Ie SportDocument432 pagesMp3 500 Ie SportJhonny RicoNo ratings yet

- CoatingDocument28 pagesCoatingKumarNo ratings yet

- Sejong Coating System Brochure 6-15-15 Small eDocument12 pagesSejong Coating System Brochure 6-15-15 Small erahmanNo ratings yet

- Energy Saving Presentation Version 2.2 - For Customer - ADocument80 pagesEnergy Saving Presentation Version 2.2 - For Customer - AElsan BalucanNo ratings yet

- FUOOTECH Series TY Vacuum Turbine Oil PurifierDocument15 pagesFUOOTECH Series TY Vacuum Turbine Oil PurifierKevin Chiang100% (1)

- Brochure Lubrication Trainer KitDocument7 pagesBrochure Lubrication Trainer KitwasundesagarNo ratings yet

- (FM CBMTEC) 240123#catalog For Air Compressors and Vacuum PlantsDocument6 pages(FM CBMTEC) 240123#catalog For Air Compressors and Vacuum PlantsslimaniNo ratings yet

- Service Station Manual: Mss Zip 100 4TDocument192 pagesService Station Manual: Mss Zip 100 4TBorja ZapateraNo ratings yet

- Process Pigging SystemDocument22 pagesProcess Pigging SystemAKKI KUMARNo ratings yet

- 1 OTG SD FlushingofLubeOilSystemsusingUniquePulsationTechnology 2017Document2 pages1 OTG SD FlushingofLubeOilSystemsusingUniquePulsationTechnology 2017Anonymous zMWvcTNo ratings yet

- Automatic Lubricvation SystemDocument9 pagesAutomatic Lubricvation Systemsamadhan khaireNo ratings yet

- Bomba de Vacio Gast Lubricated Laboratory 23 Series RotaryDocument8 pagesBomba de Vacio Gast Lubricated Laboratory 23 Series RotaryRafael Rueda AlvarezNo ratings yet

- Mann+Hummel: Filtration Solutions For CompressorsDocument8 pagesMann+Hummel: Filtration Solutions For CompressorsSethuraman Kumarappan (KPCL)No ratings yet

- Air Saver CatalogDocument16 pagesAir Saver CatalogBalázs Tipi TipcsákNo ratings yet

- 2004 08 Refrigeration Applications - Selecting Lubricant For The Ammonia Refrigeration System - BrileyDocument1 page2004 08 Refrigeration Applications - Selecting Lubricant For The Ammonia Refrigeration System - BrileymeomeportabNo ratings yet

- ProSpray3 BrochureDocument4 pagesProSpray3 BrochureMariano GiaquintaNo ratings yet

- GT 125Document294 pagesGT 125swistakosNo ratings yet

- Diagnostic Manual V2Document10 pagesDiagnostic Manual V2Moppie HofstedeNo ratings yet

- KENCO MQL Advance PDFDocument13 pagesKENCO MQL Advance PDFvinothkumarNo ratings yet

- Mantenimiento Compresor ScrollDocument8 pagesMantenimiento Compresor ScrollHugovillarruelNo ratings yet

- Vespa Gts - 250 - IeDocument317 pagesVespa Gts - 250 - IegilmotoNo ratings yet

- Service Station Manual: Runner RST 50 SPDocument183 pagesService Station Manual: Runner RST 50 SPMindaugas VizbarasNo ratings yet

- Workshop Manual: MSS Fly 50 4TDocument189 pagesWorkshop Manual: MSS Fly 50 4TJesus Machuca EstebanNo ratings yet

- TM410B Optimizing Your Spray SystemDocument36 pagesTM410B Optimizing Your Spray SystemqhpuongNo ratings yet

- Users ManualDocument98 pagesUsers ManualWilmar Raul Hancco ZaraviaNo ratings yet

- Reliable Processes Thanks To Perfect Compressed Air PreparationDocument24 pagesReliable Processes Thanks To Perfect Compressed Air PreparationИван ЧечушковNo ratings yet

- Руководство По Ремонту Brp CanDocument513 pagesРуководство По Ремонту Brp CanvaleriyNo ratings yet

- TM410BC Optimizing Your Spray SystemDocument36 pagesTM410BC Optimizing Your Spray Systemno TengoNo ratings yet

- CS134A Concrete Forms WebDocument2 pagesCS134A Concrete Forms WebRifai IndraswariNo ratings yet

- Rifai - Claim May 2023Document49 pagesRifai - Claim May 2023Rifai IndraswariNo ratings yet

- CS127A Pan Coating Choc Centers WebDocument2 pagesCS127A Pan Coating Choc Centers WebRifai IndraswariNo ratings yet

- Rifai - Claim Jan 2023Document41 pagesRifai - Claim Jan 2023Rifai IndraswariNo ratings yet

- Mixing Vat Cleaning-26343Document1 pageMixing Vat Cleaning-26343Rifai IndraswariNo ratings yet

- Rifai - Claim Agt 2023Document52 pagesRifai - Claim Agt 2023Rifai IndraswariNo ratings yet

- Spray Flavoring Into Tobacco-6820Document1 pageSpray Flavoring Into Tobacco-6820Rifai IndraswariNo ratings yet

- MalindoDocument1 pageMalindoRifai IndraswariNo ratings yet

- Rekap Analisis SampelDocument8 pagesRekap Analisis SampelRifai IndraswariNo ratings yet

- Moisturizing Container Packaging-37411Document1 pageMoisturizing Container Packaging-37411Rifai IndraswariNo ratings yet

- Moisture Control Application - 45285Document1 pageMoisture Control Application - 45285Rifai IndraswariNo ratings yet

- Meat Processing-36156Document1 pageMeat Processing-36156Rifai IndraswariNo ratings yet

- CHICK Program BrochureDocument2 pagesCHICK Program BrochureRifai IndraswariNo ratings yet

- Moisturizing Tobacco 38279Document1 pageMoisturizing Tobacco 38279Rifai IndraswariNo ratings yet

- C H I C K +app+brochureDocument2 pagesC H I C K +app+brochureRifai IndraswariNo ratings yet

- VMWARE InterviewDocument4 pagesVMWARE InterviewBaiju ManiNo ratings yet

- Pakistan Education Statistics 2015-16Document199 pagesPakistan Education Statistics 2015-16samer iqbalNo ratings yet

- Pelican Stores Case StudyDocument9 pagesPelican Stores Case StudypoollookNo ratings yet

- CUETPGAdmitCard 243510100767Document2 pagesCUETPGAdmitCard 243510100767kunthaladhanalaxmiNo ratings yet

- Toyota SystemsDocument45 pagesToyota SystemsImjusttryingtohelpNo ratings yet

- Axm-II Configurable Motion PlatformDocument88 pagesAxm-II Configurable Motion PlatformLeunamezNo ratings yet

- 0818 Gearsolutions PDFDocument76 pages0818 Gearsolutions PDFdesetekNo ratings yet

- Zigbee WirelessDocument9 pagesZigbee WirelessSajad RatherNo ratings yet

- PHP Architect - 2017 01 JanuaryDocument52 pagesPHP Architect - 2017 01 JanuaryRafi SMNo ratings yet

- Museum of Science, Boston: Annual Report 2007Document16 pagesMuseum of Science, Boston: Annual Report 2007Lisa Yoon100% (1)

- Thesis Topics For Architectural DesignDocument6 pagesThesis Topics For Architectural Designfc2b5myj100% (2)

- VLSI Custom Microelectronics - Digital, Analog and Mixed-SignalDocument479 pagesVLSI Custom Microelectronics - Digital, Analog and Mixed-Signalbkrebtel100% (1)

- Fundamentals of Digital Signal Processing: Dr. D. K. MohantaDocument48 pagesFundamentals of Digital Signal Processing: Dr. D. K. MohantaKalamchety Ravikumar Srinivasa100% (1)

- Steam ReformingDocument24 pagesSteam ReformingRodrigo Farias100% (2)

- 3405P369 - Tool For Tightness TestDocument4 pages3405P369 - Tool For Tightness TestSylvek91No ratings yet

- Masterflow 880: Cementitious High Strength, Non-Shrink, Iron Reinforced Precision GroutDocument2 pagesMasterflow 880: Cementitious High Strength, Non-Shrink, Iron Reinforced Precision GroutMu FaddaNo ratings yet

- Vendor List - Page 12Document1 pageVendor List - Page 12Tanpreet SinghNo ratings yet

- API-1000-11 Rev 0 PDFDocument3 pagesAPI-1000-11 Rev 0 PDF213eknoNo ratings yet

- 1600 - Design Optimization - Fabrication - and - Testing of A 3D Printed Aircraft Structure Using FDMDocument16 pages1600 - Design Optimization - Fabrication - and - Testing of A 3D Printed Aircraft Structure Using FDMOKA FATRANo ratings yet

- HCI in Health Informatics EssayDocument1 pageHCI in Health Informatics EssaySteven EntezariNo ratings yet

- WMOGI 2024 - English Version Registration Form-IndustryDocument2 pagesWMOGI 2024 - English Version Registration Form-IndustryAli MalikiNo ratings yet

- Com1205 Unit PlanDocument19 pagesCom1205 Unit Planapi-237366460No ratings yet

- Stepper Catalog PDFDocument36 pagesStepper Catalog PDFCano VoyNo ratings yet

- Superlux HD681 EVODocument14 pagesSuperlux HD681 EVOGeorge TschulevinhoNo ratings yet

- Fluidmatic DCT MV 1013Document3 pagesFluidmatic DCT MV 1013Çağatay AtaNo ratings yet

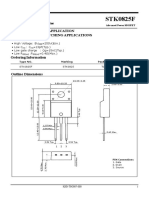

- STK0825F: DC-DC Converter Application High Voltage Switching Applications FeaturesDocument8 pagesSTK0825F: DC-DC Converter Application High Voltage Switching Applications FeaturesRICHIHOTS2No ratings yet

- Offshore201309 DLDocument120 pagesOffshore201309 DLmayav1No ratings yet

- Basic Remote Pilot Course Basic Aerodynamic 2021Document71 pagesBasic Remote Pilot Course Basic Aerodynamic 2021sembiringheinz1No ratings yet

- 7a - Work and Energy WorksheetDocument2 pages7a - Work and Energy Worksheetpicket1019No ratings yet