Professional Documents

Culture Documents

059-B01-MC020 - Mechanical Schedules - Sheet (20 of 23)

059-B01-MC020 - Mechanical Schedules - Sheet (20 of 23)

Uploaded by

omar nasrallahCopyright:

Available Formats

You might also like

- Case Ih Schematic Electrical 6-12750 Mx210 Mx230 Mx255 Mx285Document4 pagesCase Ih Schematic Electrical 6-12750 Mx210 Mx230 Mx255 Mx285gregfortkamp0% (4)

- ISB6.7 CM2250 Wiring Diagram: Data Links GreenDocument1 pageISB6.7 CM2250 Wiring Diagram: Data Links GreenORLANDONo ratings yet

- DF M1Document2 pagesDF M1plj0001No ratings yet

- 2019 PreboarsuejeDocument11 pages2019 PreboarsuejeImmanuel Conrey0% (1)

- Arquitectura (2) Sistema de Control CONCENTRADORADocument12 pagesArquitectura (2) Sistema de Control CONCENTRADORAJORGEHNo ratings yet

- B130279002P03Document1 pageB130279002P03Mohammad ShayanNo ratings yet

- SLD For CPP Metering SystemDocument1 pageSLD For CPP Metering SystemJagadeesh rNo ratings yet

- 01 - Amort. Pulsação - 1# Sucção - LP-1Document1 page01 - Amort. Pulsação - 1# Sucção - LP-1joaofbragasNo ratings yet

- DMM 1 e 007Document1 pageDMM 1 e 007mahesh reddy mNo ratings yet

- Ee PlanDocument1 pageEe PlanPaul MendozaNo ratings yet

- A036513001 PDFDocument1 pageA036513001 PDFanon_929347044100% (2)

- Basden Steel Corp: Bill of MaterialDocument1 pageBasden Steel Corp: Bill of MaterialsateeshdonkadaNo ratings yet

- Quality Control: Lap Joint DetailDocument2 pagesQuality Control: Lap Joint DetailariNo ratings yet

- NCGM XX XX D Aec DR 930 1103Document1 pageNCGM XX XX D Aec DR 930 1103yusufuNo ratings yet

- NCGM XX XX D Aec DR 930 1103Document1 pageNCGM XX XX D Aec DR 930 1103yusufuNo ratings yet

- MRT2 ME Drawing8Document1 pageMRT2 ME Drawing8qinxuekunNo ratings yet

- Foundation Details of Raft & Footing Details Key Plan: Scale - (NTS) Scale - (NTS)Document1 pageFoundation Details of Raft & Footing Details Key Plan: Scale - (NTS) Scale - (NTS)GUNJAN KUMBHARNo ratings yet

- P002-Y004-112 - Sh1of13 - Deck Outfit Plan and DetailsDocument1 pageP002-Y004-112 - Sh1of13 - Deck Outfit Plan and DetailsMahendra SunarNo ratings yet

- GA Drawings For ProcurementDocument19 pagesGA Drawings For ProcurementRAJESHWARNo ratings yet

- Disco Borger TX - A9 (1) - Engine Accessories - Cat Wiring SchematicsDocument2 pagesDisco Borger TX - A9 (1) - Engine Accessories - Cat Wiring SchematicsRohit Roy100% (1)

- Steel Drawing For LvupDocument1 pageSteel Drawing For LvupvivekNo ratings yet

- TEST (6,7) Design Conditions (4) Operating Conditions (4) Line Number Insulation (2) Process ParametersDocument1 pageTEST (6,7) Design Conditions (4) Operating Conditions (4) Line Number Insulation (2) Process Parameterscharles tempNo ratings yet

- GN 300 001Document1 pageGN 300 001Xavier LeeNo ratings yet

- Saudi Arabian Oil Company: 282 A BA-274759 006 0A2Document1 pageSaudi Arabian Oil Company: 282 A BA-274759 006 0A2Mohamed Wasim ShaikhNo ratings yet

- Electrical Specifications: Get AnDocument1 pageElectrical Specifications: Get Anflor johnNo ratings yet

- Beam 2Document1 pageBeam 2xmsasmzwofjqvqbwsdNo ratings yet

- 03 FinalDocument1 page03 FinalMeghana NavuluruNo ratings yet

- PDF CropDocument1 pagePDF CropAditiNo ratings yet

- PEDWPRTS771025A1 - Main Compressor B Train 1 - 5Document1 pagePEDWPRTS771025A1 - Main Compressor B Train 1 - 5macielNo ratings yet

- C15 and C18 Industrial Engine Electrical System: View ADocument4 pagesC15 and C18 Industrial Engine Electrical System: View AOecox Cah Djadoel100% (2)

- LPS Juice Factory - Design.Document2 pagesLPS Juice Factory - Design.Bilal KhalidNo ratings yet

- Main Feeder Line Layout: Transformer PlatformDocument1 pageMain Feeder Line Layout: Transformer Platformalezandro del rossiNo ratings yet

- Main Feeder Line Layout: Transformer PlatformDocument1 pageMain Feeder Line Layout: Transformer Platformalezandro del rossiNo ratings yet

- 002 Nordic London General Arrangement1Document1 page002 Nordic London General Arrangement1Melissa Ezgi KaradenizNo ratings yet

- Project Title: All Dimensions Are in MetersDocument1 pageProject Title: All Dimensions Are in MetersMeghana NavuluruNo ratings yet

- Foundation Plan and Anchor Locations: Section CDocument1 pageFoundation Plan and Anchor Locations: Section CJavier Guerra TriviñoNo ratings yet

- 07A. Section-Sub-station Automation - System Architecture 1 - 2Document1 page07A. Section-Sub-station Automation - System Architecture 1 - 2Prashant SinghNo ratings yet

- 3406C Marine Auxillary Generator Set Electrical System: Pfh1-Up Generator Set: Engine: 1SS1-UP Generator: 8LF1-UP 9FF1-UPDocument2 pages3406C Marine Auxillary Generator Set Electrical System: Pfh1-Up Generator Set: Engine: 1SS1-UP Generator: 8LF1-UP 9FF1-UPLượng Nguyễn XuânNo ratings yet

- Electrical Layout.3Document1 pageElectrical Layout.3Khushi RathodNo ratings yet

- T80-B002 - LaboratoryDocument2 pagesT80-B002 - LaboratoryTayyab AchakzaiNo ratings yet

- Segundo Borrador Cerco HuachipaDocument1 pageSegundo Borrador Cerco HuachipaCarlos Carlitos TNo ratings yet

- Co17pr Esme E01 r03 RDocument1 pageCo17pr Esme E01 r03 RBenjamin Ricardo Nasrallah AlvarezNo ratings yet

- VH Ad 2 VHHH Aoc 4 (Typec)Document1 pageVH Ad 2 VHHH Aoc 4 (Typec)Loïc GIROUDNo ratings yet

- c15 Main Schematic ECM PDFDocument4 pagesc15 Main Schematic ECM PDFWill ?No ratings yet

- 02 FinalDocument1 page02 FinalMeghana NavuluruNo ratings yet

- Pid Orifice - MS HilirDocument1 pagePid Orifice - MS HiliradjiNo ratings yet

- 825H Soil Compactor Hydraulic SystemDocument2 pages825H Soil Compactor Hydraulic SystemTom SouzaNo ratings yet

- Robex HiundayDocument21 pagesRobex HiundayPedro Lucas Rodrigues QueirozNo ratings yet

- 3412 Shematic 4 PDFDocument2 pages3412 Shematic 4 PDFDmitry100% (2)

- (0030) Salman Town Solar Project Solar SMDBDocument6 pages(0030) Salman Town Solar Project Solar SMDBSavio SunnyNo ratings yet

- Circuit Diagrams: MAIN PWB CIRCUIT DIAGRAM (AV-29B316/B) (1/4) (2/4) SHEET1Document4 pagesCircuit Diagrams: MAIN PWB CIRCUIT DIAGRAM (AV-29B316/B) (1/4) (2/4) SHEET1Fede DiNo ratings yet

- Training MatrixDocument1 pageTraining Matrixpratishtha chaudharyNo ratings yet

- Ohtl Route and Profile. Rev.0 - Part-3-1Document1 pageOhtl Route and Profile. Rev.0 - Part-3-1Hassan H AlshokyNo ratings yet

- Package Computer Room Unit: Saudi Arabian Oil CompanyDocument1 pagePackage Computer Room Unit: Saudi Arabian Oil CompanyWaqarNo ratings yet

- Package Computer Room Unit: Saudi Arabian Oil CompanyDocument1 pagePackage Computer Room Unit: Saudi Arabian Oil CompanyWaqarNo ratings yet

- Package Computer Room Unit: Saudi Arabian Oil CompanyDocument1 pagePackage Computer Room Unit: Saudi Arabian Oil CompanyWaqarNo ratings yet

- Package Computer Room Unit: Saudi Arabian Oil CompanyDocument1 pagePackage Computer Room Unit: Saudi Arabian Oil CompanyWaqarNo ratings yet

- Package Computer Room Unit: Saudi Arabian Oil CompanyDocument1 pagePackage Computer Room Unit: Saudi Arabian Oil CompanyWaqarNo ratings yet

- Instant Assessments for Data Tracking, Grade 2: MathFrom EverandInstant Assessments for Data Tracking, Grade 2: MathNo ratings yet

- Instant Assessments for Data Tracking, Grade 1: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 1: Language ArtsNo ratings yet

- Instant Assessments for Data Tracking, Grade 1: MathFrom EverandInstant Assessments for Data Tracking, Grade 1: MathRating: 4 out of 5 stars4/5 (1)

- Ashrae 15 Package Unit Refrigerant Amount CalculationDocument2 pagesAshrae 15 Package Unit Refrigerant Amount Calculationomar nasrallahNo ratings yet

- NPSA CalculationDocument2 pagesNPSA Calculationomar nasrallahNo ratings yet

- Dehumidifier SizingDocument6 pagesDehumidifier Sizingomar nasrallahNo ratings yet

- Medical Gas Pressure Drop Calculator - BC (Protected Inspect)Document6 pagesMedical Gas Pressure Drop Calculator - BC (Protected Inspect)omar nasrallahNo ratings yet

- Chimney Diameter CalculationDocument4 pagesChimney Diameter Calculationomar nasrallahNo ratings yet

- @water & Drainage Equipement DesignDocument46 pages@water & Drainage Equipement DesignDesigner ForeverNo ratings yet

- ACCA Manual D SheetDocument96 pagesACCA Manual D Sheetomar nasrallahNo ratings yet

- 18 - د - - - à - - - ص - éDocument126 pages18 - د - - - à - - - ص - éomar nasrallahNo ratings yet

- Water Heater CalculationDocument3 pagesWater Heater Calculationomar nasrallahNo ratings yet

- 03 - ث - - - à - د - - - د - - - « - - - - - د - - - رDocument111 pages03 - ث - - - à - د - - - د - - - « - - - - - د - - - رomar nasrallahNo ratings yet

- Design Engineer Roles and Responsibilities ChecklistDocument1 pageDesign Engineer Roles and Responsibilities Checklistomar nasrallahNo ratings yet

- 08 - د - - - ث - - - - - è - د - زDocument74 pages08 - د - - - ث - - - - - è - د - زomar nasrallahNo ratings yet

- Real Gases - Vanderwall EquationDocument6 pagesReal Gases - Vanderwall EquationViejayNo ratings yet

- Corafix Rubine GDNDocument3 pagesCorafix Rubine GDNDHRUVNo ratings yet

- Physico Chemical Treatment Solid Hazardous WasteDocument22 pagesPhysico Chemical Treatment Solid Hazardous WasteTejinder singhNo ratings yet

- Marine Coating - Sealer - Hempadur Sealer 05990Document2 pagesMarine Coating - Sealer - Hempadur Sealer 05990Sandro BNo ratings yet

- DO - 147 - s2017 - Item 706 - Concrete, Clay, Plastic & Fiber PipeDocument5 pagesDO - 147 - s2017 - Item 706 - Concrete, Clay, Plastic & Fiber PipeFaustino AbadNo ratings yet

- Ice Handout2Document17 pagesIce Handout2Camilo Jose100% (2)

- Design, Synthesis, and Antibacterial Activity of Novel MyricetinDocument12 pagesDesign, Synthesis, and Antibacterial Activity of Novel MyricetinFauzan NurdianaNo ratings yet

- Lesson 4 - Activation Energy and How Catalyst Affects Rate of ReactionDocument5 pagesLesson 4 - Activation Energy and How Catalyst Affects Rate of ReactionJeff ValdezNo ratings yet

- Chemistry For First Year FBISE PDFDocument58 pagesChemistry For First Year FBISE PDFMinahil Noor50% (2)

- Bare FoamDocument3 pagesBare FoamDanang WibisanaNo ratings yet

- The Extractive Distillation Process For Nitric Acid Concentration Using Magnesium NitrateDocument15 pagesThe Extractive Distillation Process For Nitric Acid Concentration Using Magnesium NitrateAlejandro Duvan Lopez RojasNo ratings yet

- Solid States Question PaperDocument1 pageSolid States Question PaperSomu Yashawant ChaudhariNo ratings yet

- Consumables GC ClarusDocument12 pagesConsumables GC ClarusG_ASantosNo ratings yet

- Proofs Pagination IPVP 3734Document17 pagesProofs Pagination IPVP 3734Hui DaiNo ratings yet

- MMZ 18 Mar 23Document6 pagesMMZ 18 Mar 23Ryan MinnNo ratings yet

- MaterialDocument109 pagesMaterialsarathsaravananNo ratings yet

- Lecture 9 - Solid State ChemistryDocument47 pagesLecture 9 - Solid State ChemistryMuhIlhamNo ratings yet

- Chemistry Practice Question Paper Class 12Document7 pagesChemistry Practice Question Paper Class 12tony starkNo ratings yet

- Hard StandDocument10 pagesHard StandYatendra TyagiNo ratings yet

- Lec 17 Concrete EquipmentDocument16 pagesLec 17 Concrete EquipmentMohammad AL-HajNo ratings yet

- DNA BIOSENSOR Review and PrincipleDocument37 pagesDNA BIOSENSOR Review and PrincipleoOyanaOoNo ratings yet

- 6th Grade 2nd Exam 2nd TermDocument2 pages6th Grade 2nd Exam 2nd TermKurtulus UzunNo ratings yet

- Marcet BoilerDocument14 pagesMarcet BoilerPeter LauNo ratings yet

- Soil Mechanics: Stress Distribution in SoilDocument86 pagesSoil Mechanics: Stress Distribution in SoilArnold FranciscoNo ratings yet

- Polypropylene (PP) Plastic - Types, Properties, Uses & Structure InfoDocument11 pagesPolypropylene (PP) Plastic - Types, Properties, Uses & Structure InfoPrashant SinghNo ratings yet

- Scs2000 Silpruf: Ge SiliconesDocument8 pagesScs2000 Silpruf: Ge SiliconesThiagoAgNo ratings yet

- General Notes:: Schedule of EquipmentDocument1 pageGeneral Notes:: Schedule of EquipmentBilly Joe BreakfastNo ratings yet

- Mineral Properties - Mohs Hardness Scale (Grade 7) - Free Printable Tests and Worksheets - HelpTeaching PDFDocument2 pagesMineral Properties - Mohs Hardness Scale (Grade 7) - Free Printable Tests and Worksheets - HelpTeaching PDFnick210700% (1)

059-B01-MC020 - Mechanical Schedules - Sheet (20 of 23)

059-B01-MC020 - Mechanical Schedules - Sheet (20 of 23)

Uploaded by

omar nasrallahOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

059-B01-MC020 - Mechanical Schedules - Sheet (20 of 23)

059-B01-MC020 - Mechanical Schedules - Sheet (20 of 23)

Uploaded by

omar nasrallahCopyright:

Available Formats

PROCURER

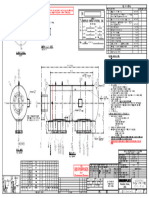

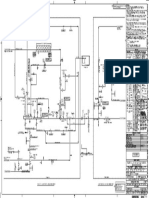

FUEL TANKS SCHEDULE COMPUTER ROOM AIR CONDITIONER SCHEDULE (CRAC-01) - CHILLED WATER-

SUPPLY FAN FAN ELECTRICAL DATA COIL LOAD CHILLED QUANTITY HUMIDIFIER ELECTRIC ELECTRICAL ELECTRICAL

TITLE DESIGNATION TYPE COMPARTMENT MATERIAL CAPACITY DIAMETER LENGTH QTY. EQUIPMENT TAG LOCATION SYSTEM SERVED

(m3) (m) (m) REMARKS HEATER POWER DATA EMERGENCY REMARKS

TOTAL SENSIBLE (kg/hr)

ESP Pa FLOW L/s V Hz Phase POWER (kW) L/s ENT. C LVG. C DUTY STAND BY TOTAL (KW) (KW) (V/hz/phase)

kW kW PROJECT

FT-01 DIESEL STORAGE TANK BELOW GROUND ,DOUBLE SINGLE CARBON STEEL 60 2.9 10.2 2 TANK SHALL BE DESIGNED AS PER EN 12285-1 SUITABLE FOR UNDERGROUND INSTALLATION, WITH PROTECTIVE

SKINNED STEEL CONFIGURATION. COATING, CATHODIC PROTECTION, NORMAL VENT, SUPPORTS AND ALL NECESSARY ACCESSORIES. DUAL CIRCUIT WITH DX COOLING COIL, COMPLETE

TANK SHALL BE DESIGNED AS PER EN 12285-1 SUITABLE FOR UNDERGROUND INSTALLATION, WITH PROTECTIVE CRAC-01 L03 SERVER ROOM 5000 400 60 3 4.0 1.66 1 1 2 10.0 10.0 35.0 400/60/3 YES WITH MICROPROCESSOR CONTROLLER AND ALL

BELOW GROUND ,DOUBLE 100 62.0 62.0 5.6 14.5

FT-02 DIESEL STORAGE TANK SINGLE CARBON STEEL 80 2.9 13.2 1 REQUIRED ACCESSORIES UNIT SHALL FLOOR

SKINNED STEEL CONFIGURATION. COATING, CATHODIC PROTECTION, NORMAL VENT, SUPPORTS AND ALL NECESSARY ACCESSORIES.

STANDING TOP DISCHARGE & BOTTOM RETURN

BELOW GROUND ,DOUBLE TANK SHALL BE DESIGNED AS PER EN 12285-1 SUITABLE FOR UNDERGROUND INSTALLATION, WITH PROTECTIVE

FT-03 DIESEL STORAGE TANK SINGLE CARBON STEEL 120 3.0 17.9 2

SKINNED STEEL CONFIGURATION. COATING, CATHODIC PROTECTION, NORMAL VENT, SUPPORTS AND ALL NECESSARY ACCESSORIES.

NOTE:

NOTES:- NORMAL VENT PIPES SHALL BE TERMINATED AT LEAST 3.6 m ABOVE GROUND LEVEL. * EACH CRAC UNIT SHALL BE EQUIPPED WITH CONDENSATE PUMP.

* CONTRACTOR SHALL FINALIZE THE POWER REQUIREMENTS BASED ON THE FINAL SELECTION OF THE UNITS NOT BASED ON THE DESIGN VALUES. CONSORTIUM

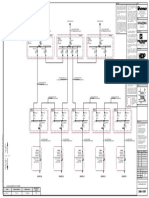

FUEL GEAR PUMPS SCHEDULE SCHEDULE OF HOT WATER EXPANSION TANK * CRAC UNITS SERVING DATA SERVER ROOM SHALL BE CAPABLE OF PROVIDING COOLING IN WINTER AND SUMMER.

* THE SHOWN UNITS CAPACITIES ARE CALCULATED & SHALL BE CAPABLE OF SATISFYING THE ACTUAL COOLING LOAD, TAKING INTO CONSIDERATION

ELECTRICAL DATA* each set pumps QUANTITY UNIT REFERENCE NO. EXP-01 EXP-02

FLOW ESTIMATED AMBIENT CONDITIONS DRY BULB 47.7°C & ROOM TEMP 22°C FOR INDOOR UNIT SELECTION.

PUMPS SETS REMARKS

PUMP

(M3/HR) HEAD (M) ESTM. * V / Hz / Ph QUANTITY TOTAL DUTY STAND BY * THE SHOWN UNITS SHALL BE EQUIPPED WITH ULTRA SONIC HUMIDIFIER.

EXPANSION TANK (L) 300 150

(KW)

GEAR FUEL PUMPS COMPLETE * AT EMERGENCY MODE, MEAN WHEN THE MAIN ELECTRICAL POWER IS SHUT DOWN AND THE GENERATOR WILL START AND SUPPLY POWER TO SPECIFIC SERVICES.

LOCATION TECHNICAL FLOOR TECHNICAL FLOOR

FGP-01 2.0 25 1.0 220/60/1 5 2 1 1 WITH CONTROL PANEL AND ALL

REQUIRED ACCESSORIES QTY 5 2

AUTOMATIC PRESSURIZATION SET SCHEDULE

REMARKS COMPLETE WITH ALL NECESSARY ACCESSORIES COMPLETE WITH ALL NECESSARY ACCESSORIES TAMASUK – ALGHANIM CONSORTIUM

TANK ELECTRICAL DATA

VOLUME NOTES

EQUIPMENT TAG LOCATION SERVICE (L) kW VOLT PHASE HZ HEALTHCARE PLANNER

* TWIN PUMPS, HORIZONTAL PERIPHERAL TYPE

SUBMERSIBLE PUMPS SCHEDULE * PLASTIC ENCLOSURE

APS-01 ETS ROOM CHILLED WATER 21 0.9 400 3 60

* 800 LITER FABRICATED STEEL EXPANSION TANK

* 21 POLYETHYLENE BREAK TANK

NOTE:

PUMP QUANTITY PER EACH SET 1- THE FINAL UNITS SELECTION AND CAPACITY SHALL BE ACCORDING TO MANUFACTURE SELECTION

FLOW HEAD M.C.C. NO. PUMP SET

PUMP ELECTRICAL DATA*

LOCATION REMARKS CHEMICAL POT FEEDER SCHEDULE DESIGN TEAM

L/S BAR

ESTIM. QUANTITY

(Kw) V / Hz / Ph NORMAL EMERGENCY TOTAL DUTY STAND BY CAPACITY

EQUIPMENT TAG LOCATION SERVICE NOTES

(L)

SUBMERSIBLE PUMP COMPLETE WITH CONTROL PANEL AND

SUMP-01 BASEMENT 4 FLOOR 3 3.0 2.5 400/60/3Ø Y Y 1 2 1 1 -

ALL REQUIRED ACCESSORIES CPF-01 ETS ROOM CHILLED WATER 25

SUBMERSIBLE PUMP COMPLETE WITH CONTROL PANEL AND

SUMP-02 BASEMENT 4 FLOOR 3 3.0 2.5 400/60/3Ø Y Y 1 2 1 1 ALL REQUIRED ACCESSORIES

SUBMERSIBLE PUMP COMPLETE WITH CONTROL PANEL AND AIR AND DIRT SEPARATOR SCHEDULE

SUMP-03 BASEMENT 4 FLOOR 1 3.0 1.5 400/60/3Ø Y Y 1 1 1 0 ALL REQUIRED ACCESSORIES

CONNECTION SIZE

SUBMERSIBLE PUMP COMPLETE WITH CONTROL PANEL AND EQUIPMENT TAG LOCATION SERVICE NOTES

SUMP-04 BASEMENT 4 FLOOR 4 3.0 2.5 400/60/3Ø Y Y 1 2 1 1 (mm)

ALL REQUIRED ACCESSORIES

* MAXIMUM VELOCITY: 1.8 m/s

SUBMERSIBLE PUMP COMPLETE WITH CONTROL PANEL AND AS-01 ETS ROOM CHILLED WATER 500 * WATER FLOWRATE REQUIRED: 300 L/s

SUMP-05 BASEMENT 4 FLOOR 3 3.0 2.5 400/60/3Ø Y Y 1 2 1 1 ALL REQUIRED ACCESSORIES

SUBMERSIBLE PUMP COMPLETE WITH CONTROL PANEL AND

SUMP-06 BASEMENT 4 FLOOR 3 3.0 2.5 400/60/3Ø Y Y 1 2 1 1 ALL REQUIRED ACCESSORIES

CHILLED WATER BIOCIDE DOSING PUMP AND TANK

SUBMERSIBLE PUMP COMPLETE WITH CONTROL PANEL AND ELECTRICAL DATA

SUMP-07 BASEMENT 4 FLOOR 3 3.0 2.5 400/60/3Ø Y Y 1 2 1 1 EQUIPMENT TAG LOCATION QTY FLOW RATE TANK SIZE

ALL REQUIRED ACCESSORIES POWER (kW) V/PH/Hz NOTE

(L/Hr) (L)

SUBMERSIBLE PUMP COMPLETE WITH CONTROL PANEL AND

SUMP-08 BASEMENT 4 FLOOR 3 3.0 2.5 400/60/3Ø Y Y 1 2 1 1 DP-01 ETS ROOM 1 60 1.0 220/ 1 /60 500 -

ALL REQUIRED ACCESSORIES

SUBMERSIBLE PUMP COMPLETE WITH CONTROL PANEL AND

SUMP-09 BASEMENT 4 FLOOR 1 3.0 1.5 400/60/3 Y Y 1 1 1 0 ALL REQUIRED ACCESSORIES

SUBMERSIBLE PUMP COMPLETE WITH CONTROL PANEL AND REVERSE OSMOSIS SCHEDULE - CSSD UNITS

SUMP-10 BASEMENT 4 FLOOR 3 3.0 2.5 400/60/3Ø Y Y 1 2 1 1 ALL REQUIRED ACCESSORIES

WORKING

POWER SUPPLY

EQUIPMENT TAG LOCATION DESCRIPTION QTY PRESSURE EMERGENCY

SUBMERSIBLE PUMP COMPLETE WITH CONTROL PANEL AND

SUMP-11 BASEMENT 4 FLOOR 15 3.5 12 400/60/3Ø Y Y 1 3 2 1 (BAR) Kw V

ALL REQUIRED ACCESSORIES

R.O UNIT SET FOR CSSD

SUBMERSIBLE PUMP COMPLETE WITH CONTROL PANEL AND CAPACITY:10.0 m3/DAY

SUMP-12 BASEMENT 4 FLOOR 10 3.5 9.0 400/60/3Ø Y Y 1 3 2 1 ALL REQUIRED ACCESSORIES MAX. FEED WATER TEMP: 25°C

L03 MIN. FEED WATER PRESSURE: 1.5 bar

* CONTRACTOR SHALL TAKE INTO CONSIDERATION THE ACTUAL RESISTANCE THROUGH THE EQUIP., VALVES, ...ETC. RO-01 1 7.0 25.0 400 3 YES

* CONTRACTOR SHALL SUBMIT CALCULATIONS OF PUMPS TOTAL HEAD. COMPONENTS:

(5.0 FOR RO UNIT)

* CHLORINE METERING PUMP (3.9 L/hr) WITH CHEMICAL TANK (20.0 FOR HEATER UNIT)

* PH METERING (3.9 L/hr) WITH CHEMICAL TANK

* 1X2000 L POLYETHYLENE BREAK TANK AND 1X700 LITER STAINLESS STEEL 316 L PRODUCT TANK

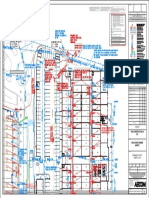

PUMPS SCHEDULE

* STAINLESS STEEL TANKS TO BE EQUIPPED WITH 316 L STAINLESS STEEL

ELECTRIC HEAT TRACED VENT 0.2 MICRON HYDROPHOBIC VENT FILTER

REF NO. FLOW For HEAD ELEC DATA ESTIMATED LOCATION QTY AREA SERVED NOTES EMERGENCY

POWER REMARKS * 5 MICRON CARTRIDGE FILTER

Each (m) V/PH/HZ Y/N

(KW) * UV LAMP

(L/S) * 0.5 MICRON FILTER

TECHNICAL FLOOR 2 DUTY &1 STAND BY COMPLETE WITH CONTROL PANEL AND ALL NECESSARY ACCESSORIES * HEAT UNIT FOR DISINFECTION COMPLETE WITH PUMPS, HEATERS, ...ETC.

SWP-T-01 5.5 30.0 400/3/60 5.0 THIRD FLOOR LEVEL 3 COLD WATER FOR WC (B4-L3) Y

(VARIABLE SPEED PUMP'S) INCLUDING PRESSURE VESSEL * UNIT SHALL BE EQUIPPED WITH STAND-BY RO MEMBRANE.

TECHNICAL FLOOR * ALL REQUIRED RO PUMPS.

2 DUTY &1 STAND BY COMPLETE WITH CONTROL PANEL AND ALL NECESSARY ACCESSORIES

SWP-T-02 5.0 60.0 400/3/60 10.0 THIRD FLOOR LEVEL 3 COLD WATER FOR WC (L4-L9) Y * CONTROL AND CONTROL PANEL

(VARIABLE SPEED PUMP'S) INCLUDING PRESSURE VESSEL

TECHNICAL FLOOR 2 DUTY &1 STAND BY COMPLETE WITH CONTROL PANEL AND ALL NECESSARY ACCESSORIES

SWP-T-03 5.8 30.0 400/3/60 5.0 THIRD FLOOR LEVEL 3 HOT WATER CYLINDER (B1-L3) Y * SKID MOUNTED FACTORY ASSEMBLED UNIT.

(VARIABLE SPEED PUMP'S) INCLUDING PRESSURE VESSEL

* REDUNDANT UNIT AND PIPING SHALL MAINTAIN COMPLETE FLOW DURING

TECHNICAL FLOOR 2 DUTY &1 STAND BY COMPLETE WITH CONTROL PANEL AND ALL NECESSARY ACCESSORIES MAINTENANCE.

SWP-T-04 5.0 60.0 400/3/60 10.0 THIRD FLOOR LEVEL 3 HOT WATER CYLINDER (L4-L9) Y

(VARIABLE SPEED PUMP'S) INCLUDING PRESSURE VESSEL * MEMBRANE SHALL BE WASHABLE TYPE .

TECHNICAL FLOOR COMPLETE WITH CONTROL PANEL AND ALL NECESSARY ACCESSORIES * ALL RO STORAGE TANKS SHALL BE STAINLESS STEEL 316.

SWP-T-05 7.2 30.0 400/3/60 6.0 3 COOLING WATER (B1-L3) 2 DUTY &1 STAND BY Y

THIRD FLOOR LEVEL INCLUDING PRESSURE VESSEL * FULL CONTROL OF PLANT AND PUMP BY SAME MANUFACTURER.

(VARIABLE SPEED PUMP'S)

* FILTERS AND CHEMICALS FOR 2 YEARS SHALL BE INCLUDED.

TECHNICAL FLOOR 2 DUTY &1 STAND BY COMPLETE WITH CONTROL PANEL AND ALL NECESSARY ACCESSORIES

SWP-T-06 5.8 60.0 400/3/60 10.0 3 COOLING WATER (L4-L9) Y

THIRD FLOOR LEVEL (VARIABLE SPEED PUMP'S) INCLUDING PRESSURE VESSEL

* PUMPS SHALL BE PACKAGED BOOSTER PUMPS FACTORY ASSEMBLED.

* PUMPS CONTROLLER SHALL BE RATED TEMPERATURE TILL 50 C.

HOT WATER CIRCULATING PUMPS SCHEDULE

* PUMPS CONTROLLER SHALL BE WATER PROOF TYPE.

* EACH PUMP IN THE SET TO HAVE OWN VFD. M.C.C. NO. PUMP QUANTITY PER EACH SET

FLOW HEAD ELECTRICAL DATA* PUMPS SETS

* PUMPS SKID SHALL BE FACTORY ASSEMBLED FROM SAME MANUFACTURER. PUMP LOCATION REMARKS

NO. (L/SEC) (m) ESTIM.

* PUMPS AND ACCESSORIES SHALL BE SUITABLE FOR DRINKING WATER APPLICATION AND RO WATER. V / Hz / Ph NORMAL EMERGENCY QUANTITY TOTAL DUTY STAND BY

* EACH PACKAGED PUMP SHALL INCLUDE PRESSURE TANKS. (Kw)

* VERTICAL INLINE MULTISTAGE PUMPS WITH VIBRATION ISOLATOR, CHECK VALVE, GATE VALVES, FLEXILE INLINE HOT WATER CIRCULATING PUMP COMPLETE WITH

HWCP-01 TECHNICAL LEVEL 2.60 20 1.0 400/60/3 Y Y 1 2 1 1

CONNECTIONS ALL ACCESSORIES AND PIPES STAINLESS STEEL 316 TYPE. CONTROL PANEL AND ALL REQUIRED ACCESSORIES.

* PUMPS SHALL HAVE STAINLESS STEEL 316 HEADER AND ACCESSORIES.

* CONTROLLER SHALL BE INTEGRATED WITH BMS TO ALLOW FOR COMPLETE MONITOR AND CONTROL PUMPS. ALSO TO INLINE HOT WATER CIRCULATING PUMP COMPLETE WITH

HWCP-02 TECHNICAL LEVEL 0.50 10 0.25 230/60/1 Y Y 1 2 1 1

ALLOW KNOW THE STATUS OF THE PUMPS AND PRESSURE DIFFERENCE. CONTROL PANEL AND ALL REQUIRED ACCESSORIES.

* CONTRACTOR SHALL TAKE INTO CONSIDERATION THE ACTUAL RESISTANCE THROUGH THE EQUIP., VALVES, ...ETC.

* CONTRACTOR SHALL SUBMIT CALCULATIONS OF PUMPS TOTAL HEAD. INLINE HOT WATER CIRCULATING PUMP COMPLETE WITH

HWCP-03 TECHNICAL LEVEL 1.80 20 0.75 230/60/1 Y Y 1 2 1 1

CONTROL PANEL AND ALL REQUIRED ACCESSORIES.

LIFTING PUMPS SCHEDULE * PUMP SHALL BE SUITABLE FOR WATER APPLICATION. * CONTRACTOR SHALL TAKE INTO CONSIDERATION THE ACTUAL

* CONTROLLER SHALL BE INCLUDED FROM SAME MANUFACTURER. RESISTANCE THROUGH THE EQUIP., VALVES, ...ETC.

* CONTROLLER SHALL BE INTEGRATED WITH BMS TO ALLOW FOR * CONTRACTOR SHALL SUBMIT CALCULATIONS OF PUMPS TOTAL

FLOW ELECTRICAL DATA* M.C.C. NO. PUMPS SETS EACH SET PUMPS QUANTITY COMPLETE MONITOR AND CONTROL PUMPS. HEAD.

PUMP LOCATION HEAD

(L/SEC) REMARKS

NO. (m) ESTIM. NORMAL EMERGENCY QUANTITY TOTAL DUTY STAND BY

(Kw)* V / Hz / Ph

DOMESTIC WATER EQUIPMENT SCHEDULE

CWFP-01 12.0 40 11.0 400/60/3Ø Y Y 1 2 1 1 COMPLETE WITH CONTROL PANEL AND ALL NECESSARY ACCESSORIES

BASEMENT 4 LEVEL

FLOW ELECTRICAL DATA*

CWLP-01 6.0 60 11.0 400/60/3Ø Y Y 1 2 1 1 COMPLETE WITH CONTROL PANEL AND ALL NECESSARY ACCESSORIES TITLE DESIGNATION QTY. DUTY STAND BY LOCATION REMARKS

BASEMENT 4 LEVEL

(L/SEC) ESTIM.

(Kw)* V / Hz / Ph

* PUMPS SHALL BE PACKAGED LIFTING PUMPS FACTORY ASSEMBLED.

* PUMPS CONTROLLER SHALL BE RATED TEMPERATURE TILL 50 C. AUTOMATIC SAND COMPLETE WITH AUTOMATIC BACK WASHING VALVE

SF-01 FILTER 12.0 2 1 1 BASEMENT 4 LEVEL 0.1 220/60/1

* PUMPS CONTROLLER SHALL BE WATER PROOF TYPE. AND ALL NECESSARY ACCESSORIES

* EACH PUMP IN THE SET TO HAVE OWN VFD. ACTIVATED CARBON COMPLETE WITH AUTOMATIC BACK WASHING VALVE

* PUMPS SKID SHALL BE FACTORY ASSEMBLED FROM SAME MANUFACTURER. CF-01 FILTER 12.0 2 1 1 BASEMENT 4 LEVEL 0.1 220/60/1

AND ALL NECESSARY ACCESSORIES

* PUMPS AND ACCESSORIES SHALL BE SUITABLE FOR DRINKING WATER APPLICATION AND RO WATER.

* EACH PACKAGED PUMP SHALL INCLUDE PRESSURE TANKS. SEDIMENT CARTRIDGE

* VERTICAL INLINE MULTISTAGE PUMPS WITH VIBRATION ISOLATOR, CHECK VALVE, GATE VALVES, FLEXILE CAF-01 6.00 4 2 2 BASEMENT 4 LEVEL - - COMPLETE WITH ALL NECESSARY ACCESSORIES

5 MICRON FILTER

CONNECTIONS ALL ACCESSORIES AND PIPES STAINLESS STEEL 316 TYPE.

* PUMPS SHALL HAVE STAINLESS STEEL 316 HEADER AND ACCESSORIES. WS-01 DUPLEX WATER SOFTENER 12.00 1 1 - BASEMENT 4 LEVEL COMPLETE WITH AUTOMATIC BACK WASHING VALVE

0.1 220/60/1

* CONTROLLER SHALL BE INTEGRATED WITH BMS TO ALLOW FOR COMPLETE MONITOR AND CONTROL PUMPS. ALSO TO AND ALL NECESSARY ACCESSORIES

ALLOW KNOW THE STATUS OF THE PUMPS AND PRESSURE DIFFERENCE.

* CONTRACTOR SHALL TAKE INTO CONSIDERATION THE ACTUAL RESISTANCE THROUGH THE EQUIP., VALVES, ...ETC. UV-01 UV LIGHT 12.00 2 1 1 BASEMENT 4 LEVEL 1.0 220/60/1 COMPLETE WITH ALL NECESSARY ACCESSORIES

* CONTRACTOR SHALL SUBMIT CALCULATIONS OF PUMPS TOTAL HEAD.

UV-02 UV LIGHT (KITCHEN) 1.00 1 1 - L03 LEVEL 0.3 220/60/1 COMPLETE WITH ALL NECESSARY ACCESSORIES

CIRCULATION PUMPS SCHEDULE

* SEDIMENT CARTRIDGE 5 MICRON FILTER CAPACITY NEED TO BE * FILTERS SHALL HAVE FACTORY ASSEMBLED PANELS FROM SAME

EACH SET PUMPS QUANTITY INCREASED TO MATCH OTHER FILTERS. MANUFACTURER WITH CONNECTION TO BMS.

FLOW HEAD ELECTRICAL DATA* M.C.C. NO. PUMPS SETS * USED PIPES AND ACCESSORIES SHALL BE PN24.

PUMP LOCATION

(L/SEC) REMARKS

NO. (m) ESTIM. QUANTITY TOTAL DUTY

NORMAL EMERGENCY STAND BY

(Kw)* V / Hz / Ph

WCP-01 B04 4.50 15 1.5 220/60/1Ø Y Y 1 2 1 1 COMPLETE WITH CONTROL PANEL AND ALL NECESSARY ACCESSORIES DOMESTIC HOT WATER CALORIFIERS SCHEDULE

WCP-02 1.20 15 1.0 220/60/1Ø Y Y 1 2 1 1 COMPLETE WITH CONTROL PANEL AND ALL NECESSARY ACCESSORIES

L03 CAPACITY OPERATING

DESIGNATION TYPE LOCATION ELECTRICAL DATA QTY. REMARKS

TEMPERATURE INSTALLATION

( LITERS )

WCP-03 1 1 1 COMPLETE WITH CONTROL PANEL AND ALL NECESSARY ACCESSORIES ( °C ) ESTIM. N

L03 1.80 15 1.0 220/60/1Ø Y Y 2

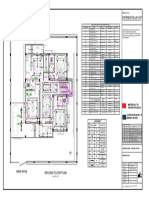

(Kw)* V / Hz / Ph KEY PLAN

COMPLETE WITH THERMOSTATIC MIXING VALVES, PRESSURE AND TEMPERATURE GAUGES, SAFETY

HWC-01 ELECTRIC TECHNICAL LEVEL (3RD FLOOR) 2500 65 70 400/60/3 VERTICAL 5

* VERTICAL INLINE WATER CIRCULATING PUMP VALVES GAUGES, SAFETY VALVES AND ALL NECESSARY ACCESSORIES

* PUMP SHALL BE SUITABLE FOR WATER APPLICATION. COMPLETE WITH THERMOSTATIC MIXING VALVES, PRESSURE AND TEMPERATURE GAUGES, SAFETY

* CONTROLLER SHALL BE INCLUDED FROM SAME MANUFACTURER. HWC-02 ELECTRIC TECHNICAL LEVEL (3RD FLOOR) 500 80 20 400/60/3 VERTICAL 2

VALVES GAUGES, SAFETY VALVES AND ALL NECESSARY ACCESSORIES

* CONTROLLER SHALL BE INTEGRATED WITH BMS TO ALLOW FOR COMPLETE MONITOR AND CONTROL PUMPS.

* CONTRACTOR SHALL TAKE INTO CONSIDERATION THE ACTUAL RESISTANCE THROUGH THE EQUIP., VALVES, ...ETC.

* CONTRACTOR SHALL SUBMIT CALCULATIONS OF PUMPS TOTAL HEAD. * CALORIFIRES SHALL BE RATED TO 16 BAR.

* PROVIDE CONTROLLER FROM SAME SUPPLIER OF CALORIFIRES AND TO BE

CONNECTED WITH BMS TO CONTROL CIRCULATION PUMPS. ELECTRICAL WATER HEATER

* PROVIDE PRVS AND CHECK VALVES. DOMESTIC WATER ELECTRICAL DATA

* ALL VALVES SHALL BE STAINLESS STEEL CORE SUITABLE FOR DRINKING CAPACITY

WATER REF. LOCATION TYPE REMARKS QUANTITY

(L) TARGET H.W. TEMP. ENTERING POWER VOLT PHASE

* THERMAL INSULATION SHALL BE 10 CM MINIMUM. IP RATING

(°C) C.W. TEMP. (°C) (kW) (V) ()

* CONTROLLER SHALL BE INTEGRATED WITH BMS TO ALLOW FOR MONITOR

FIRE PUMPS SCHEDULE AIR CURTAIN SCHEDULE THE HEATERS.

EWH-01 GUARD HOUSE 50 60 10 1.20 220 1 IPX3 VERTICAL TYPE - WITH ELECTRIC HEATING ELEMENT 1

ITEM NO. REF NO. DESCRIPTION TYPE OF MATERIAL CAPACITY ELEC. DATA ELECTRICAL

SAND INTERCEPTOR

EQUIPMENT LENGTH QTY REMARKS

TAG KW VOLT PH Hz TANK

ELECTRIC, MOTOR DRIVEN, CENTRIFUGAL, PUMP CAP. : DIMENSIONS

MAIN DUTY FIRE PUMP TITLE FLOW (L/s) QTY.

HORIZONTAL, SINGLE-STAGE, SPLIT-CASE 1000 GPM 155 KW TO PROVIDE AIR LOCK FROM

01. FP-01 (AS PART OF A COMPLETE FIRE PUMP

STAR/DELTA (CLOSED TYPE) 400V/3PH/60HZ

(W x L x H mm) GREASE INTERCEPTORS SCHEDULE

SET) AT 14.6 BAR HEAD AC-01 1600 mm 9 0.50 230 1 60 EXTERNAL

PUMP TO NFPA 20, UL LISTED AND FM APPROVED

INTERCEPTOR APPROXIMATE

TO PROVIDE AIR LOCK FROM FLOW TYPE DIMENSIONS

MAIN STANDBY FIRE PUMP ELECTRIC, MOTOR DRIVEN, CENTRIFUGAL, PUMP CAP. : S.INT-01 3.15 1200x1200x1000 08 REF.

155 KW AC-02 1000 mm 5 0.50 230 1 60 EXTERNAL (GPM) (L x W x H mm)

(AS PART OF A COMPLETE FIRE PUMP HORIZONTAL, SINGLE-STAGE, SPLIT-CASE 1000 GPM

02. FP-02 AT 14.6 BAR HEAD 400V/3PH/60HZ

SET) STAR/DELTA (CLOSED TYPE)

PUMP TO NFPA 20, UL LISTED AND FM APPROVED TO PROVIDE AIR LOCK FROM GREASE INTERCEPTOR 271 HYDRO MECHANICAL 1930 x 1219 x 1219

CONNECTED TO EMERGENCY POWER SOURCE AC-03 1200 mm 5 0.25 230 1 60 * DIMENSION SHALL BE VERIFIED ACCORDING TO THE SELECTION.

EXTERNAL

* CONTROL PANEL FOR ALARM CONNECTED TO BMS.

JOCKEY FIRE PUMP TO PROVIDE AIR LOCK FROM

ELECTRIC, MOTOR DRIVEN, CENTRIFUGAL, PUMP CAP. :

03. JFP

(AS PART OF A COMPLETE FIRE PUMP

VERTICAL, MULTI-STAGE. 35 GPM 12.0 KW AC-04 2100 mm 12 1.00 230 1 60 EXTERNAL OIL INTERCEPTORS SCHEDULE NEUTRALIZATION TANK

SET) AT 15 BAR HEAD 400V/3PH/60HZ

TO PROVIDE AIR LOCK FROM INTERCEPTOR APPROXIMATE TANK

AC-05 1400 mm 2 0.25 230 1 60 EXTERNAL FLOW TITLE DESIGNATION DIMENSIONS QTY.

DIMENSIONS Limestone

REF. (GPM) XH

(L x W x H mm) lb

TYPE (mm)

DUCTED DX SPLIT AC UNITS NEUTRALIZATION TANK

OIL INTERCEPTOR 20.0 HYDRO MECHANICAL 640 x 360 x 350 NT-01 1000 711X1067 1

FAN COOLING COIL 284 LITTER

AMBIENT

OPERATING THEATRE CANOPIES

TOTAL SENSIBLE

REF. EXT. STATIC

COOLING COOLING AIR ELECTRICAL DATA REFRIGERANT TYPETEMP. QTY. EMERGENCY SCHEDULE * CONTROL PANEL FOR ALARM CONNECTED TO BMS. * CONTROL PANEL FOR ALARM CONNECTED TO BMS.

PRESSURE

CAPACITY CAPACITY

MAXIMUM DESIGN

Pa kW kW ENT. DB °C ENT. WB °C kW V PH Hz °C TAG SPACE NAME QUANTITY AIR (L/s) @0.15 m/s

OUTFLOW SPEED

CANOPY SIZE

FUEL INTERCEPTOR FOR HELICOPTER WATER TANKS ( GRP TANK ) DISCIPLINE MECHANICAL

SU/OU-01 50 5.20 4.70 25.00 18.00 2.50 230 1 60 R-410A 47.70 51 YES

F2.01-01

OPERATING

ROOM

1 1050 2.7X2.6

TITLE DESIGNATION LOCATION

EFFECTIVE

VOLUME QTY. REMARKS

REF NO.

VOLUME

(m )

3

DIMENSION

( LxWxH ) m

TYPE QTY SHEET TYPE MECHANICAL SCHEDULES

SU/OU-02 150 21.90 19.40 25.00 18.00 9.50 400 3 60 R-410A 47.70 20 YES OPERATING

F2.01-02 1 1050 2.7X2.6

ROOM

OPERATING

(L) COOLED 40 4X4X2.5 INSULATED TANK 2 MECHANICAL SCHEDULES -

NOTES: F2.01-03 1 1050 2.7X2.6 SHEET NAME

* THE CAPACITY SHOWN IN THE SCHEDULE OF EQUIPMENT IS THE SELECTED CAPACITY, IT IS THE CONTRACTOR F2.01-04

ROOM

OPERATING

1 1050 2.7X2.6

FUEL

FUEL SEPARATOR ROOF 1800 1 SOFT 40 4X4X2.5 NON INSULATED TANK 2 SHEET (20 OF 23)

ROOM SEPARATOR

RESPONSIBILITY TO TAKE INTO CONSIDERATION (WHILE DOING THE SELECTION) THE LONG PIPES RUN & THE AMBIENT CONDITIONS

* GRP TANKS ACCESSORIES SHALL BE STAINLESS STEEL 316,

* CONTROL PANEL FOR ALARM CONNECTED TO BMS. TANK SHALL BE NFS CERTIFIED FOR DRINKING WATER DATE 07/12/2023

APPLICATION .

SCALE NTS

DESIGNED BY M.T

CHECKED BY M.M SHEET NO.

APPROVED BY H.H 059-B01-MC020

You might also like

- Case Ih Schematic Electrical 6-12750 Mx210 Mx230 Mx255 Mx285Document4 pagesCase Ih Schematic Electrical 6-12750 Mx210 Mx230 Mx255 Mx285gregfortkamp0% (4)

- ISB6.7 CM2250 Wiring Diagram: Data Links GreenDocument1 pageISB6.7 CM2250 Wiring Diagram: Data Links GreenORLANDONo ratings yet

- DF M1Document2 pagesDF M1plj0001No ratings yet

- 2019 PreboarsuejeDocument11 pages2019 PreboarsuejeImmanuel Conrey0% (1)

- Arquitectura (2) Sistema de Control CONCENTRADORADocument12 pagesArquitectura (2) Sistema de Control CONCENTRADORAJORGEHNo ratings yet

- B130279002P03Document1 pageB130279002P03Mohammad ShayanNo ratings yet

- SLD For CPP Metering SystemDocument1 pageSLD For CPP Metering SystemJagadeesh rNo ratings yet

- 01 - Amort. Pulsação - 1# Sucção - LP-1Document1 page01 - Amort. Pulsação - 1# Sucção - LP-1joaofbragasNo ratings yet

- DMM 1 e 007Document1 pageDMM 1 e 007mahesh reddy mNo ratings yet

- Ee PlanDocument1 pageEe PlanPaul MendozaNo ratings yet

- A036513001 PDFDocument1 pageA036513001 PDFanon_929347044100% (2)

- Basden Steel Corp: Bill of MaterialDocument1 pageBasden Steel Corp: Bill of MaterialsateeshdonkadaNo ratings yet

- Quality Control: Lap Joint DetailDocument2 pagesQuality Control: Lap Joint DetailariNo ratings yet

- NCGM XX XX D Aec DR 930 1103Document1 pageNCGM XX XX D Aec DR 930 1103yusufuNo ratings yet

- NCGM XX XX D Aec DR 930 1103Document1 pageNCGM XX XX D Aec DR 930 1103yusufuNo ratings yet

- MRT2 ME Drawing8Document1 pageMRT2 ME Drawing8qinxuekunNo ratings yet

- Foundation Details of Raft & Footing Details Key Plan: Scale - (NTS) Scale - (NTS)Document1 pageFoundation Details of Raft & Footing Details Key Plan: Scale - (NTS) Scale - (NTS)GUNJAN KUMBHARNo ratings yet

- P002-Y004-112 - Sh1of13 - Deck Outfit Plan and DetailsDocument1 pageP002-Y004-112 - Sh1of13 - Deck Outfit Plan and DetailsMahendra SunarNo ratings yet

- GA Drawings For ProcurementDocument19 pagesGA Drawings For ProcurementRAJESHWARNo ratings yet

- Disco Borger TX - A9 (1) - Engine Accessories - Cat Wiring SchematicsDocument2 pagesDisco Borger TX - A9 (1) - Engine Accessories - Cat Wiring SchematicsRohit Roy100% (1)

- Steel Drawing For LvupDocument1 pageSteel Drawing For LvupvivekNo ratings yet

- TEST (6,7) Design Conditions (4) Operating Conditions (4) Line Number Insulation (2) Process ParametersDocument1 pageTEST (6,7) Design Conditions (4) Operating Conditions (4) Line Number Insulation (2) Process Parameterscharles tempNo ratings yet

- GN 300 001Document1 pageGN 300 001Xavier LeeNo ratings yet

- Saudi Arabian Oil Company: 282 A BA-274759 006 0A2Document1 pageSaudi Arabian Oil Company: 282 A BA-274759 006 0A2Mohamed Wasim ShaikhNo ratings yet

- Electrical Specifications: Get AnDocument1 pageElectrical Specifications: Get Anflor johnNo ratings yet

- Beam 2Document1 pageBeam 2xmsasmzwofjqvqbwsdNo ratings yet

- 03 FinalDocument1 page03 FinalMeghana NavuluruNo ratings yet

- PDF CropDocument1 pagePDF CropAditiNo ratings yet

- PEDWPRTS771025A1 - Main Compressor B Train 1 - 5Document1 pagePEDWPRTS771025A1 - Main Compressor B Train 1 - 5macielNo ratings yet

- C15 and C18 Industrial Engine Electrical System: View ADocument4 pagesC15 and C18 Industrial Engine Electrical System: View AOecox Cah Djadoel100% (2)

- LPS Juice Factory - Design.Document2 pagesLPS Juice Factory - Design.Bilal KhalidNo ratings yet

- Main Feeder Line Layout: Transformer PlatformDocument1 pageMain Feeder Line Layout: Transformer Platformalezandro del rossiNo ratings yet

- Main Feeder Line Layout: Transformer PlatformDocument1 pageMain Feeder Line Layout: Transformer Platformalezandro del rossiNo ratings yet

- 002 Nordic London General Arrangement1Document1 page002 Nordic London General Arrangement1Melissa Ezgi KaradenizNo ratings yet

- Project Title: All Dimensions Are in MetersDocument1 pageProject Title: All Dimensions Are in MetersMeghana NavuluruNo ratings yet

- Foundation Plan and Anchor Locations: Section CDocument1 pageFoundation Plan and Anchor Locations: Section CJavier Guerra TriviñoNo ratings yet

- 07A. Section-Sub-station Automation - System Architecture 1 - 2Document1 page07A. Section-Sub-station Automation - System Architecture 1 - 2Prashant SinghNo ratings yet

- 3406C Marine Auxillary Generator Set Electrical System: Pfh1-Up Generator Set: Engine: 1SS1-UP Generator: 8LF1-UP 9FF1-UPDocument2 pages3406C Marine Auxillary Generator Set Electrical System: Pfh1-Up Generator Set: Engine: 1SS1-UP Generator: 8LF1-UP 9FF1-UPLượng Nguyễn XuânNo ratings yet

- Electrical Layout.3Document1 pageElectrical Layout.3Khushi RathodNo ratings yet

- T80-B002 - LaboratoryDocument2 pagesT80-B002 - LaboratoryTayyab AchakzaiNo ratings yet

- Segundo Borrador Cerco HuachipaDocument1 pageSegundo Borrador Cerco HuachipaCarlos Carlitos TNo ratings yet

- Co17pr Esme E01 r03 RDocument1 pageCo17pr Esme E01 r03 RBenjamin Ricardo Nasrallah AlvarezNo ratings yet

- VH Ad 2 VHHH Aoc 4 (Typec)Document1 pageVH Ad 2 VHHH Aoc 4 (Typec)Loïc GIROUDNo ratings yet

- c15 Main Schematic ECM PDFDocument4 pagesc15 Main Schematic ECM PDFWill ?No ratings yet

- 02 FinalDocument1 page02 FinalMeghana NavuluruNo ratings yet

- Pid Orifice - MS HilirDocument1 pagePid Orifice - MS HiliradjiNo ratings yet

- 825H Soil Compactor Hydraulic SystemDocument2 pages825H Soil Compactor Hydraulic SystemTom SouzaNo ratings yet

- Robex HiundayDocument21 pagesRobex HiundayPedro Lucas Rodrigues QueirozNo ratings yet

- 3412 Shematic 4 PDFDocument2 pages3412 Shematic 4 PDFDmitry100% (2)

- (0030) Salman Town Solar Project Solar SMDBDocument6 pages(0030) Salman Town Solar Project Solar SMDBSavio SunnyNo ratings yet

- Circuit Diagrams: MAIN PWB CIRCUIT DIAGRAM (AV-29B316/B) (1/4) (2/4) SHEET1Document4 pagesCircuit Diagrams: MAIN PWB CIRCUIT DIAGRAM (AV-29B316/B) (1/4) (2/4) SHEET1Fede DiNo ratings yet

- Training MatrixDocument1 pageTraining Matrixpratishtha chaudharyNo ratings yet

- Ohtl Route and Profile. Rev.0 - Part-3-1Document1 pageOhtl Route and Profile. Rev.0 - Part-3-1Hassan H AlshokyNo ratings yet

- Package Computer Room Unit: Saudi Arabian Oil CompanyDocument1 pagePackage Computer Room Unit: Saudi Arabian Oil CompanyWaqarNo ratings yet

- Package Computer Room Unit: Saudi Arabian Oil CompanyDocument1 pagePackage Computer Room Unit: Saudi Arabian Oil CompanyWaqarNo ratings yet

- Package Computer Room Unit: Saudi Arabian Oil CompanyDocument1 pagePackage Computer Room Unit: Saudi Arabian Oil CompanyWaqarNo ratings yet

- Package Computer Room Unit: Saudi Arabian Oil CompanyDocument1 pagePackage Computer Room Unit: Saudi Arabian Oil CompanyWaqarNo ratings yet

- Package Computer Room Unit: Saudi Arabian Oil CompanyDocument1 pagePackage Computer Room Unit: Saudi Arabian Oil CompanyWaqarNo ratings yet

- Instant Assessments for Data Tracking, Grade 2: MathFrom EverandInstant Assessments for Data Tracking, Grade 2: MathNo ratings yet

- Instant Assessments for Data Tracking, Grade 1: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 1: Language ArtsNo ratings yet

- Instant Assessments for Data Tracking, Grade 1: MathFrom EverandInstant Assessments for Data Tracking, Grade 1: MathRating: 4 out of 5 stars4/5 (1)

- Ashrae 15 Package Unit Refrigerant Amount CalculationDocument2 pagesAshrae 15 Package Unit Refrigerant Amount Calculationomar nasrallahNo ratings yet

- NPSA CalculationDocument2 pagesNPSA Calculationomar nasrallahNo ratings yet

- Dehumidifier SizingDocument6 pagesDehumidifier Sizingomar nasrallahNo ratings yet

- Medical Gas Pressure Drop Calculator - BC (Protected Inspect)Document6 pagesMedical Gas Pressure Drop Calculator - BC (Protected Inspect)omar nasrallahNo ratings yet

- Chimney Diameter CalculationDocument4 pagesChimney Diameter Calculationomar nasrallahNo ratings yet

- @water & Drainage Equipement DesignDocument46 pages@water & Drainage Equipement DesignDesigner ForeverNo ratings yet

- ACCA Manual D SheetDocument96 pagesACCA Manual D Sheetomar nasrallahNo ratings yet

- 18 - د - - - à - - - ص - éDocument126 pages18 - د - - - à - - - ص - éomar nasrallahNo ratings yet

- Water Heater CalculationDocument3 pagesWater Heater Calculationomar nasrallahNo ratings yet

- 03 - ث - - - à - د - - - د - - - « - - - - - د - - - رDocument111 pages03 - ث - - - à - د - - - د - - - « - - - - - د - - - رomar nasrallahNo ratings yet

- Design Engineer Roles and Responsibilities ChecklistDocument1 pageDesign Engineer Roles and Responsibilities Checklistomar nasrallahNo ratings yet

- 08 - د - - - ث - - - - - è - د - زDocument74 pages08 - د - - - ث - - - - - è - د - زomar nasrallahNo ratings yet

- Real Gases - Vanderwall EquationDocument6 pagesReal Gases - Vanderwall EquationViejayNo ratings yet

- Corafix Rubine GDNDocument3 pagesCorafix Rubine GDNDHRUVNo ratings yet

- Physico Chemical Treatment Solid Hazardous WasteDocument22 pagesPhysico Chemical Treatment Solid Hazardous WasteTejinder singhNo ratings yet

- Marine Coating - Sealer - Hempadur Sealer 05990Document2 pagesMarine Coating - Sealer - Hempadur Sealer 05990Sandro BNo ratings yet

- DO - 147 - s2017 - Item 706 - Concrete, Clay, Plastic & Fiber PipeDocument5 pagesDO - 147 - s2017 - Item 706 - Concrete, Clay, Plastic & Fiber PipeFaustino AbadNo ratings yet

- Ice Handout2Document17 pagesIce Handout2Camilo Jose100% (2)

- Design, Synthesis, and Antibacterial Activity of Novel MyricetinDocument12 pagesDesign, Synthesis, and Antibacterial Activity of Novel MyricetinFauzan NurdianaNo ratings yet

- Lesson 4 - Activation Energy and How Catalyst Affects Rate of ReactionDocument5 pagesLesson 4 - Activation Energy and How Catalyst Affects Rate of ReactionJeff ValdezNo ratings yet

- Chemistry For First Year FBISE PDFDocument58 pagesChemistry For First Year FBISE PDFMinahil Noor50% (2)

- Bare FoamDocument3 pagesBare FoamDanang WibisanaNo ratings yet

- The Extractive Distillation Process For Nitric Acid Concentration Using Magnesium NitrateDocument15 pagesThe Extractive Distillation Process For Nitric Acid Concentration Using Magnesium NitrateAlejandro Duvan Lopez RojasNo ratings yet

- Solid States Question PaperDocument1 pageSolid States Question PaperSomu Yashawant ChaudhariNo ratings yet

- Consumables GC ClarusDocument12 pagesConsumables GC ClarusG_ASantosNo ratings yet

- Proofs Pagination IPVP 3734Document17 pagesProofs Pagination IPVP 3734Hui DaiNo ratings yet

- MMZ 18 Mar 23Document6 pagesMMZ 18 Mar 23Ryan MinnNo ratings yet

- MaterialDocument109 pagesMaterialsarathsaravananNo ratings yet

- Lecture 9 - Solid State ChemistryDocument47 pagesLecture 9 - Solid State ChemistryMuhIlhamNo ratings yet

- Chemistry Practice Question Paper Class 12Document7 pagesChemistry Practice Question Paper Class 12tony starkNo ratings yet

- Hard StandDocument10 pagesHard StandYatendra TyagiNo ratings yet

- Lec 17 Concrete EquipmentDocument16 pagesLec 17 Concrete EquipmentMohammad AL-HajNo ratings yet

- DNA BIOSENSOR Review and PrincipleDocument37 pagesDNA BIOSENSOR Review and PrincipleoOyanaOoNo ratings yet

- 6th Grade 2nd Exam 2nd TermDocument2 pages6th Grade 2nd Exam 2nd TermKurtulus UzunNo ratings yet

- Marcet BoilerDocument14 pagesMarcet BoilerPeter LauNo ratings yet

- Soil Mechanics: Stress Distribution in SoilDocument86 pagesSoil Mechanics: Stress Distribution in SoilArnold FranciscoNo ratings yet

- Polypropylene (PP) Plastic - Types, Properties, Uses & Structure InfoDocument11 pagesPolypropylene (PP) Plastic - Types, Properties, Uses & Structure InfoPrashant SinghNo ratings yet

- Scs2000 Silpruf: Ge SiliconesDocument8 pagesScs2000 Silpruf: Ge SiliconesThiagoAgNo ratings yet

- General Notes:: Schedule of EquipmentDocument1 pageGeneral Notes:: Schedule of EquipmentBilly Joe BreakfastNo ratings yet

- Mineral Properties - Mohs Hardness Scale (Grade 7) - Free Printable Tests and Worksheets - HelpTeaching PDFDocument2 pagesMineral Properties - Mohs Hardness Scale (Grade 7) - Free Printable Tests and Worksheets - HelpTeaching PDFnick210700% (1)