Professional Documents

Culture Documents

Job Safety Carpenter

Job Safety Carpenter

Uploaded by

tsnevin26Copyright:

Available Formats

You might also like

- Design Calculation For ScaffoldingDocument7 pagesDesign Calculation For ScaffoldingAhmad Mensa86% (71)

- Civil Engineering Interview QuestionsDocument17 pagesCivil Engineering Interview Questionsgaza man100% (1)

- Basic Scaffolding Knowledge QuestionsDocument11 pagesBasic Scaffolding Knowledge QuestionsHSE INTECHNo ratings yet

- Skil 3385Document56 pagesSkil 3385Jose da SilvaNo ratings yet

- Sop - Bar BendingDocument1 pageSop - Bar BendingHARSHAD50% (2)

- RA-Suspended Gypsum, Metallic Tiles Celling WorksDocument4 pagesRA-Suspended Gypsum, Metallic Tiles Celling Worksfaizan khanNo ratings yet

- MS For Lead LiningDocument19 pagesMS For Lead LiningJervino RuahNo ratings yet

- Safety PlanDocument45 pagesSafety PlanBspeedman17564100% (4)

- SOP ScaffoldingDocument7 pagesSOP ScaffoldingNakkolop100% (1)

- Post Test Answer Key PDFDocument2 pagesPost Test Answer Key PDFRashad FaizNo ratings yet

- Gin WheelDocument10 pagesGin WheelBarkat Ullah100% (2)

- Los Rios Community College District - Job Safety Analysis: Job Category: Carpenter (For Specifics See Below )Document5 pagesLos Rios Community College District - Job Safety Analysis: Job Category: Carpenter (For Specifics See Below )Tiffany NNo ratings yet

- SGD Saipem Camp Accomodation and Building Facilities Job Safety Analysis Project Operational CampDocument2 pagesSGD Saipem Camp Accomodation and Building Facilities Job Safety Analysis Project Operational CampMaxNo ratings yet

- Zelios: Saw and Reciprocating Saw Hand Power Tools - Including: Drills, CircularDocument3 pagesZelios: Saw and Reciprocating Saw Hand Power Tools - Including: Drills, CircularLuke CornettNo ratings yet

- nrcs144p2 042421Document3 pagesnrcs144p2 042421Mohd AleemNo ratings yet

- JSA Hand Held Portable Power ToolDocument2 pagesJSA Hand Held Portable Power Toolsajjadliaqat3No ratings yet

- Manual RIDGID R5010Document18 pagesManual RIDGID R5010Victor ReyesNo ratings yet

- Powered Hand Tool Safety: Lawn CareDocument2 pagesPowered Hand Tool Safety: Lawn CareuserNo ratings yet

- Saber BDS69 100379 Belt Disc Sander BDS-69 MANUALDocument14 pagesSaber BDS69 100379 Belt Disc Sander BDS-69 MANUALDesotoJoeNo ratings yet

- Sears Scroll SawDocument6 pagesSears Scroll Sawamauri bittencourtNo ratings yet

- #Safety Equipment and PrecautionsDocument44 pages#Safety Equipment and PrecautionsMarvin PattyNo ratings yet

- JSA #28 - Use of Hand ToolsDocument1 pageJSA #28 - Use of Hand ToolsSubham SohalNo ratings yet

- Dewalt DW304p PDFDocument5 pagesDewalt DW304p PDFName NameNo ratings yet

- Angle GrinderDocument16 pagesAngle GrinderSumairBrohiNo ratings yet

- Power ToolsDocument2 pagesPower ToolspradheepNo ratings yet

- RT3422 Tapping Tool ManualDocument48 pagesRT3422 Tapping Tool ManualJesus amésquitaNo ratings yet

- Excavation (Company Name) : Phase Hazard AnalysisDocument11 pagesExcavation (Company Name) : Phase Hazard AnalysisDenease CrummieNo ratings yet

- GT Table Saw Manual PDFDocument92 pagesGT Table Saw Manual PDFkikuNo ratings yet

- Sharpener Affuteuse de Delames Afilador: Instruction Manual Manuel D'Instruction Manual de InstruccionesDocument24 pagesSharpener Affuteuse de Delames Afilador: Instruction Manual Manuel D'Instruction Manual de InstruccionesFatyan YanNo ratings yet

- Manual de Instruccion Esmeril Heavy - Duty Bench GrinderDocument27 pagesManual de Instruccion Esmeril Heavy - Duty Bench GrinderArgenis MarinNo ratings yet

- Operator'S Manual: 1/2 In. 18 V Lithium-Ion Drill Two-Speed/ReversibleDocument18 pagesOperator'S Manual: 1/2 In. 18 V Lithium-Ion Drill Two-Speed/ReversibleNdao86No ratings yet

- Taladro de Banco 10Document40 pagesTaladro de Banco 10pablo.e.m.g.93No ratings yet

- 1'' Air Impact WrenchDocument12 pages1'' Air Impact Wrenchhaimay118No ratings yet

- Manual 3385 PDFDocument61 pagesManual 3385 PDFJose GonzalezNo ratings yet

- Excavation (Company Name) : Safe Work Plan (SWP) /phase Hazard Analysis (Pha)Document11 pagesExcavation (Company Name) : Safe Work Plan (SWP) /phase Hazard Analysis (Pha)PABITRA PANDANo ratings yet

- Operating/Safety Instructions Consignes de Fonctionnement/sécurité Instrucciones de Funcionamiento y SeguridadDocument68 pagesOperating/Safety Instructions Consignes de Fonctionnement/sécurité Instrucciones de Funcionamiento y SeguridadVictor PerezNo ratings yet

- Skill Drill ManualDocument60 pagesSkill Drill ManualA.j. FerreiraNo ratings yet

- Job Hazard Analysis: Task/Procedure Hazard Safe ProcedureDocument1 pageJob Hazard Analysis: Task/Procedure Hazard Safe ProcedureAbdullah KamilNo ratings yet

- Swj802e Manual Eng Mr9 08112020 FinalDocument20 pagesSwj802e Manual Eng Mr9 08112020 FinalRose CosenStudioNo ratings yet

- Toolbox Topic - Hand Injury & PreventionDocument1 pageToolbox Topic - Hand Injury & PreventionSUNIL KUMARNo ratings yet

- Owner'S Manual: Affordable Tools Achieve MoreDocument31 pagesOwner'S Manual: Affordable Tools Achieve MoreOSCAR LUNANo ratings yet

- Electric Power ToolsDocument1 pageElectric Power ToolsJaya KarthickNo ratings yet

- Job Hazard AnalysisDocument2 pagesJob Hazard AnalysisElisha JadormeoNo ratings yet

- Electric Jackhammers: User ManualDocument12 pagesElectric Jackhammers: User ManualWojciech WawrzyniakNo ratings yet

- 19.2 Volt Cordless Jig Saw Variable Speed / OrbitalDocument18 pages19.2 Volt Cordless Jig Saw Variable Speed / OrbitaljewettgNo ratings yet

- Recipro Saw: Model Jr3000VDocument12 pagesRecipro Saw: Model Jr3000VPéter Farkas (fpjanos)No ratings yet

- Safe Working Procedure (SWP) General Office Equipment: Safe Work Procedures and Basic DescriptionDocument4 pagesSafe Working Procedure (SWP) General Office Equipment: Safe Work Procedures and Basic DescriptionArnulfoCruzNo ratings yet

- Heavy-Duty Circuit Tester: Item 30779Document4 pagesHeavy-Duty Circuit Tester: Item 30779isshmangNo ratings yet

- Plant Safety Instructions PDFDocument16 pagesPlant Safety Instructions PDFapsNo ratings yet

- Site Clearing (Company Name) : Phase Hazard AnalysisDocument7 pagesSite Clearing (Company Name) : Phase Hazard AnalysisElvyn Fabellore HerreraNo ratings yet

- Lixadeira Orbital DeWalt Amarela - D26441Document6 pagesLixadeira Orbital DeWalt Amarela - D26441Ponte FerreiraNo ratings yet

- SP-020-B Electrically Powered Hand Tools SOPDocument1 pageSP-020-B Electrically Powered Hand Tools SOPDeon Pillay100% (1)

- Instructivo de Operacion Amoladora DW402Document5 pagesInstructivo de Operacion Amoladora DW402Junior L. SirculiandoNo ratings yet

- Miter Saw: Equipped With Electric Blade Brake 255 MM (10") Model Ls1030NDocument24 pagesMiter Saw: Equipped With Electric Blade Brake 255 MM (10") Model Ls1030NjariouNo ratings yet

- JLA Hand Power ToolsDocument2 pagesJLA Hand Power ToolsFaisal KhanNo ratings yet

- Manual Ryobi ThicknesserDocument11 pagesManual Ryobi ThicknesserRogerNo ratings yet

- Dremei Moto-Tool Manual: o ° Owner'sDocument8 pagesDremei Moto-Tool Manual: o ° Owner'scarlos avilésNo ratings yet

- Manual de Esmerilador de Disco (Ingles) PDFDocument32 pagesManual de Esmerilador de Disco (Ingles) PDFfrancescoNo ratings yet

- IRP-Toolbox HandSafetyDocument1 pageIRP-Toolbox HandSafetyRoman Streliaiev0% (1)

- Operator'S Manual: 12 In. Compound Miter Saw With LaserDocument36 pagesOperator'S Manual: 12 In. Compound Miter Saw With LaserChad McmillanNo ratings yet

- Radial Arm SawsDocument4 pagesRadial Arm SawsVitabuNo ratings yet

- Makita 3709 Manual de UsuarioDocument28 pagesMakita 3709 Manual de UsuarioHernando PuglieseNo ratings yet

- Toolbox Topic - Hand Injury & PreventionDocument1 pageToolbox Topic - Hand Injury & PreventionSUNIL KUMARNo ratings yet

- Air Grease GunDocument12 pagesAir Grease GunAlan TagueNo ratings yet

- Operator'S Manual Manuel de L'Utilisateur Manual Del OperadorDocument24 pagesOperator'S Manual Manuel de L'Utilisateur Manual Del OperadorREVECANo ratings yet

- Picture of Task/equipment: Task: Name of Shop or Dept: Job Title(s) : Analyzed By: Date: Required PPEDocument2 pagesPicture of Task/equipment: Task: Name of Shop or Dept: Job Title(s) : Analyzed By: Date: Required PPEArif RachmanNo ratings yet

- The Handy Homeowner's Repair Manual Comprehensive Guide to the Most Common DIY Home RepairsFrom EverandThe Handy Homeowner's Repair Manual Comprehensive Guide to the Most Common DIY Home RepairsNo ratings yet

- Woodworking Tips, Tools & Projects: Comprehensive and Easy-to-Follow Instructions for Learning All the Fundamental Woodworking Techniques (2022 Guide for Beginners)From EverandWoodworking Tips, Tools & Projects: Comprehensive and Easy-to-Follow Instructions for Learning All the Fundamental Woodworking Techniques (2022 Guide for Beginners)No ratings yet

- Worker Safety Series GCT 7204Document5 pagesWorker Safety Series GCT 7204rey sambitanNo ratings yet

- Work at Height ProcedureDocument36 pagesWork at Height ProcedureKhaled ElsayedNo ratings yet

- 4.assembly & Erection of StructureDocument3 pages4.assembly & Erection of StructureFrancis Vinoj100% (2)

- Hazrat Ali (Safety Notes)Document60 pagesHazrat Ali (Safety Notes)rizvidawar221No ratings yet

- 1414.01: Definition of Terms.: Republic of The PhilippinesDocument50 pages1414.01: Definition of Terms.: Republic of The PhilippinesRollie MimisNo ratings yet

- Calculator Aluminum Formwork Kamkung KindDocument92 pagesCalculator Aluminum Formwork Kamkung KindphamducquangNo ratings yet

- Timber Scaffold Boards - BS2482:2009: 1 of 6 January 2018Document6 pagesTimber Scaffold Boards - BS2482:2009: 1 of 6 January 2018Shery TentionNo ratings yet

- IS 7205 Safety Code For Erection of Structural Steelwork R0 PDFDocument15 pagesIS 7205 Safety Code For Erection of Structural Steelwork R0 PDFKrishna MurariNo ratings yet

- Shor BraceDocument1 pageShor BraceMuhammad ZuhayrNo ratings yet

- Standards New Zealand Essentials Catalogue PricingDocument9 pagesStandards New Zealand Essentials Catalogue Pricingshanky agarwalNo ratings yet

- Structural Design Calculation Structural Design CalculationDocument107 pagesStructural Design Calculation Structural Design CalculationQadeer AhmedNo ratings yet

- Acrow: The First in The WorldDocument6 pagesAcrow: The First in The Worldneilh39No ratings yet

- JSA - Floating RoofDocument2 pagesJSA - Floating RoofBIBEK MOHANTYNo ratings yet

- Wah InductionDocument38 pagesWah InductionkashralNo ratings yet

- Working at Height Is One of The Hazardous OccupationsDocument6 pagesWorking at Height Is One of The Hazardous OccupationsHemaNo ratings yet

- S - PCM - Scaffold ErectionDocument8 pagesS - PCM - Scaffold Erectionsudeesh kumarNo ratings yet

- JSA Format Erection of Column 901-C-01Document9 pagesJSA Format Erection of Column 901-C-01sakthi venkatNo ratings yet

- Kwikstage Scaffolding SystemDocument7 pagesKwikstage Scaffolding SystemJyles SirabNo ratings yet

- L&T Construction - Water & Effluent Treatment IC: Master List of Formwork ComponentsDocument21 pagesL&T Construction - Water & Effluent Treatment IC: Master List of Formwork ComponentsDheena ThayalanNo ratings yet

- JSA For Hydro Test Activites (Generic)Document4 pagesJSA For Hydro Test Activites (Generic)Khaled Ismail88% (25)

- JSA For GIR 11.01.23Document16 pagesJSA For GIR 11.01.23imranNo ratings yet

Job Safety Carpenter

Job Safety Carpenter

Uploaded by

tsnevin26Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Job Safety Carpenter

Job Safety Carpenter

Uploaded by

tsnevin26Copyright:

Available Formats

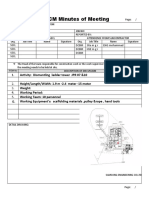

Los Rios Community College District – Job Safety Analysis

Job Category: Carpenter (For Specifics See Below*)

Required and/or recommended personal protective equipment: Respirator/dust mask, eye protection / safety glasses/goggles, gloves, hard hats, protective

clothing/shoes, ear protection

Sequence of Basic Job Steps Potential Hazards Recommended Action or Procedure

Hand tools Hand, eye injuries Use eye protection as needed. Keep tools used

for cutting, sharp at all times. Never use

screwdrivers as chisels or pry bars. Never use

cheaters, get a larger tool if needed. Never alter a

tool. If metal chisel is mushroomed, do not use

until it is ground down. Use tools only for the

intended use.

Hand-held power tools Hand, eye, ear, shock injuries Never remove ground prong from tools or cords

so it will work in receptacles that have no ground.

Repair or replace frayed or damaged cord prior to

using. Never use power tools while standing on

wet or dampened surfaces. Never bypass safety

devices or work with tools where guards are not

operable. Use two hands on power tools

designed for two hand operations. Use sharp bits

and blades. Use tools only for use they were

intended. Use no tools until you have been

trained in its proper use and understand the safety

rules of that particular tool. Use eye and ear

protection as needed.

Grinders Flying metal; pieces Wear protective goggles and gloves when

needed.

Hot molten substances Skin, eye and respiratory irritations Wear protective clothing, shoes, goggles and

mask when needed. Use caution when moving in

area where wet surfaces may exist. Observe all

no smoking rules near flammable substances.

Air powered nailer Eye and puncture injuries Never use tools with inoperable or bypassed,

safety features. Never shoot nail guns while any

part of your body or anyone is in line of fire.

Never use an air tool with the pressure set above

its safe operating capacity. Use safety glasses or

goggles. Use no air tool until you have been

trained in its use and have read and understood its

operating and safety manual.

Page 1 of 5 Carpenter Job Analysis Rev: 9/2018

Los Rios Community College District – Job Safety Analysis

Job Category: Carpenter (For Specifics See Below*)

Sequence of Basic Job Steps Potential Hazards Recommended Action or Procedure

Power saw operation Hand, eye, ear and lung injuries Insure all guards are in place. Insure blade is

sharp and set at proper depth. Turn dust

collection system on, if provided. Use pus sticks

when working in close proximity to saw blade. If

noise level is high, use ear protection. Wear a

dust mask if dust collection is not provided. Use

proper blades for material being cut. Use support

system when working with long materials. Turn

machinery off when not in use. Use no tools until

you have been trained in its proper use and have

read and understood its operating safety manual.

Powder actuated tools Eye, ear and puncture injuries Never use powder actuated tool unless you are

licensed by its manufacturer or its representative

to do so. Use eye and ear protection. Never

shoot into a wall that has occupants behind it.

Never point tool at self or others. Use tool only

as prescribed by the manufacturer.

Building renovation Trip, fall, back, head, eye, shock, hand, ear and Remove materials from buildings as they are

lung injuries being disassembled. Get help with heavy items.

Use dollies, hand trucks, winches and other

mechanical devices whenever possible. Lockout

any power that may be disturbed during

renovation prior to beginning work. Wear hard

hats in all areas where work is being preformed.

Wear eye protection. Wear an approved dust

mask or respirator. Wear gloves and safety

shoes. Wear ear protection when needed.

Sidewalk, asphalt and masonry repairs Back, hand, foot, ear and eye injuries Use proper lifting and bending techniques. Use

ear and eye protection when using jackhammers

and sledgehammers. Wear gloves and safety

shoes. Barricade area.

Painting or finishing with toxic materials Skin, eye and respiratory irritations, allergies, Wear respirator, gloves and eye protection when

slips and falls needed. Work in well-ventilated areas. Clean up

all spills on floor immediately. Keep working

area clear of materials and scattered tools.

Observe no smoking rules near flammable

substances.

Page 2 of 5 Carpenter Job Analysis Rev: 9/2018

Los Rios Community College District – Job Safety Analysis

Job Category: Carpenter (For Specifics See Below*)

Sequence of Basic Job Steps Potential Hazards Recommended Action or Procedure

Vehicle operation, loading, and towing Collision, load loss, hand and back injuries Do not consume alcoholic beverages or other

intoxicants prior to or during work hours. Obey

all posted speed limits. Drive defensively. Wear

seat/shoulder belts at all times. Use mirrors

before backing up. Use extra caution when

driving in student areas. Do vehicle safety check

each day prior to use. Do not drive vehicles that

do not clear the safety check. Wear gloves when

loading and unloading. Get assistance for loading

or unloading heavy objects. Use proper body

mechanics to avoid back injury. Secure all

lumber, ladders, scaffold, etc. securely prior to

moving vehicle. Never overload a trailer or

vehicle. Always secure trailers with approved

safety chain. Always set emergency brake when

parking a vehicle.

Ladders Falls, hand, back, shock injuries Never use a metal ladder near electrical conduits

or power lines. Never use stepladder leaned

against a wall. Extension ladders must extend at

least 3 feet above a roof or landing. Never use

extension ladders to reach heights greater than 44

feet. Use scaffolds. Set ladders at 75 degree with

the floor or ground. The horizontal distance from

the wall to the foot of the ladder should never be

more than ¼ the ladder’s length. Never go up or

down a ladder with tools in your hand. It is best

to raise them using a bucket and rope. Always

face the ladder and grasp the side rails or rungs

with both hands when going up or down, taking

one-step at a time - do not hurry. One person at a

time on a ladder. Check ladder for cracked or

split side rails, for missing, broken, or otherwise

defective steps (cleats, rungs, treads or U-shapes).

Check for sharp edges and splinters on cleats,

rungs, and side rails. Check for general

weakened conditions. Keep ladder clean. If

found to be unsafe, withdraw it from use and fix

it at once, if possible. If irreparable, destroy it

Page 3 of 5 Carpenter Job Analysis Rev: 9/2018

Los Rios Community College District – Job Safety Analysis

Job Category: Carpenter (For Specifics See Below*)

Sequence of Basic Job Steps Potential Hazards Recommended Action or Procedure

Ladders (continued) Falls, hand, back, shock injuries (continued) immediately to make sure it will never be used

again. Never stand on the top or next to the top

rung of ladder that does not have a guardrail.

Select the right type of ladder for the job to be

done. Do not use two ladders spliced together.

Do not use light household ladder for a heavy

construction job. Make sure the ladder is not

placed on a loose object or on uneven footing.

To prevent slipping, equip the ladder with non-

slip points or safety shoes, if practical. If not,

secure the ladder firmly by lashing it with rope or

by other means. Do not lean a ladder against a

moveable object or against window sashes.

Fasten a board securely across the top of the

ladder to give a bearing on each side of the

window. See that a helper stands guard in

dangerous circumstances, as when a ladder is in

front of a door. If there is a danger of a person or

vehicle bumping into the ladder, have a helper

stand guard or rope off the space with caution

tape around the ladder. Remove any oil or grease

from the soles of your shoes before using the

ladder. Never work above the second rung from

the top of a straight ladder. Hold on with one

hand when working from a ladder. Do not over

reach and do not push or pull if it will cause the

ladder to move. If you are far away from

something, you have to reach, take time to move

the ladder closer. Do not straddle the space

between the ladder and another object. Do not

work on a ladder in high winds.

Use stepladders less than 10 feet long, if possible.

Never use a stepladder more than 20 feet long.

Do not work higher than the second or third step

from the top. Open the stepladder all the way and

lock the spreader. Do not use stepladders with

chain/rope spreaders. Fixed ladders should be

placed so that there is a clearance of at least 24

Page 4 of 5 Carpenter Job Analysis Rev: 9/2018

Los Rios Community College District – Job Safety Analysis

Job Category: Carpenter (For Specifics See Below*)

Sequence of Basic Job Steps Potential Hazards Recommended Action or Procedure

Ladders (continued) Falls, hand, back, shock injuries (continued) inches on the climbing side, and they should be

built out from the building at least 6 inches.

Fixed ladders should be fastened securely

throughout their length. Refer to the construction

safety orders for ladder standards for construction

and painting trades.

Scaffolds Falls, broken bones, cuts, scrapes, back injuries Inspect scaffold prior to use. Erect the scaffold to

a comfortable working height. Do not jump from

a landing or scaffold. Keep work surface clear of

tools and debris. Lock all joints when erecting

metal scaffolds. Do not, except under specific

conditions, ride a moving scaffold. Do not allow

platform planks on rolling or tower scaffolds to

overhand support more than 18”. Use outriggers

on, or anchor, scaffolds with a ration greater than

3 feet of height to 1 foot of base to prevent

tipping. Always level your scaffold. Do not use

ladder jack scaffold when height is over 16 feet.

Be certain there are never more than two people

on a ladder jack platform. Do not use ordinary

ladders as planking even though a working

surface has been placed over the rungs. Use a

safety line for each person on ladder jack

platforms 10 feet high or more. Do not place

ladders on top of rolling scaffolds. Set a ladder

jack so the plank is level or slants into the

building. Do not use ladder jack wider than 16

feet center-to-center and only 12 feet where

single dressed 2 inch by 14-inch planks are used.

Chemically, emotionally and psychologically Physical harm Contact college police for assistance and

imbalanced students protection if student appears to be out of control.

Use non-aggressive communication skills.

Office work (after hours, evenings/weekends) Physical harm Lock office door if working late at night and alert

college police of your presence on campus.

Date: June 28, 1991 / Analysis By: Clarice Bettencourt / Reviewed By: Pete Sorrell

*Note: This Job Safety Analysis form includes the following positions in the Los Rios Community College District: Lead Maintenance Cabinetmaker; Locksmith/Glazier; Maintenance Cabinetmaker; Maintenance

Carpenter and Maintenance Roofer/Carpenter.

Page 5 of 5 Carpenter Job Analysis Rev: 9/2018

You might also like

- Design Calculation For ScaffoldingDocument7 pagesDesign Calculation For ScaffoldingAhmad Mensa86% (71)

- Civil Engineering Interview QuestionsDocument17 pagesCivil Engineering Interview Questionsgaza man100% (1)

- Basic Scaffolding Knowledge QuestionsDocument11 pagesBasic Scaffolding Knowledge QuestionsHSE INTECHNo ratings yet

- Skil 3385Document56 pagesSkil 3385Jose da SilvaNo ratings yet

- Sop - Bar BendingDocument1 pageSop - Bar BendingHARSHAD50% (2)

- RA-Suspended Gypsum, Metallic Tiles Celling WorksDocument4 pagesRA-Suspended Gypsum, Metallic Tiles Celling Worksfaizan khanNo ratings yet

- MS For Lead LiningDocument19 pagesMS For Lead LiningJervino RuahNo ratings yet

- Safety PlanDocument45 pagesSafety PlanBspeedman17564100% (4)

- SOP ScaffoldingDocument7 pagesSOP ScaffoldingNakkolop100% (1)

- Post Test Answer Key PDFDocument2 pagesPost Test Answer Key PDFRashad FaizNo ratings yet

- Gin WheelDocument10 pagesGin WheelBarkat Ullah100% (2)

- Los Rios Community College District - Job Safety Analysis: Job Category: Carpenter (For Specifics See Below )Document5 pagesLos Rios Community College District - Job Safety Analysis: Job Category: Carpenter (For Specifics See Below )Tiffany NNo ratings yet

- SGD Saipem Camp Accomodation and Building Facilities Job Safety Analysis Project Operational CampDocument2 pagesSGD Saipem Camp Accomodation and Building Facilities Job Safety Analysis Project Operational CampMaxNo ratings yet

- Zelios: Saw and Reciprocating Saw Hand Power Tools - Including: Drills, CircularDocument3 pagesZelios: Saw and Reciprocating Saw Hand Power Tools - Including: Drills, CircularLuke CornettNo ratings yet

- nrcs144p2 042421Document3 pagesnrcs144p2 042421Mohd AleemNo ratings yet

- JSA Hand Held Portable Power ToolDocument2 pagesJSA Hand Held Portable Power Toolsajjadliaqat3No ratings yet

- Manual RIDGID R5010Document18 pagesManual RIDGID R5010Victor ReyesNo ratings yet

- Powered Hand Tool Safety: Lawn CareDocument2 pagesPowered Hand Tool Safety: Lawn CareuserNo ratings yet

- Saber BDS69 100379 Belt Disc Sander BDS-69 MANUALDocument14 pagesSaber BDS69 100379 Belt Disc Sander BDS-69 MANUALDesotoJoeNo ratings yet

- Sears Scroll SawDocument6 pagesSears Scroll Sawamauri bittencourtNo ratings yet

- #Safety Equipment and PrecautionsDocument44 pages#Safety Equipment and PrecautionsMarvin PattyNo ratings yet

- JSA #28 - Use of Hand ToolsDocument1 pageJSA #28 - Use of Hand ToolsSubham SohalNo ratings yet

- Dewalt DW304p PDFDocument5 pagesDewalt DW304p PDFName NameNo ratings yet

- Angle GrinderDocument16 pagesAngle GrinderSumairBrohiNo ratings yet

- Power ToolsDocument2 pagesPower ToolspradheepNo ratings yet

- RT3422 Tapping Tool ManualDocument48 pagesRT3422 Tapping Tool ManualJesus amésquitaNo ratings yet

- Excavation (Company Name) : Phase Hazard AnalysisDocument11 pagesExcavation (Company Name) : Phase Hazard AnalysisDenease CrummieNo ratings yet

- GT Table Saw Manual PDFDocument92 pagesGT Table Saw Manual PDFkikuNo ratings yet

- Sharpener Affuteuse de Delames Afilador: Instruction Manual Manuel D'Instruction Manual de InstruccionesDocument24 pagesSharpener Affuteuse de Delames Afilador: Instruction Manual Manuel D'Instruction Manual de InstruccionesFatyan YanNo ratings yet

- Manual de Instruccion Esmeril Heavy - Duty Bench GrinderDocument27 pagesManual de Instruccion Esmeril Heavy - Duty Bench GrinderArgenis MarinNo ratings yet

- Operator'S Manual: 1/2 In. 18 V Lithium-Ion Drill Two-Speed/ReversibleDocument18 pagesOperator'S Manual: 1/2 In. 18 V Lithium-Ion Drill Two-Speed/ReversibleNdao86No ratings yet

- Taladro de Banco 10Document40 pagesTaladro de Banco 10pablo.e.m.g.93No ratings yet

- 1'' Air Impact WrenchDocument12 pages1'' Air Impact Wrenchhaimay118No ratings yet

- Manual 3385 PDFDocument61 pagesManual 3385 PDFJose GonzalezNo ratings yet

- Excavation (Company Name) : Safe Work Plan (SWP) /phase Hazard Analysis (Pha)Document11 pagesExcavation (Company Name) : Safe Work Plan (SWP) /phase Hazard Analysis (Pha)PABITRA PANDANo ratings yet

- Operating/Safety Instructions Consignes de Fonctionnement/sécurité Instrucciones de Funcionamiento y SeguridadDocument68 pagesOperating/Safety Instructions Consignes de Fonctionnement/sécurité Instrucciones de Funcionamiento y SeguridadVictor PerezNo ratings yet

- Skill Drill ManualDocument60 pagesSkill Drill ManualA.j. FerreiraNo ratings yet

- Job Hazard Analysis: Task/Procedure Hazard Safe ProcedureDocument1 pageJob Hazard Analysis: Task/Procedure Hazard Safe ProcedureAbdullah KamilNo ratings yet

- Swj802e Manual Eng Mr9 08112020 FinalDocument20 pagesSwj802e Manual Eng Mr9 08112020 FinalRose CosenStudioNo ratings yet

- Toolbox Topic - Hand Injury & PreventionDocument1 pageToolbox Topic - Hand Injury & PreventionSUNIL KUMARNo ratings yet

- Owner'S Manual: Affordable Tools Achieve MoreDocument31 pagesOwner'S Manual: Affordable Tools Achieve MoreOSCAR LUNANo ratings yet

- Electric Power ToolsDocument1 pageElectric Power ToolsJaya KarthickNo ratings yet

- Job Hazard AnalysisDocument2 pagesJob Hazard AnalysisElisha JadormeoNo ratings yet

- Electric Jackhammers: User ManualDocument12 pagesElectric Jackhammers: User ManualWojciech WawrzyniakNo ratings yet

- 19.2 Volt Cordless Jig Saw Variable Speed / OrbitalDocument18 pages19.2 Volt Cordless Jig Saw Variable Speed / OrbitaljewettgNo ratings yet

- Recipro Saw: Model Jr3000VDocument12 pagesRecipro Saw: Model Jr3000VPéter Farkas (fpjanos)No ratings yet

- Safe Working Procedure (SWP) General Office Equipment: Safe Work Procedures and Basic DescriptionDocument4 pagesSafe Working Procedure (SWP) General Office Equipment: Safe Work Procedures and Basic DescriptionArnulfoCruzNo ratings yet

- Heavy-Duty Circuit Tester: Item 30779Document4 pagesHeavy-Duty Circuit Tester: Item 30779isshmangNo ratings yet

- Plant Safety Instructions PDFDocument16 pagesPlant Safety Instructions PDFapsNo ratings yet

- Site Clearing (Company Name) : Phase Hazard AnalysisDocument7 pagesSite Clearing (Company Name) : Phase Hazard AnalysisElvyn Fabellore HerreraNo ratings yet

- Lixadeira Orbital DeWalt Amarela - D26441Document6 pagesLixadeira Orbital DeWalt Amarela - D26441Ponte FerreiraNo ratings yet

- SP-020-B Electrically Powered Hand Tools SOPDocument1 pageSP-020-B Electrically Powered Hand Tools SOPDeon Pillay100% (1)

- Instructivo de Operacion Amoladora DW402Document5 pagesInstructivo de Operacion Amoladora DW402Junior L. SirculiandoNo ratings yet

- Miter Saw: Equipped With Electric Blade Brake 255 MM (10") Model Ls1030NDocument24 pagesMiter Saw: Equipped With Electric Blade Brake 255 MM (10") Model Ls1030NjariouNo ratings yet

- JLA Hand Power ToolsDocument2 pagesJLA Hand Power ToolsFaisal KhanNo ratings yet

- Manual Ryobi ThicknesserDocument11 pagesManual Ryobi ThicknesserRogerNo ratings yet

- Dremei Moto-Tool Manual: o ° Owner'sDocument8 pagesDremei Moto-Tool Manual: o ° Owner'scarlos avilésNo ratings yet

- Manual de Esmerilador de Disco (Ingles) PDFDocument32 pagesManual de Esmerilador de Disco (Ingles) PDFfrancescoNo ratings yet

- IRP-Toolbox HandSafetyDocument1 pageIRP-Toolbox HandSafetyRoman Streliaiev0% (1)

- Operator'S Manual: 12 In. Compound Miter Saw With LaserDocument36 pagesOperator'S Manual: 12 In. Compound Miter Saw With LaserChad McmillanNo ratings yet

- Radial Arm SawsDocument4 pagesRadial Arm SawsVitabuNo ratings yet

- Makita 3709 Manual de UsuarioDocument28 pagesMakita 3709 Manual de UsuarioHernando PuglieseNo ratings yet

- Toolbox Topic - Hand Injury & PreventionDocument1 pageToolbox Topic - Hand Injury & PreventionSUNIL KUMARNo ratings yet

- Air Grease GunDocument12 pagesAir Grease GunAlan TagueNo ratings yet

- Operator'S Manual Manuel de L'Utilisateur Manual Del OperadorDocument24 pagesOperator'S Manual Manuel de L'Utilisateur Manual Del OperadorREVECANo ratings yet

- Picture of Task/equipment: Task: Name of Shop or Dept: Job Title(s) : Analyzed By: Date: Required PPEDocument2 pagesPicture of Task/equipment: Task: Name of Shop or Dept: Job Title(s) : Analyzed By: Date: Required PPEArif RachmanNo ratings yet

- The Handy Homeowner's Repair Manual Comprehensive Guide to the Most Common DIY Home RepairsFrom EverandThe Handy Homeowner's Repair Manual Comprehensive Guide to the Most Common DIY Home RepairsNo ratings yet

- Woodworking Tips, Tools & Projects: Comprehensive and Easy-to-Follow Instructions for Learning All the Fundamental Woodworking Techniques (2022 Guide for Beginners)From EverandWoodworking Tips, Tools & Projects: Comprehensive and Easy-to-Follow Instructions for Learning All the Fundamental Woodworking Techniques (2022 Guide for Beginners)No ratings yet

- Worker Safety Series GCT 7204Document5 pagesWorker Safety Series GCT 7204rey sambitanNo ratings yet

- Work at Height ProcedureDocument36 pagesWork at Height ProcedureKhaled ElsayedNo ratings yet

- 4.assembly & Erection of StructureDocument3 pages4.assembly & Erection of StructureFrancis Vinoj100% (2)

- Hazrat Ali (Safety Notes)Document60 pagesHazrat Ali (Safety Notes)rizvidawar221No ratings yet

- 1414.01: Definition of Terms.: Republic of The PhilippinesDocument50 pages1414.01: Definition of Terms.: Republic of The PhilippinesRollie MimisNo ratings yet

- Calculator Aluminum Formwork Kamkung KindDocument92 pagesCalculator Aluminum Formwork Kamkung KindphamducquangNo ratings yet

- Timber Scaffold Boards - BS2482:2009: 1 of 6 January 2018Document6 pagesTimber Scaffold Boards - BS2482:2009: 1 of 6 January 2018Shery TentionNo ratings yet

- IS 7205 Safety Code For Erection of Structural Steelwork R0 PDFDocument15 pagesIS 7205 Safety Code For Erection of Structural Steelwork R0 PDFKrishna MurariNo ratings yet

- Shor BraceDocument1 pageShor BraceMuhammad ZuhayrNo ratings yet

- Standards New Zealand Essentials Catalogue PricingDocument9 pagesStandards New Zealand Essentials Catalogue Pricingshanky agarwalNo ratings yet

- Structural Design Calculation Structural Design CalculationDocument107 pagesStructural Design Calculation Structural Design CalculationQadeer AhmedNo ratings yet

- Acrow: The First in The WorldDocument6 pagesAcrow: The First in The Worldneilh39No ratings yet

- JSA - Floating RoofDocument2 pagesJSA - Floating RoofBIBEK MOHANTYNo ratings yet

- Wah InductionDocument38 pagesWah InductionkashralNo ratings yet

- Working at Height Is One of The Hazardous OccupationsDocument6 pagesWorking at Height Is One of The Hazardous OccupationsHemaNo ratings yet

- S - PCM - Scaffold ErectionDocument8 pagesS - PCM - Scaffold Erectionsudeesh kumarNo ratings yet

- JSA Format Erection of Column 901-C-01Document9 pagesJSA Format Erection of Column 901-C-01sakthi venkatNo ratings yet

- Kwikstage Scaffolding SystemDocument7 pagesKwikstage Scaffolding SystemJyles SirabNo ratings yet

- L&T Construction - Water & Effluent Treatment IC: Master List of Formwork ComponentsDocument21 pagesL&T Construction - Water & Effluent Treatment IC: Master List of Formwork ComponentsDheena ThayalanNo ratings yet

- JSA For Hydro Test Activites (Generic)Document4 pagesJSA For Hydro Test Activites (Generic)Khaled Ismail88% (25)

- JSA For GIR 11.01.23Document16 pagesJSA For GIR 11.01.23imranNo ratings yet