Professional Documents

Culture Documents

Internet of Things Master Class Notes

Internet of Things Master Class Notes

Uploaded by

vvip420.84.2Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Internet of Things Master Class Notes

Internet of Things Master Class Notes

Uploaded by

vvip420.84.2Copyright:

Available Formats

Hardware

Combination of + + TO DO SPECIFIC TASK

Mechanical Parts

#1 Embedded Systems Software

#1 Printer

#2 Mouse

Example #3 Washing Machine

It is a General Purpose Machine

Not COMPUTER / Mobile

Completes task in a specific time

#1 Real Time Embedded System Nuclear Reactors

Hard Realtime Ex

Air Bag - 4 Wheelers

Type

Soft Realtime Ex Game Controllers

Communicating other Embedded System

#2 Classification of Embedded System #2 Network Embedded System

IoT

Ex

Routers

Operated with a battery for a long time

#3 Mobile Embedded System

Ex Pacemakers

Details 12

#1 Microprocessor

8085

Ex

8065

Details 9

#2 Microcontroller 8051

8 / 16 / 32 Bit

Ex ARM

PIC

Digital Signal Processor

#3 DSP Details 29

Ex TMS320C6000

Digital Signal Controller

#4 DSC Details

Ex TMS320C2000

Field Programmable Gate Array

#5 FPGA Details 5

#3 Types of Embedded System Zync Pynq Z2 2

Ex ZYNQ

Spartan

Complex Programmable Logic Device

#6 CPLD Details 4

Ex Xilinx Coolrunner

Application Specific Integrated Circuit

#7 ASIC Details

Intel Movidius

Ex

TGAM

System On Chip

#8 SOC Details 1

ESP-32

Ex

TI OMAP

#9 GPU

#10 TPU

Anything which is connected with Cloud via Internet

physical devices

vehicles

Things

Internet of Things buildings

Master Class and other items

#4 Internet of Things Revolution

1700s and early 1800s | optimized form of labor performed by people through the use of water and

INDUSTRY 1.0

steam-powered engines and other types of machine tools

Early part of the 20th century | The introduction of electricity enabled manufacturers to increase

INDUSTRY 2.0

efficiency and helped make factory machinery more mobile

Late 1950s |manufacturers began experiencing a shift that put less emphasis on analog and

Evolution of Industry INDUSTRY 3.0

mechanical technology and more on digital technology and automation software.

Interconnectivity through the Internet of Things (IoT), access to real-time data, and the

INDUSTRY 4.0

introduction of cyber-physical systems.

Industry 5.0 refers to robot and smart machines working alongside people with added resilience and

INDUSTRY 5.0 sustainability goals included. Where Industry 4.0 focused on technologies such as the Internet of

Things and big data, Industry 5.0 seeks to add human, environmental and social aspects back

into the equation.

Sensors/Devices Collect data from the surrounding environment

Connectivity Connect devices to the internet through various means (Wi-Fi, Cellular, Satellite)

#5 Key Components of IoT

Data Processing Process the collected data, either on the edge or in the cloud

Action Perform a task based on the processed data, such as sending an alert or adjusting settings

#6 4

#7 9

#8 9

#9 9

#10 7

#11 58

#12 25

#13 47

#14 16

#15 52

#16 24

#17 60

#18 58

You might also like

- Lisec Glass Cutting Table Machine Retrofit - Saint GobainDocument1 pageLisec Glass Cutting Table Machine Retrofit - Saint GobaineacondeNo ratings yet

- Allen-Bradley Stratix 5700™ Network Address Translation (NAT)Document20 pagesAllen-Bradley Stratix 5700™ Network Address Translation (NAT)Max100% (1)

- C - Documents and Settings - O - Local Settings - Application Data - Opera - Opera - Cache - G - 007D - opr011OHDocument2 pagesC - Documents and Settings - O - Local Settings - Application Data - Opera - Opera - Cache - G - 007D - opr011OHOleh PoNo ratings yet

- GP-Pro Ex-Basic TrainingDocument244 pagesGP-Pro Ex-Basic TrainingDAJIMMANZ TVNo ratings yet

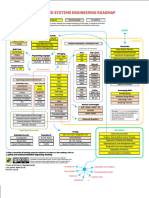

- Embedded Engineer RoadMap 2022Document1 pageEmbedded Engineer RoadMap 2022CHEEDARA BHAVANI0% (1)

- Summer Training ON Embedded SystemsDocument26 pagesSummer Training ON Embedded SystemshimanicNo ratings yet

- Sargodha Institute of Technology: ProgramingDocument3 pagesSargodha Institute of Technology: ProgramingUsman UlHaqNo ratings yet

- Main Items BOQ Per SS: 4. Ethernet Switch 1. Control Panel & Panel Accessories 2. RTU System 5. Maintenance ToolsDocument1 pageMain Items BOQ Per SS: 4. Ethernet Switch 1. Control Panel & Panel Accessories 2. RTU System 5. Maintenance ToolsTarek KhafagaNo ratings yet

- Draft SylabbusDocument146 pagesDraft SylabbusKiambisNo ratings yet

- Generation First Second Third Fourth Fifth YearDocument2 pagesGeneration First Second Third Fourth Fifth Yearkeerthana vijayakumarNo ratings yet

- Group3 Tabulation IIOTDocument26 pagesGroup3 Tabulation IIOTdark knightNo ratings yet

- Dynatrace Introduction To TaspenDocument32 pagesDynatrace Introduction To TaspenANDIKA SUDARMANNo ratings yet

- Temas de ClaseDocument381 pagesTemas de ClaseterterNo ratings yet

- Microprogrammed ControlDocument30 pagesMicroprogrammed ControlRajdeep BiswasNo ratings yet

- Poster Schvar C Bacher RossiDocument1 pagePoster Schvar C Bacher RossiDraoui AhmedNo ratings yet

- Control and Modelling of Wireless RobotDocument4 pagesControl and Modelling of Wireless RobotPhaniendra KundetiNo ratings yet

- Wireless Data Aquisition System Sample2Document1 pageWireless Data Aquisition System Sample2Crescendo Solusi TamaNo ratings yet

- Ativa Slide Presentation - Infovista DetailDocument34 pagesAtiva Slide Presentation - Infovista Detailnhatnd88No ratings yet

- Faldic BDocument24 pagesFaldic BgsNo ratings yet

- Building Management - Monitor Building Power SupplyDocument1 pageBuilding Management - Monitor Building Power SupplyMusembiNo ratings yet

- Computer Science NotesDocument4 pagesComputer Science Notesemmastark2773No ratings yet

- Daikin SVM SG CatalogueDocument12 pagesDaikin SVM SG CatalogueChithravelu TamilkumaranNo ratings yet

- El Impacto en El Software de Las Arquitecturas MulticoreDocument48 pagesEl Impacto en El Software de Las Arquitecturas MulticoreXavier Gracia CervantesNo ratings yet

- Motionsuite Mp940 Machine Controller Hardware ManualDocument72 pagesMotionsuite Mp940 Machine Controller Hardware ManualJULIAN ANDRES ROJASNo ratings yet

- C4 EngineDocument1 pageC4 Engine姚飞No ratings yet

- Creative Computing v06 n12 1980 DecemberDocument232 pagesCreative Computing v06 n12 1980 Decemberdarkstar314No ratings yet

- Mind Map 01Document1 pageMind Map 01Dr. Suna PaanaNo ratings yet

- DENSO Robotics Online EXPO Catalog Set en 1Document15 pagesDENSO Robotics Online EXPO Catalog Set en 1docteur stringoNo ratings yet

- CTC 03Document53 pagesCTC 03BIBHISHAN MUNDENo ratings yet

- Euf Aut T2835 - EtasDocument28 pagesEuf Aut T2835 - EtaskuronoshirorespawnNo ratings yet

- DCOMP05R41 DIPC TS M Module 3 v.3BDocument90 pagesDCOMP05R41 DIPC TS M Module 3 v.3BThanh Kieu TienNo ratings yet

- Diagrama D6NDocument2 pagesDiagrama D6NPlstina Rams100% (1)

- ZONITH Dimetra Micro Fail Over SolutionDocument8 pagesZONITH Dimetra Micro Fail Over SolutionSohaib Omer SalihNo ratings yet

- Measurement and Automation Systems: The Iba SystemDocument11 pagesMeasurement and Automation Systems: The Iba Systemryan940No ratings yet

- FDM Printers Portfolio - EN A4 Quick Reference GuideDocument1 pageFDM Printers Portfolio - EN A4 Quick Reference GuideGokul SivaramanNo ratings yet

- Avrcam Code Commentary: JrobotDocument26 pagesAvrcam Code Commentary: JrobotAhmed Abd elmoneimNo ratings yet

- Visio AutomationDocument49 pagesVisio AutomationJAMNo ratings yet

- 2DRV YASKAWA ConM 124407 GB 2070-4Document13 pages2DRV YASKAWA ConM 124407 GB 2070-4jose luis mejia cortezNo ratings yet

- GI MicroElectronics Data Catalog 1978 Index PDFDocument22 pagesGI MicroElectronics Data Catalog 1978 Index PDFAnonymous KuTQvYTuNo ratings yet

- Isobus - The CAN-based Network System For Agriculture and Forestry MachinesDocument6 pagesIsobus - The CAN-based Network System For Agriculture and Forestry MachinesCARLA EMANOELE LABIAPARI NASCIMENTONo ratings yet

- Distributed Control SystemDocument15 pagesDistributed Control SystemLudwig MensahNo ratings yet

- Poster Presentation Prateek RastogiDocument1 pagePoster Presentation Prateek RastogiprateekNo ratings yet

- Embedded Engineering RoadmapDocument1 pageEmbedded Engineering Roadmapaksak4010No ratings yet

- Master 1Document1 pageMaster 1Quality Manager Jet ServeNo ratings yet

- Must KnowDocument1 pageMust KnowaeNo ratings yet

- Firmware Engineer Roadmap 2021 1632678252Document1 pageFirmware Engineer Roadmap 2021 1632678252Joao DuqueNo ratings yet

- CMW-Platform Bro en 5214-2833-12 v0500Document36 pagesCMW-Platform Bro en 5214-2833-12 v0500deve1986No ratings yet

- Memminger Networker Monitoring SystemDocument16 pagesMemminger Networker Monitoring SystemsentyNo ratings yet

- DecodeDocument79 pagesDecodeforfives2No ratings yet

- System Architecture - Fosber Master Cut Off Esursa EcuadorDocument1 pageSystem Architecture - Fosber Master Cut Off Esursa EcuadoreacondeNo ratings yet

- IPANema PDFDocument16 pagesIPANema PDFE. 17No ratings yet

- Home AutomationDocument9 pagesHome Automationvysnavi vrpNo ratings yet

- Welcome To Your Digital Edition Of: Tech Briefs, Photonics & Imaging Technology, and Sensor TechnologyDocument126 pagesWelcome To Your Digital Edition Of: Tech Briefs, Photonics & Imaging Technology, and Sensor TechnologyPetros TsenesNo ratings yet

- System Architecture - Fosber Compact Slitter Scorer Retrofit - Esursa EcuadorDocument1 pageSystem Architecture - Fosber Compact Slitter Scorer Retrofit - Esursa EcuadoreacondeNo ratings yet

- Intellisolar InsertDocument2 pagesIntellisolar Insertrahulasdfsharma1986No ratings yet

- MTConnect Information FlyerDocument2 pagesMTConnect Information FlyerMatheus SanderNo ratings yet

- Motion Smarter: Powerful Control Solutions For Demanding Multi-Axis MachineryDocument13 pagesMotion Smarter: Powerful Control Solutions For Demanding Multi-Axis MachineryTofel EmedNo ratings yet

- Spare Items BOM - Per SSDocument1 pageSpare Items BOM - Per SSTarek KhafagaNo ratings yet

- TP-Wireless-5.2.2-LRC-OSS Interface Developer Guide (Cellular)Document16 pagesTP-Wireless-5.2.2-LRC-OSS Interface Developer Guide (Cellular)Ofer KrausNo ratings yet

- IGS-6329 Series - LDocument14 pagesIGS-6329 Series - Lmayraelisa.salgadoNo ratings yet

- Wheatstone Bridge's Sensitivity, Resistors' Values Effect PDFDocument6 pagesWheatstone Bridge's Sensitivity, Resistors' Values Effect PDFMostafa KhaledNo ratings yet

- Problems Chptrs 19-30Document54 pagesProblems Chptrs 19-30Pawan NarayanNo ratings yet

- 2Q QuizDocument4 pages2Q QuizjcvoscribNo ratings yet

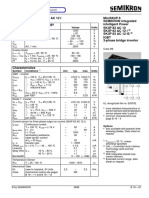

- SKii P83 AC12Document3 pagesSKii P83 AC12DYLAN JOSUE (SOLUCIONES TECNOLOGICA)No ratings yet

- 19EC516 - QR - HDL Programming APRIL 2024Document15 pages19EC516 - QR - HDL Programming APRIL 2024Nanda KishoreNo ratings yet

- ICA-UNIT-III - R19-CompleteDocument28 pagesICA-UNIT-III - R19-CompleteBhanu Kiran BKNo ratings yet

- Lesson 1 - Basic Computer OrganizationDocument17 pagesLesson 1 - Basic Computer OrganizationSteph Kier PonterasNo ratings yet

- ATP 250 Lyon 2023 Schematic 21 MayDocument1 pageATP 250 Lyon 2023 Schematic 21 MayHa Duc ThanhNo ratings yet

- A100K11013 Pulse - Getting - StartedDocument4 pagesA100K11013 Pulse - Getting - StartedMahran MastouriNo ratings yet

- College Name Course Name Closing Rank Category QuotaDocument31 pagesCollege Name Course Name Closing Rank Category QuotaLokesh KumarNo ratings yet

- Price List Royu Electrical November 2019 Issue PDFDocument16 pagesPrice List Royu Electrical November 2019 Issue PDFJeff CabusasNo ratings yet

- Basic Electronics and Electricity Assembly Kits - M-KITSDocument15 pagesBasic Electronics and Electricity Assembly Kits - M-KITSpfalencarNo ratings yet

- Interfacing The ADS8361 To The TMS320F2812 DSPDocument11 pagesInterfacing The ADS8361 To The TMS320F2812 DSPasokanenNo ratings yet

- A - V Sorround Receiver Avr-4806Document2 pagesA - V Sorround Receiver Avr-4806Jonathan NavasNo ratings yet

- AT89C5131 USB BootloaderDocument33 pagesAT89C5131 USB Bootloadercarlos augusto do carmo braiaNo ratings yet

- Design of A Smart Safety Device For Women Using Iot Design of A Smart Safety Device For Women Using IotDocument7 pagesDesign of A Smart Safety Device For Women Using Iot Design of A Smart Safety Device For Women Using Iotamta nadeemNo ratings yet

- 1986 NEC Linear ProductsDocument442 pages1986 NEC Linear ProductsJosé InácioNo ratings yet

- L3000A Manual de ServicioDocument44 pagesL3000A Manual de ServiciocarlosxxiNo ratings yet

- List of Top Polytechnic Colleges in Chennai and Their DetailsDocument6 pagesList of Top Polytechnic Colleges in Chennai and Their DetailsMahesh Divakar100% (1)

- Advantest R6243 PDFDocument12 pagesAdvantest R6243 PDFangelo_lopez1993No ratings yet

- Synopsis Mini ProjectDocument6 pagesSynopsis Mini ProjectMadan R HonnalagereNo ratings yet

- CH 6-q 1Document2 pagesCH 6-q 1মজুমদার অলিনNo ratings yet

- Ieee 1184Document37 pagesIeee 1184Jose Antonio EstofaneroNo ratings yet

- E-Ball Research PaperDocument4 pagesE-Ball Research PaperNarasimha LeViNo ratings yet

- Vestel DVB 4 - Sat 3600 - (ET)Document53 pagesVestel DVB 4 - Sat 3600 - (ET)peraja12No ratings yet

- LM629 Salida PWMDocument25 pagesLM629 Salida PWMLuis VarelaNo ratings yet

- UMCEE Presentation 06102015Document149 pagesUMCEE Presentation 06102015aryoNo ratings yet

- Se-330 Manual Neutral-Grounding-Resistor Monitor: All Rights ReservedDocument44 pagesSe-330 Manual Neutral-Grounding-Resistor Monitor: All Rights ReservedAlmir GarciaNo ratings yet

- Modeling and System-Level Performance Evaluation of Sub-Band Full Duplexing For 5G-AdvancedDocument15 pagesModeling and System-Level Performance Evaluation of Sub-Band Full Duplexing For 5G-AdvancedSimegnew ademeNo ratings yet