Professional Documents

Culture Documents

Superpan Decor Data Sheet

Superpan Decor Data Sheet

Uploaded by

malkawi60 MalikOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Superpan Decor Data Sheet

Superpan Decor Data Sheet

Uploaded by

malkawi60 MalikCopyright:

Available Formats

SUPERPAN DECOR

TECHNICAL DATA-AVERAGE VALUES Rev: 03/02/2020

PROPERTIES TEST METHOD UNITS THICKNESSES mm

8-13 >13-20 >20-25 >25-32 >32-40

DENSITY (*) EN 323 kg/m3 720/680 650-640 625 620 610

INTERNAL BOND EN 319 N/mm2 ≥ 0,40 ≥ 035 ≥ 0,30 ≥ 0,25 ≥ 0,20

BENDING STRENGTH EN 310 N/mm2 ≥ 14 ≥ 14 ≥ 13 ≥ 12 ≥ 11

MODULUS OF ELASTICITY EN 310 N/mm2 ≥ 2200 ≥ 2100 ≥ 1800 ≥ 1500 ≥ 1300

MOISTURE CONTENT EN 322 % 8+/-3 8+/-3 8+/-3 8+/-3 8+/-3

≤ 0.05 ≤ 0.05 ≤ 0.05 ≤ 0.05 ≤ 0.05

FORMALDEHYDE EMISSION EN 717-1 ppm

(VI*) (VI*) (VI*) (VI*) (VI*)

REACTION TO FIRETABLA 8 EN EN 13501-1 Class D- D- D-s2,d0 D-s2,d0 D-s2,d0

13986:2004+A1:2015 I s2,d0** s2,d0***

REACTION TO FIRETABLA 8 EN EN 13501-1 Class Dfl-s1 Dfl-s1**** Dfl-s1 Dfl-s1 Dfl-s1

13986:2004+A1:2015 I

SOUND ABSORPTION COEFFICIENT (Α) EN 13984:2004+A1:2015 α 0.10 0.10 0.10 0.10 0.10

(250 A 500 HZ)

SOUND ABSORPTION COEFFICIENT (Α) EN 13984:2004+A1:2015 α 0.25 0.25 0.25 0.25 0.25

(1000 A 2000 HZ)

THERMAL CONDUCTIVITY EN 13984:2004+A1:2015 W/ (m·K) 0.14 0.14 0.13 0.12 0.12

AIRBORNE SOUND INSULATION EN 13986:2004+A1:2015 db 24 26 28 29 31

(SURFACE MASS) (R)

WATER VAPOUR PERMEABILITY DRY CUP EN 13986:2004+A1:2015 μ 50 50 50 50 50

WATER VAPOUR PERMEABILITY WET CUP EN 13986:2004+A1:2015 μ 17 16 15 15 15

BIOLOGICAL DURABILITY USE EN 13986:2004+A1:2015 Class of use 1 1 1 1 1

CONTENT OF PENTACHLOROPHENOL EN 13986:2004+A1:2015 ppm <5 <5 <5 <5 <5

(PCP)

TOLERANCE ON NOMINAL DIMENSIONS

PROPERTIES TEST METHOD UNITS THICKNESSES mm

8-13 >13-20 >20-25 >25-32 >32-40

THICKNESS ON NOMINAL DIMENSIONS EN 14323 mm +/-0.3 +/-0.3 +/- 0,5 +/- 0,5 +/- 0,5

(Clase 1) (Clase 1)

+0.5/-0.3 +0.5/-0.3

(Clase (Clase

3A) 3A)

THICKNESS WITHIN THE BOARD EN 14323 mm max-min max-min max-min max-min max-min

<0.6 <0.6 <0.6 <0.6 <0.6

LENGHT & WIDTH EN 14323 mm +/-5 +/-5 +/-5 +/-5 +/-5

FLATNESS (SOLAMENTE EN UNE-EN-14323 mm/m -- ≤2 (VI*) ≤2 (VI*) ≤2 (VI*) ≤2 (VI*)

REVESTIMIENTOS EQUILIBRADOS)

COATING PROPERTIES

PROPERTIES TEST METHOD UNITS THICKNESSES mm

RESISTANCE TO SCRATCHING EN 14323 N ≥ 1.5

RESISTANCE TO CRACKING EN 14323 Rating ≥3

SURFACE ASPECT EN 14323 Rating 4

RESISTANCE TO STAINING (GROUPS 1 Y 2) EN 14323 Rating 5

RESISTANCE TO STAINING (GROUP 3) EN 14323 Rating 4

COLOR RESISTANCE TO UV LIGHT (XENON EN 14323 Blue wool scale, nº >6

LAMP)

VISUAL DEFECTS

EDGES DAMAGED EN 14323 mm ≤2

SURFACE DEFECTS. POINTS EN 14323 mm2/m2 ≤2

SURFACE DEFECTS. LENGHT EN 14323 mm/m2 ≤ 10

RESISTANCE TO ABRASION: TEST METHOD CLASS IP NUMBER OF TURNS

RESISTANCE TO ABRASION:. DESIGNS (GENERAL EN 14323 1 < 50

APPLICATIONS)

RESISTANCE TO ABRASION. UNICOLORS AND AH EN 14323 3A ≥ 150

PRODUCTS

(*) VALUES TO BE CONSIDERED AS A ROUGH GUIDE ONLY.

(**) Minimun thickness 9mm.Mounted without an air gap behind the SUPERPAN DECOR. Mounted with a closed air gap not more than 22 mm behind the SUPERPAN

DECOR classificationD-s2,d2. Classification E for any other more restrictive condition. Commission Decision 2007/348/EC.

(***) Mounted without an air gap behind the SUPERPAN DECOR, or with a closed air gap behind the SUPERPAN DECOR for thicknesses equal or greater than 15mm or with

an open air gap behind the SUPERPAN DECOR for thicknesses equal or greater than 18 mm. Mounted with a closed air gap not more than 22 mm behind the SUPERPAN

DECOR classification D-s2,d2 in thicknesses between 10 and 18 mm. Commission Decision 2007/348/EC

(****) Minimun thickness 9 mm

(V*) Applies only when balanced papers are used in both faces

These physical-mechanical values improve/comply with the P2 classification established in EN 312:2010 European Standard, Table 3. Boards for indoor applications (including

furniture) in dry environments (Type P2). Requirements for the specified mechanical properties.

This product meets Class E1 requirements as defined in EN 14322:2017 European Standard.

(VI*) Very low formaldehyde emission product E05 (<0.05 ppm EN 717-1) (Both faces covered boards).

This product is endorsed by AITIM Quality Labels.

HANDLING/STORAGE:

It must always be stored under cover and on a flat surface.

65% of humidity is the ideal condition for its storage, dryer or more moist environments should be avoided.

It must never be in direct contact with water.

Blocks must always be lined up with the vertical.

Never pile up more than 4 heights.

If the packaging is damaged during its handling, it must be packed again so the product is correctly preserved.

If the piling-up conditions or the changes in moisture or temperature above mentioned are not respected in the warehouses or the processing areas, they may cause

irreversible deformations and warpings.

<div style='visibility:hidden;'>(SELECT)</div>

Non dangerous product. Adequate ergonomic techniques and IPEs must be used when handling. Dust generated in cutting, sanding, drawmilling and other processes

must be extracted from the working environment with the usual procedures in the wood industry as industrial vacuum systems and IPEs use must be observed

according to law.

You might also like

- Uv Lac 5KDocument8 pagesUv Lac 5KboldllinesNo ratings yet

- Luxe Technical Data Sheet: CompositionDocument4 pagesLuxe Technical Data Sheet: CompositionRosa Marie GreenNo ratings yet

- ENG Melamine Faced Particle BoardDocument2 pagesENG Melamine Faced Particle BoardedymicNo ratings yet

- A2 Technical Specifications - en 4Document1 pageA2 Technical Specifications - en 4Anuja JadhavNo ratings yet

- Ficha Tecnica 60X120-F M 017.250. .04227Document2 pagesFicha Tecnica 60X120-F M 017.250. .04227oelfahli1117No ratings yet

- Danopol HS 1.5 - CeDocument4 pagesDanopol HS 1.5 - CeWES QingNo ratings yet

- Item Conductive Tile Static-Disiipative TileDocument3 pagesItem Conductive Tile Static-Disiipative Tilebheemannadora sappaNo ratings yet

- Deckshield Id May 2019Document2 pagesDeckshield Id May 2019Ursulet SilviuNo ratings yet

- Melamine Faced MDF Technical DataDocument1 pageMelamine Faced MDF Technical Databahoxa3115No ratings yet

- Extreme - PVC SportivDocument1 pageExtreme - PVC SportivAnca IlinaNo ratings yet

- Ftec - 100324950 - 20230119 - 164143 - 115151633 Bottega AceroDocument1 pageFtec - 100324950 - 20230119 - 164143 - 115151633 Bottega AceroSilviu CiuleiNo ratings yet

- Exalite-10 GB PDFDocument2 pagesExalite-10 GB PDFvijayNo ratings yet

- PB p2 Technical Datasheet PDFDocument2 pagesPB p2 Technical Datasheet PDFbelal545No ratings yet

- TDS EGGER Comfort Flooring en PDFDocument2 pagesTDS EGGER Comfort Flooring en PDFAndrej SetkaNo ratings yet

- Especificación Membrana GeotextilDocument1 pageEspecificación Membrana GeotextilMiguel RamírezNo ratings yet

- TD EGGER Eurospan E1E05 TSCA Hydro P3 (Rec 224) enDocument2 pagesTD EGGER Eurospan E1E05 TSCA Hydro P3 (Rec 224) enClarencegiNo ratings yet

- PorcelainDocument5 pagesPorcelainabdulrahman hallakNo ratings yet

- Porcelanosa: Model: Codes: Water AbsorptionDocument1 pagePorcelanosa: Model: Codes: Water Absorptionmick hughesNo ratings yet

- Imperdan FP 50 GP (10X1) : Bituminous WaterproofingDocument3 pagesImperdan FP 50 GP (10X1) : Bituminous WaterproofingAANo ratings yet

- Technical Data Sheet Mirror Gloss 2 1Document3 pagesTechnical Data Sheet Mirror Gloss 2 1bk.lazar2010No ratings yet

- Sarnafil® S 327-20 L: Product Data SheetDocument5 pagesSarnafil® S 327-20 L: Product Data SheetAhmed MontashNo ratings yet

- TDS Glasdan 40 GP ElastDocument5 pagesTDS Glasdan 40 GP ElastMohamed SaadNo ratings yet

- Fs Porto Amaral: Water AbsorptionDocument2 pagesFs Porto Amaral: Water AbsorptionMiloš BasarićNo ratings yet

- BE - YOND-SWISSSPAN-P2-NAF ProductDatasheet 10695 ENDocument1 pageBE - YOND-SWISSSPAN-P2-NAF ProductDatasheet 10695 ENNesa XxxNo ratings yet

- Technical Description Tychem-6000-F-Tfcha5tgy00 enDocument23 pagesTechnical Description Tychem-6000-F-Tfcha5tgy00 enMuhammad FaizNo ratings yet

- TS - PSV - 650 EycDocument2 pagesTS - PSV - 650 Eycconvocatoria.recomosaNo ratings yet

- 1 18168 TD Eurospan E1 p4 CTB S enDocument2 pages1 18168 TD Eurospan E1 p4 CTB S enMitar MirićNo ratings yet

- Sikaplan-Sgma 2.0 PB EngDocument5 pagesSikaplan-Sgma 2.0 PB EngstilpgNo ratings yet

- Sintec Technical Data Sheet Urdin MP 1.5 Eng PDFDocument2 pagesSintec Technical Data Sheet Urdin MP 1.5 Eng PDFMukhripah DamaiyantiNo ratings yet

- TD EGGER Eurospan E1 P2 (Rec 1 107 108) ENDocument2 pagesTD EGGER Eurospan E1 P2 (Rec 1 107 108) ENSukiNo ratings yet

- SELIT Depron 6 MM KartaDocument2 pagesSELIT Depron 6 MM Kartajanuszkunce57No ratings yet

- Flagon E: Technical Data Sheet No. WPSIT0027-14.04Document2 pagesFlagon E: Technical Data Sheet No. WPSIT0027-14.04Rodrigues1392No ratings yet

- Tds Deckdrain 1200s nw8 GCD A01 Deck1200s 0518 001Document1 pageTds Deckdrain 1200s nw8 GCD A01 Deck1200s 0518 001AladinNo ratings yet

- Fisa Tehnica Linoleum Natural MarmoretteDocument1 pageFisa Tehnica Linoleum Natural MarmoretteSurdu AncaNo ratings yet

- Properties Test Method Property or Attribute Surface QualityDocument6 pagesProperties Test Method Property or Attribute Surface QualitytimuionutNo ratings yet

- Phoenix Super 5,4 KG Mineral BlackDocument1 pagePhoenix Super 5,4 KG Mineral BlackNur Arhami LailaNo ratings yet

- Page 0160Document1 pagePage 0160syedrajak.barcNo ratings yet

- TECNOLEN 25 Bs1d0 - 42234 - 42344 - V5 - ENDocument2 pagesTECNOLEN 25 Bs1d0 - 42234 - 42344 - V5 - ENKarima ABOUALINo ratings yet

- EN 14411 BI: Quality Assurance DepartmentDocument2 pagesEN 14411 BI: Quality Assurance DepartmentBožidarKojićNo ratings yet

- FTL enDocument2 pagesFTL enclaudiu.gheorghe5710No ratings yet

- DatasheetDocument1 pageDatasheetAli Civil007No ratings yet

- TechnicalDataSheet EffisusEcofacadeMembrane ENGDocument1 pageTechnicalDataSheet EffisusEcofacadeMembrane ENGPaula MoçoNo ratings yet

- Diamond P4Kg Mineral GrayDocument1 pageDiamond P4Kg Mineral GrayTasos SkordarisNo ratings yet

- Ply Wood DATASheetDocument2 pagesPly Wood DATASheetmohammed mustafaNo ratings yet

- Technical Data Sheet: Board Type in Line With EN 622-5Document2 pagesTechnical Data Sheet: Board Type in Line With EN 622-5JulioG.CamposCadenaNo ratings yet

- Sarnafil® G 410-15 L: Product Data SheetDocument4 pagesSarnafil® G 410-15 L: Product Data SheetAhmed MontashNo ratings yet

- Auto TakDocument1 pageAuto Takuocmogiandi_aNo ratings yet

- 07 VESDA-E VEA Microbore Tubes Fittings UL TDS A4 IE LoresDocument2 pages07 VESDA-E VEA Microbore Tubes Fittings UL TDS A4 IE LoresLídia FlorenzianoNo ratings yet

- Waterproofing Membrane, CharacteristicsDocument4 pagesWaterproofing Membrane, CharacteristicsyamegNo ratings yet

- 3p Atk Foam 35d Dop Ce en 2016Document3 pages3p Atk Foam 35d Dop Ce en 2016Nicu MercoreNo ratings yet

- CTM PP TX 160 Technical Data SheetDocument2 pagesCTM PP TX 160 Technical Data SheetJeetendra SinghNo ratings yet

- Trelleborg Dielectric MattingDocument2 pagesTrelleborg Dielectric MattingStephenNo ratings yet

- Ovr 1N 10 275 - AbbDocument1 pageOvr 1N 10 275 - AbbVladimir FernándezNo ratings yet

- T935 Inclinometer: DC-Operated, Gravity-ReferencedDocument4 pagesT935 Inclinometer: DC-Operated, Gravity-ReferencedNicolasSuchNo ratings yet

- 0.4mm Nitrile Nylon Diaphragm RubberDocument1 page0.4mm Nitrile Nylon Diaphragm Rubber4D EngineeringNo ratings yet

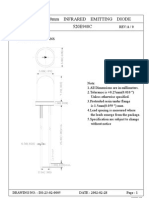

- 5.0Mm Infrared Emitting Diode 520E940CDocument4 pages5.0Mm Infrared Emitting Diode 520E940CRonald TucumanNo ratings yet

- Merino Ecoclick + Technical Data Sheet PDFDocument1 pageMerino Ecoclick + Technical Data Sheet PDFPankaj AgateNo ratings yet

- TechnicalDataSheet EffisusEcofacadeMembrane ENGDocument1 pageTechnicalDataSheet EffisusEcofacadeMembrane ENGPaula MoçoNo ratings yet

- Lexan F6000 Series Us Datasheet 2021Document3 pagesLexan F6000 Series Us Datasheet 2021agungrizky.batNo ratings yet

- PWM Manual English InnerPagesDocument92 pagesPWM Manual English InnerPagesSeenivasagam CNo ratings yet

- 11 SMAW Q4 Module 4Document13 pages11 SMAW Q4 Module 4Mark Johnson VillaronNo ratings yet

- 23 M-AstDocument4 pages23 M-AstLegi YangNo ratings yet

- Prod and Upgrading of Recovered Carbon Black 2022Document19 pagesProd and Upgrading of Recovered Carbon Black 2022yasirNo ratings yet

- Pipemill Fluxes FinalDocument1 pagePipemill Fluxes Finaltanveer ahmedNo ratings yet

- Dawlance Electronics - Installment PlansDocument1 pageDawlance Electronics - Installment PlansIrshad BalochNo ratings yet

- Irjet V6i41288Document5 pagesIrjet V6i41288veerNo ratings yet

- Telescoping Guide Rhs and Chs Aug13 sj0510-1Document2 pagesTelescoping Guide Rhs and Chs Aug13 sj0510-1Richard GrahamNo ratings yet

- (Scharvogel 2011) Metal Injection Molding of Titanium For Medical and Aerospace ApplicationsDocument3 pages(Scharvogel 2011) Metal Injection Molding of Titanium For Medical and Aerospace ApplicationsChristian MohammadNo ratings yet

- 3f Adhesive Tape GuideDocument16 pages3f Adhesive Tape GuideThien PhamNo ratings yet

- Article June 2023 Edition of World Pipelines Magazine 1692894876Document4 pagesArticle June 2023 Edition of World Pipelines Magazine 1692894876fahid masoodNo ratings yet

- Textile Era - Airlaid Web Formation TechniqueDocument11 pagesTextile Era - Airlaid Web Formation Techniqueneuzainamine48No ratings yet

- DNM S SeriesDocument20 pagesDNM S SeriesJesus D. Gutierrez G.No ratings yet

- Eih Machinery ListDocument6 pagesEih Machinery ListzaimNo ratings yet

- Oisd STD 177Document26 pagesOisd STD 177yandiNo ratings yet

- Compression Molding AbstractDocument2 pagesCompression Molding AbstractFAIZ RASOOL100% (1)

- Bakelite PF 31Document3 pagesBakelite PF 31dioguitomsolhaNo ratings yet

- Sheet Metal Fabrication IndustryDocument63 pagesSheet Metal Fabrication IndustryGino George100% (7)

- Injection of Flux Into The BlastDocument8 pagesInjection of Flux Into The BlastWesley CostaNo ratings yet

- B12X9WR - Wear RunnersDocument1 pageB12X9WR - Wear Runnerscarlos hernandezastNo ratings yet

- Proposed STP For Equinox (A1)Document1 pageProposed STP For Equinox (A1)Aly ReyesNo ratings yet

- Spesifikasi Ipal BRM-5 (Mesin)Document1 pageSpesifikasi Ipal BRM-5 (Mesin)Adi SaputraNo ratings yet

- ISOBOND FLOOR enDocument2 pagesISOBOND FLOOR enNovingroupNo ratings yet

- Ch26 - Grinding - Abrasive - Machining - Finishing - Operations-Part 1Document42 pagesCh26 - Grinding - Abrasive - Machining - Finishing - Operations-Part 1Muhammad YusufNo ratings yet

- GM StudentDocument16 pagesGM StudentShuvranil SahaNo ratings yet

- 6 BricksDocument59 pages6 BricksMian Afzaal 72No ratings yet

- BF02660998Document12 pagesBF02660998Ahmad Zulfy AlhamdyNo ratings yet

- Nordson XALOY - Extrusion - Catalogue - PC - Rev0Document20 pagesNordson XALOY - Extrusion - Catalogue - PC - Rev0berryeletricaNo ratings yet

- FlooringDocument30 pagesFlooringSakshiNo ratings yet

- Astm E340 23Document6 pagesAstm E340 23ARINDAM SETTNo ratings yet