Professional Documents

Culture Documents

Kryteria Oceny Jakosci Wyrobu ENG

Kryteria Oceny Jakosci Wyrobu ENG

Uploaded by

Serci35Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kryteria Oceny Jakosci Wyrobu ENG

Kryteria Oceny Jakosci Wyrobu ENG

Uploaded by

Serci35Copyright:

Available Formats

1/6

Criteria for quality assessment of glass products manufactured by

Pilkington IGP Sp. z o.o.

1. General provisions

Following we present information to explain the correct procedure to control and assess the quality of glass

delivered by Pilkington IGP Sp. z o.o. with acceptable tolerances for glass manufacturing and phenomena

that may occur while using the products. The collected information shall be useful in answering the questions

about the quality of the glass that may arise before, during and after the installation of the glass.

The described principles of assessment result directly from the applicable European standards for types of

glass and base on rules used for many years on the European market.

Generally, the quality parameters declared below by Pilkington IGP Sp. z o.o. ensure higher standard of the

product compared to the standard and market requirements.

The given amounts, sizes and types of all acceptable defects refer only to standards products of Pilkington

IGP Sp. z o.o.

In the case of products for special applications (fireproof, bulletproof, anti-burglary, safe, structural, enamel

coated, with additional internal elements such as bars, blinds, etc.) - other assessment criteria may apply,

resulting from the characteristics of the product and the materials used.

If the quality requirements of the Buyer are different than those specified in these Criteria and in the

standards specific to the product, Pilkington IGP Sp. z o.o. shall confirm such deviation before proceeding

with the contract.

The presented method of glass assessment is also a basis for evaluation of the justifiability of submitted

complaints.

In accordance with the "General Terms and Conditions of Contracts Pilkington IGP Sp. z o.o. " and "General

Terms and Conditions of the Standard Warranty for Insulating Glass Units Manufactured by Pilkington IGP Sp.

z o.o.” the Buyer is obliged to record in the Delivery Acceptance Protocol any observed scratches, breaks or

cracks of the insulating glass unit and/or individual glass units. Lack of such remarks in the Delivery

Acceptance Protocol may cause rejection by Pilkington IGP Sp. z o.o. of possible complaints and other claims

arising from such defects. The Buyer shall test the quality of delivered products within 14 days of their

delivery, before further processing.

2. Method of assessment the quality of insulating glass and single glass units

The defects are assessed by looking through the glass at a right angle, with the glass in vertical position and

bright diffused lighting. The assessment is performed from min. 2 m distance, on a solid grey background or

against a cloudy sky. Only product defects, visible in these conditions, are assessed for compliance with the

requirements specified by Pilkington IGP Sp. z o.o.

PILKINGTON IGP Sp. z o.o. based in Sandomierz

27-600 Sandomierz, 24 Portowa Street, tel. 48 15 8323041-49 or 48 15 8326100 fax 48 15 832 62 89

REGON 006911139 NIP (Tax Identity Number) 123-00-06-857 District Court in Kielce, X Commercial Division of the National Court

Register under KRS number 0000012897 Individual BDO Number 000003517

Share Capital: 506 500 PLN

Management Board: President – Krzysztof Granicki

www.pilkington.pl

2/6

For the purposes of glass quality assessment, the glass surface is divided into three

conventional areas: edge (K), border (B) and main (G).

K = 15 mm (zone that in most cases is covered by window frame)

B = 50 mm (edge area)

G = central area of the glass

3. Acceptable tolerances of insulating glass and single glass units

3.1. Acceptable defects visible from 2 m

Defect name K B G

Edge area Border area Central area of

(15 mm) (50 mm) glass

Hair-scratches acceptable but not accumulated

acceptable, scratch ≤ 30 mm scratch ≤ 15 mm

without limits acceptable, the total acceptable, the

Scratches

length of the total length of the

scratches ≤ 90 mm scratches ≤ 15 mm

Point defects Ø (mm)

Ø ≤ 0,5 acceptable

0,5 < Ø ≤ 1,0 acceptable, not accumulated

acceptable,

without limits 1 pc/lm for each 2 pcs/m2

1,0 < Ø ≤ 2,0

side of the glass max. 5 items

> 2,0 not acceptable

PILKINGTON IGP Sp. z o.o. based in Sandomierz

27-600 Sandomierz, 24 Portowa Street, tel. 48 15 8323041-49 or 48 15 8326100 fax 48 15 832 62 89

REGON 006911139 NIP (Tax Identity Number) 123-00-06-857 District Court in Kielce, X Commercial Division of the National Court

Register under KRS number 0000012897 Individual BDO Number 000003517

Share Capital: 506 500 PLN

Management Board: President – Krzysztof Granicki

www.pilkington.pl

3/6

3.2. Acceptable tolerances for insulating glass dimensions and thickness

Parameter Acceptable tolerance

Dimensions +2,0 / -1,0 mm

Thickness ±1,0 mm (annealed glass)

±1,5 mm (toughened glass, laminated glass)

Diagonal difference < 2 mm/m

Glass displacement < 2,0 mm

3.3. Other defects

Glass dirt

Except for the edges area, dirt inside of product visible from a 2 m distance, larger than indicated in

the table of defects, is not accepted.

Chipping, dents, edge damages

On not-treated glass edges, damage is allowed up to 2 mm and 20% of the glass thickness, and

individual chips are accepted up to 6 mm. Cracks, even small ones - are unacceptable and should be

reported on delivery protocol.

Spacer bars faults

The internal surfaces of the spacer bars should be free of stains, spots visible from a 2 m distance.

In standard insulating glass, the distance of spacer bar to the edge of the glass shall not exceed 15

mm. The distance of the bars to each other or to the edge of the glass should not vary by more

than 2 mm for a given side of the glass length. Deviation from the straightness of the spacer bar

shall not exceed 2 mm.

Defects related to Georgian bars / Sprossen

The decorative bars installed inside the insulating glass may show vibrations and sometimes cause

noticeable clicking noise. Depending on the type of decorative bar and technical possibilities, small

transparent silicone elements are attached in the connection points of the bars, which dampen

vibrations and knocking sound. In the case of strong external vibrations transmitted to the glass

(e.g. passing a heavy car) or by opening/closing windows and doors, these protections may be

insufficient to full eliminate the knocking sound.

Unsealing

Unsealing is a defect of the insulating glass unit consisting in the loss of internal tightness of the

insulated glass chamber. Such defect is signalled by visible (permanent or periodic) fogging inside

the insulated glass, as well as accumulation of water in the bottom part of the cavity.

The tightness guarantee granted by Pilkington IGP Sp. z o.o. for insulating glass units covers only

such cases when the loss of tightness is caused due to defective manufacturing of product or

material defects in the delivered insulated glass, if those defects were caused by Pilkington IGP Sp.

z o.o.

PILKINGTON IGP Sp. z o.o. based in Sandomierz

27-600 Sandomierz, 24 Portowa Street, tel. 48 15 8323041-49 or 48 15 8326100 fax 48 15 832 62 89

REGON 006911139 NIP (Tax Identity Number) 123-00-06-857 District Court in Kielce, X Commercial Division of the National Court

Register under KRS number 0000012897 Individual BDO Number 000003517

Share Capital: 506 500 PLN

Management Board: President – Krzysztof Granicki

www.pilkington.pl

4/6

4. Physical phenomena associated with the using of insulating glass units, which

are not caused by the poor quality of the product

Thermal cracks

Cracks caused by thermal stress occur in the event of sudden temperature changes of glass surface.

The risk of thermal cracks increases when blinds, adhesive foils are installed, and when radiators or

air conditioners are pointing directly at the glass. Thermal cracks can also occur when the glass

units are exposed to strong sunlight and high temperatures during transport or storage.

Image distortion in reflected light

After the insulating glass unit is manufactured, natural changes in outside temperature and air

pressure increase or decrease the gas pressure inside the unit. The reaction to these changes of

internal pressure may be the convex or concavity of the glass surface. Such deflection of glass

surface may be notices as distortion of the reflected image.

In extreme cases, too high pressure inside the insulating glass may result in self-breakage of the

component glass. In order to prevent such problems, it is crucial to select the proper glass structure

and type of glass used for the anticipated dimensions of the glass and operating conditions.

Moisture condensation / fogging of the outside surface of glass

Moisture condensation / fogging on the outside surface of the glass is a natural phenomenon

associated with the position of the glass and very good thermal insulation parameters of the unit (U-

value).

The occurrence of such phenomenon confirms the parameters and is not deemed as a defect of the

insulating glass. Similar, in such conditions may occur traces of stickers, distance elements which

disappear when the glass is dry.

Moisture condensation / fogging of inside surface of the glass

The effect of fogging the inside surface of the glass is caused by too high humidity inside the room

and is not deemed as a defect of the insulating glass unit.

PILKINGTON IGP Sp. z o.o. based in Sandomierz

27-600 Sandomierz, 24 Portowa Street, tel. 48 15 8323041-49 or 48 15 8326100 fax 48 15 832 62 89

REGON 006911139 NIP (Tax Identity Number) 123-00-06-857 District Court in Kielce, X Commercial Division of the National Court

Register under KRS number 0000012897 Individual BDO Number 000003517

Share Capital: 506 500 PLN

Management Board: President – Krzysztof Granicki

www.pilkington.pl

5/6

Anisotropy / Leopard spots

The anisotropy effect can be observed in toughened glass and in insulating glass units with the

toughened glass. During the toughening process, areas with different stresses are generated on

glass pane. The stress areas produce the effect of birefringence in glass, visible in polarized light.

When observed in polarized light, areas with different stress appear as coloured zones, sometimes

called "leopard spots". The effect could be visible for human eyes because lLight polarization may

occur also in normal daylight, and the degree of polarization of light depends on the weather

conditions and angle of sunlight. The birefringence effect increases when observed at an angle or

through polarized glasses. Anisotropy is not a defect but is a visible effect of the glass toughening

process.

Fine colour differences of insulating glass units

The facades made of glass units with coatings may present fine, different shades of the same

colour. This effect may be strengthened when observing the glass at an angle. Such small

differences may by caused by tiny changes in the colour of the ground glass on which the coating is

applied and by slight differences in the thickness of the coating itself. The shade difference can be

objective assessed based on measurements in accordance with ISO 11479-2.

5. List of reference standards for the quality assessment of glass products

manufactured by Pilkington IGP Sp. z o.o.

• For insulating glass: EN 1279-1 “Glass in building. Insulating glass units. Part 1:

Generalities, system description, rules for substitution, tolerances and visual quality.”

• For toughened glass units: EN 12150-1 “Glass in building. Thermally toughened soda lime

silicate safety glass. Part 1: Definition and description.”

• For float glass units: EN 572-8 “Glass in building. Basic soda-lime silicate glass products.

Supplied and final cut sizes.”

• For coated glass units: EN 1096-1 “Glass in building. Coated glass. Part 1: Definitions and

classification.”

• For laminated glass units: EN ISO 12543-6 “Glass in building. Laminated glass and

laminated safety glass. Appearance.”

• For heat strengthened glass units: EN 1863-1 “Glass in building. Heat strengthened soda

lime silicate glass. Part 1: Definition and description.”

• For heat soaked thermally toughened glass units: EN 14179-1 “Glass in building. Heat

soaked thermally toughened soda lime silicate safety glass. Part 1: Definition and

description.”

6. CE marking and Declarations of Performance for glass products manufactured

by Pilkington IGP Sp. z o.o.

Each product of Pilkington IGP Sp. z o.o. has a label with the CE marking, identification data,

identification number and declared parameters. The product Declaration of Performance shall be

downloaded from www.pilkington.com/CE by entering the identification number from the label.

The “Transport, storage, installation, use and maintenance instruction for glass products” is

available at www.pilkington.pl.

PILKINGTON IGP Sp. z o.o. based in Sandomierz

27-600 Sandomierz, 24 Portowa Street, tel. 48 15 8323041-49 or 48 15 8326100 fax 48 15 832 62 89

REGON 006911139 NIP (Tax Identity Number) 123-00-06-857 District Court in Kielce, X Commercial Division of the National Court

Register under KRS number 0000012897 Individual BDO Number 000003517

Share Capital: 506 500 PLN

Management Board: President – Krzysztof Granicki

www.pilkington.pl

6/6

7. Final provisions

The main intended use of glass products produced by Pilkington IGP Sp. z o.o. is their installation in

windows, doors, walls, glued glazing for doors, windows, and walls, in roofs and partitions.

Responsibility of Pilkington IGP Sp. z o.o. is limited to delivering the product in accordance with the

order, of agreed quality and parameters. Pilkington IGP Sp. z o.o. does not guarantee that the

product acquired by the Buyer will be suitable for specific purposes assumed by the Buyer or for use

in specific conditions and place, even in a situation where such purpose or conditions may be known

or disclosed to Pilkington IGP Sp. z o.o.

16 June 2020

Krzysztof Skarbiński

Quality Director

Pilkington IGP Sp. z o.o.

phone.: +48 601 50 60 51

e-mail: Krzysztof.Skarbinski@pl.nsg.com

PILKINGTON IGP Sp. z o.o. based in Sandomierz

27-600 Sandomierz, 24 Portowa Street, tel. 48 15 8323041-49 or 48 15 8326100 fax 48 15 832 62 89

REGON 006911139 NIP (Tax Identity Number) 123-00-06-857 District Court in Kielce, X Commercial Division of the National Court

Register under KRS number 0000012897 Individual BDO Number 000003517

Share Capital: 506 500 PLN

Management Board: President – Krzysztof Granicki

www.pilkington.pl

You might also like

- Test Bank For Dewits Fundamental Concepts and Skills For Nursing 5th Edition Patricia WilliamsDocument36 pagesTest Bank For Dewits Fundamental Concepts and Skills For Nursing 5th Edition Patricia Williamsumbrella.intrauofs100% (52)

- Code of Federal Regulations 49 Parts 100-185Document1,254 pagesCode of Federal Regulations 49 Parts 100-185Sean80% (5)

- GEN ED 8 - ETHICS Questions-for-ReviewDocument11 pagesGEN ED 8 - ETHICS Questions-for-ReviewLady Jane Cainong100% (3)

- Commercial Law Suggested Answers To Bar ExamsDocument79 pagesCommercial Law Suggested Answers To Bar ExamsJfm A Dazlac100% (1)

- Jjwa 9344 & 10630 2020Document34 pagesJjwa 9344 & 10630 2020Geramer Vere Durato100% (1)

- Spirit Levels - Block LevelsDocument4 pagesSpirit Levels - Block LevelsGia Minh Tieu Tu100% (1)

- Toilet Facilities (Philippines Setting)Document5 pagesToilet Facilities (Philippines Setting)Nasripha Malawani0% (1)

- Request Letter (Typhoon Ursula)Document15 pagesRequest Letter (Typhoon Ursula)Joemar Cafranca100% (2)

- quality_criteria_enDocument8 pagesquality_criteria_enKhurshed alamNo ratings yet

- Area of Interest Acceptable DefectsDocument1 pageArea of Interest Acceptable DefectsRimon GawandeNo ratings yet

- Quality Complaint FormDocument7 pagesQuality Complaint Formsaint Gobain1No ratings yet

- Laksam (FX+SL) - QTDocument4 pagesLaksam (FX+SL) - QTAinul Islam ShaownNo ratings yet

- Material: Technical Data SheetDocument4 pagesMaterial: Technical Data SheetWaseem AkramNo ratings yet

- Visual Quality Standard 1Document1 pageVisual Quality Standard 1Khurshed Alam IndiaNo ratings yet

- Glass Inspection Standards For Filmed GlassDocument1 pageGlass Inspection Standards For Filmed GlassKhurshed Alam IndiaNo ratings yet

- Glass Specifications ClicktouchDocument7 pagesGlass Specifications ClicktouchAldrian BarbasanNo ratings yet

- VT-620/ 620S LM MS SealantDocument2 pagesVT-620/ 620S LM MS SealantditronzNo ratings yet

- Et Iso 25537 2008Document17 pagesEt Iso 25537 2008Bálint Póth100% (1)

- KGC Instructions For Use and Maintenance PDFDocument20 pagesKGC Instructions For Use and Maintenance PDFMahindaNo ratings yet

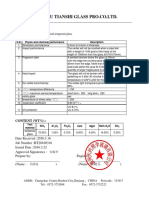

- Huzhou Tianshi Glass Pro - Co.Ltd.: Products/Raw Materials: Thermal Tempered GlassDocument1 pageHuzhou Tianshi Glass Pro - Co.Ltd.: Products/Raw Materials: Thermal Tempered GlassAbraham Seco ArmestoNo ratings yet

- Specification of Production: Pos. Type Width X Height Sqr. M. Price Price Quanti Ty Total MM EUR/sqr.m. EUR EURDocument2 pagesSpecification of Production: Pos. Type Width X Height Sqr. M. Price Price Quanti Ty Total MM EUR/sqr.m. EUR EURbcachNo ratings yet

- NL Master Specification Guide For Public Funded Buildings: Re-Issued 2020/08/28Document8 pagesNL Master Specification Guide For Public Funded Buildings: Re-Issued 2020/08/28Shamim Ahsan ZuberyNo ratings yet

- QCS 2010 Section 25 Part 2 Glass PDFDocument5 pagesQCS 2010 Section 25 Part 2 Glass PDFbryanpastor1060% (1)

- Factors That Caused Glass Curtain Wall Visual DistortionDocument4 pagesFactors That Caused Glass Curtain Wall Visual DistortionHAN HAN100% (1)

- Laminated Glass and Laminated Safety GlassDocument7 pagesLaminated Glass and Laminated Safety Glasstroyel99No ratings yet

- Fotovoltaicos Bipv Catalogue(Johnson)(2024!06!10 23-39-53)Document48 pagesFotovoltaicos Bipv Catalogue(Johnson)(2024!06!10 23-39-53)Revista MuyUNo ratings yet

- Technical Advisory Note - 020 Barriers Checklist NEW June 19Document1 pageTechnical Advisory Note - 020 Barriers Checklist NEW June 19Joni StulicNo ratings yet

- ISO 16163 - (2012) - (Continuos HDG-Dimensional and Shape-Tolerances) - 10pgsDocument10 pagesISO 16163 - (2012) - (Continuos HDG-Dimensional and Shape-Tolerances) - 10pgsdpfloresNo ratings yet

- Technical Advisory Note - 117 Free Standing Barriers Checklist NEW June 19Document1 pageTechnical Advisory Note - 117 Free Standing Barriers Checklist NEW June 19Joni StulicNo ratings yet

- Clear Glass: Indof LotDocument4 pagesClear Glass: Indof LotSteviani TeddyNo ratings yet

- SSSSS PVC ProfilesDocument16 pagesSSSSS PVC ProfilesSatish PandeyNo ratings yet

- Instruction Storage of Glass Pilkington 2020Document4 pagesInstruction Storage of Glass Pilkington 2020KhaledAhmedNo ratings yet

- Sieve Bend ScreenDocument5 pagesSieve Bend Screenwedge wire screensNo ratings yet

- VL53L0X Ranging Module Cover Window GuidelinesDocument20 pagesVL53L0X Ranging Module Cover Window GuidelinespepenitoNo ratings yet

- Glazing RegulationsDocument3 pagesGlazing RegulationsDaniel ReynoldsNo ratings yet

- Ceramic BeadDocument2 pagesCeramic Beaddonhan91No ratings yet

- How To Calculate The Glass STCDocument4 pagesHow To Calculate The Glass STCHan JoeNo ratings yet

- Technical Data Sheet - ThermobelDocument10 pagesTechnical Data Sheet - ThermobelliceuNo ratings yet

- ISO 21690:2006 Glass in BuildingDocument15 pagesISO 21690:2006 Glass in BuildingBálint PóthNo ratings yet

- Technical Advisory Note - 166 Balustrade Infill Checklist NEW June 19Document1 pageTechnical Advisory Note - 166 Balustrade Infill Checklist NEW June 19Joni StulicNo ratings yet

- Corning Lotus Glass Product Information Sheet PDFDocument4 pagesCorning Lotus Glass Product Information Sheet PDFckcchenNo ratings yet

- Borofloat 33 eDocument32 pagesBorofloat 33 ePaul Hsieh Fu TsaiNo ratings yet

- Cat LogueDocument5 pagesCat Loguedevendrachaudhari9029No ratings yet

- Pilkington Profilit Techn Info enDocument12 pagesPilkington Profilit Techn Info enSalmonelo Abdul RamosNo ratings yet

- Toughened Safety GlassDocument6 pagesToughened Safety GlassNor Hasni TaibNo ratings yet

- Saint-Gobain - EPD Magnetron Coated Glass - 2021Document62 pagesSaint-Gobain - EPD Magnetron Coated Glass - 2021carlosmmmrodriguesNo ratings yet

- SGC Detector Assembly Materials Data SheetDocument2 pagesSGC Detector Assembly Materials Data Sheetformaggio869No ratings yet

- Flat Glass Inspection Criteria Per ASTM C 1036 - 06 (Abridged)Document4 pagesFlat Glass Inspection Criteria Per ASTM C 1036 - 06 (Abridged)batteekhNo ratings yet

- Frontpage Rakaa School For Windows System R3Document3 pagesFrontpage Rakaa School For Windows System R3AYSON N. DELA CRUZNo ratings yet

- MWT70 Vs Solarban 70XL-Triple Silver Low e CompareDocument2 pagesMWT70 Vs Solarban 70XL-Triple Silver Low e CompareHAN HANNo ratings yet

- How To Confirm The Best PVB Thickness For Your ProjectDocument3 pagesHow To Confirm The Best PVB Thickness For Your ProjectHAN HANNo ratings yet

- All About GlassDocument52 pagesAll About Glassnaveenarora298040No ratings yet

- COLLECTOR INSTRUCTIONS MANUAL. WUNDER CLS 1808 & 2108 & 2510 ModelsDocument19 pagesCOLLECTOR INSTRUCTIONS MANUAL. WUNDER CLS 1808 & 2108 & 2510 ModelsCiprian BalcanNo ratings yet

- Glazing SpecificationDocument6 pagesGlazing SpecificationandiNo ratings yet

- L40-General Glazing - Rev1Document6 pagesL40-General Glazing - Rev1Joe SmithNo ratings yet

- Specification of Aluminium Foil: 1. Appearance and General ConditionsDocument3 pagesSpecification of Aluminium Foil: 1. Appearance and General Conditionsraviteja tankalaNo ratings yet

- Astm C1036 16Document6 pagesAstm C1036 16MOHAMMADNo ratings yet

- Option 1 - Sticktype SystemDocument1 pageOption 1 - Sticktype SystemNick DivinagraciaNo ratings yet

- The Difference Between AG Glass, AR Glass and AF Glass.Document3 pagesThe Difference Between AG Glass, AR Glass and AF Glass.HAN HANNo ratings yet

- Build: Builders Silicone SealantsDocument3 pagesBuild: Builders Silicone SealantsAhmed KhameisNo ratings yet

- 1 HTDocument12 pages1 HTHarrison Daka LukwesaNo ratings yet

- Glass and Glazing - MSTDocument8 pagesGlass and Glazing - MSTwafikmh4No ratings yet

- Option 2 - Unitized SystemDocument1 pageOption 2 - Unitized SystemNick DivinagraciaNo ratings yet

- Mgo Green C25 M-M and C25 M-O Composite Building Panel: 1. Product Identification/Trade NameDocument2 pagesMgo Green C25 M-M and C25 M-O Composite Building Panel: 1. Product Identification/Trade NameDîrlea OtnielNo ratings yet

- Function and Production of Coatings On Architectural Glass: Basics and OverviewDocument58 pagesFunction and Production of Coatings On Architectural Glass: Basics and OverviewRattikarn RattiNo ratings yet

- Product Bulletin Obsidian AWF 2021 1Document2 pagesProduct Bulletin Obsidian AWF 2021 1Sergio MarinNo ratings yet

- Mastering Samsung Galaxy - Galaxy S10e, S10, S10 Plus Ultimate User GuideFrom EverandMastering Samsung Galaxy - Galaxy S10e, S10, S10 Plus Ultimate User GuideNo ratings yet

- ESOP Report On The St. Louis Metropolitan Police DepartmentDocument60 pagesESOP Report On The St. Louis Metropolitan Police DepartmentKevinSeanHeld0% (1)

- Understanding Federalism and FederationDocument474 pagesUnderstanding Federalism and FederationpanegiricNo ratings yet

- Xparcoac Prelims ReviewerDocument4 pagesXparcoac Prelims ReviewerPauline ValdezNo ratings yet

- More Guns, Less Crime: Understanding Crime and Gun Control LawsDocument5 pagesMore Guns, Less Crime: Understanding Crime and Gun Control Lawsapi-581432219No ratings yet

- 2 - Cfa-2018-Quest-Bank-R23-Financial-Reporting-Standards-Q-BankDocument8 pages2 - Cfa-2018-Quest-Bank-R23-Financial-Reporting-Standards-Q-BankQuyen Thanh NguyenNo ratings yet

- Contract - FraudDocument6 pagesContract - Fraudfarah athirahNo ratings yet

- Police Regulations, Bengal (PRB) 1943 PDFDocument961 pagesPolice Regulations, Bengal (PRB) 1943 PDFBudhaditya Ghosh100% (2)

- Heirs of Amparo V CADocument2 pagesHeirs of Amparo V CAGenevieve Kristine Manalac100% (2)

- Chapter 1 - Nature and Concept of ManagementDocument15 pagesChapter 1 - Nature and Concept of ManagementVennNo ratings yet

- A Central Air Conditioning Unit Was Installed On J...Document3 pagesA Central Air Conditioning Unit Was Installed On J...Jhowelaine AbrilNo ratings yet

- Dental Assistant Employment ApplicationDocument2 pagesDental Assistant Employment Applicationmarklola12No ratings yet

- Kehar Singh V Union of India (AIR 1989 SC 653)Document2 pagesKehar Singh V Union of India (AIR 1989 SC 653)ramanjeet singh100% (4)

- Community Radio PDFDocument14 pagesCommunity Radio PDFmeenal kaur100% (1)

- In Assignment: Submitted byDocument8 pagesIn Assignment: Submitted byrochel100% (1)

- Union, State and Territory - 1st - ChapterDocument6 pagesUnion, State and Territory - 1st - ChapterTNPSC GROUP 2 MATERIAL PDF 2019No ratings yet

- Information Technology in LibrarianshipDocument304 pagesInformation Technology in LibrarianshipAbdel Guerra LopezNo ratings yet

- Instructions Regarding PWBDDocument10 pagesInstructions Regarding PWBDDalchand SharmaNo ratings yet

- Bidsketch Proposal Template: Proposal For: Client Name Proposal By: Your NameDocument5 pagesBidsketch Proposal Template: Proposal For: Client Name Proposal By: Your NameMahmoud HasanNo ratings yet

- Lokesh CR 99 (Part 1)Document46 pagesLokesh CR 99 (Part 1)Hemang KhatriNo ratings yet

- CH 05Document51 pagesCH 05napan1988No ratings yet

- Principle of TaxationDocument4 pagesPrinciple of Taxationvincent manuelNo ratings yet

- Rent Control JudgmentDocument5 pagesRent Control JudgmentNidheesh TpNo ratings yet

- 2019 Foreign Trade Statistics of The Philippines Publication PDFDocument2,091 pages2019 Foreign Trade Statistics of The Philippines Publication PDFRAIHAANA MINONG NAMLANo ratings yet