Professional Documents

Culture Documents

Agrogita Super

Agrogita Super

Uploaded by

Vishal shukla0 ratings0% found this document useful (0 votes)

8 views8 pagesOriginal Title

agrogita super

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

8 views8 pagesAgrogita Super

Agrogita Super

Uploaded by

Vishal shuklaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 8

Naturehatch Solutions

Proposal for Effluent Treatment Plant

(01 KLD)

Cum

Sewage Treatment Plant

(05 KLD)

AT

M/s AROGITA SUPER SPECIALITY HOSPITAL,

5/140, LOHIYAPURAM,AWAS VIKAS,

FARRUKHABAD

Proposed by:

Nature hatch solutions

179, Pocket-17, Sector-24, Rohini,

Delhi-85

ETP cum STP

Naturehatch Solutions

To,

MR. NEERAJ KUMAR VERMA

AROGITA SUPER SPECIALITY HOSPITAL,

5/140, LOHIYAPURAM,AWAS VIKAS,

FARRUKHABAD

Subject: Effluent Treatment Plant (01 KLD) Cum Sewage Treatment Plant (05 KLD).

Dear Sir,

We are pleased to submit herewith our proposal regarding above stated subject.

Kindly find below our detailed techno-commercial offer as follows:

Operational Principle

Design/Characteristics of Effluent

Project Specification/Scope of Work

Commercial Details

We assure you of our best attention at all times.

Thanking you and assuring you of our best attention at all times.

Yours faithfully,

Kunain Siddiqui

Nature hatch solutions

179, Pocket-17, Sector-24,

Rohini, Delhi-85

+91-80916272171

ETP cum STP

Naturehatch Solutions

1, Operational Principle:

A. For Effluent Treatment Plant:

Terminator system works in two stages:

1. First: Pretreatment

2. Second: Post-Treatment

|. Pre-treatment: Small particles in the effluent are coagulated using suitable coagulants in the

flocculator. From the flocculator, the effluent passes to the tube settler zone from where it rises

upwards. During the upward flow through the inclined tubes, the coagulated particles settle down

the bottom hopper of the tube settler. Then the cleared water is collected through troughs and

guided to the clear water storage tank.

Il Post treatment: Pre- Treated water from stage 1 is filtered through ‘Dual Media Filter’ and

Activated

Carbon Filter in which unsettled suspended particles are removed.

Water at the outlet of the ACF & DME, has COD/BOD within the stipulated limits.

Around 85-90% color in the effluent from process units is removed in stage-I, the balance 10 -15%

through the stage-Il

Flocculation Tank

It is designed tank and is provided with an agitator,

a) Equalization: the effluent is collected in the tank. Because of agitation, the equalization of

theeffluent takes place which helps in achieving the homogeneity.

b) Neutralization: Wastes water from usually have pH from 6 to 12. Therefore, it is important to

maintain the effluents pH about 7 to 8 as this particular range is useful for the action of

polyelectrolytes.

Flocculation: the basics

In the initial phase coagulation produces finely divided or colloidal suspensions. These suspensions

are converted into settleable flocs by agglomeration. The agglomeration of flocs is achieved by

multiple re-contacts of the solids. This in turn is achieved by slowly stirring the coagulated water to

increase the number of collision or contacts. The increased opportunity for contacts is called

flocculation. It may beprovided by hydraulic or mechanical means,

Mechanical flocculation

The slow stirring of the fluid or coagulated water is achieved by rotating the paddles mounted over

shaft under low, controlled speed. The shaft is rotated by electrically operated motor.

If these factors are taken into consideration for designing the tanks, then the factor influencing

flocsformation is coagulant dose. The flocs are settled down in Tube settler in the form of sludge

SLUDGE REMOVAL

The sludge thus formed is removed by opening the drain valve provided for the tank, periodically.

The drain valves should be opened when the plant is under operation, for duration of 2 to 5

minutes until the sludge is drained off. Once in 6 months, the entire compartment should be

completely drained andcleaned with water hoses. In case of low turbidity, the drains of flocculator

may be opened once in

ETP cum STP

Naturehatch Solutions

Tube Settler

BASIC FUNCTION: solid liquid separation

‘The basic function of this unit is the solid liquid separation. The settle able flocs in flocculated water

areseparated and removed out from the drain as sludge. It produces clarified water or settled water

of thedesired and designed turbidity.

As the detention time of tube settling tank is only about 40 minutes, it is of extreme importance

that asfar as possible every tube should be functional at a uniform flow rate.

Media Filter:

The filtering media in the filter is fine sand and coarse anthracite, which is supported on the graded

pebbles beneath. This serves the purpose of in-depth filtration.

The output from tube settler is then passed through ‘Dual Media Filter’ and Activated Carbon

Filter.

The basic function of DMF/ACF is to trap the suspended solids.

B. For Sewage Treatment Plant:

1. Solid Separation Zone:

First stage transforms the solids in raw sewage to settled solids while allowing scum to Float on the

surface. It is a primary sedimentation zone in which settled sludge is stabilized by anaerobic

digestion.

2. Aeration Zone:

‘The sewage from solid separation zone flows to the aeration zone. Al Is diffused with help Of air

blowers which will encourage the growth of bacteria cultures in and around the Floating plastic

media inside the aeration zone. The PP media provides extended surface Area for growth of

microorganisms.

3. Sedimentation Zone:

The next step of treatment involves the sedimentation where organic wastes are settled in The

sedimentation zone. The settled waste in the bottom of the tank is pumped back to the solid

separationas a return sludge, to ensure that quality of effluent would pass the Stipulated sewage

parameters. Chlorine is offered before discharging the effluent into the Main drainage line.

4. Dual Media Filter(DMF) & Activated Carbon Filter (ACF)

The filtering media in the filter is fine sand and coarse anthracite, which is supported on the graded

pebbles beneath. This serves the purpose of in-depth filtration.

The output from tube settler is then passed through ‘Dual Media Filter’ and Activated Carbon

Filter

The basic function of DMF/ACF is to trap the suspended solids.

ETP cum STP

Naturehatch Solutions

2. Design/Characteristics of Effluent:

Flow rate of Effluent — 0.050 M3/Hr (01 KLD)

Operation Time ~ 20 Hours

Flow rate of Sewage - 0.15 M3/Hr (05 KLD)

Operation Time - 20 Hours

Effluent/Sewage parameters required at inlet of Naturehatch ETP:

Characteristics of Generated Effluent Value

Ph 58

Odour Light smell

Colour Reddish

BOD3 at 27°C (me/l) 450-1700

‘COD (me/|} 700-2000

Total Suspended Solids (mg/l) 200-1000

ics of Generated Sewage Value

65-85

Light smell

Grayish

BOD3 at 27°C (mg/l) 250-400

COD (mg/l) 400-600

Total Suspended Solids (mg/l) 200-900

parameters guaranteed at outlet of Naturehatch ETP

Characteristics of Treated Effluent & Sewage

PH 65-90

Odour ‘Odourless

Colour Colourless

BOD3 at 27°C (me/l) <10

COD (mg/l) <50

Total Suspended Solids (mg/l) <20

ETP cum STP

Naturehatch Solutions

3. Project Specification/Scope of Work:

Items Scope

Effluent Lifting Pump Naturehatch

Air Blower Naturehatch

Lime Dozing Pump Naturehatch

Lime Dozing Tank Naturehatch

‘Alum Dozing Pump Naturehatch

Alum Dozing Tank Naturehatch

Poly Dozing Pump Naturehatch

Poly Dozing Tank Naturehatch

“Agitator Naturehatch

Motor for Agitator Naturehatch

Sludge Pump Naturehatch

Filter feed pump Naturehatch

Activated Carbon Filter Naturehatch

Dual Media Filter Naturehatch

Chlorine Dozing Tank Naturehatch

Chlorine Dozing Pump Naturehatch

Electric control panel Naturehatch

Electric cables As required Naturehatch

Pipe fittings and valves As required Naturehatch

SCOPE OF OUR WORK:

The scope of our work against the proposed Waste water treatment plant will be as under:

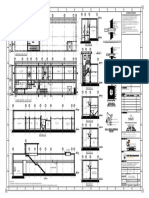

1. Detailed Design & Engineering work including preparation of various drawings as well as the civil

works as per the drawing attached.

2. Design & engineering, careful supervision in Erection& Commissioning of the whole plant.

3, Supply of all required mechanical equipment items for the proposed Wastewater treatment plant.

4, Supervision of installation and commissioning of the plant and ensuring its proper running after

installation.

5. Furnishing of “Operating Instruction and Maintenance Manual of the plant.

6. Staff training for handling of Waste water treatment plant (if required).

7. 24*7 professional assistance free of cost to deal with troubleshooting.

8. Free maintenance for 1 year.

EXCLUSION:

1. Allcivil works at site,

2, Power supply & connection to Panel.

3, Service water line at plant.

4. Roads, Pathway, Drain, Boundary Wall, Fencing ete, if required as per site location.

5. All other works not specified in our scope of work

ETP cum STP

Naturehatch Solutions

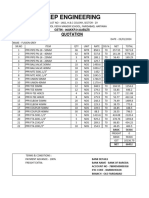

4. Commercial Details:

Our Price towards the supply of the E.T.P cum S.1.P. per the scope of work mentioned in above table

referred offer shall be Rs—- ~ (Rs —~ only.)

TTEM DESCRIPTION PRICE

Designing, Fabrication, Supply, Installation, Erection & 3,10,000

Commissioning of 01 KLD E.T.P cum 05 KLD S.T.P..

TOTAL 3,10,000

‘Amount in Words: Three Lacs Ten Thousands Rupees (Exclusive of All Taxes.)

Note: All civil work and internal piping work falls under the scope of client. TERMS OF PAYMENT

1) 25% advance with work order; 30% after receiving of Electro & Mechanical Items at site; 30%

After Commissioning and Testing of ETP cum STP; and 15% after certification with all due taxes.

2) The schedule for starting work shall be mutually decided by your Organization and ECS.

3) GST will be extra as per actual & paid by Client.

4) Legal fees will be paid by Company (if any).

5) Charges for NOC, Consent & Liaisoning work with UPPCB & CPCB will be extra.

6) This quotation valid for next 30 days from this quotation date.

Yours faithfully,

Kunain Siddiqui

Nature hatch solutions

179, Pocket-17, Sector-24,

Rohini, Delhi-85.

++91-80916272171

ETP cum STP

f

MLL

VENDOR

SCOPE

sswoct oxsrosaL,

e © >

VENDOR I

SCOPE

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Dimension & Drawing For Bio DigesterDocument1 pageDimension & Drawing For Bio DigesterVishal shuklaNo ratings yet

- Diffuser & Media Qty. SheetDocument1 pageDiffuser & Media Qty. SheetVishal shuklaNo ratings yet

- Customer QuotationDocument1 pageCustomer QuotationVishal shuklaNo ratings yet

- 3MX CatalogueDocument8 pages3MX CatalogueVishal shuklaNo ratings yet

- Plan AhaanaDocument1 pagePlan AhaanaVishal shuklaNo ratings yet

- Bio Digester Tank Qty. SheetDocument1 pageBio Digester Tank Qty. SheetVishal shuklaNo ratings yet

- KDI DetailsDocument2 pagesKDI DetailsVishal shuklaNo ratings yet

- Earthwork, Embankment & Subgrade Speci - WatermarkDocument23 pagesEarthwork, Embankment & Subgrade Speci - WatermarkVishal shuklaNo ratings yet

- Bulandshahr PlanDocument1 pageBulandshahr PlanVishal shuklaNo ratings yet

- Bulandshahr SectionDocument1 pageBulandshahr SectionVishal shuklaNo ratings yet

- Technical Spec GemDocument2 pagesTechnical Spec GemVishal shuklaNo ratings yet

- HSCC Etp DWGDocument1 pageHSCC Etp DWGVishal shuklaNo ratings yet

- GMCBS NKG MC Ovl STP STR PLN 1036Document1 pageGMCBS NKG MC Ovl STP STR PLN 1036Vishal shuklaNo ratings yet

- GMCBS NKG MC Ovl STP Arc PLN 1031Document1 pageGMCBS NKG MC Ovl STP Arc PLN 1031Vishal shuklaNo ratings yet

- SKM C224e21100613080Document5 pagesSKM C224e21100613080Vishal shuklaNo ratings yet

- Technical Spec GemDocument4 pagesTechnical Spec GemVishal shuklaNo ratings yet

- Sedron Services Sumner Washington - ST 6267 - Draft O&M Manual - Emailed 1-26-21Document31 pagesSedron Services Sumner Washington - ST 6267 - Draft O&M Manual - Emailed 1-26-21Vishal shuklaNo ratings yet

- Plan Laharpur DWWTSDocument1 pagePlan Laharpur DWWTSVishal shuklaNo ratings yet